Patents

Literature

30results about How to "Reduce damage and deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Underground cavern group layout method

ActiveCN103291331AReduce deformation and damageReduce the cost of reinforcement supportUnderground chambersUnderground cavernTransformer

The invention discloses a large-scale underground cavern group layout method applied to water conservancy and hydropower engineering and underground storage cavern engineering. The underground cavern group layout method can give overall consideration to major factors having influences on underground cavern adjoining rock stability, particularly gives overall consideration to the crucial factor of the rock strength-stress ratio, enables a large-scale underground cavern group layout designing scheme to be scientific, and is overall in considered factors. The method includes the following steps: firstly, determining the positions of main caverns, then determining the axis directions of the main caverns, determining the thickness of a rock pillar between the main caverns, and finally determining cavern shapes of the main caverns. When the cavern shapes of the main caverns are determined, each main cavern is divided into an underground main power house, a main transformer chamber and a tail water surge chamber according to functions, the hole shape of each underground main power house and the hole shape of each main transformer chamber are in circular arch straight wall shapes or egg shapes, and each tail water surge chamber is in a cylinder shape or a gallery shape.

Owner:POWERCHINA CHENGDU ENG

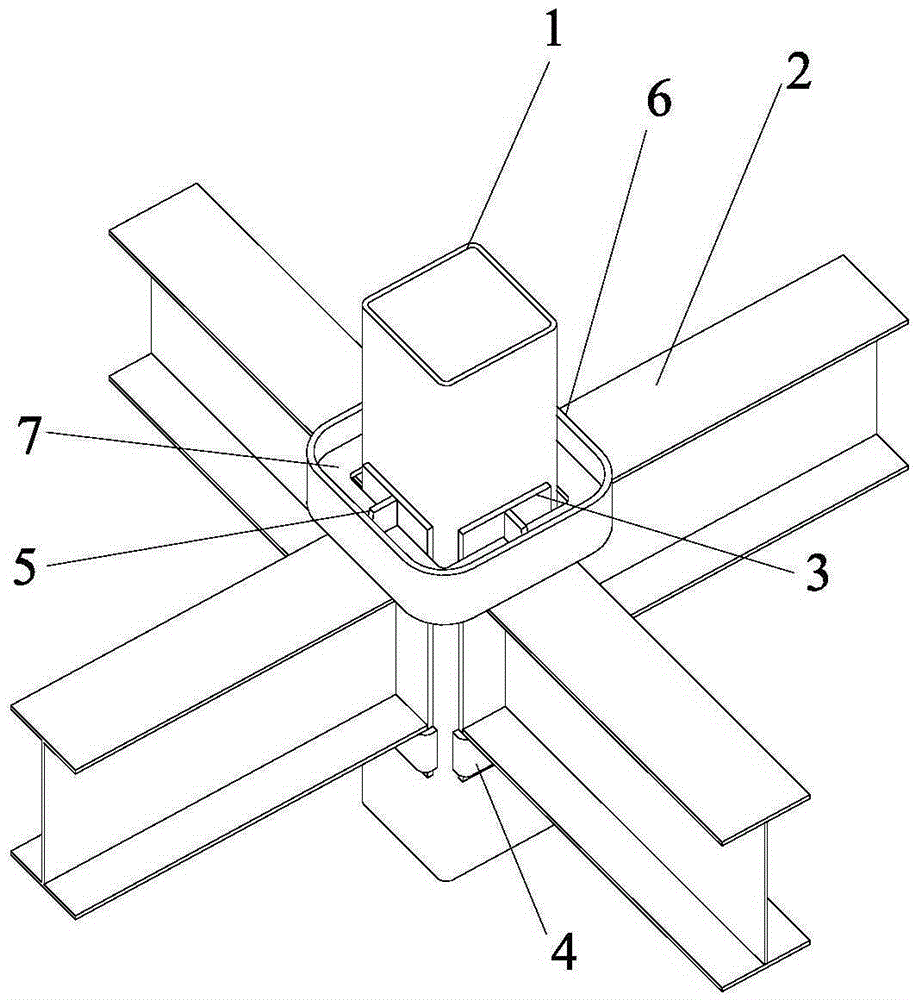

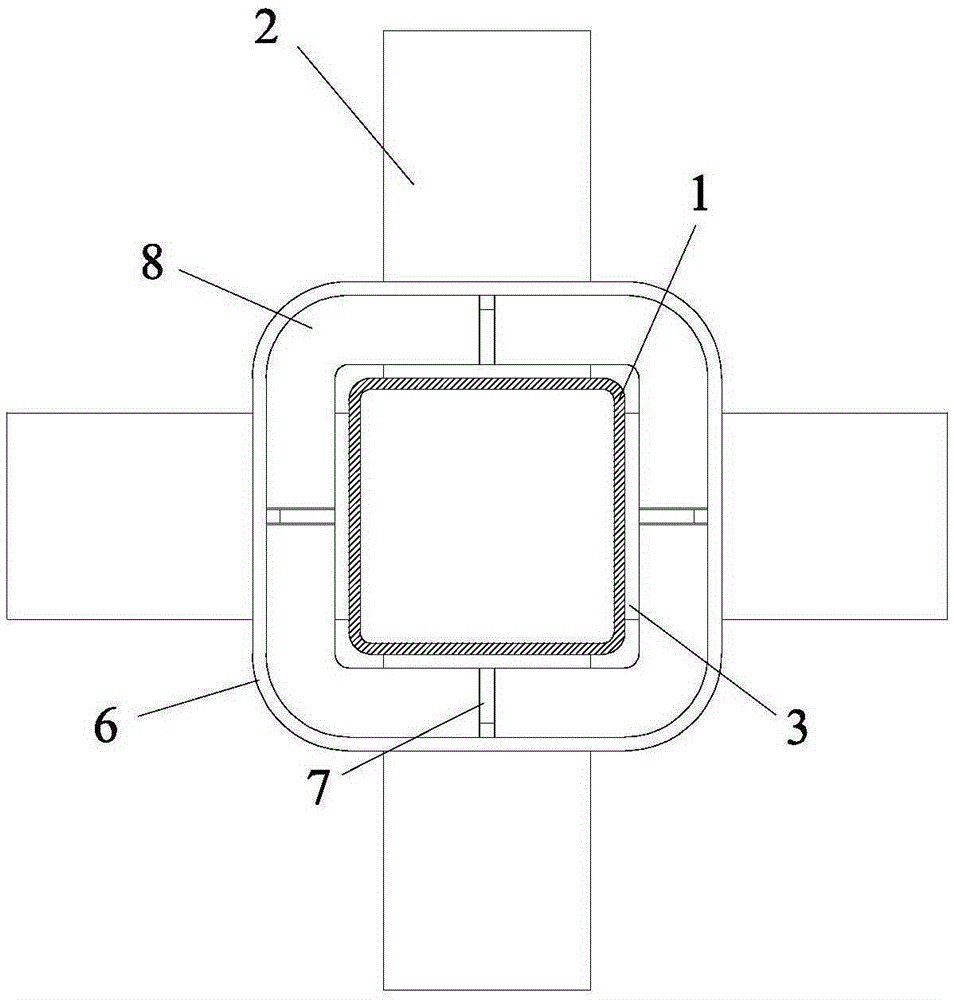

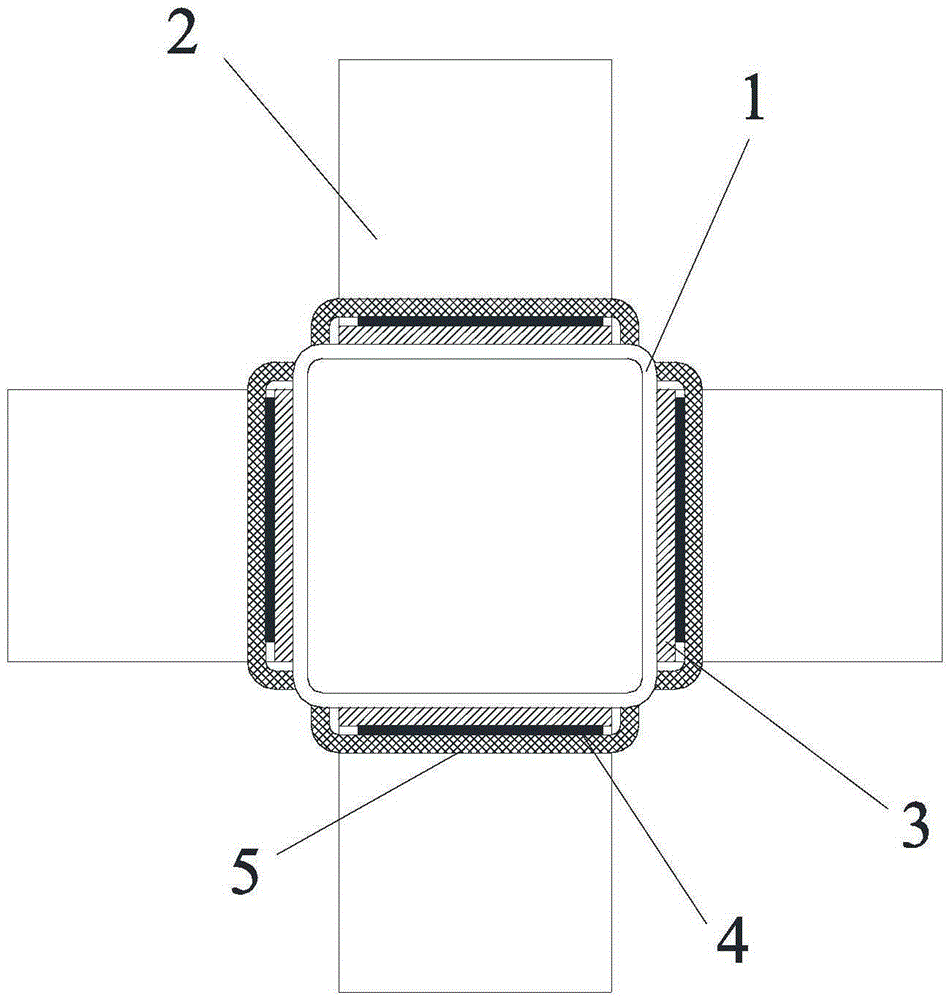

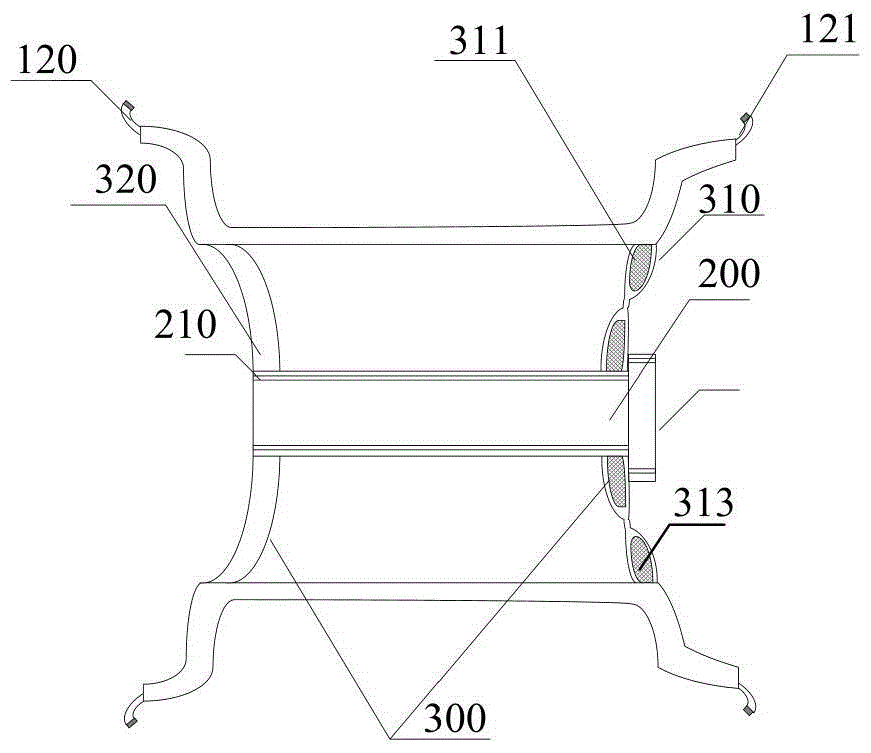

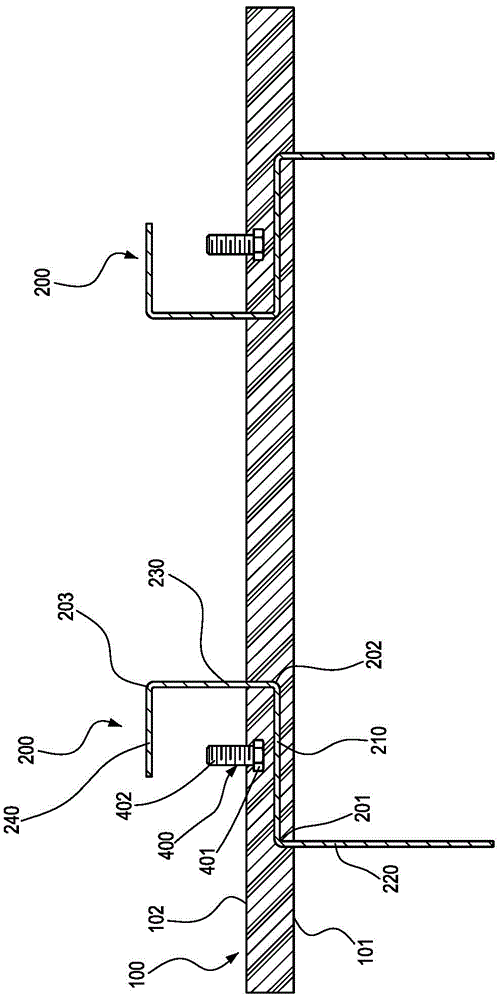

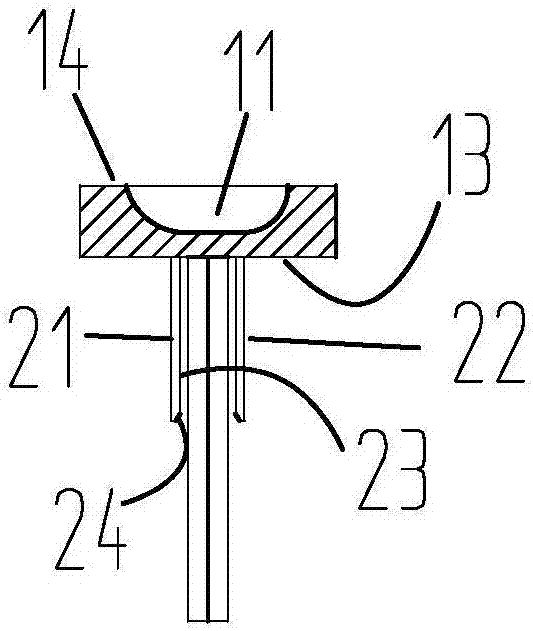

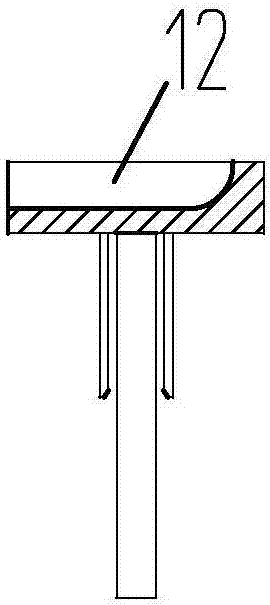

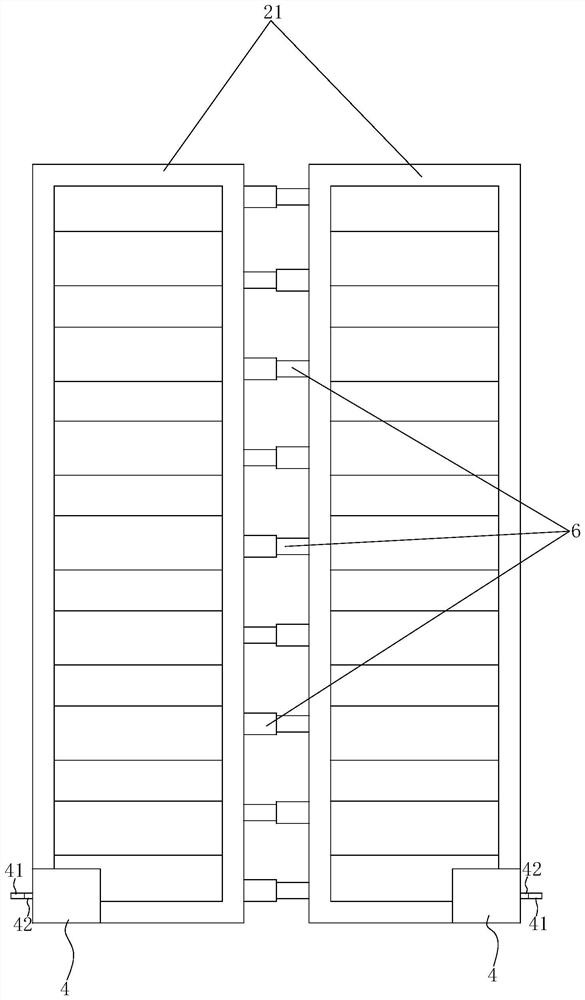

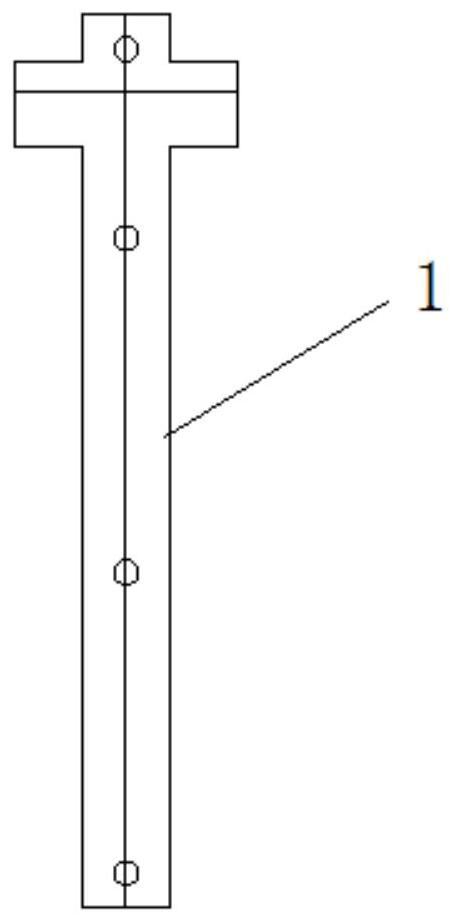

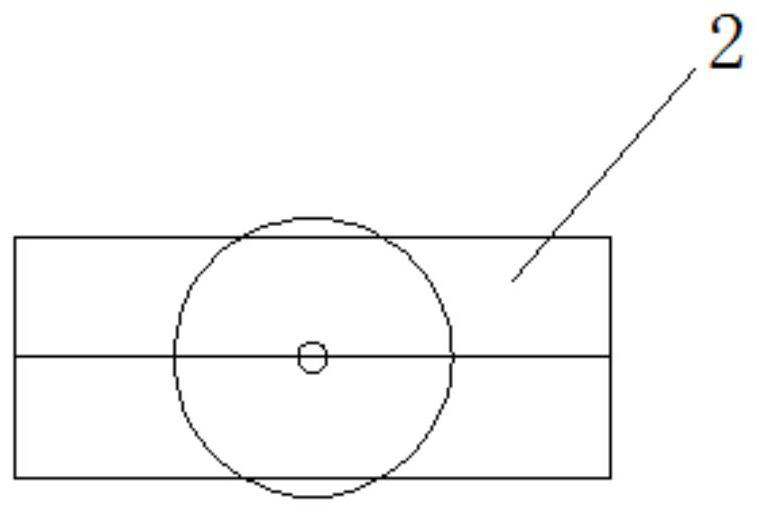

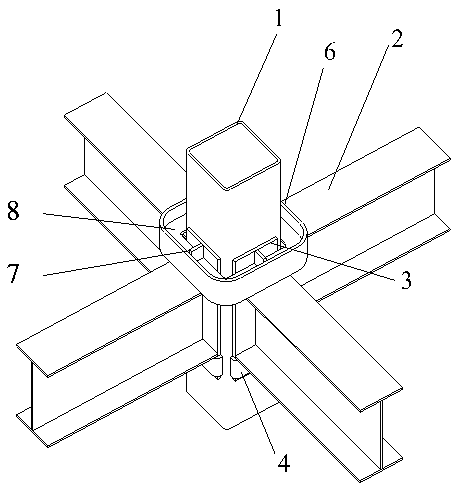

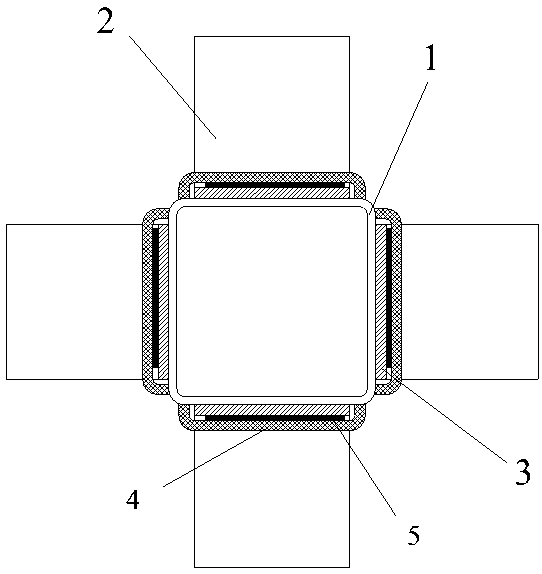

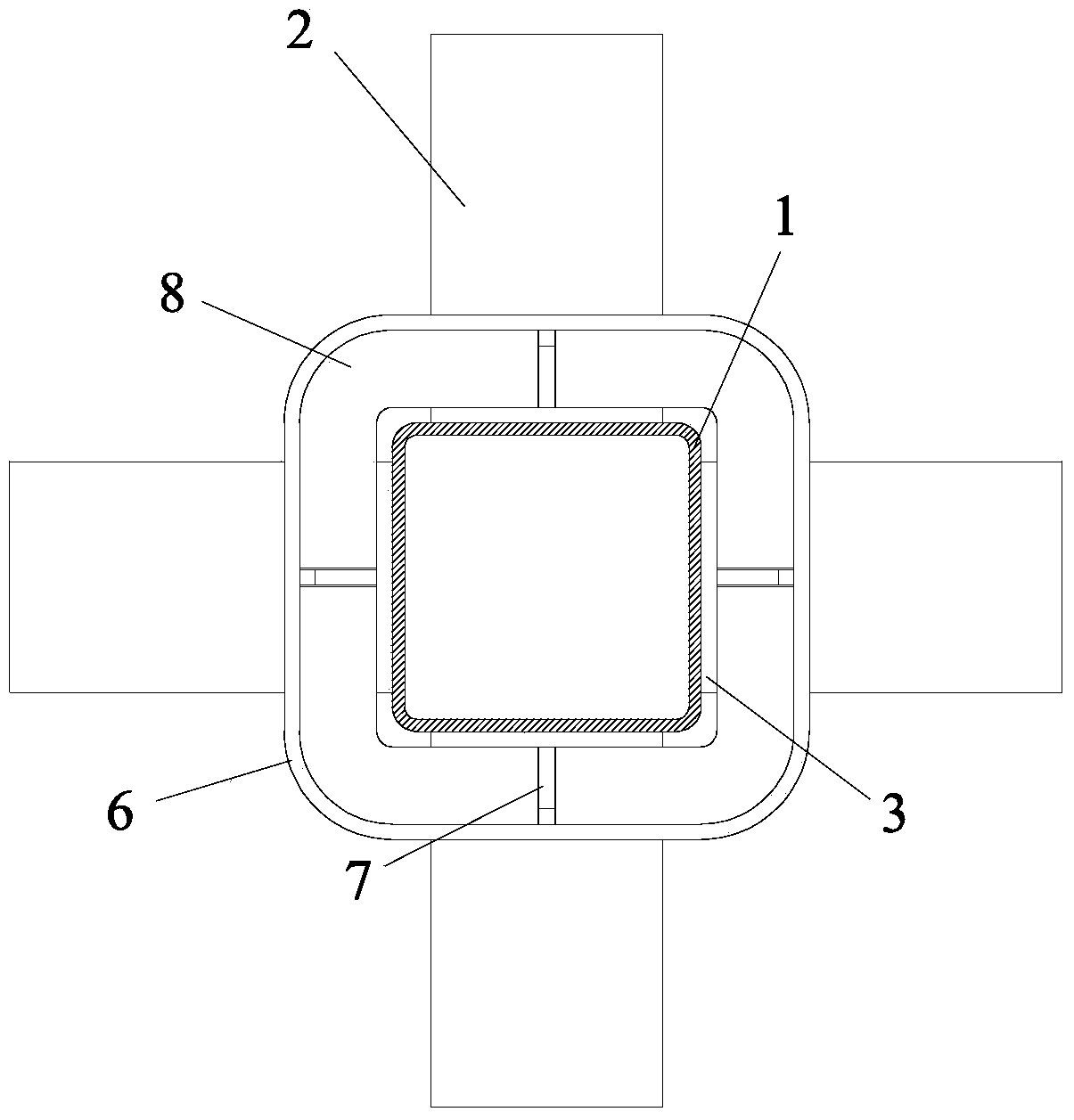

Clamping groove assembling type steel pipe column and steel beam connecting joint and construction method thereof

