Electrodialysis partitioning plate

A technology of electrodialysis and separator, which is applied in the field of electrodialysis, can solve the problems of increased equipment cost, reduced effective area of membrane, and reduced water channel area in the center of the separator, so as to achieve the effect of increasing sealing performance and sparse distribution of water distribution channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

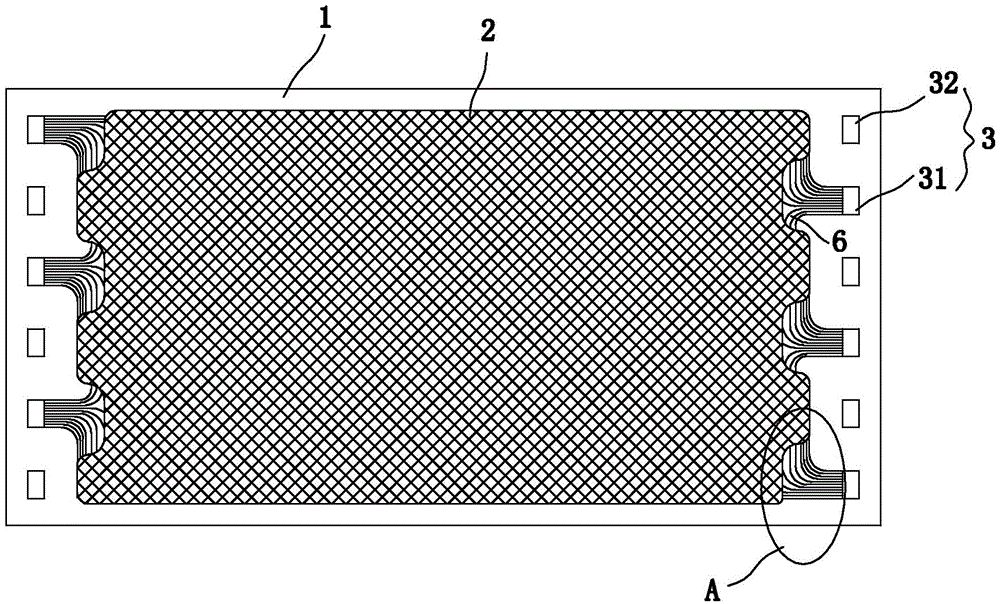

[0029] Such as Figure 1~3 As shown, an electrodialysis separator includes a plate frame 1 with a size of 200×400mm. The plate frame 1 is made of EVA resin and has a thickness of approximately 0.85mm. pp with a thickness of 0.80mm.

[0030] The upper and lower ends of the plate frame 1 are provided with liquid guide holes 3, and the liquid guide holes 3 are divided into two groups, one of which is an open liquid guide hole 31 communicating with the central cavity of the plate frame of this layer through the water distribution channel 4, and the other One group is the closed liquid guide holes 32 not connected with the central cavity of the frame of this layer, and the open liquid guide holes 31 and the closed liquid guide holes 32 are arranged at intervals. In this embodiment, the shape of the liquid guide hole 3 is rectangular, and the specification is 20×10mm, and it can also be circular or elliptical.

