Self-tightening sealing structure for single detector

A sealing structure and detector technology, which is applied in engine sealing, nuclear power generation, climate sustainability, etc., can solve problems such as gasket leakage, increased radiation dose, general sealing performance of sealing structures, etc., and achieve enhanced sealing effect , avoid leakage, improve the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

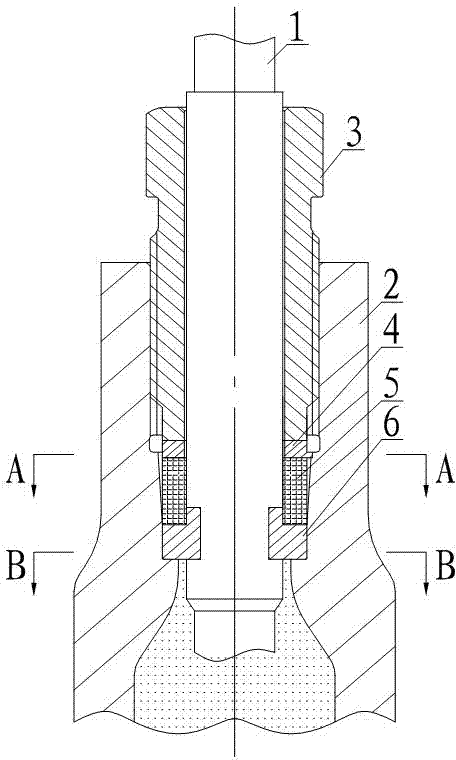

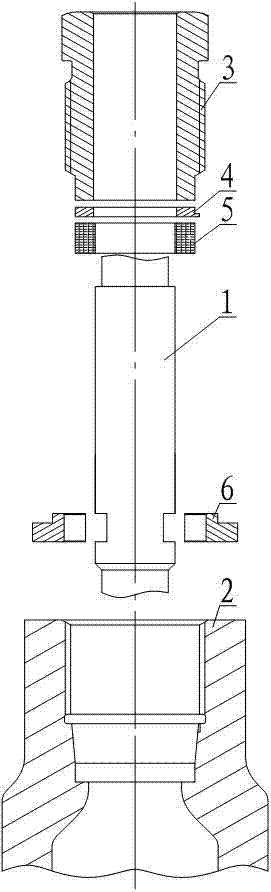

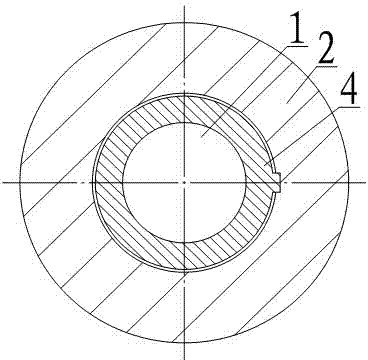

[0021] Such as figure 1 , figure 2 and Figure 4 As shown, a self-tightening sealing structure is used for a single detector, including a detector 1, a tube base 2 and a tubular connector 3. The tube base 2 is provided with a fluid cavity and a probe introduction channel, wherein the fluid cavity is in contact with the probe introduction channel. Normally, the fluid in the fluid cavity is usually coolant. The lower end of the tubular connector 3 is set in the detector introduction channel and connected to the tube base 2. The lower end of the detector 1 is arranged in the fluid chamber after passing through the inner hole of the tubular connector 3 and the detector introduction channel. The detector 1 is directly connected to the fluid chamber. The fluid contact inside can ensure the measurement response performance of the detector 1 when the detector 1 is used for measurement. The inner wall of the detector introduction channel forms an annular support platform, which can...

Embodiment 2

[0023] The main difference between this embodiment and Embodiment 1 is that this embodiment defines the following structure on the basis of Embodiment 1: the area where the packing seal 5 is accommodated in the detector introduction channel of this embodiment is large at the top and small at the bottom tapered inner hole. In this way, it can further ensure that the radial pressure distribution of the packing seal 5 is reasonable when it is compressed, which is more conducive to the self-tightening sealing of the packing seal 5 and reduces the pre-tightening force.

Embodiment 3

[0025] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the connection structure between the separation ring 6 and the detector 1 is further improved. In this embodiment, the connection between the detector 1 and the separation ring 6 forms a ring Groove, the separation ring 6 is connected with the detector 1 through its inner ring embedded in the annular groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com