ActiveCN105350658AHigh degree of factoryFast construction on siteBuilding constructionsArchitectural engineeringBolt connection

The invention discloses a clamping groove assembling type steel pipe column and steel beam connecting joint and a construction method thereof. A plurality of H-shaped steel beams are horizontally connected to the side wall of the periphery of a steel pipe column. A steel beam end plate extending in the beam height direction of the steel pipe column is fixedly welded to the end face of each H-shaped steel beam. A U-shaped clamping groove is welded to the lower side of the steel pipe column. The lower sides of the steel beam end plates are inserted into the U-shaped clamping groove. An annular movable steel hoop is installed on the upper side of the steel pipe column. The upper ends of the steel beam end plates are hooped and connected through the movable steel hoop or hooped and connected in the mode that a reinforcing plate is matched with the movable steel hoop. Insertion plates for fastening are inserted into gaps between the U-shaped clamping groove and the steel beam end plates. An annular reinforcing plate is welded to the portion, matched with the movable steel hoop, of the middle of the inner wall of the reinforcing plate. An end plate reinforcing plate is fixedly arranged at the joint of an upper wing edge and the middle of the upper end of each steel beam end plate. A notch is formed in the middle of the annular reinforcing plate on each side. The clamping groove assembling type steel pipe column and steel beam connecting joint has the advantages that the industrial degree is high, no welding or bolt connection is needed on a construction site, and the construction speed is high, and has better technical benefits.

Owner:HANGZHOU TONGMSK DESIGN CO LTD

Layout design method of underground cavern group

ActiveCN103266902AReduce damage and deformationReduce the cost of reinforcement supportUnderground chambersDesign planUnderground cavern

The invention discloses a layout design method of an underground cavern group applied to a water conservancy and hydropower project and an underground storage. According to the layout method, main factors influencing the stability of surrounding rock of the underground caverns, especially, the rock strength stress ratio which is the essential factor can be fully taken into consideration. The method comprises the following steps of: firstly determining the positions of main caverns, determining the axial line directions of the main caverns, determining the thicknesses of rock pillars among the main caverns, and finally determining the shapes of the main caverns, wherein in the process of determining the thicknesses of the rock pillars among the main caverns, the thicknesses of the rock pillars are 1.0-2.5-time mean than excavation span between two adjacent main caverns and are 0.5-0.8 times that of the height of the big one in the adjacent two main caverns. Compared with the layout design with a design plan provided by a using traditional layout method, the layout design with the layout method disclosed by the invention is more scientific; and especially, in a highland stress environment and in a condition with relatively low surrounding rock strength, the phenomena of the deformation and destruction of the surrounding rock after the surrounding rock of the underground cavern group is excavation-unloaded can be greatly reduced or the deformation and destruction degrees of the surrounding rock can be reduced.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Large-scale underground cavern group arrangement design method

ActiveCN103291316AReduce deformation and damageReduce the cost of reinforcement supportTunnelsUnderground cavernPrincipal stress

The invention discloses a large-scale underground cavern group arrangement design method applied to hydraulic and hydroelectric engineering and underground storage cavern engineering. According to the arrangement design method, principal factors, especially the essential factor of the rock strength-stress ratio, influencing underground cavern surrounding rock stability can be comprehensively taken into account, the designing scheme for large-scale underground cavern group arrangement can be more scientific, and considered factors are more comprehensive. The position of a main cave is determined at first, the orientation of an axis of the main cave is determined, then the thickness of a rock pillar in the main cave is determined, and at last the shape of the main cave is determined. When the orientation of the axis of the main cave is determined, the trend of a rock mass main structural surface on a construction site and the orientation of the maximum principal stress are measured at first, the orientation of the axis of the main cave is determined according to an included angle between the axis of the main cave and the trend of the rock mass main structural surface and an included angle between the axis of the main cave and the orientation of the maximum principal stress, the included angle between the axis of the main cave and the trend of the rock mass main structural surface is not less than 40 degrees, and the included angle between the axis of the main cave and the orientation of the maximum principal stress is 0-40 degrees.

Owner:POWERCHINA CHENGDU ENG

Large-scale underground cavern group arrangement method

ActiveCN103291332AReduce deformation and damageReduce the cost of reinforcement supportUnderground chambersUnderground cavernStress ratio

The invention discloses a large-scale underground cavern group arrangement method applied to hydraulic and hydroelectric engineering and underground storage cavern engineering. According to the arrangement method, principal factors, especially the essential factor of the rock strength-stress ratio, influencing underground cavern surrounding rock stability can be comprehensively taken into account, the designing scheme for large-scale underground cavern group arrangement can be more scientific, and considered factors are more comprehensive. The position of a main cave is determined at first, the orientation of an axis of the main cave is determined, then the thickness of a rock pillar in the main cave is determined, and at last the shape of the main cave is determined. When the position of the main cave is determined, the rock strength-stress ratio on a construction site is firstly measured, and when the rock strength-stress ratio is 2.0-4.0, the thickness from the outer edge of the main cave to a rock of a valley slope surface should be larger than 400m; when the rock strength-stress ratio is 4.0-7.0, the thickness from the outer edge of the main cave to the rock of the valley slope surface is 200-400m; when the rock strength-stress ratio is larger than 7.0, the thickness from the outer edge of the main cave to a rock of the valley slope surface is 150-200m.

