Production process of building vacuum glass plate

A technology of vacuum glass plate and production method, which is applied in glass forming, glass re-forming, glass manufacturing equipment and other directions, can solve the problems of low pumping rate, difficult to achieve vacuum degree, and many operation links, etc., and improve the overall strength. and stiffness, enhanced wind pressure resistance, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

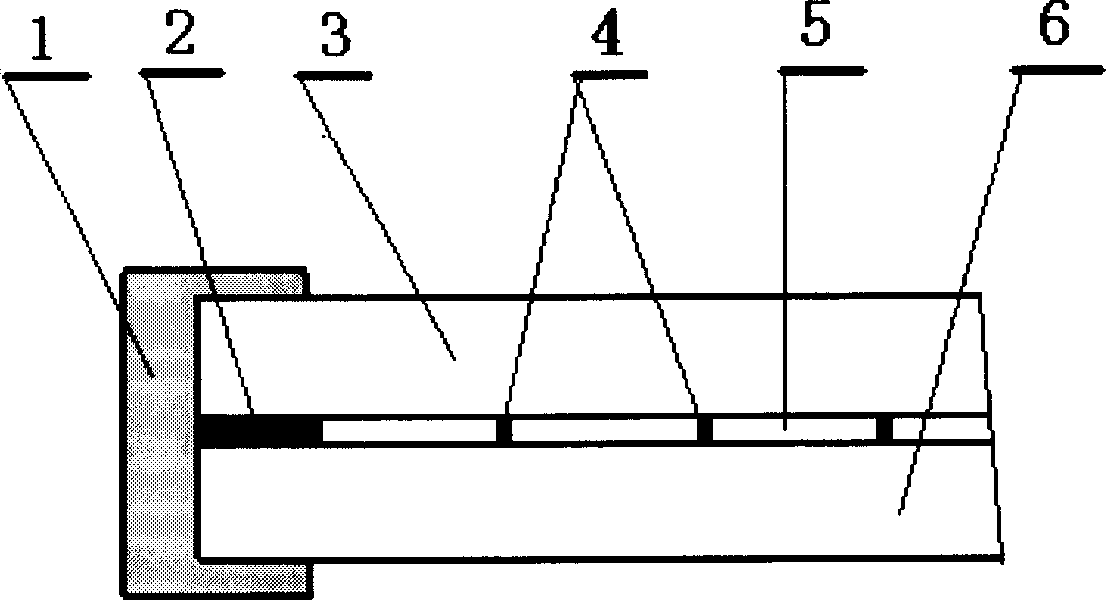

Image

Examples

example 1

[0009] Example 1. Cut the purchased ordinary float glass with a thickness of 3mm and the Low-E glass with online coating to the required size, such as a rough board of 1000mm×600mm, and process it with an edger and a cleaning and drying machine Finally, it is sent to the screen printing process with clean environment; use a screen printing machine to print the pattern of the peripheral welding strip and the supporting welding point in the middle area on the frosted glass. The printing ink is prepared from solder glass powder and scraper oil. The printed peripheral welding width is 8mm, the diameter of the supporting welding spot in the middle area is 0.5mm, the interval is 25mm, and the thickness is 0.32mm. After being heated and dried by the dryer, it is sent to the purification studio for lamination operation; the float glass with the printed pattern is placed on a special fixture car, and the processed Low-E glass is laminated and fixed. Position, there is a certain gap bet...

example 2

[0010] Example 2. Order or process the required specifications, such as toughened glass with an overall size of 3m×2m and a thickness of 15mm. The purchased Low-E glass with a thickness of 5mm and online coating is cut into the same specification and size, and processed by an edging machine and a cleaning and drying machine; use a screen printing machine to print peripheral welding strips on the tempered glass, And the middle area supports the pattern of solder joints, and the printing ink is prepared from solder glass powder, scraper oil, etc. The printed welding width is 15mm, the diameter of the supporting welding spot in the middle area is 2mm, the interval is 50mm, and the thickness is 0.32mm. After being heated and dried by the dryer, it is sent to the purification studio for assembling operation; the tempered glass with printed pattern is placed on a special fixture car, and the processed Low-E glass is stacked on it, and the position is fixed. There is a certain gap b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com