Sealing cover sealing device of storage tank

A sealing device and storage tank technology, which is applied in the field of oil and gas storage tank sealing, can solve problems such as sealing ring fire, sealing ring burning, and insufficient air tightness, and achieve the effects of enhanced sealing performance, easy installation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

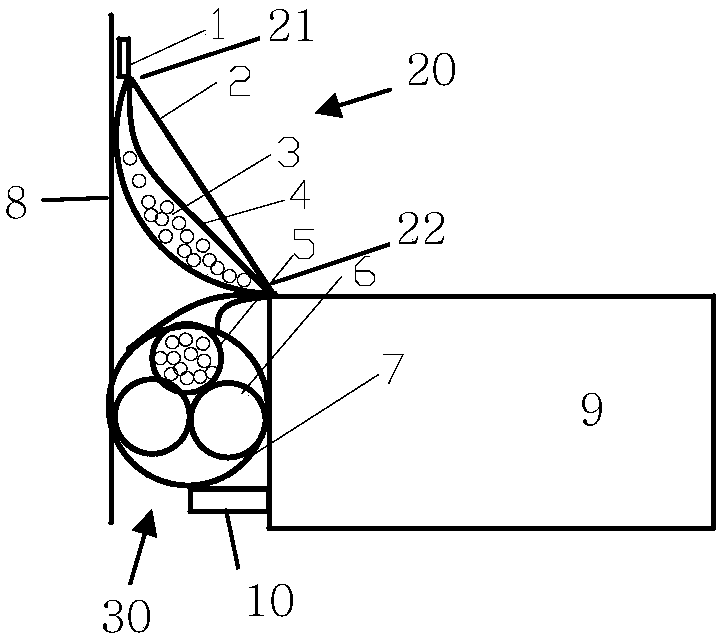

[0044] Such as figure 1 As shown, the cover sealing device for a storage tank according to the present invention includes a first sealing assembly 30 located in the gap between the tank wall 8 and the cover 9 . The first sealing assembly 30 includes a sealing bag 7 connected to the cover 9 and a flexible sealing ring 6 accommodated in the sealing bag 7, the flexible sealing ring 6 and the tank wall 8 and the flexible sealing ring Extrusion exists between 6 and cover 9.

[0045]In the process of oil and gas extraction, processing, application, storage and sales, it is inevitable to contain or store volatile petroleum products such as crude oil, gasoline or kerosene in storage tanks. For flammable and explosive products, the tightness of the storage tank is extremely important. For example, it is often faced with the problem of how to improve the tightness between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com