Owner:POWERCHINA CHENGDU ENG

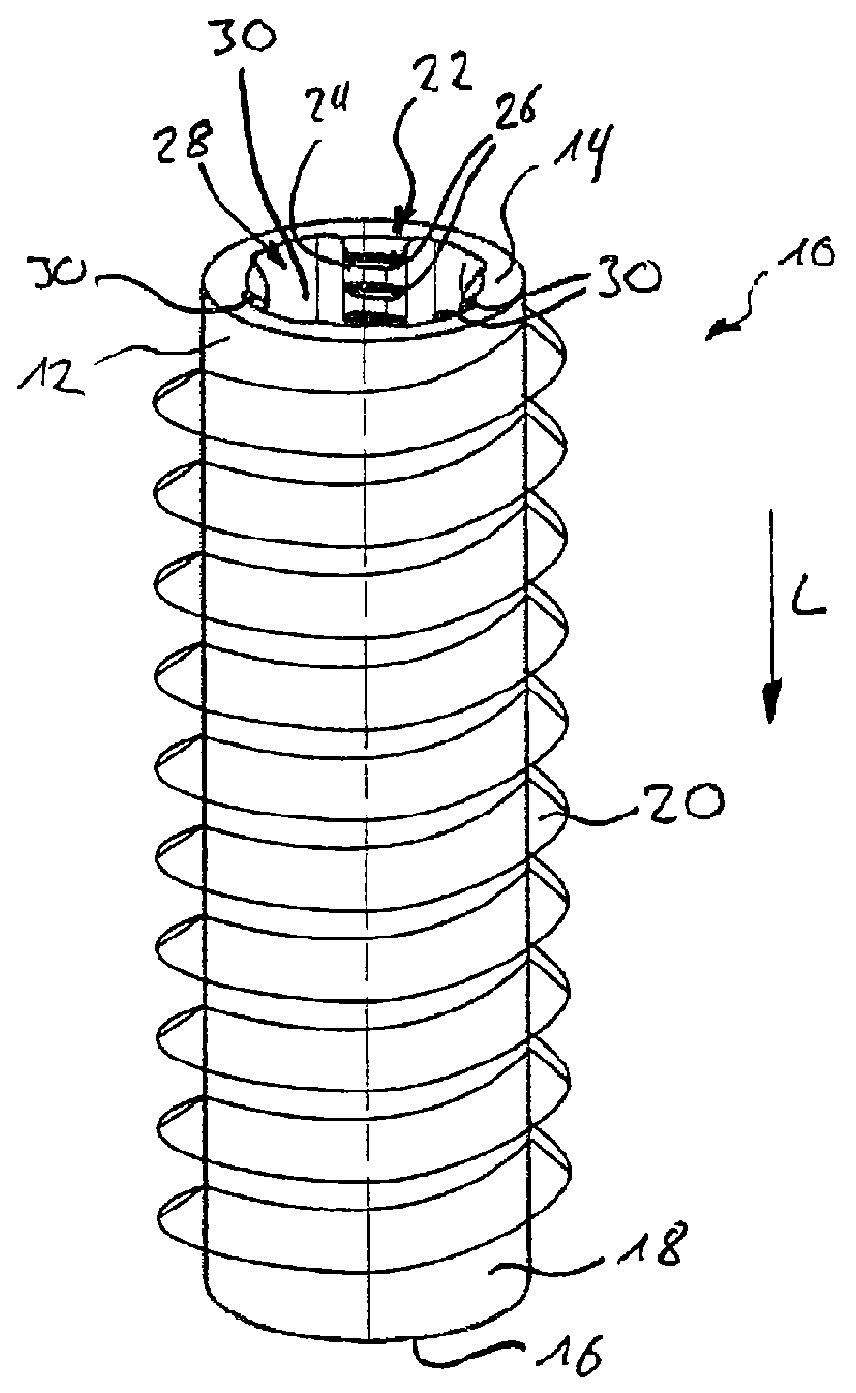

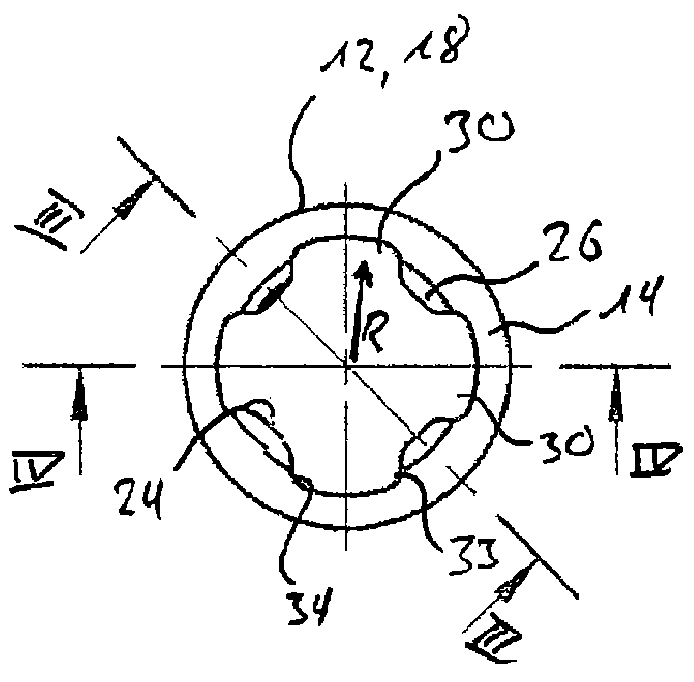

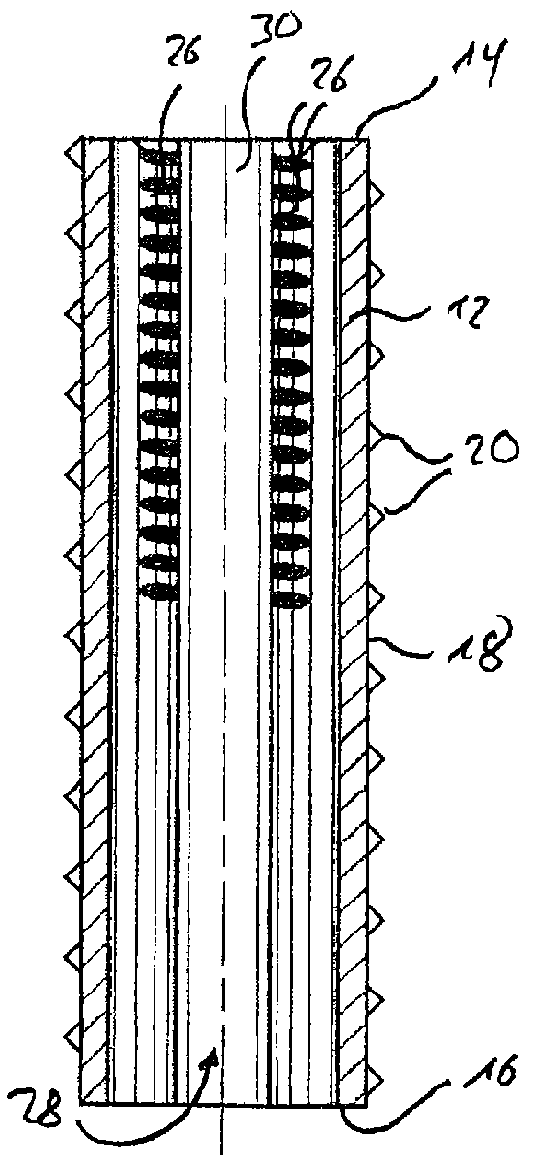

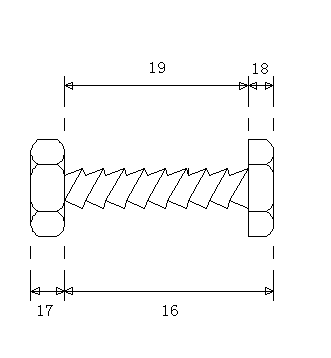

Screw anchor and method for producing a screw anchor

ActiveUS20120183372A1Reduce damage and deformationReduce torque loadWashersNutsLoad bearingScrew thread

Owner:HILTI AG

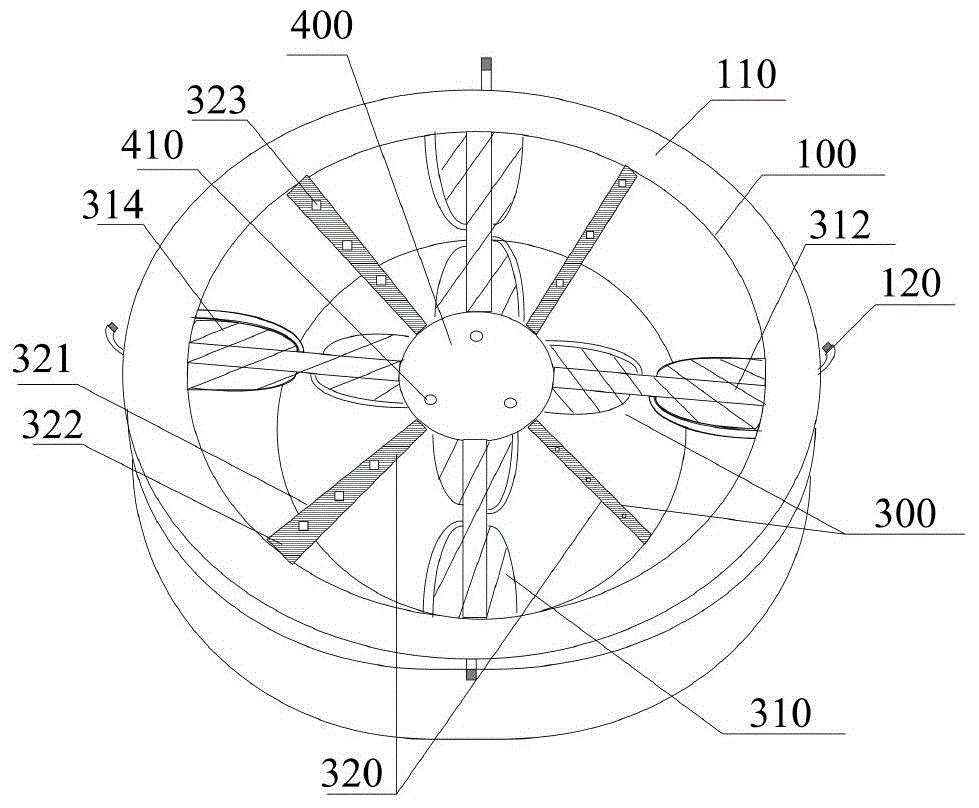

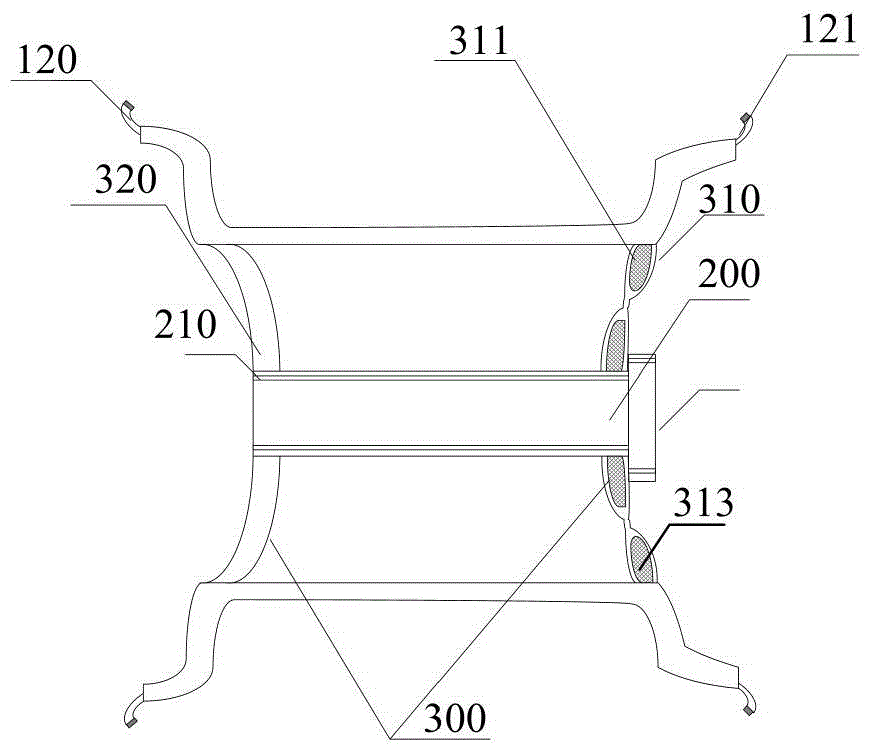

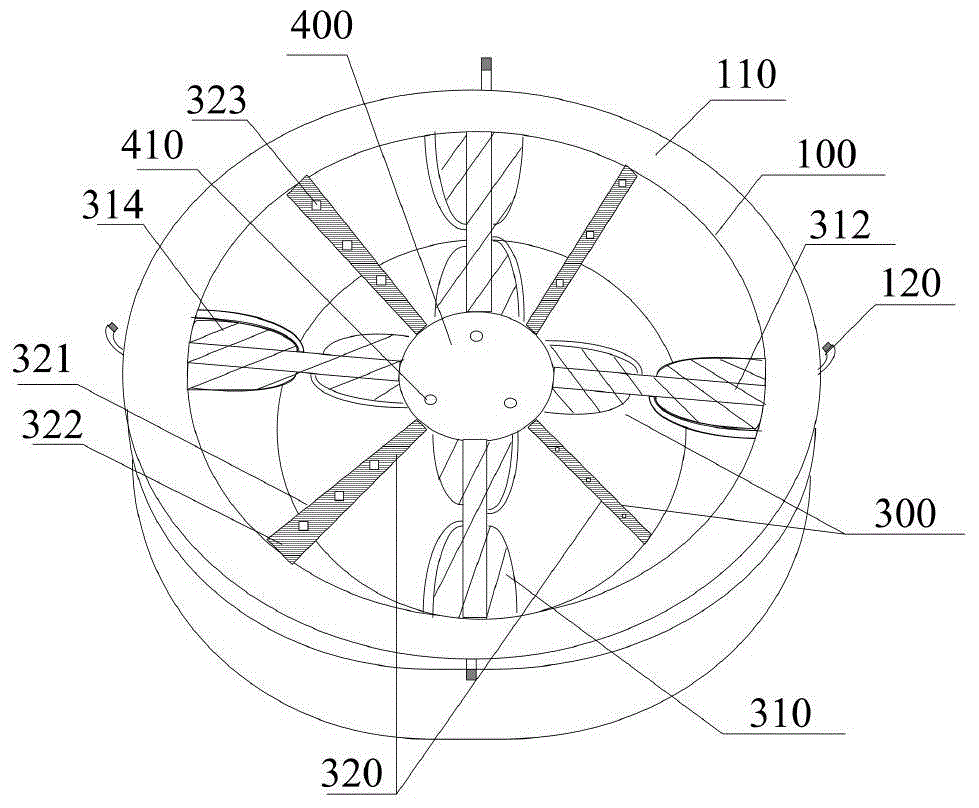

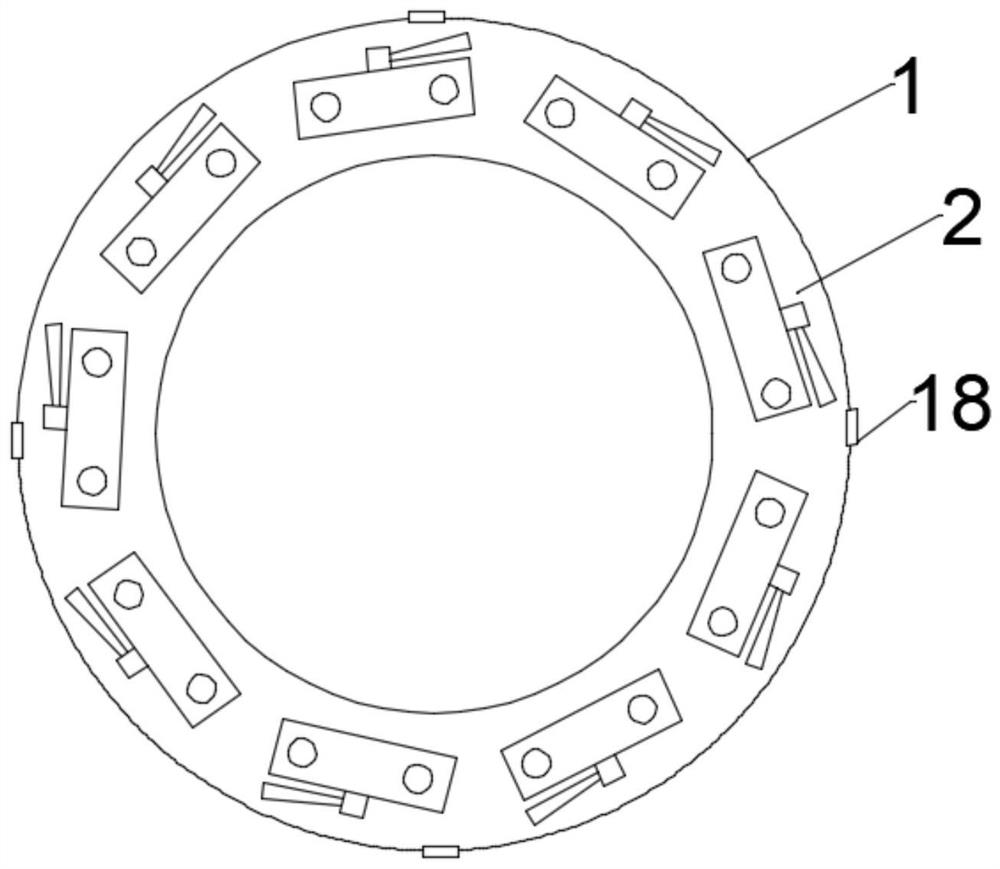

Novel automobile hub

The invention discloses a novel automobile hub. The novel automobile hub comprises a rim, an axle hub and a spoke set, wherein the wheel edge on the edge of the rim is provided with a plurality of clamping bars which are evenly distributed along the outer circumference of the wheel edge and used for clamping a tire, the axle hub is arranged on the axis of the rim, the spoke set comprises a plurality of first spokes and a plurality of second spokes, the first spokes and the second spokes are evenly distributed along the outer circumference of the axle hub in a radial shape, connected to the two sides of the rim respectively and used for supporting the rim, the width of the two side ends of each first spoke is larger than the width of the center position of the first spoke, first inclination angles opposite in direction are formed at the two side ends of each first spoke and are opposite to the outer surface of the first spoke, the two side ends of each first spoke are each provided with a cavity, and reinforcing ribs connected to the rim and the axle hub are further arranged on the outer surfaces of the first spokes; the rim and the axle hub are connected through the spoke set so that an automobile hub body can be formed. The novel automobile hub has the advantages of being good in stability, light in weight, fast in heat dissipation and high in safety coefficient.