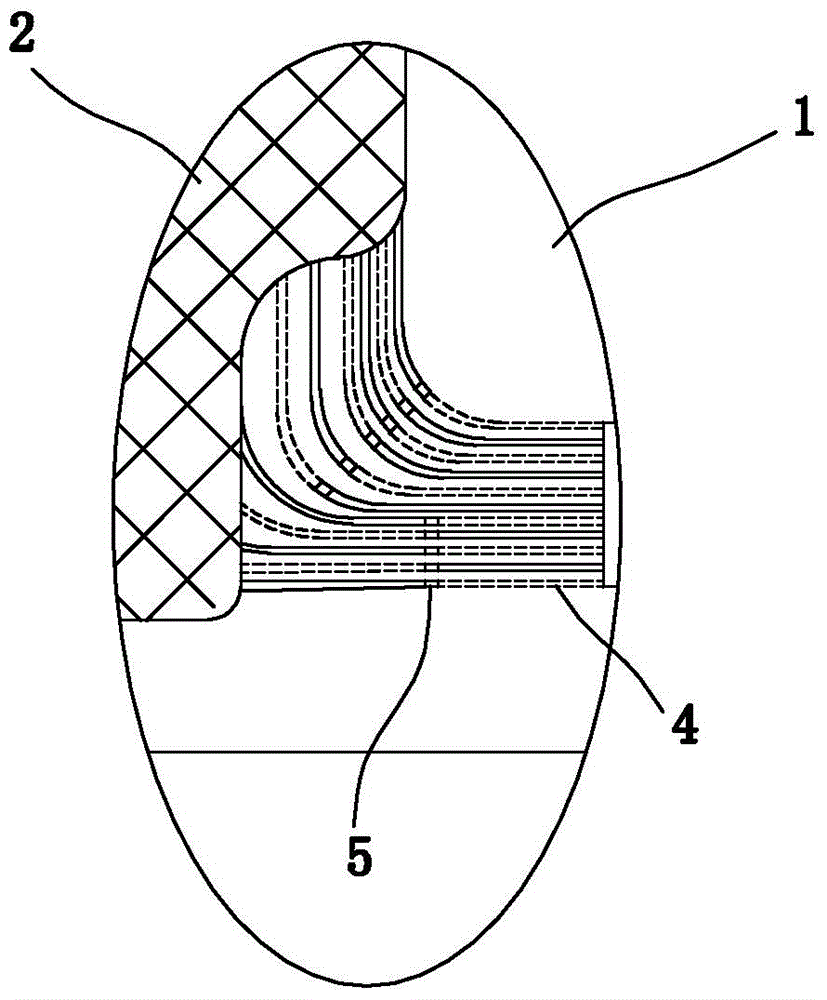

[0031] The improvement of the present invention mainly lies in the st...

Embodiment 2

[0040] Use 20 pairs of 200×400mm homogeneous ion-exchange membranes, and 40 pieces of electrodialysis separators with a vinyl acetate content of 15%, and assemble them into a membrane stack according to the installation order of the electrodialysis membrane stack. L of NaCl solution, the flow rate is 0.5m3 / h, the test voltage is 30V DC, the water inlet pressure of the membrane stack is 0.05MPa, the test shows that the membrane stack has no leakage during long-term operation, and the primary desalination rate of the membrane stack reaches 39%. .

Embodiment 3

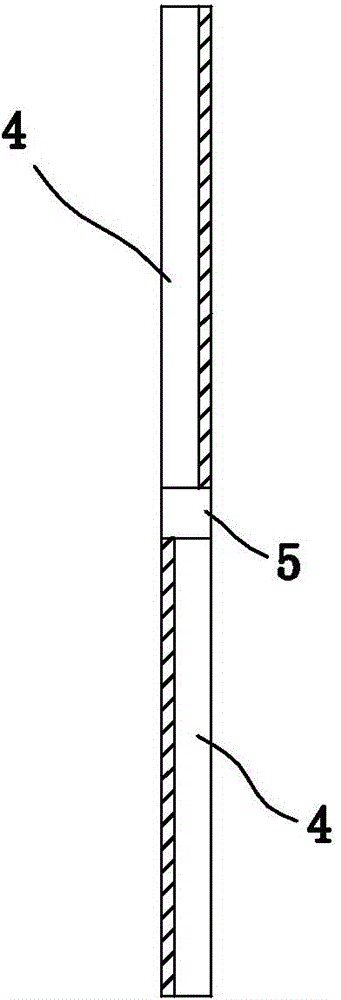

[0042] The partition is 800mm long and 400mm wide. The frame 1 is made of EVA sheet with a vinyl acetate content of 15%, and the thickness is 0.9mm. The thickness of the partition 2 is 0.80mm. The liquid guide holes 3 are 6 rectangular holes of 25×15 mm, and each open liquid guide hole 31 is correspondingly provided with 12 water distribution channels 4 with a depth of 0.72 mm, the length of the perforation 5 is 1.5 mm, and the initial width of the water distribution channel 4 The width of the curved part is increased to 1.5mm after being arced, the distance between adjacent water distribution channels in the initial section is 1.2mm, the distance between the edge of the protrusion 6 and the end edge of the plate frame 1 is 90mm, and the rest are the same as in embodiment 1.

[0043] Form the membrane stack according to the method of Example 1, the NaCl solution with an inflow concentration of 1000mg / L in the concentration chamber, and a flow rate of 1m 3 / h, the test voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com