Air-vibrating type jet-boosted discharging device

A technology of boosting and air vibration, which is applied in the direction of transportation, packaging, and slipway, etc. It can solve the problems that the coal humidity control system cannot run continuously and stably, the chute conveying equipment is cracked, and the coal material is not smoothly conveyed, etc., and it is easy to install and debug , Small size of the equipment, prolonging the service life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

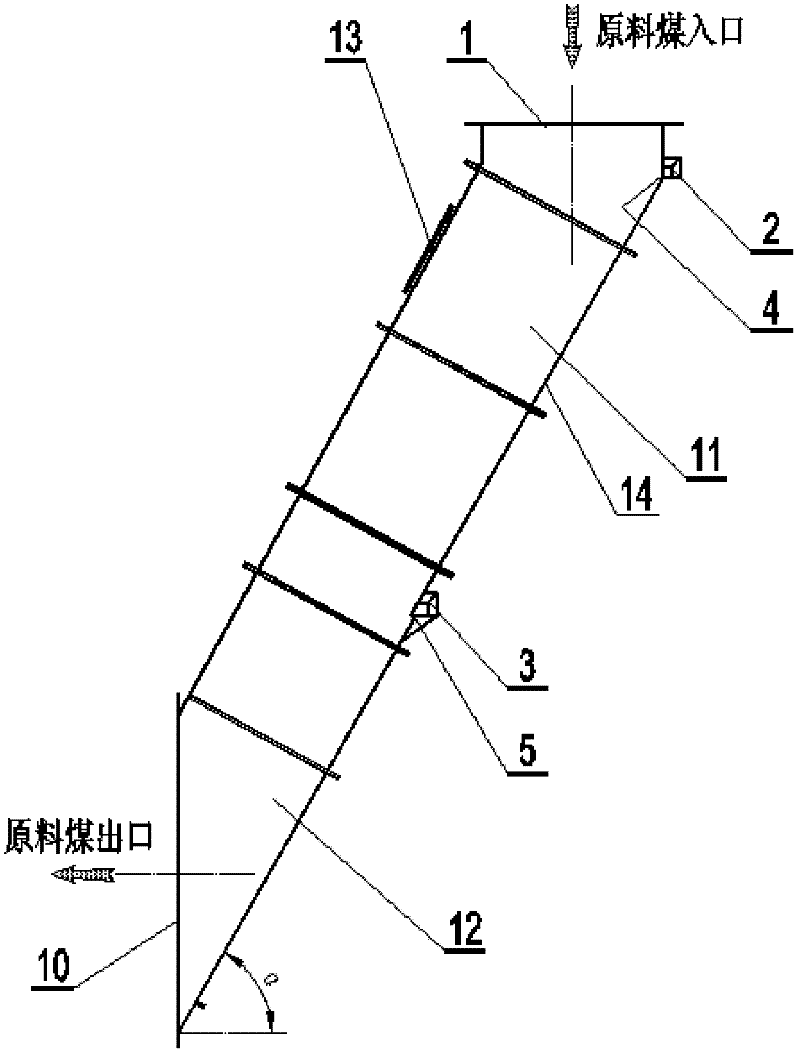

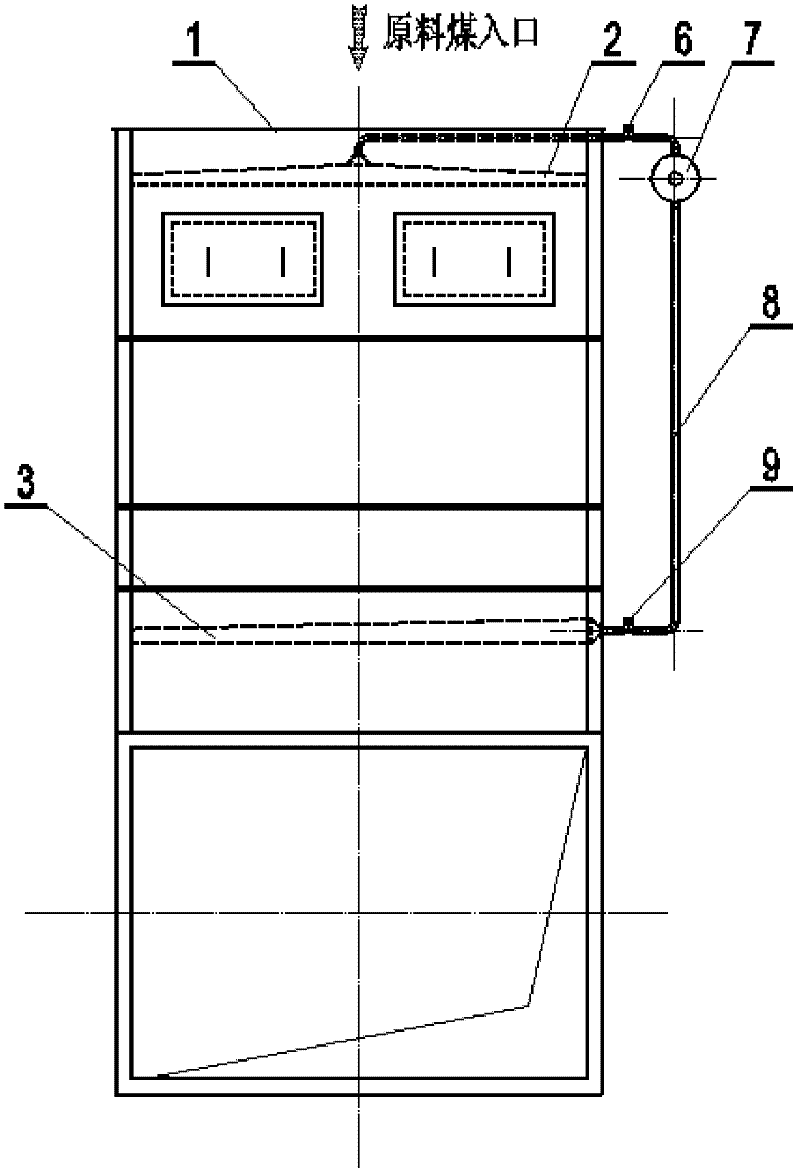

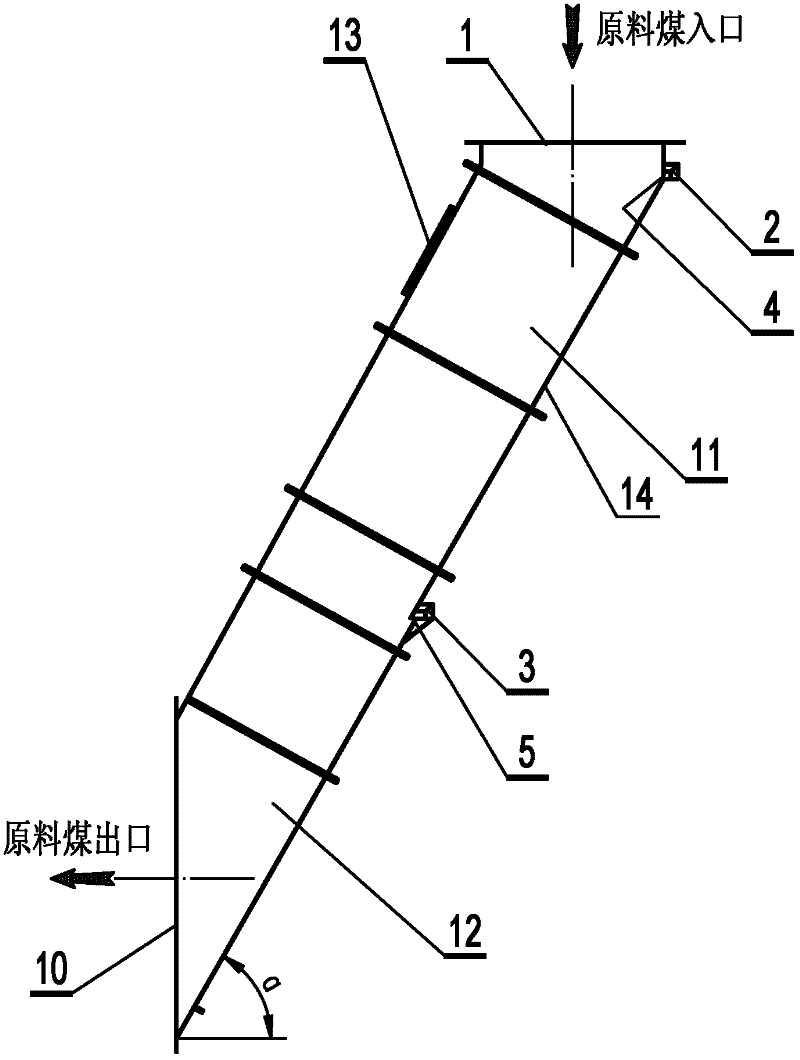

[0021] Combine below figure 1 , figure 2 The present invention is described in further detail:

[0022] See figure 1 , figure 2 , an air-vibration blowing booster feeding device, comprising a first-stage spraying and conveying material section, a second-stage blowing and conveying material section, and an electromagnetic pulse generating device. The raw coal inlet section 1 is arranged at the top of the first-stage injection material delivery section, and the raw coal outlet section 10 is arranged at the bottom of the second-stage injection material delivery section. Each injection material delivery section is equipped with an injection pulse generator. The injection pulse generator is controlled by a program to form a pulsed air flow in an instant, and an air flow shovel is formed on the bottom surface of the raw coal delivery section at each level, which will bond the coal in each level. The wet coal materials on the bottom surface of the stage conveying section are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com