Owner:SICHUAN XUNJI TECH CO LTD

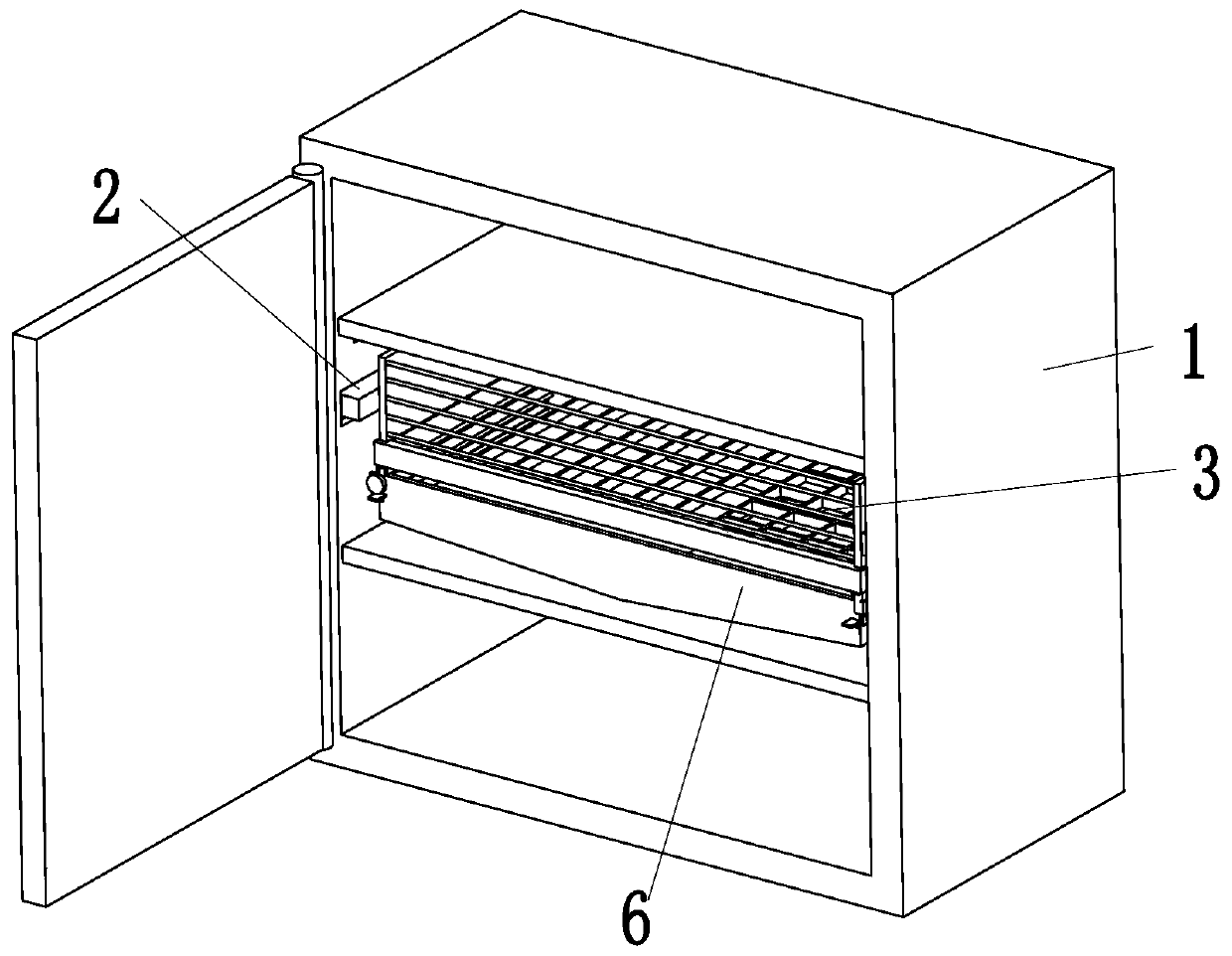

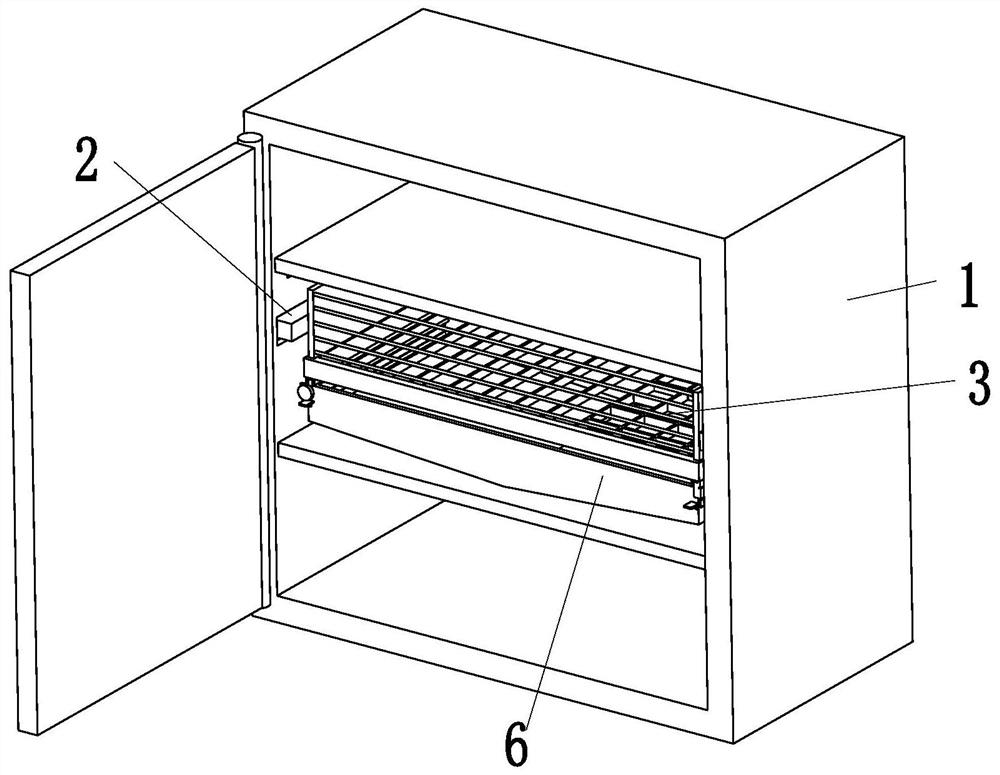

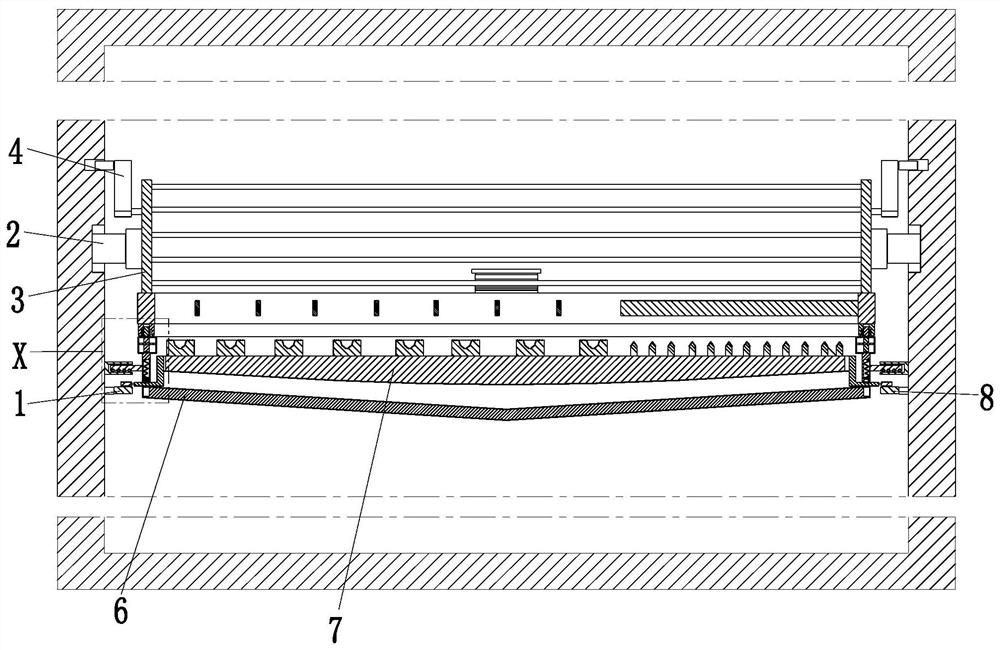

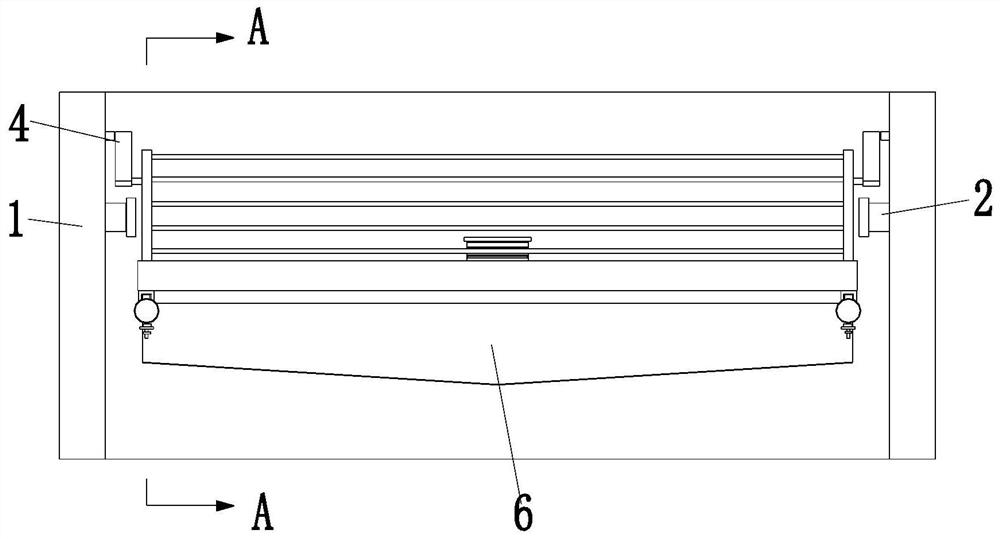

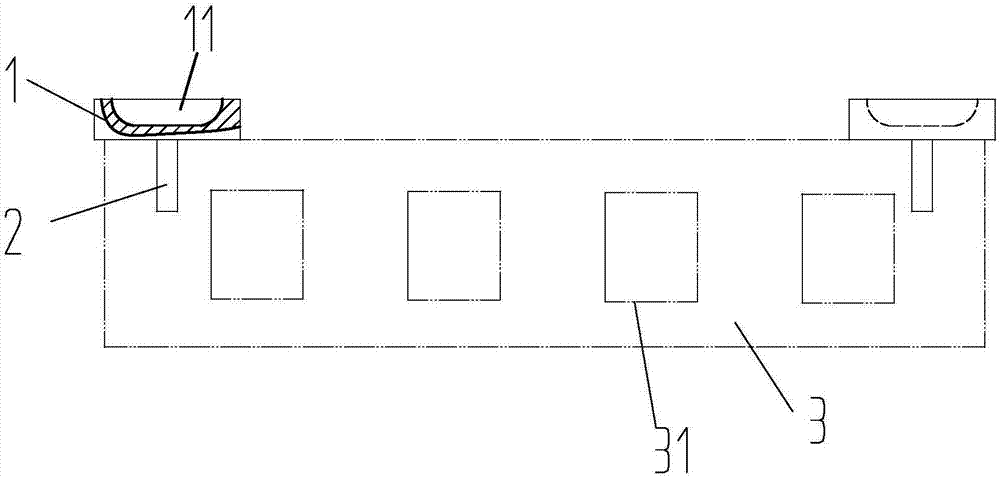

Intelligent cabinet

ActiveCN110169664APrevent deformationAvoid dripping onto the inner bulkheadFurniture partsKitchen cabinetsEngineeringMechanical engineering

