Electric jet printing device capable of dredging spray head through variable-pressure airflow

A technology of electrojet printing and nozzles, applied in coating devices, manufacturing auxiliary devices, additive manufacturing, etc., can solve the problems of functional ink texture stability, long processing cycle, and difficulty in dredging, and achieve the optimization of micro-nano functional structure , short processing cycle and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

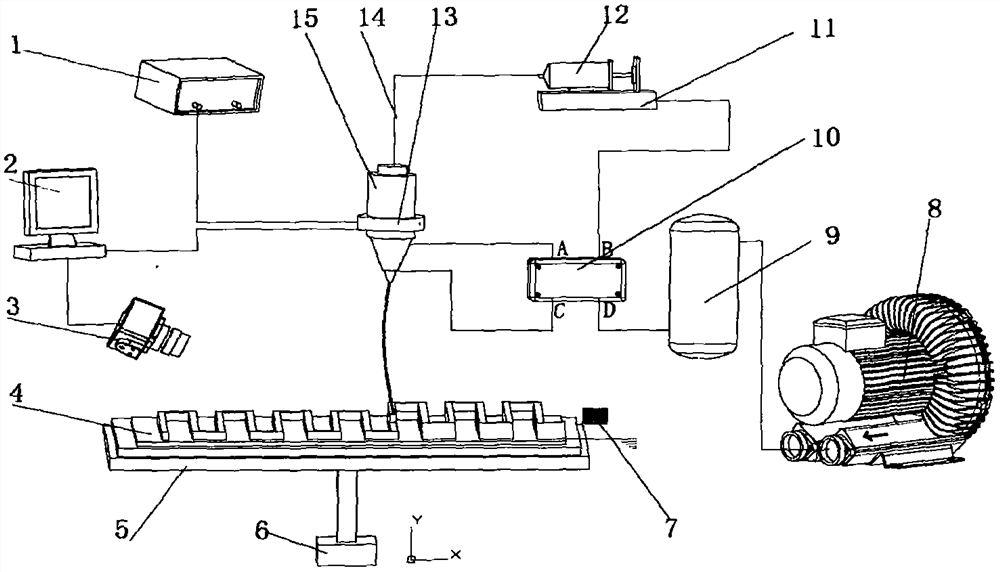

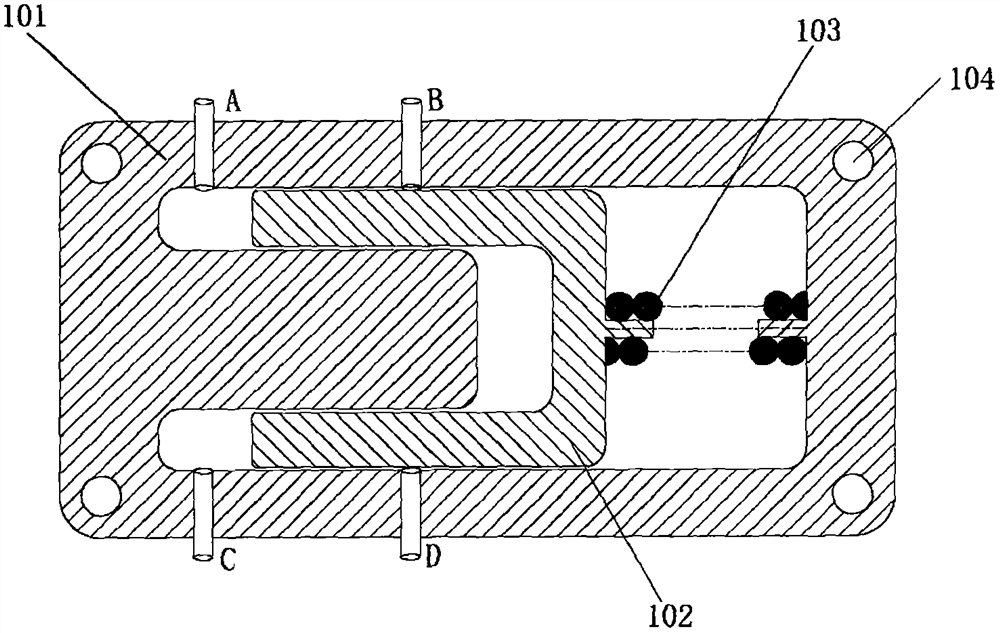

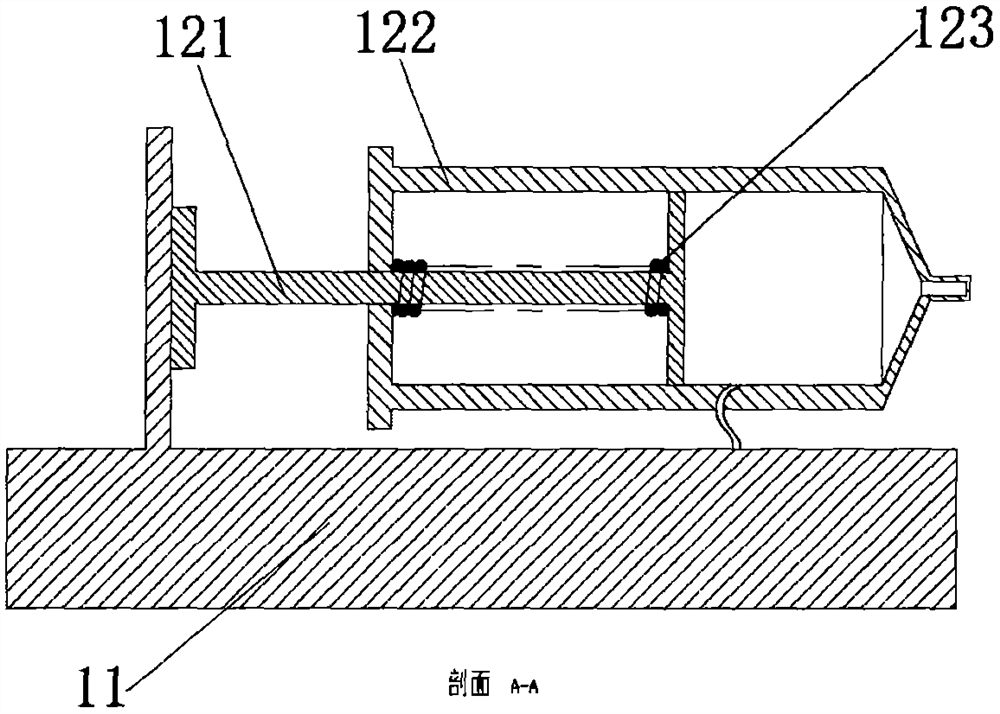

[0026] The specific implementation manner of the present invention will be described in detail below in conjunction with the technical scheme and the accompanying drawings. see Figure 1 to Figure 3 .

[0027] This embodiment discloses an electrojet printing device for dredging nozzles with variable pressure airflow, which includes four parts: a jet printing module, a visual detection module, an adsorption module and an air pressure dredging nozzle module. Based on the electrohydrodynamic effect, the functional ink 14 is delivered to the nozzle at a fixed flow rate, and then under the combined action of electric field force, gravity, and surface tension, a nano-scale fine jet is formed to quickly realize the preparation of micro-nano functional structures; when the nozzle is blocked , two-position four-way valve 10 actions, using variable pressure airflow to apply reciprocating pressure and suction to the blockage of the nozzle, realizing disassembly-free, automatic dredging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com