Expansion flat gate valve

A flat gate valve, expansion type technology, applied in the direction of sliding valve, valve device, engine components, etc., can solve the problems of easy leakage, valve cover sealing ring and valve stem sealing pressure, etc., to improve sealing performance, sealing performance Good, prevent leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

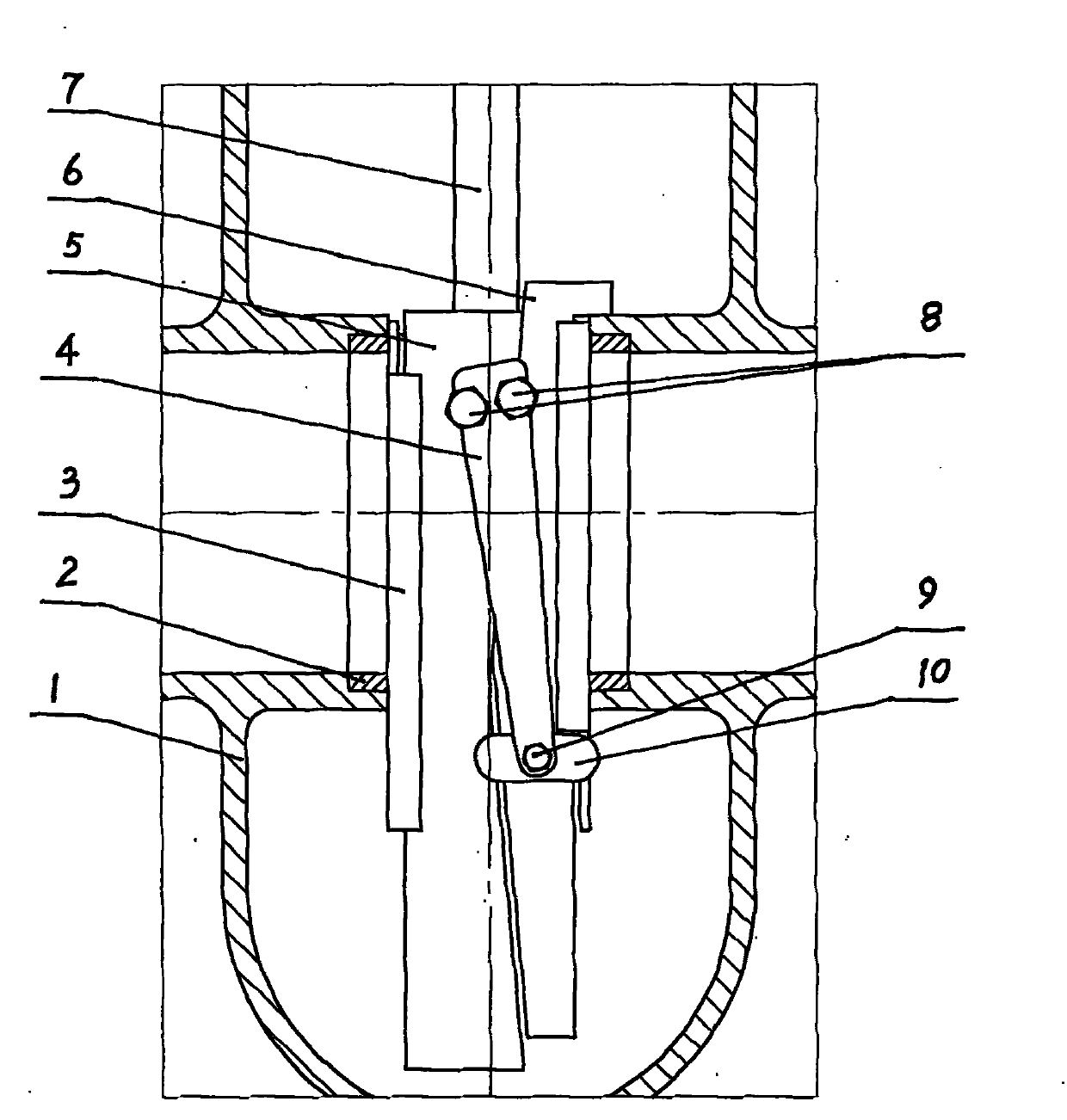

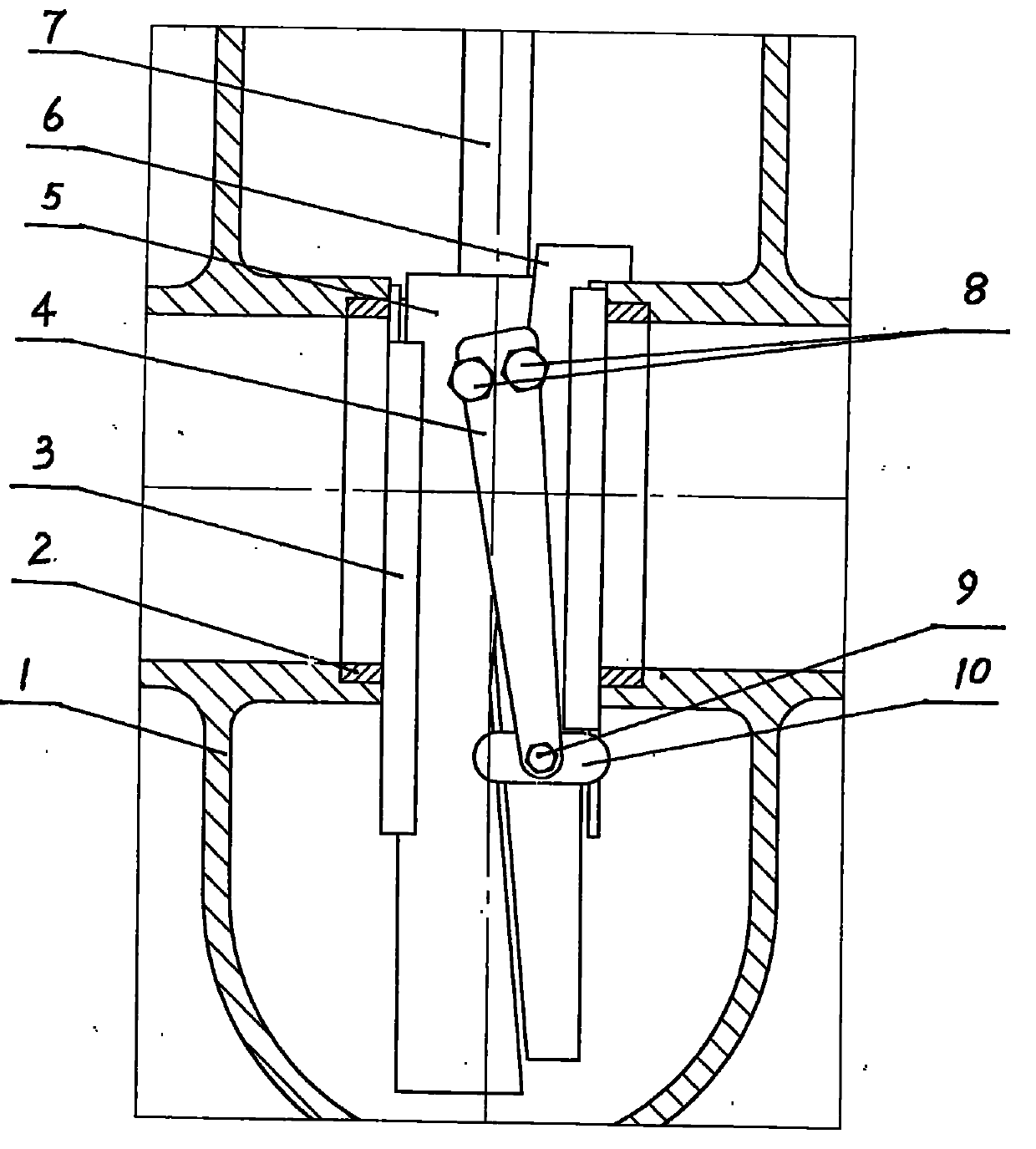

[0007] Such as figure 1 The expansion slab gate valve shown includes a valve body 1, a valve seat 2, a valve stem 7 and a gate plate. The gate plate is composed of a main gate plate 5 and a secondary gate plate 6. The upper end of the main gate plate 5 is fixedly connected to the lower end of the valve stem 7. , There is a V-shaped matching slope between the contact surfaces of the main gate 5 and the slave gate 6, and a lever lock mechanism is provided on the side planes of the master gate 5 and the slave gate 6. Described lever lock mechanism is made up of lever arm 4 and pendulum block 10, and pendulum block 10 is fixedly connected on the lower end of lever arm 4 by connecting pin 9, and the upper end of lever arm 4 is shaped on left and right two positioning grooves, left, right The two right locating grooves are movably installed on the main ram 5 and the slave ram 6 respectively by the pin shaft 8, wherein the left locating groove is movably positioned on the main ram 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com