Owner:广东亿科不锈钢制品有限公司

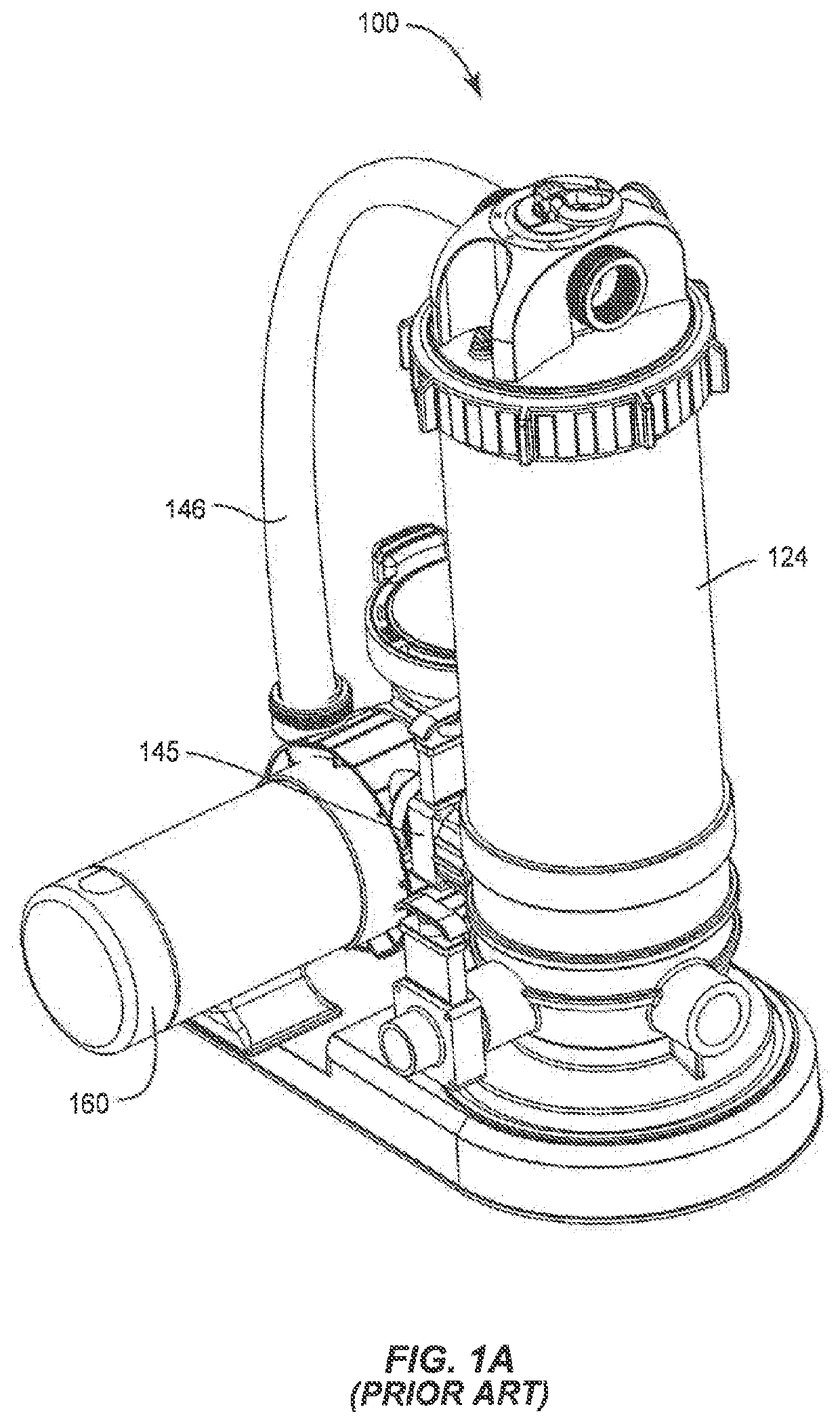

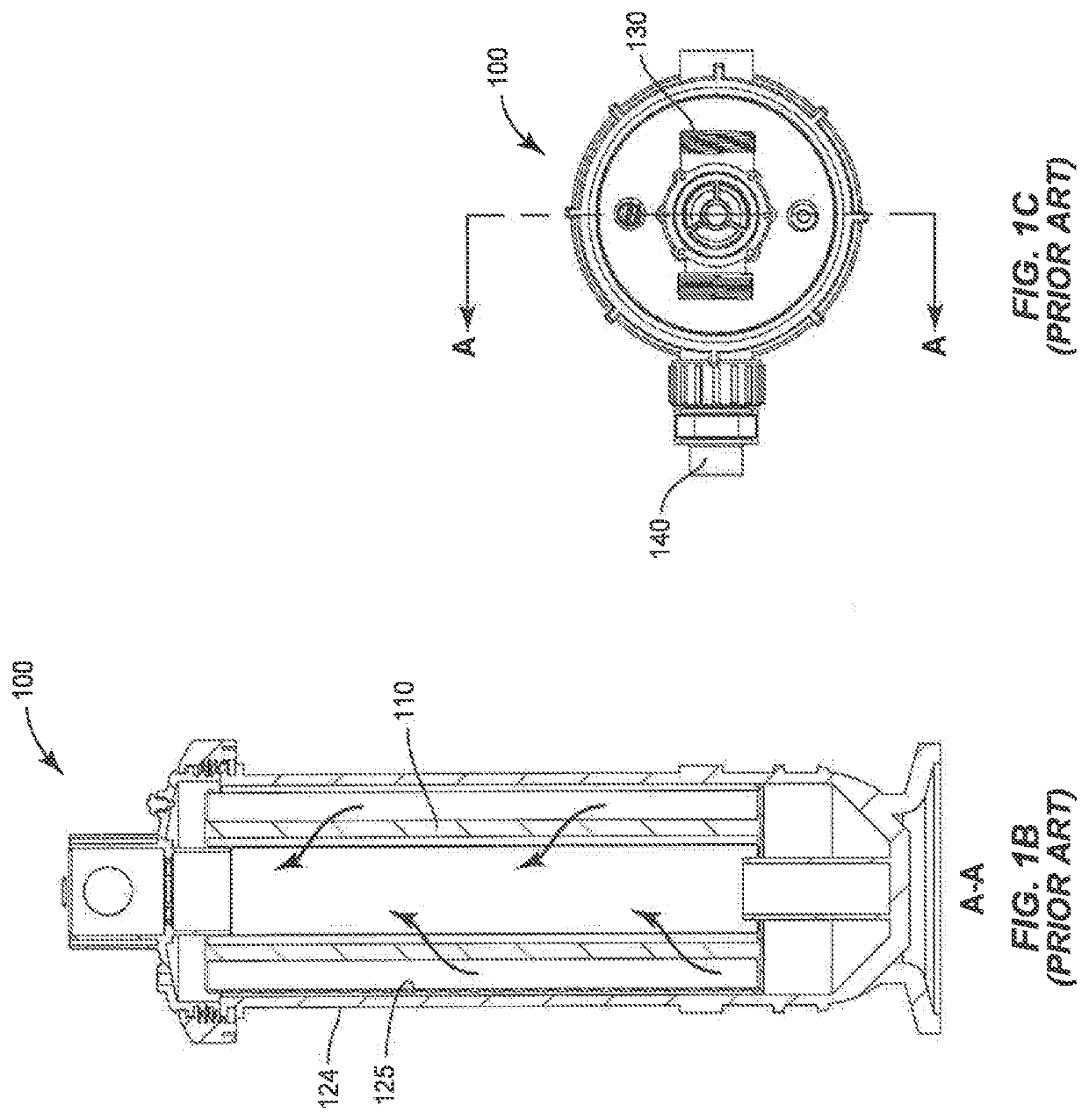

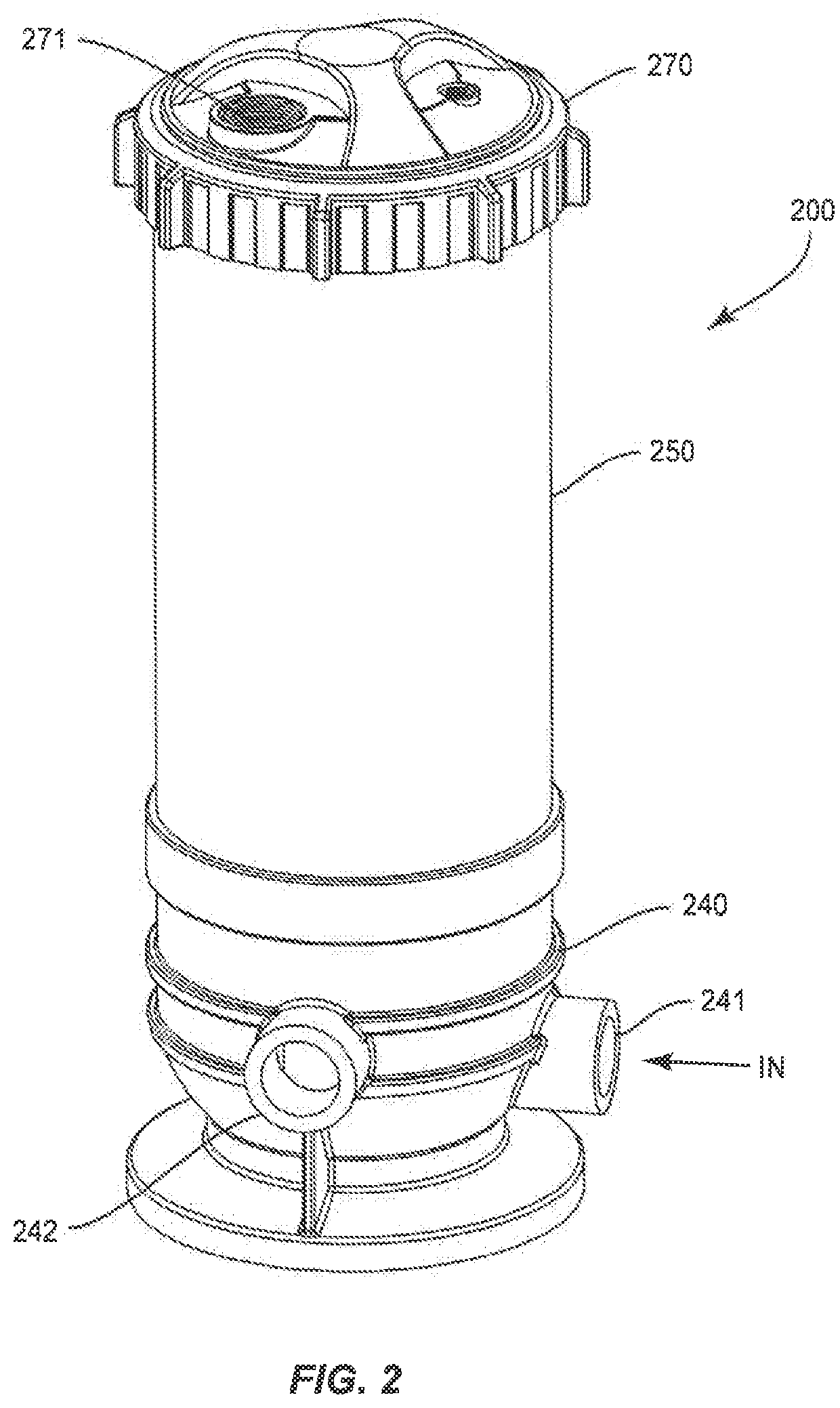

Self cleaning filter system and method

ActiveUS20210236964A1More cleanOperation moreSpecific water treatment objectivesTreatment involving filtrationFiltrationFilter system

A filter apparatus includes a filter, such as a cartridge, positioned within a housing. The filter apparatus has multiple ports and valves, so as to allow a user to easily switch between a filtration mode of filtering fluids and a maintenance mode of cleaning the filter. The filter can have a filter substrate in a housing and after filtrate builds up on the substrate, the substrate can be cleaned by directing a spray of fluid, such as from a ring of nozzles at the top of the housing, onto the substrate. A maintenance port can be provided to drain the debris washed from the substrate. The filter can switch between a backwash mode and a filtration mode.

