Metal roof boards and metal roof system

A technology for metal roofing and metal houses, which is applied to roofing, roof cladding, and roofs using flat/curved panels, etc. It can solve the problems of easy connection of metal roof panels, weak connections, wind damage, and insufficient waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

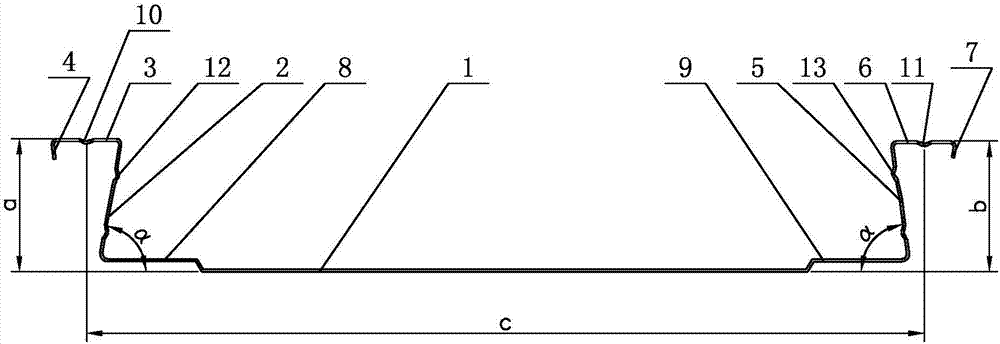

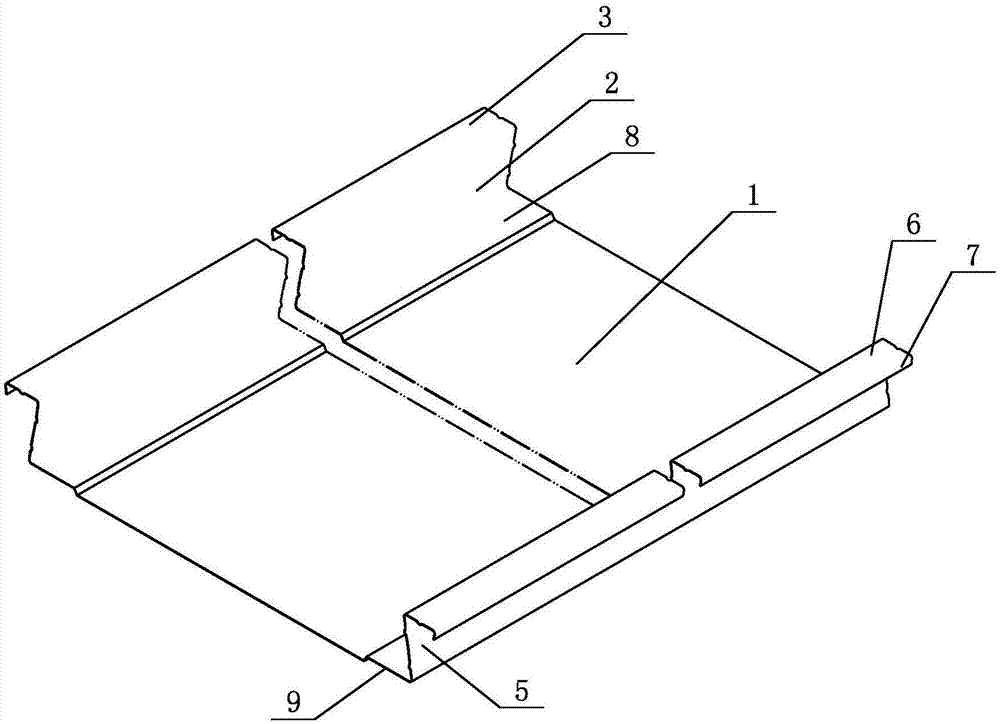

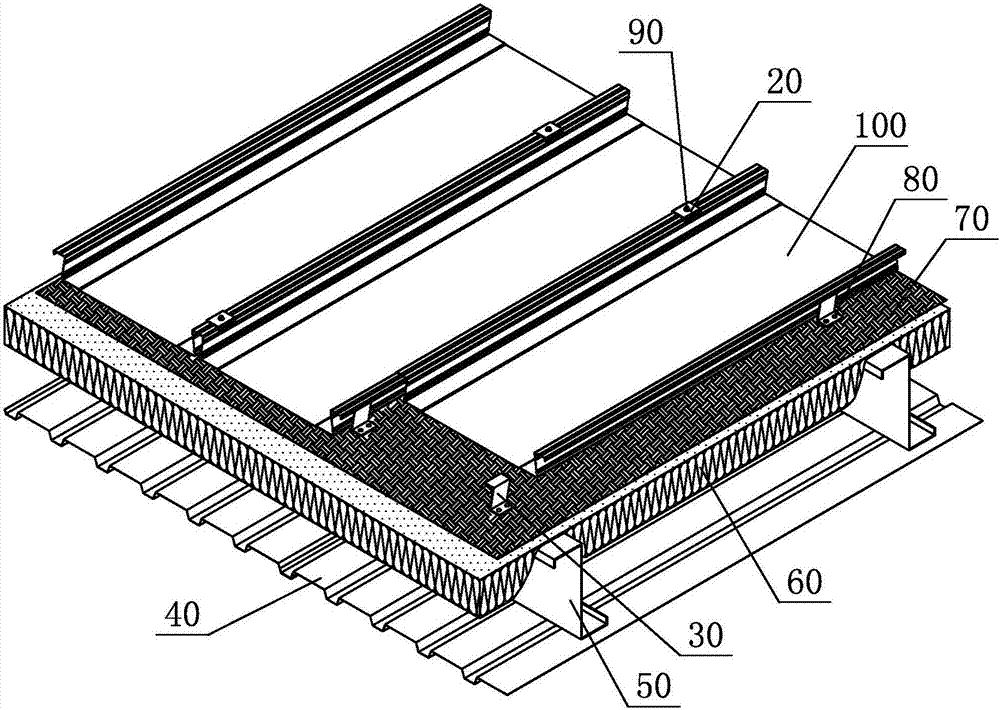

[0032] Such as Figure 1 to Figure 5As shown, the metal roof system of this embodiment includes a roof base plate 40, purlins 50, metal roof panels 100, fixing seats 30, and clip covers 20. The metal roof panels 100 include a base plate 1 and a left Upright rib, right upright rib, described left upright rib comprises the left upright plate 2, left horizontal plate 3, left folded edge 4 that are connected successively, and described right upright rib comprises right vertical plate 5, right horizontal plate 6, right folded edge that are connected successively Side 7, the left horizontal board 3 and the right horizontal board 6 are all in a horizontal state, and between the left vertical board 2 and the bottom board 1 and between the right vertical board 5 and the bottom board 1 are horizontal. An inclination angle, the inclination angle between the left vertical plate 2 and the bottom plate 1 and between the right vertical plate 5 and the bottom plate 1 is α, α=75°~85°, the left...

Embodiment 2

[0034] Such as figure 1 , figure 2 , Figure 6 As shown, the difference between the metal roofing system of this embodiment and Embodiment 1 is that in this embodiment, the fixing seat 30 is in the shape of a strip, and bridges over different purlins 50, and the fixing The seat 30 is combined into an auxiliary support system because the length spans the purlins, which can greatly improve the wind resistance of the roof panel and further enhance the wind pressure resistance of the entire metal roof system. Its span is larger than normal, so it is cost-effective, easy and quick to install, and is suitable for large factories and other buildings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com