Leakage-proof pressure-bearing hydraulic cylinder

A hydraulic cylinder and anti-leakage technology, applied in the field of hydraulic machinery, can solve problems such as flattening and leakage of sealing rings, and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

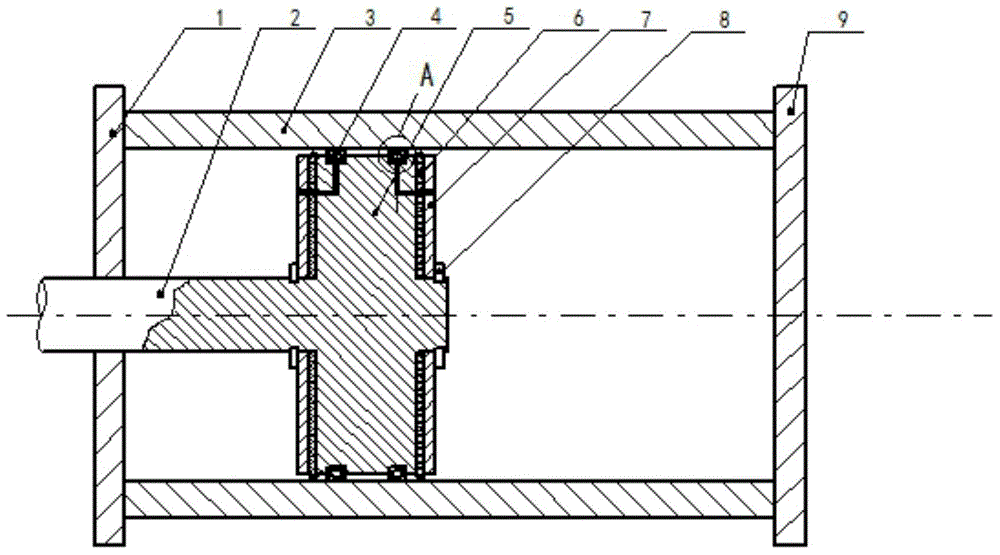

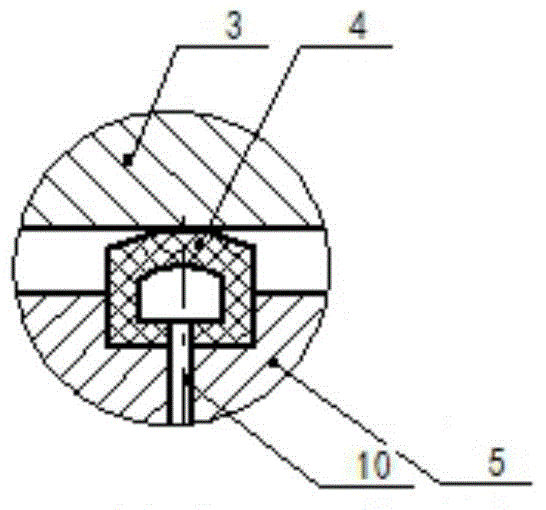

[0013] An anti-leakage pressurized hydraulic cylinder, comprising a left cylinder head 1, a right cylinder head 9, a cylinder barrel 3, a cylinder rod 2, a piston 5 and a pressure bearing plate 7, which are coaxially fixed between the left cylinder head and the right cylinder head Cylinder, coaxial sliding piston in the cylinder, the piston and the cylinder rod are coaxially produced in one body; the pressure bearing plates are symmetrically installed on the front and rear diameter surfaces of the piston, and the pressure bearing plates are coaxially fixed by the snap ring 8 On the piston, a seal 6 is installed coaxially between the pressure bearing plate and the radial surface of the piston.

[0014] The innovation point of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com