Owner:ASIA CONNECTION

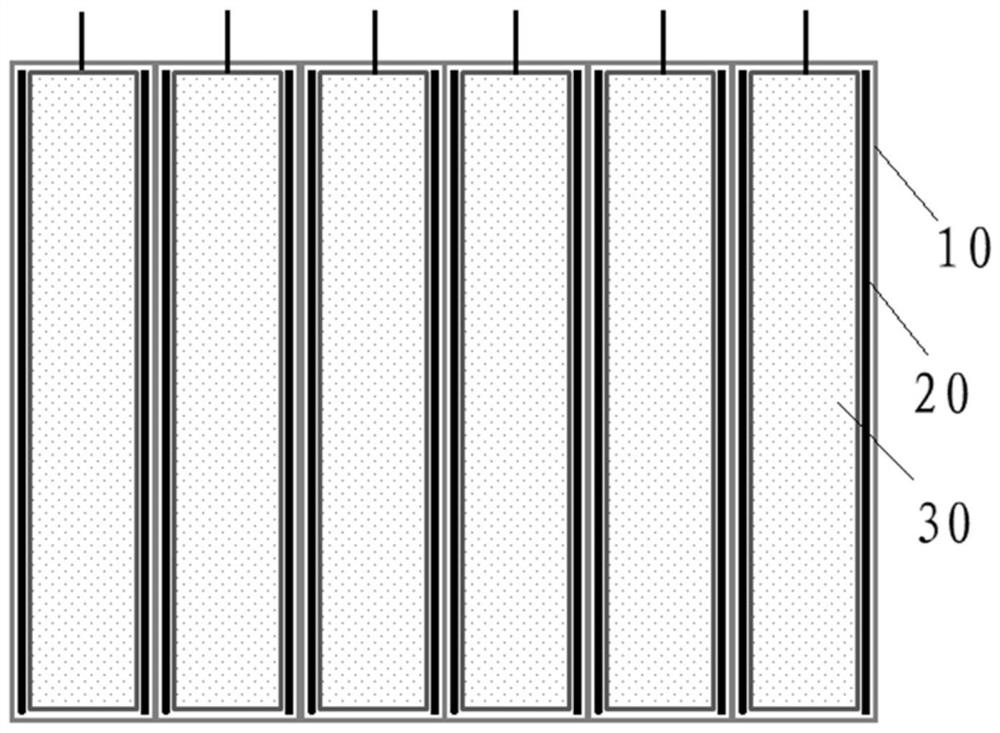

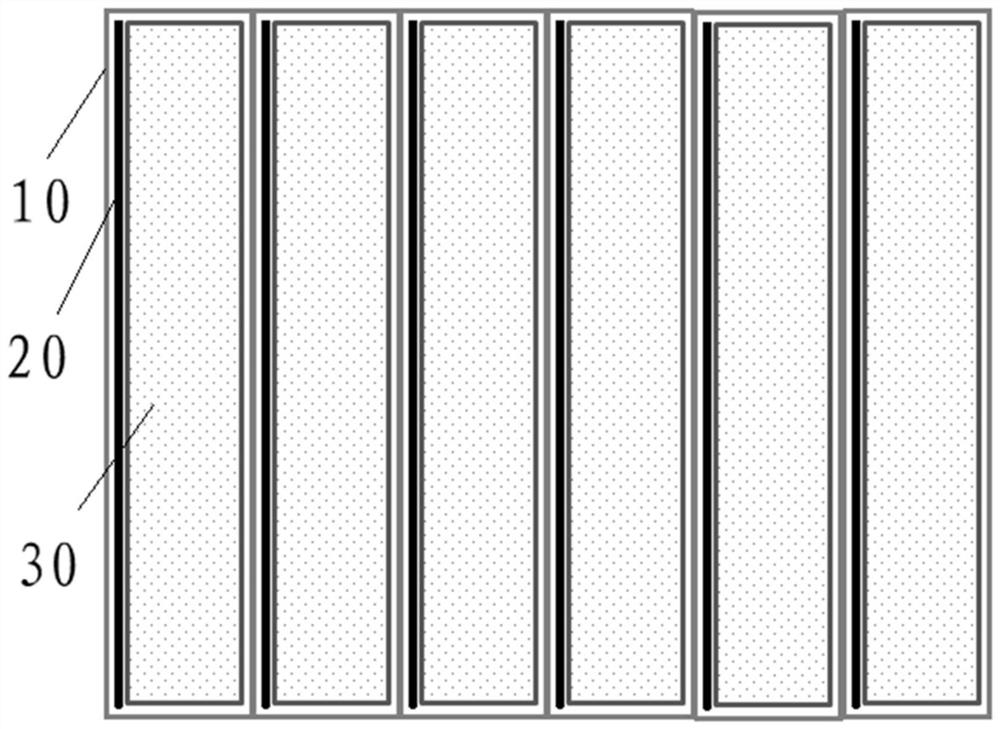

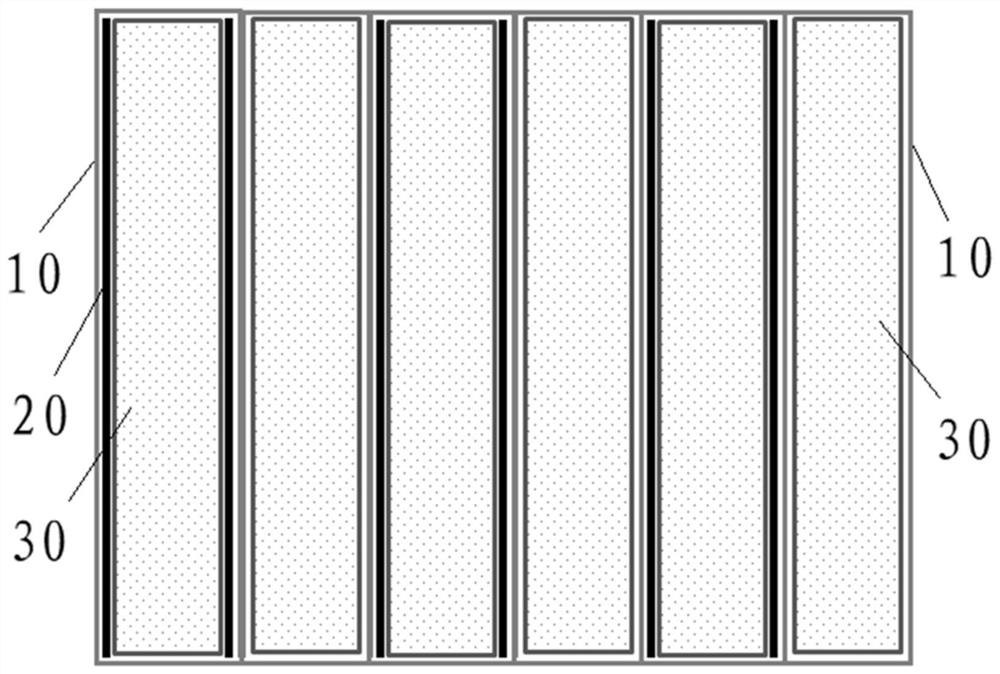

Battery pack and method of manufacturing battery pack

PendingCN111725442AIncrease reservesReduce damage and deformationFinal product manufactureCell component detailsAutomotive engineeringElectrical and Electronics engineering

The invention provides a battery pack and a preparation method of the battery pack. The battery pack includes multiple batteries, wherein a plurality of batteries are arranged in sequence, each battery comprises a shell and a battery cell arranged in the shell, the battery cell is filled with electrolyte, a functional layer is arranged on a first side of the battery cell in at least one battery, the first side of the battery cell is the side, facing the arrangement direction of the batteries, of the battery cell, and the functional layer is provided with a pore structure. The battery pack is advantaged in that the electrolyte can be stored through a pore structure in the functional layer, the storage capacity of the electrolyte in the battery is improved, the electrolyte can be released inthe compression deformation process of the battery, the functional layer has certain buffering and protecting effects, a problem that the battery pack deforms or is damaged when being extruded or collided by the outside is solved, safety of the battery is improved, the service life of the battery is prolonged, and use requirements are met.

