Connectable chamber for porthole testing

A porthole and connecting flange technology, which is applied in the field of shipbuilding, can solve the problems of inability to ensure the sealing of the connection, increase the risk of material transfer, and complicated testing of small submarines, and achieve the effect of improving the sealing performance and eliminating leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

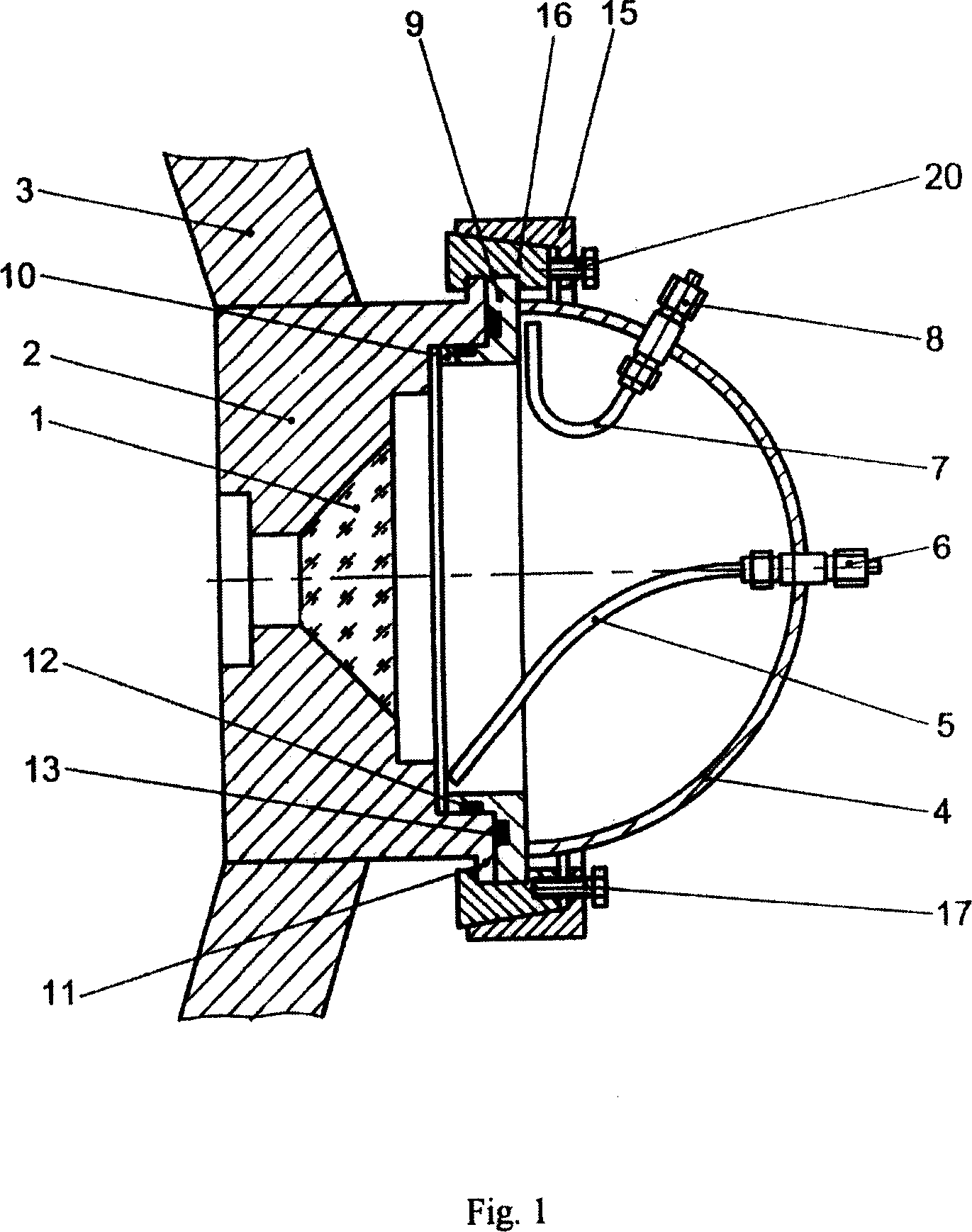

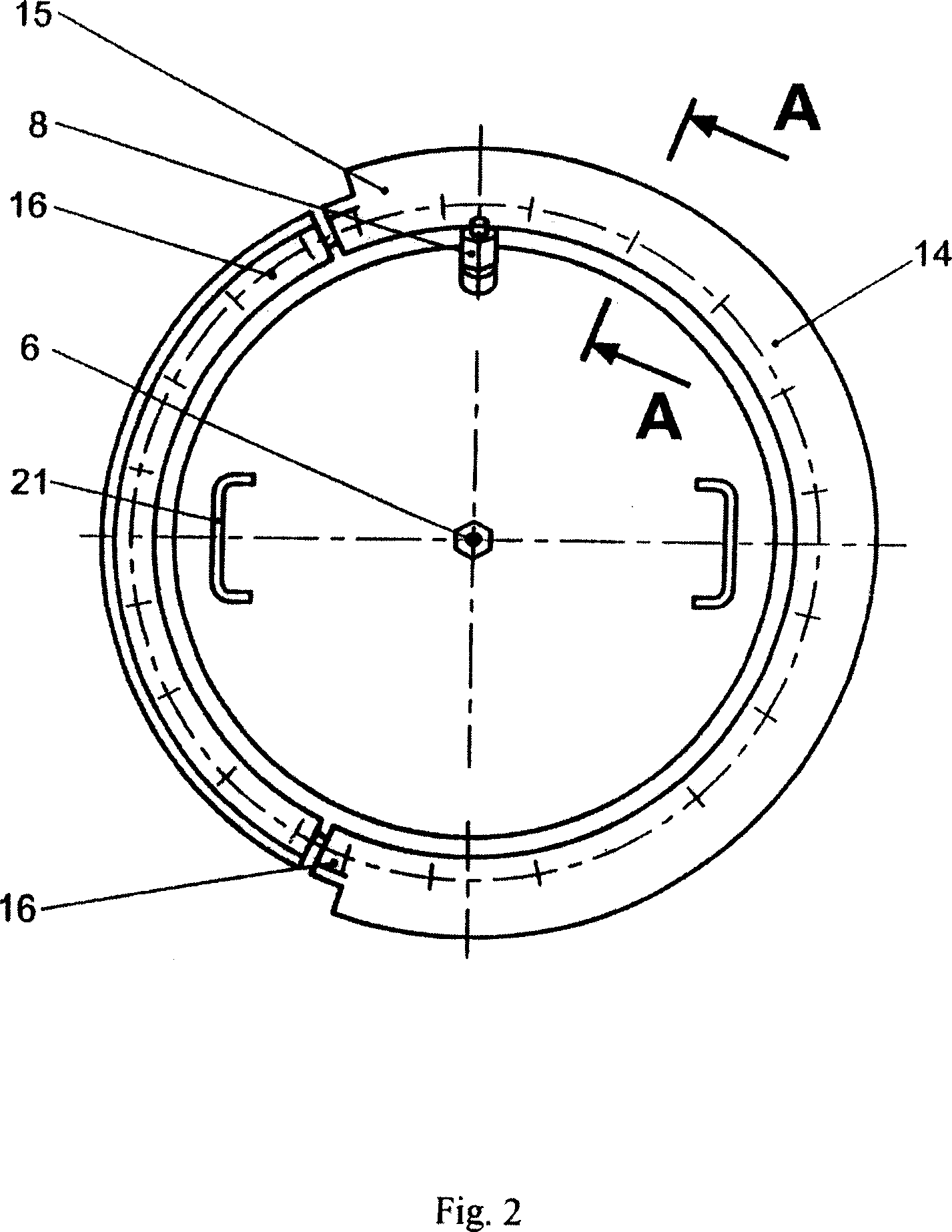

