Lithium battery diaphragm compound device and compound method thereof

A lithium battery diaphragm and composite device technology, which is applied in lamination devices, chemical instruments and methods, and layered products, can solve the problems of low bonding strength of the diaphragm and poor composite effect, and achieve continuous and stable transportation. Improve quality and efficiency, composite better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

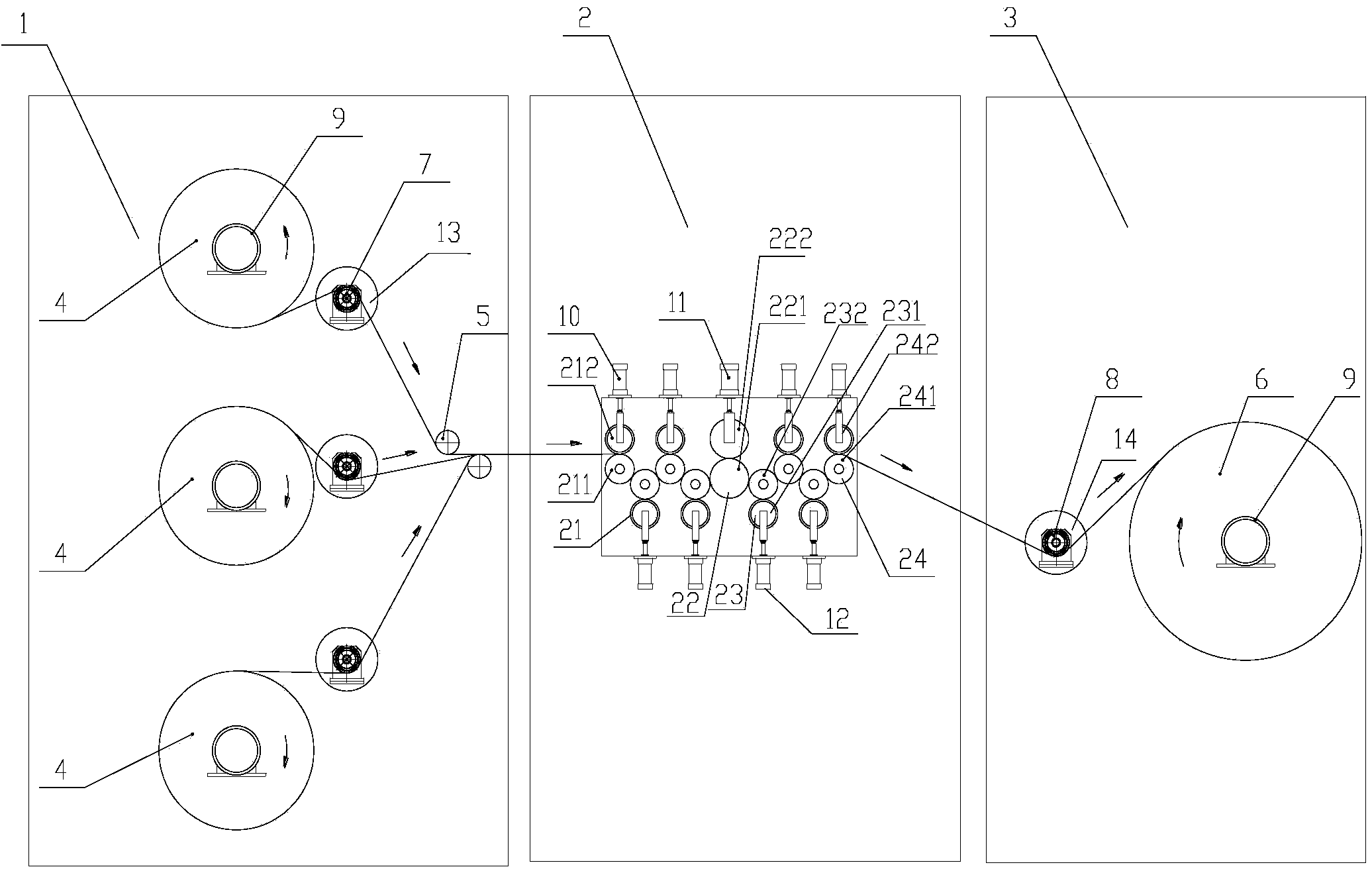

[0048] The single-layer PP and PE films are unwound by three unwinding rollers 4, and the unwinding rollers 4 control the tension of the film through the servo motor 9. There are three sets of unwinding guide rollers 13 behind the unwinding rollers, which are used to unwind the lithium battery. The diaphragm is guided to the rolling device 2, the direction guide roller 5 is used to change the introduction angle of the film, and the three-layer film is rewound together to form a PP / PE / PP three-layer diaphragm, wherein the PE film is located between the two layers of PP film middle;

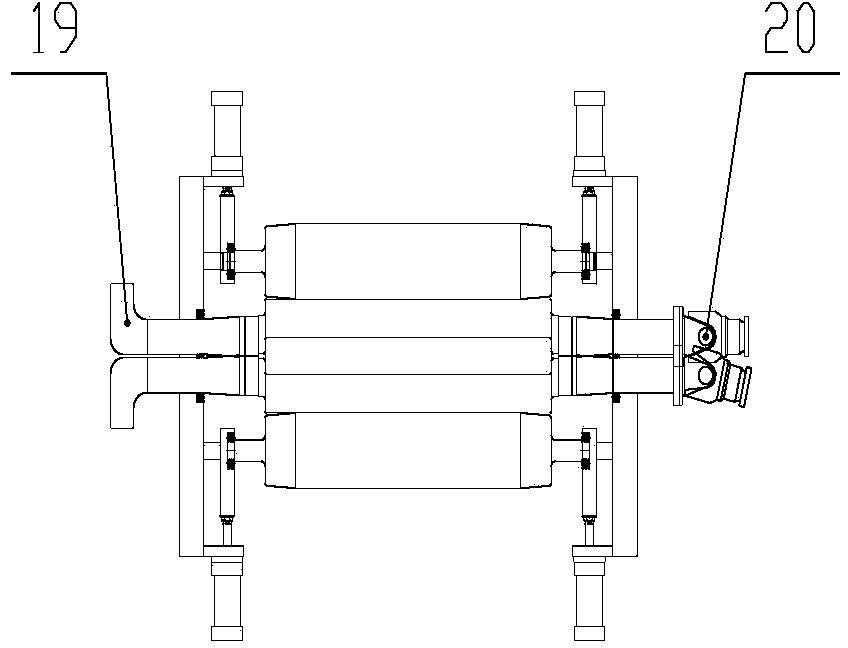

[0049] The three-layer PP / PE / PP separator is rolled and laminated through a rolling device. The rolling device 2 includes a preheating roller 21, a hot pressing roller 22, a heat setting roller 23 and a cooling roller 24, and all rollers are connected with a drive motor through a universal joint 20 and driven by a reduction motor. The three-layer PP / PE / PP diaphragm is uniformly preheated by the pr...

Embodiment 2

[0052] The single-layer PP and PE films are unwound through the unwinding roller 4, which controls the tension of the film through the servo motor 9, and there are three sets of unwinding guide rollers 13 behind the unwinding roller, which are used to guide the lithium battery diaphragm To the rolling device 2, the direction guide roller 5 is used to change the introduction angle of the film, and rewind the three-layer film together to form a PP / PE / PP three-layer diaphragm, wherein the PE film is located in the middle of the two-layer PP film;

[0053] The three-layer PP / PE / PP separator is rolled and laminated through a rolling device. The rolling device 2 includes a preheating roller 21, a hot pressing roller 22, a heat setting roller 23 and a cooling roller 24, and all rollers are connected with a drive motor through a universal joint 20 and driven by a reduction motor. The three-layer PP / PE / PP diaphragm is uniformly preheated by the preheating roller 21 in sequence, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com