Low-leakage high-temperature resistant asbestos-free plate or cushion

An asbestos-free and fluororubber-free technology, which is applied in the field of gaskets or sealing plates, can solve problems such as poor sealing performance (poor leakage rate), and achieve the effects of improved sealing performance, high sealing performance, and optimized product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

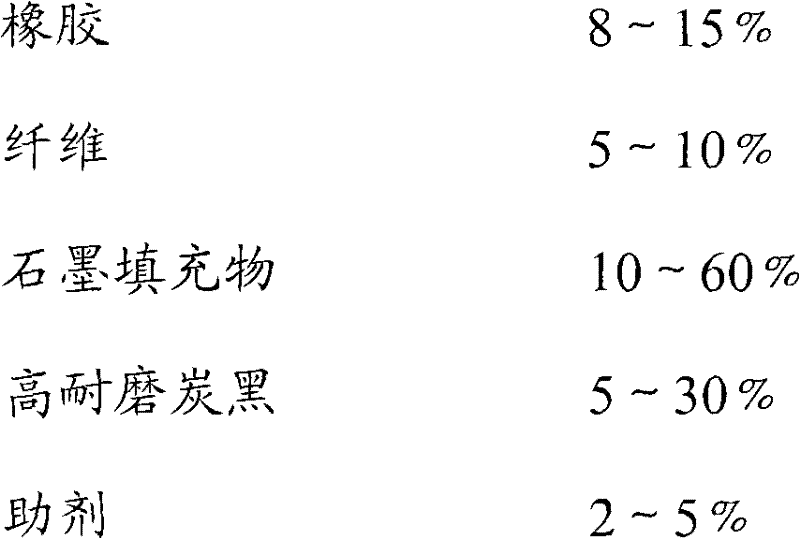

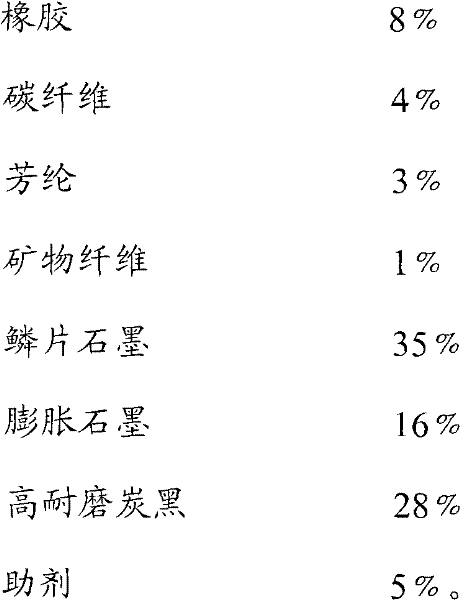

[0044] Prepare materials according to the following specific compositions and proportions, and the percentages of all substances are mass percentages:

[0045]

[0046] Prepare asbestos-free panels as follows:

[0047] (1) Mixing material: DF-JBJ800 flip mixing machine is used, with a charging capacity of 250-300kg, according to the specific feeding sequence of powder → carbon fiber → organic fiber → rubber → mineral fiber → vulcanizing agent, and then carry out mixing. The material temperature is 55°C, the mixing time is 4 hours, and the aging time is 5 hours;

[0048] (2) Sheeting: CKCJ-1.3×1.590 CNC sheeting machine is adopted, the temperature of the large roll is controlled at 80°C, the temperature of the small roll is 6°C, the speed of both large and small rolls is 30 m / min, the line pressure of sheeting is 5 tons, and the speed of the advancing and retreating rolls It is 18, and the large and small rolls of the sheet forming machine are both steamed and cooled.

[0...

Embodiment 2

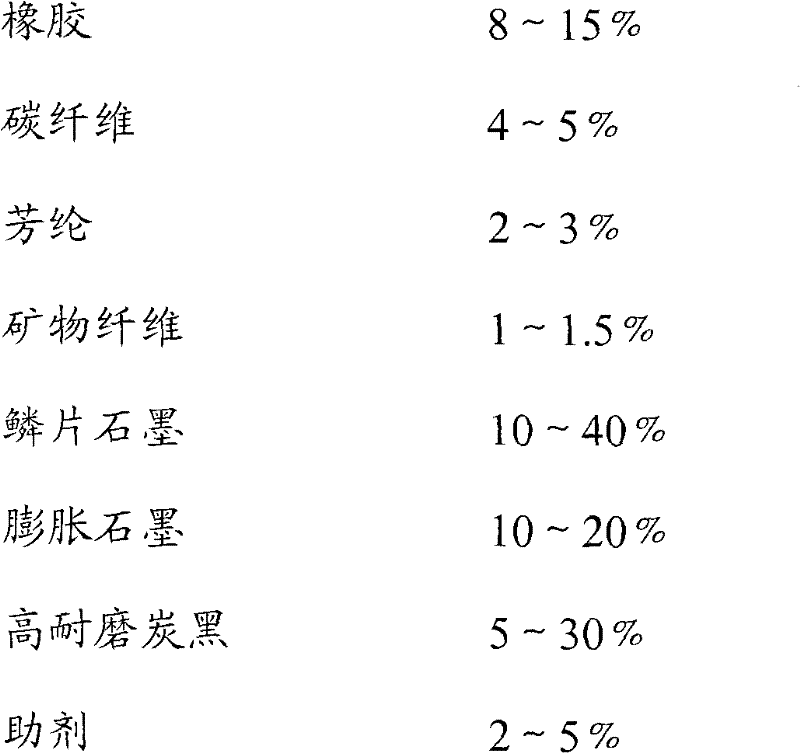

[0054] Prepare materials according to the following specific compositions and proportions, and the percentages of all substances are mass percentages:

[0055]

[0056] Prepare asbestos-free panels as follows:

[0057] (1) Mixing material: DF-JBJ800 flip mixing machine is used, with a charging capacity of 250-300kg, according to the specific feeding sequence of powder → carbon fiber → organic fiber → rubber → mineral fiber → vulcanizing agent, and then carry out mixing. The material temperature is 50°C, the mixing time is 4 hours, and the aging time is 4.5 hours;

[0058] (2) Sheeting: CKCJ-1.3×1.590 CNC sheeting machine is used, the temperature of the large roll is controlled at 90°C, the temperature of the small roll is 6°C, the speed of the large and small rolls is 30 m / min, the line pressure of the sheet is 4 tons, and the speed of the advancing and retreating rolls It is 20, and the large and small rolls of the sheet forming machine are both steamed and cooled.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com