Limiting type conveying device for food packaging bags

A conveying device and packaging bag technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of easy slipping of packaging bags, and achieve the effects of improving loading efficiency, preventing slippage and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

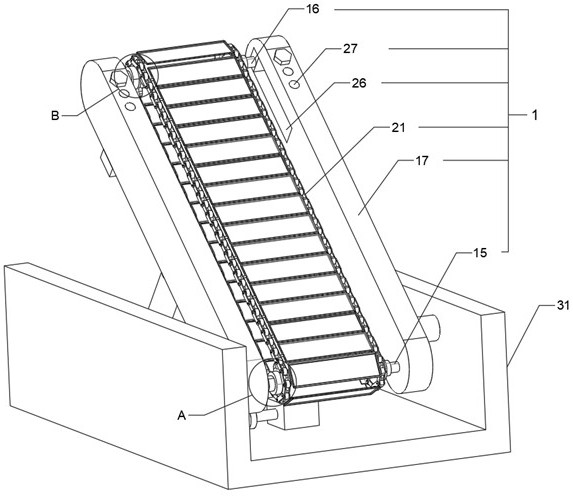

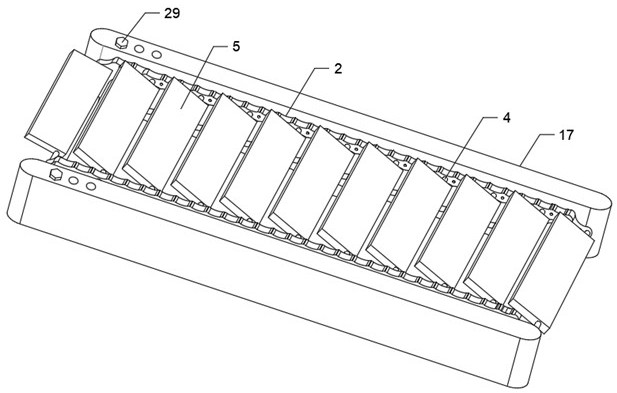

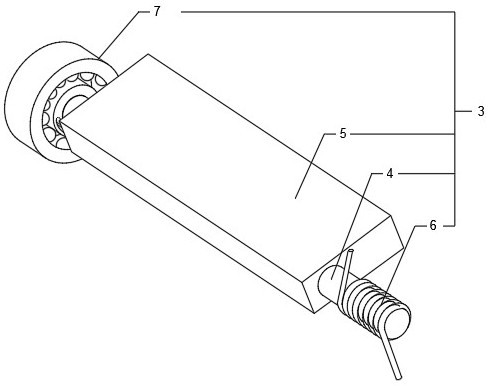

[0030] Embodiment one, as Figure 1 to Figure 4As shown, a position-limiting conveying device for food packaging bags includes a chain conveying mechanism 1 arranged obliquely. The chain conveying mechanism 1 includes two sets of chain transmission mechanisms 2 arranged in parallel. There are a number of rotating support devices 3, which are evenly arranged along the transmission direction of the chain transmission mechanism 2. The rotating support device 3 includes a support shaft 4 and a support plate 5. One end of the support shaft 4 is connected to one of the chains through a torsion spring 6. The transmission mechanism 2 is connected, and the other end of the support shaft 4 is connected with another chain transmission mechanism 2 through the limit rotating member 7. The support plate 5 is fixedly sleeved on the support shaft 4, and the transmission direction of the support plate 5 and the chain transmission mechanism 2 is in the direction of Set at an acute angle (that i...

Embodiment 2

[0032] Embodiment two, such as figure 1 , figure 2 , Figure 7 and Figure 8 As shown, the chain transmission mechanism 2 includes a driving sprocket 19 and a driven sprocket 20 arranged in rotation, and the driven sprocket 20 is connected to the driving sprocket 19 through an endless chain 21. The chain transmission mechanism 1 also includes a driving shaft 15, Driven shaft 16 and two conveying plates 17, two conveying plates 17 are arranged in parallel, and driving shaft 15 and driven shaft 16 are all positioned between two conveying plates 17, and driving shaft 15 is rotationally connected with conveying plate 17, and driven shaft Both ends of 16 are rotatably connected with a sliding mechanism 18, the sliding mechanism 18 is slidingly connected with the conveying plate 17, the driving sprocket 19 is fixedly sleeved on the driving shaft 15, and the driven sprocket 20 is fixedly sleeved on the driven shaft 16 Above, the driving shaft 15 is connected to the driving mechan...

Embodiment 3

[0033] Embodiment three, as figure 1 and Figure 9 As shown, it also includes a movable bottom frame 31, and the chain conveying mechanism 1 is obliquely arranged on the movable bottom frame 31. The height of the input end of the chain conveying mechanism 1 is lower than the height of the output end, and the side wall of the conveying plate 17 passes through the pin shaft and moves The inner side walls of the bottom frame 31 are hinged, the bottoms of the two conveying plates 17 are connected by connecting rods 32, the moving bottom frame 31 is hinged with a cylinder 33, and the telescopic shaft of the cylinder 33 is hinged with the connecting rod 32; the bottom of the moving bottom frame 31 is provided with a ten thousand To the wheel, it is convenient to move the bottom frame 31 to drive the chain conveying mechanism to move. The inclination angle of the chain conveying mechanism 1 can be adjusted through the cylinder 33, which can adapt to various loading heights. At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com