Micropressure pot

A technology of pressure relief valve and pot cover, applied in cooking utensils, household utensils, applications and other directions, can solve the problems of inconvenience in daily life, long time for stewing dishes or soup, taking away nutrients, etc., to improve heating efficiency and energy Utilization rate, the effect of shortening the time of stewing dishes or soup, and improving the heat preservation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

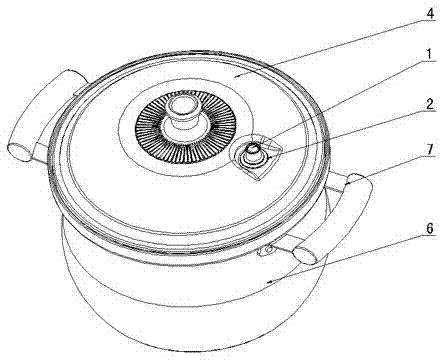

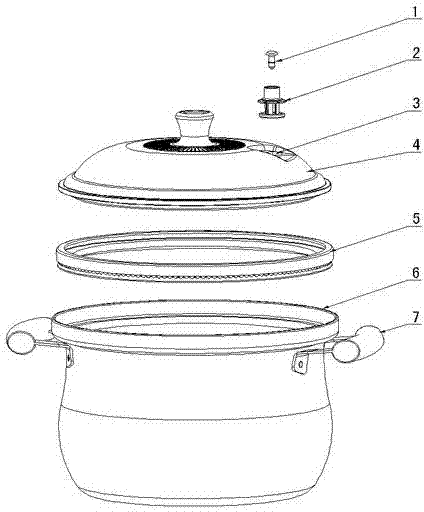

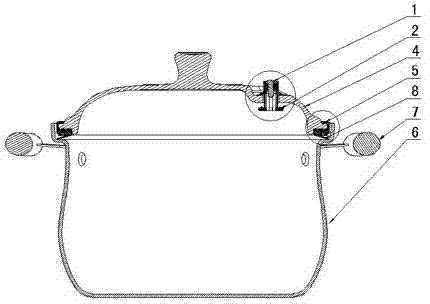

[0025] Figure 1 to Figure 5 Shown, for the specific embodiment that the present invention creates micro pressure cooker, it comprises pot body 6, pot cover 4, sealing ring 5, and described pot cover 4 is preferably made of glass or purple sand material, makes pot cover 4 have With a certain weight, the size of the slight pressure in the pot depends on the weight of the pot cover 4. The pot body 6 is provided with a reverse side step 8, and the pot cover 4 is provided with a pot cover convex edge 14 and a right angle On the side, the pot cover 4 is provided with an air vent 11, the pot body 6 is fixed with a handle 7, and the sealing ring 5 is provided with an inner card slot with an inward opening and a V-shaped mouth 17 with an outward opening. , the inner card slot of the sealing ring 5 is buckled on the flange 14 of the pot cover, the inner side of the V-shaped mouth 17 is on the right-angled edge of the pot cover 4, and the upper bottom surface of the V-shaped mouth 17 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com