Method for conveying medium-concentration stuff and medium-concentration stuff pump system device for implementing same

A system device and thick stock pump technology, which is applied in the liquid flow control device, distribution device, transportation and packaging, etc., can solve the problems of large friction coefficient between pulp fiber and screw rubber bushing, unstable pulp feeding, failure, etc. , to achieve the effect of continuous and stable transportation, safe operation and effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

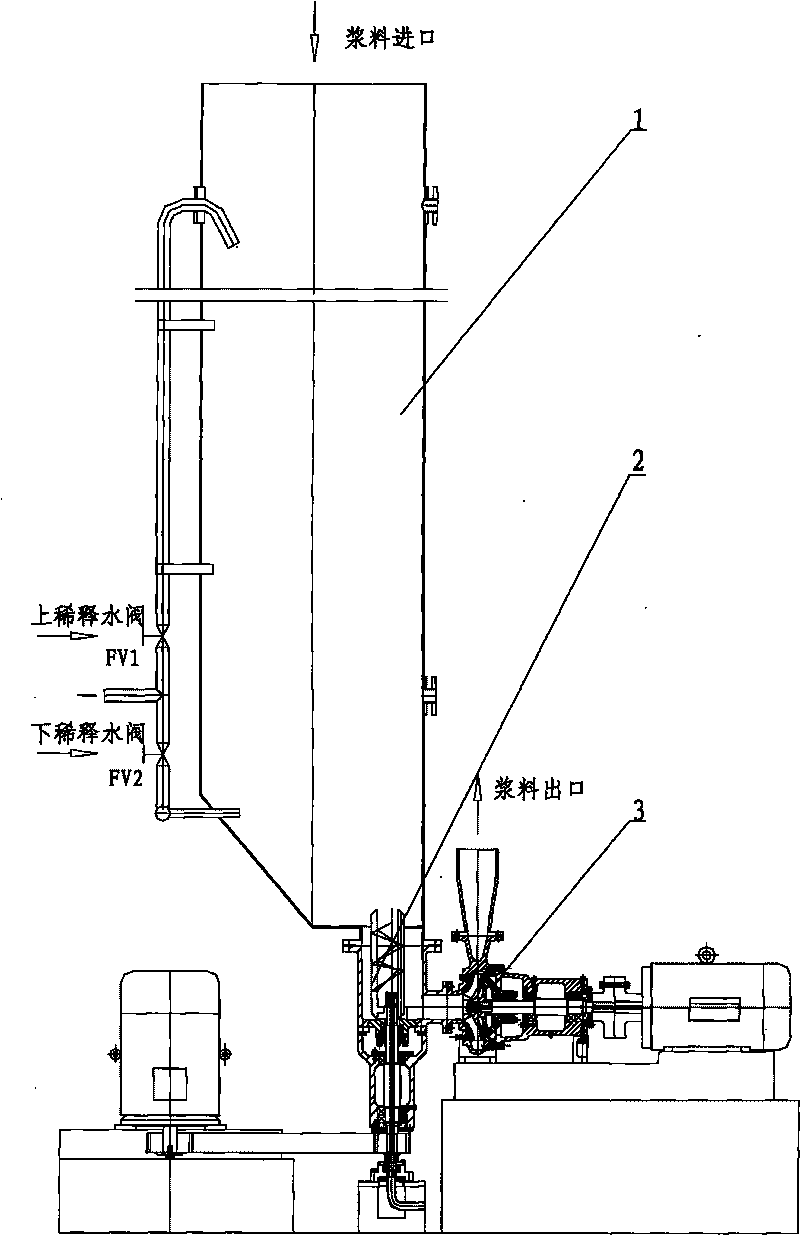

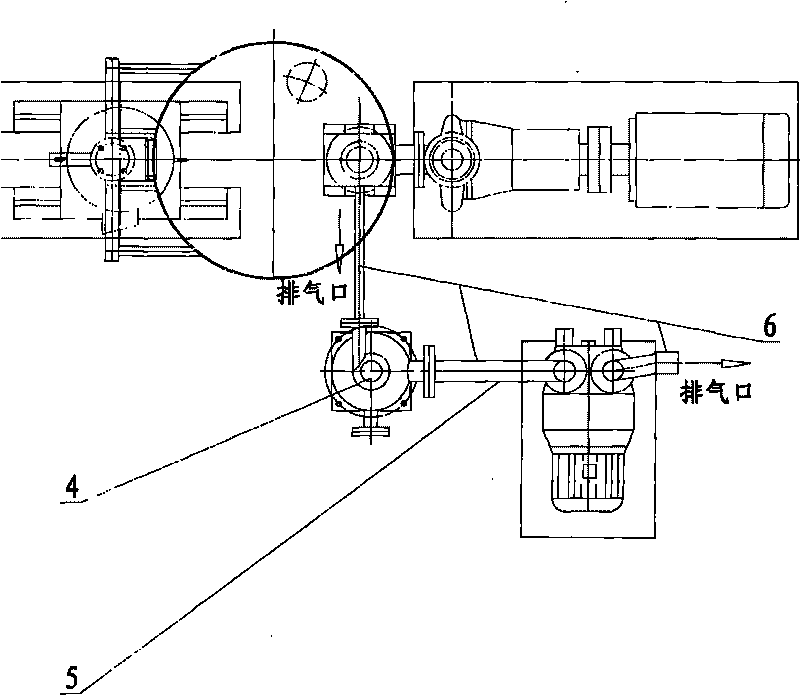

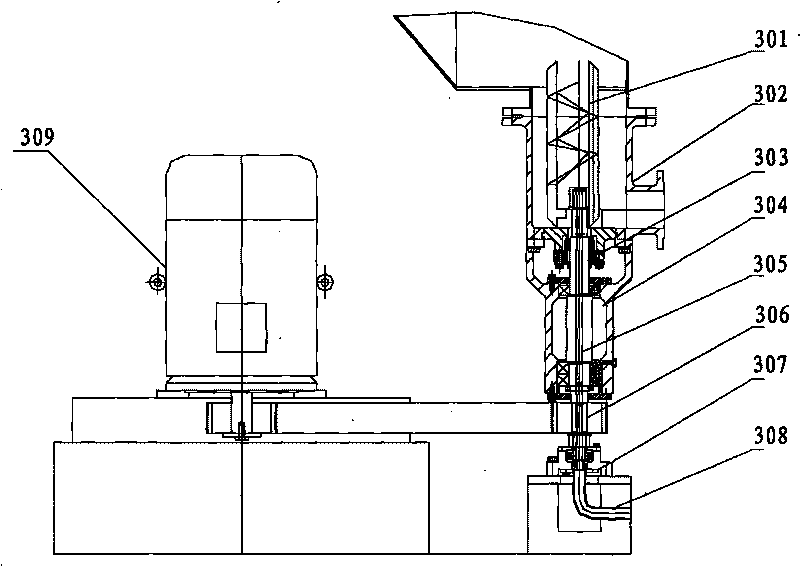

[0028] figure 1 A specific embodiment of the present invention is shown, by figure 1 , figure 2 As shown, the medium-consistency pump system device of the present invention includes a medium-consistency riser 1 , a turbulence generator 2 , a centrifugal medium-consistency pump 3 , a three-phase separator 4 , a vacuum pump 5 and a system connecting pipeline 6 .

[0029] The medium concentration standpipe 1 has a diameter of less than 900mm and a cylinder height greater than 3000mm, and the bottom of the medium concentration standpipe is folded at an angle of 45 degrees along the center line of the medium concentration standpipe, and the bottom of the medium concentration standpipe is connected with medium concentration slurry Dilution water pipes are installed on the medium concentration standpipe, and upper and lower dilution water valves FV1 and FV2 are installed. The medium concentration slurry enters from the top of the medium concentration standpipe 1 and is discharged f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com