Pre-tightening optimization method of bolt connecting component

A technology for connecting components and optimization methods, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as increasing device energy consumption, equipment shutdown, polluting the environment, and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

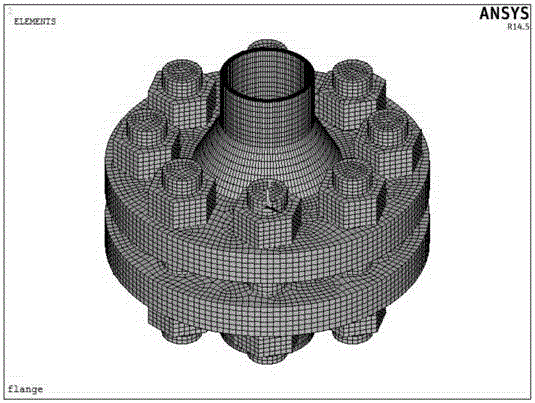

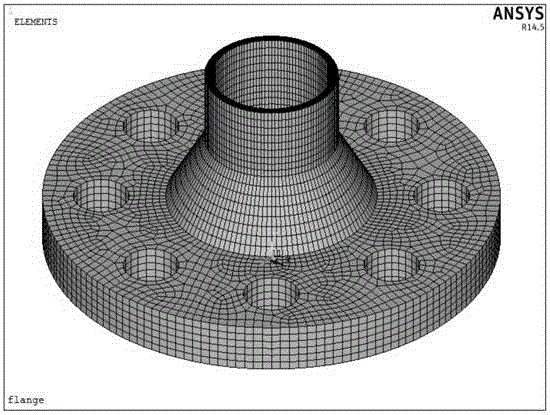

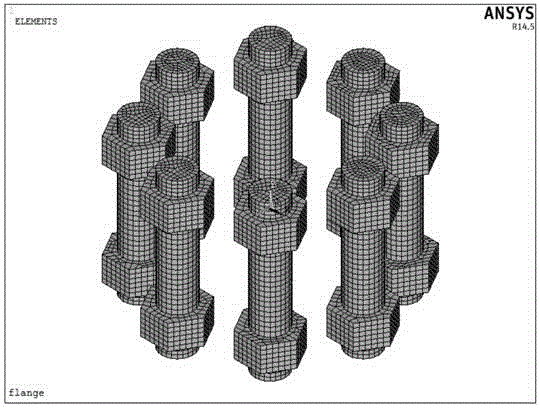

[0028] figure 1 It is a structural schematic diagram of the bolt connection assembly of the present invention. like figure 1 As shown, the bolted connection assembly of the present invention includes two connecting pieces 1 , the two connecting pieces are fixedly connected by a bolt group 3 , and a gasket 2 is arranged between the contact surfaces of the two connecting pieces 1 . In the present invention, the connecting piece can be a flange, and there are multiple bolt groups 3, including studs and nuts matched therewith. In this way, the bolted connection assembly of the present invention can also be referred to as a bolted flange connection structure. This structure mainly uses the clamping force generated by tightening the bolts to form a tight connection between the upper and lower flanges and the sealing gasket. Cover, so as to achieve the purp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com