Biomass fuel conveying deivce

A biomass fuel and delivery device technology, applied in fuel supply, combustion method, combustion equipment, etc., can solve the problems that powdery fuel cannot be delivered to the combustion device, the equipment structure is complicated, and the difficulty of delivery is increased, so as to achieve continuous stability The effect of fuel delivery, clean working environment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

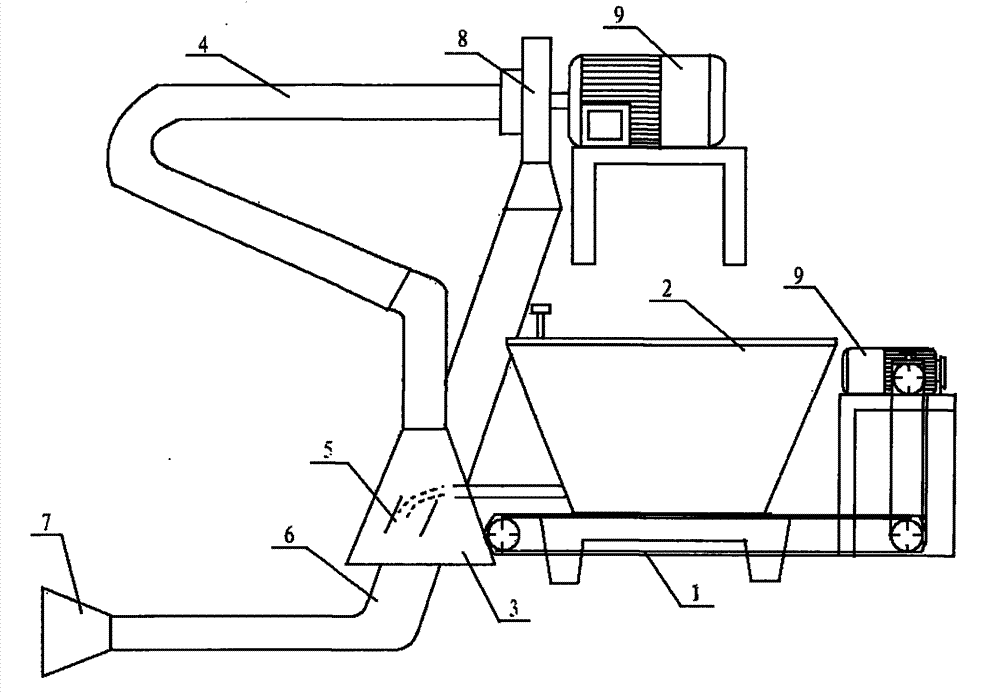

[0017] Attached below figure 1 Further explain the preferred embodiment of the biomass fuel delivery device of the present invention:

[0018] as attached figure 1 As shown in , the conveyor belt 1, the dumping funnel 2, the feeding hopper 3, the blower fan 8, and the motor 9 are used. 7. Install according to the following plan: a chain reducer is installed at one end of the conveyor belt 1, and the discharge funnel 2 is fixedly installed above the conveyor belt 1. The optimal length and width of the upper port is 1.3×0.8m, and the optimal length and width of the lower port 1.3×0.3m, the best height is 0.5m, there is a gate valve made of iron plate at the lower opening of the discharge funnel 2, the best length and width are 0.2m×0.15m, and eight gears are set according to the air flow , the gate valve can effectively save combustion fuel. The feed hopper 3 is respectively provided with a side port, an upper port and a lower port, the upper port is connected to the floating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com