High-pressure continuous dense-phase biomass powder conveying device with height of delivery outlet adjustable

A technology of dense phase conveying and biomass, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., to achieve the effect of small pulsation and continuous conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

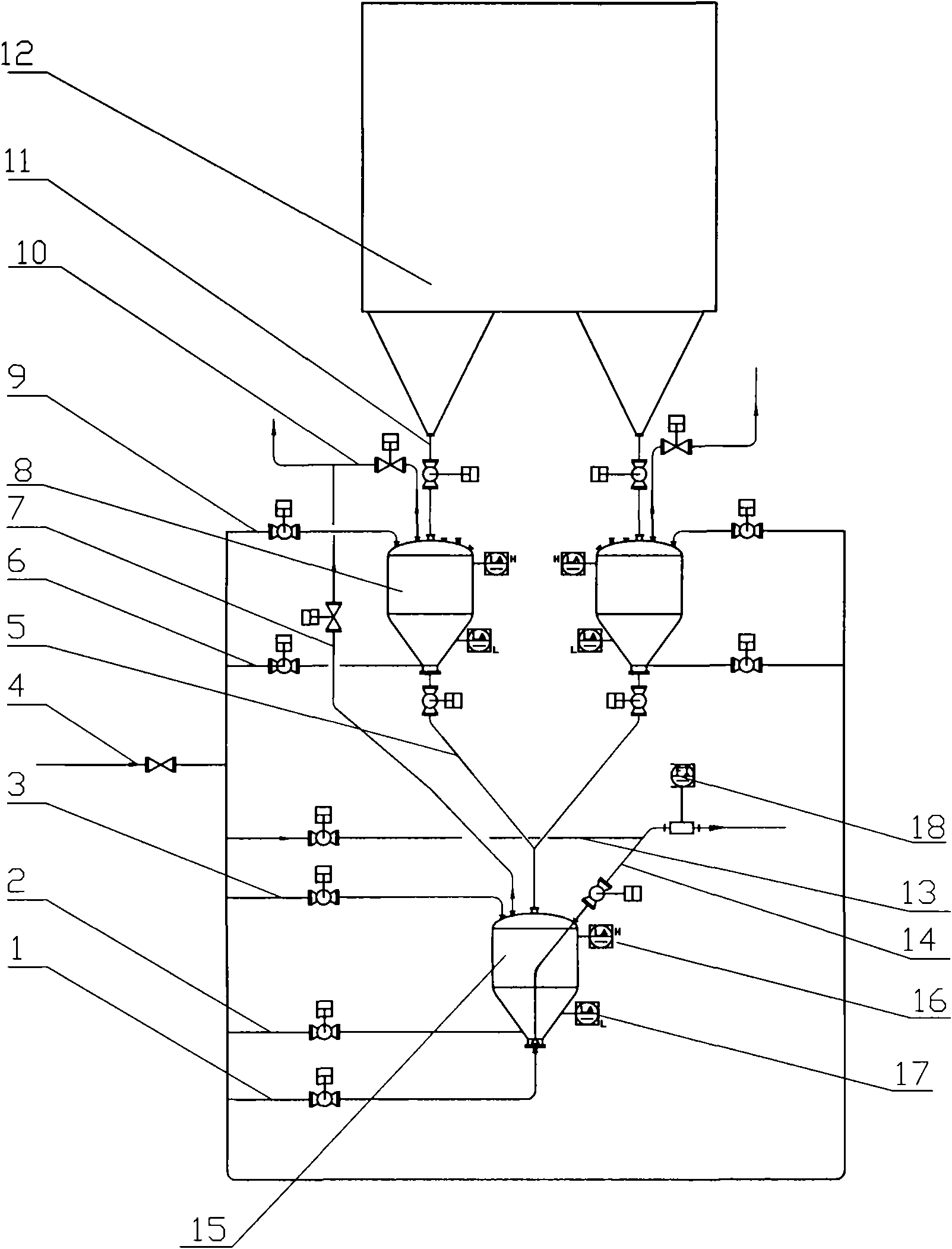

[0020] Example: Combine figure 1 , the conveying device of the present embodiment, its working process and working principle:

[0021] When the work starts, close the control valve of the feeding bin discharge pipe (that is, the feeding pipe of the sending bin) 5, open the control valve of the feeding bin feeding pipe 11, and the material is fed to the feeding bin 8 by the storage bin 12, when Stop feeding when the material in the feeding bin reaches the high material level, close the control valve of the feeding pipe 11 of the feeding bin, open the control valve of the stamping air pipe 9 of the feeding bin, add N2 to the feeding bin to pressurize, when the pressure of the feeding bin 8 is higher than the sending When the pressure of the warehouse 15 is high, open the control valve of the feeding warehouse discharge pipe 5 (that is, the feed pipe of the sending warehouse), and simultaneously adjust the control valve of the sending warehouse pressure regulating air pipe 7 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com