Coated hollow composite glass and manufacturing method thereof

A composite glass, hollow technology, applied in parallel glass structure, building structure, climate change adaptation and other directions, can solve the problems of insufficiency, damage, aerogel powderization, etc., to improve wind pressure resistance, improve heat insulation Performance, soft light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

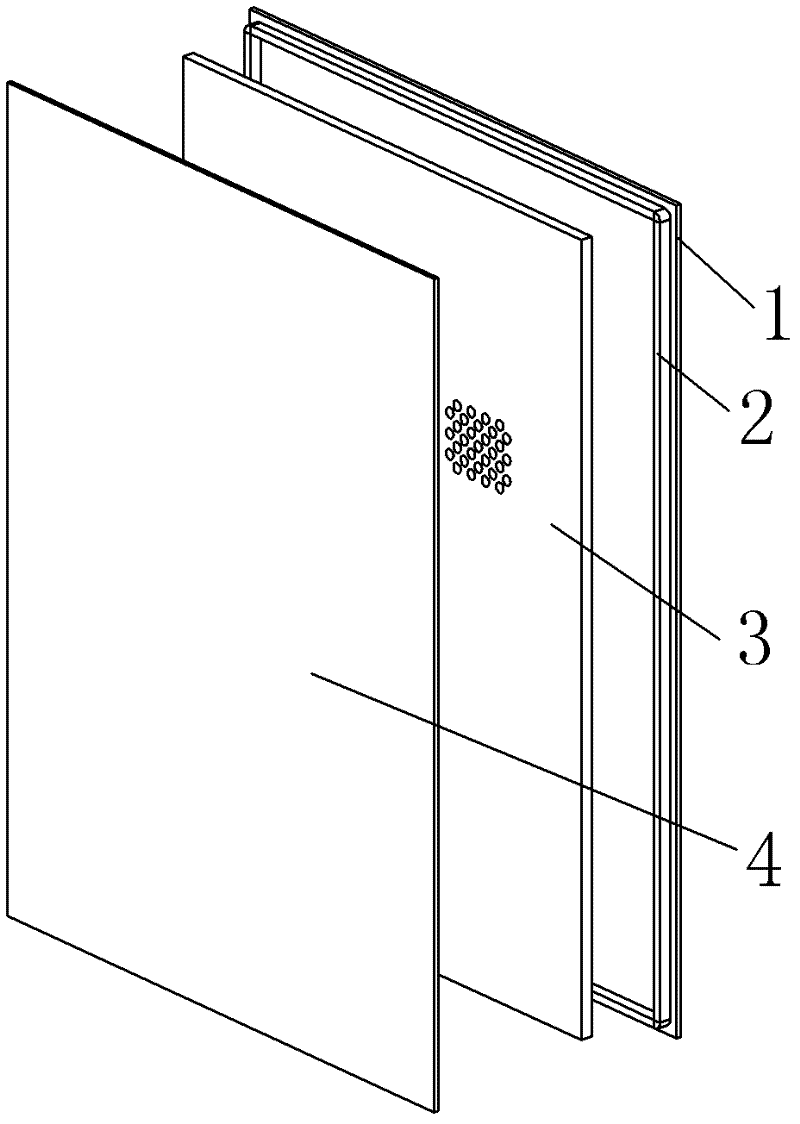

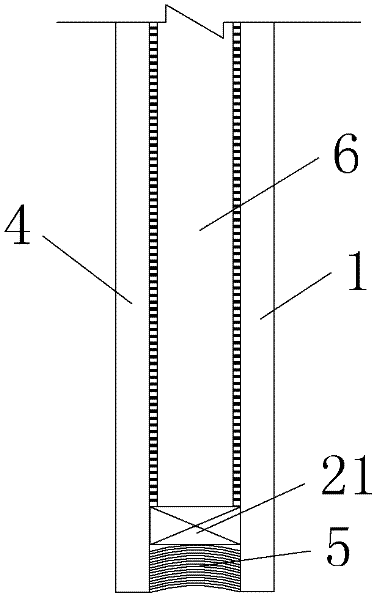

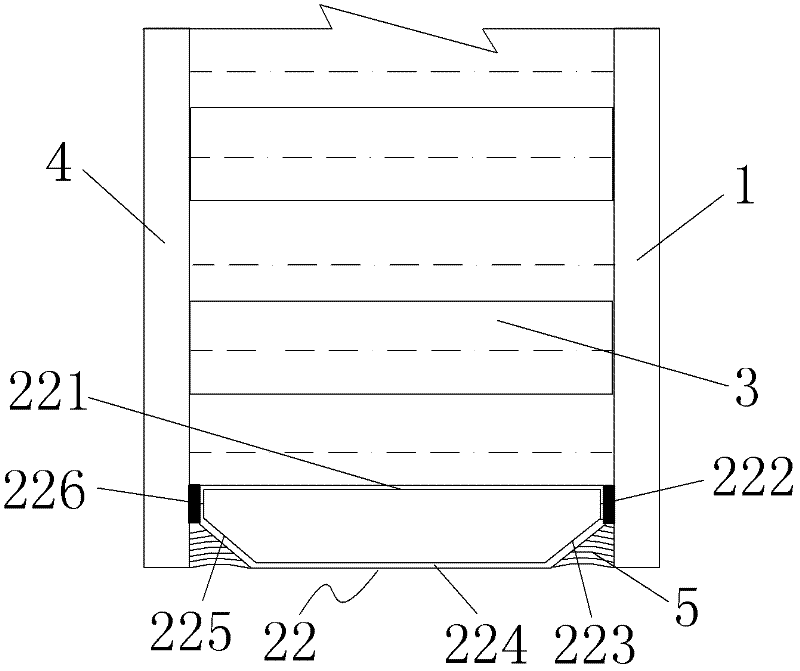

[0045] see figure 1 , figure 1 It is a schematic structural diagram of a coated hollow composite glass according to an embodiment of the present invention. The coated hollow composite glass of the present invention comprises a glass upper substrate 1, a glass lower substrate 4, a spacer frame 2 and a hollow filler 3, and the spacer frame 2 is bonded to the glass upper substrate 1 and the glass body respectively. The surroundings of the lower substrate 4 are sealed by a sealant 5, the glass upper substrate 1, the glass lower substrate 4 and the spacer frame 2 jointly form a hollow cavity 6, and the hollow filler 3 is filled In the hollow cavity 6, the hollow filler 3 is a honeycomb panel, and the honeycomb holes of the honeycomb panel are filled with airgel. In this embodiment, the honeycomb plate is preferably a porous plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com