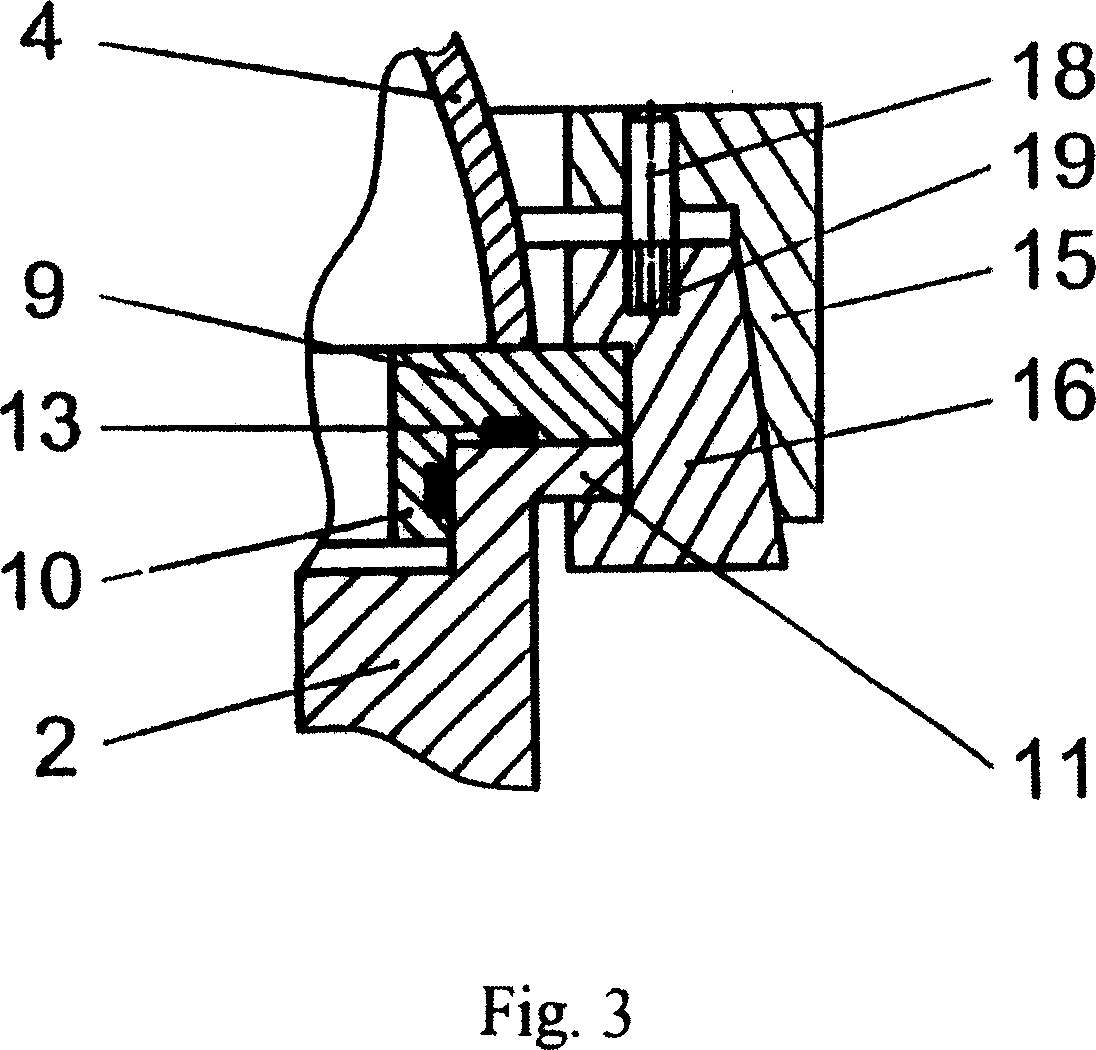

[0017] A connectable cabin for testing portholes 1, with a cylindrical cabin 2, located on a submarine 3. The cylindrical cabin body 2 adopts a socket-type welding connection (hereinafter referred to as "socket-type welding connection 2"). Said connectable tank has a body 4 (shown in Figure 1) of at least partially spherical surface and has a conduit 5 for supplying a working medium (fresh water) from an external pressure source (not shown in Figure 1). Said duct has a duct seal 6 and a duct 7 for exhausting air from 5. Said pipe 7 also has a pipe seal 8 on it. The cabin body 4 is provided with a connecting flange 9 , and the connecting flange 9 is provided with an annular ring 10 whose diameter is smaller than the diameter of the spherical portion of the cabin body 4 . The size of the cross section of the inner annular ring 10 exceeds that of the porthole 1, which ensures that the former completely encloses the latter. The connecting flange 9 corresponds to a bearing flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com