Owner:ZHUHAI COSMX BATTERY CO LTD

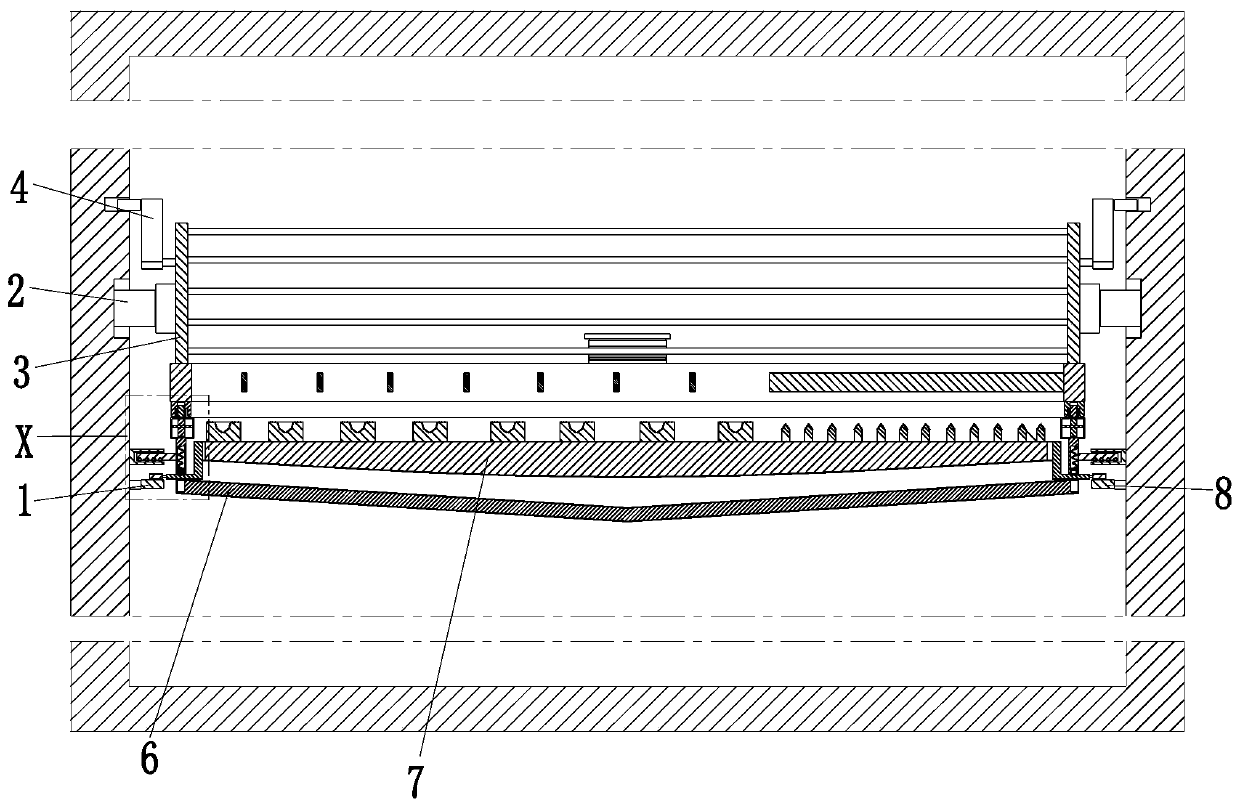

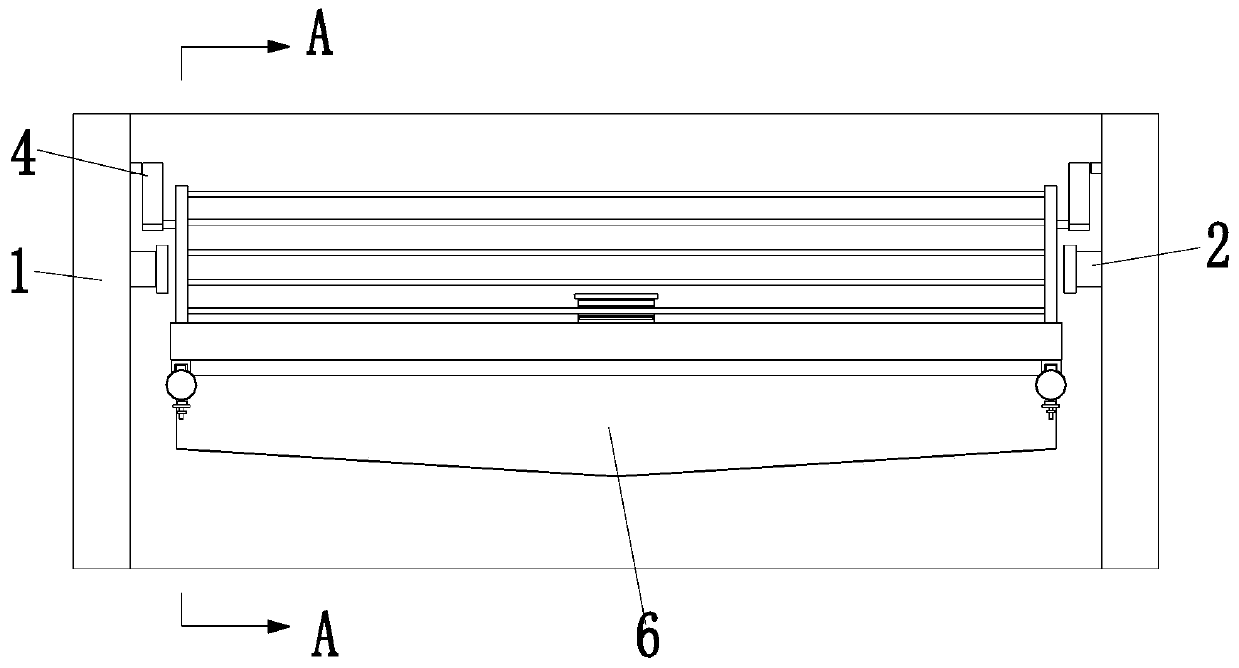

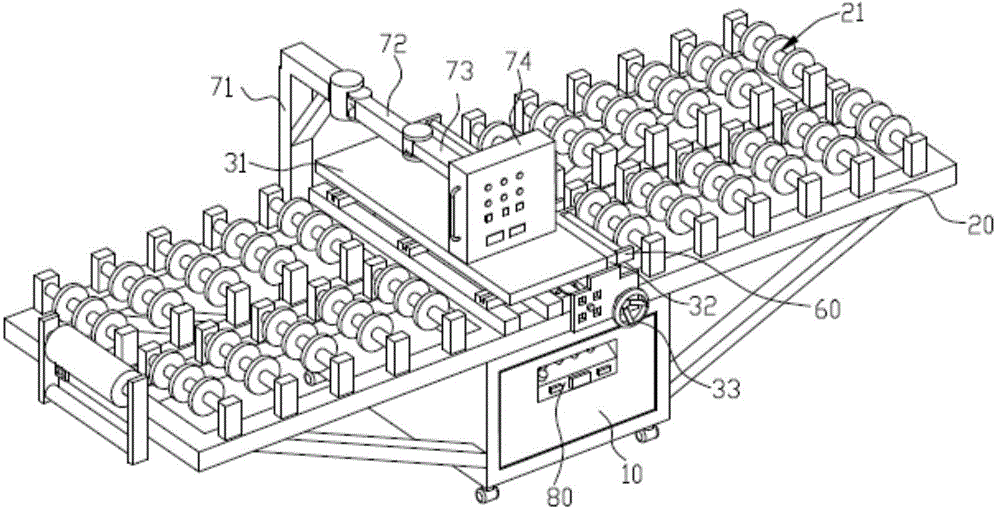

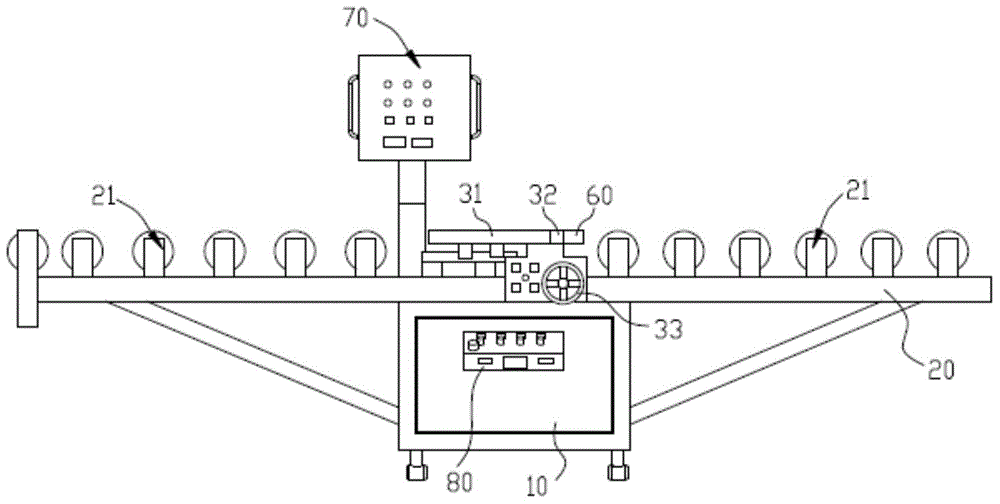

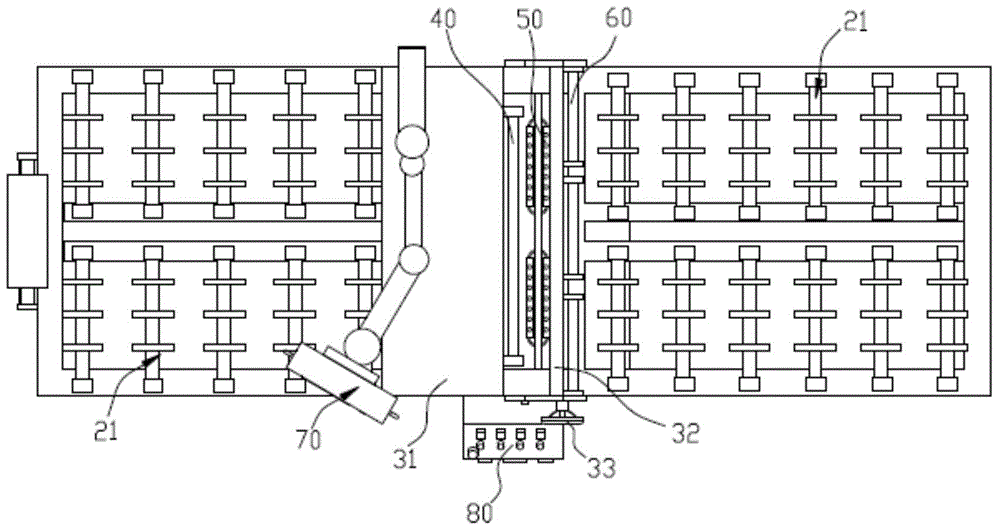

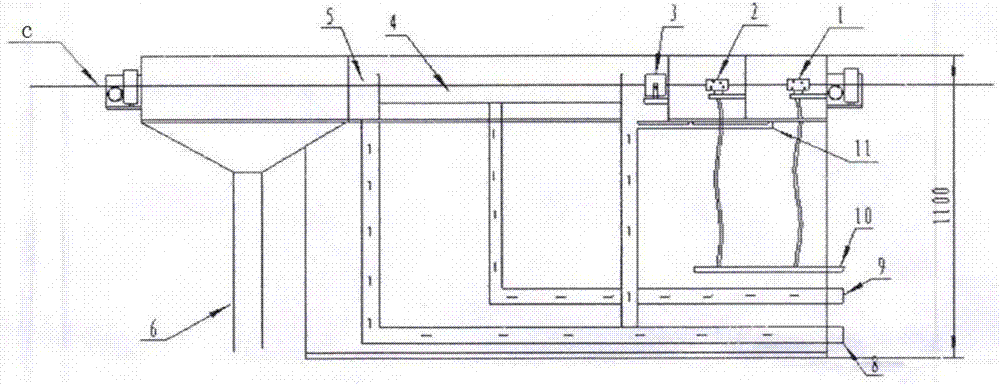

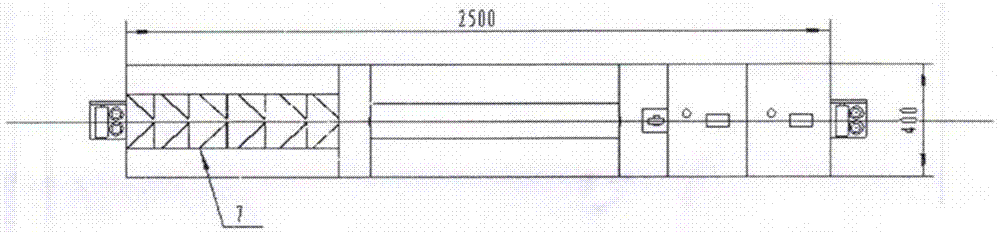

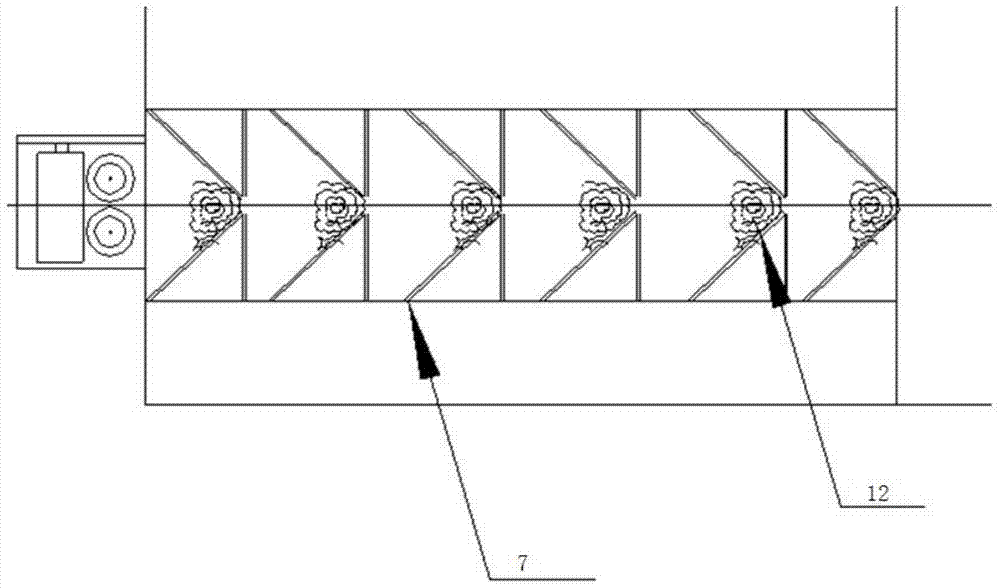

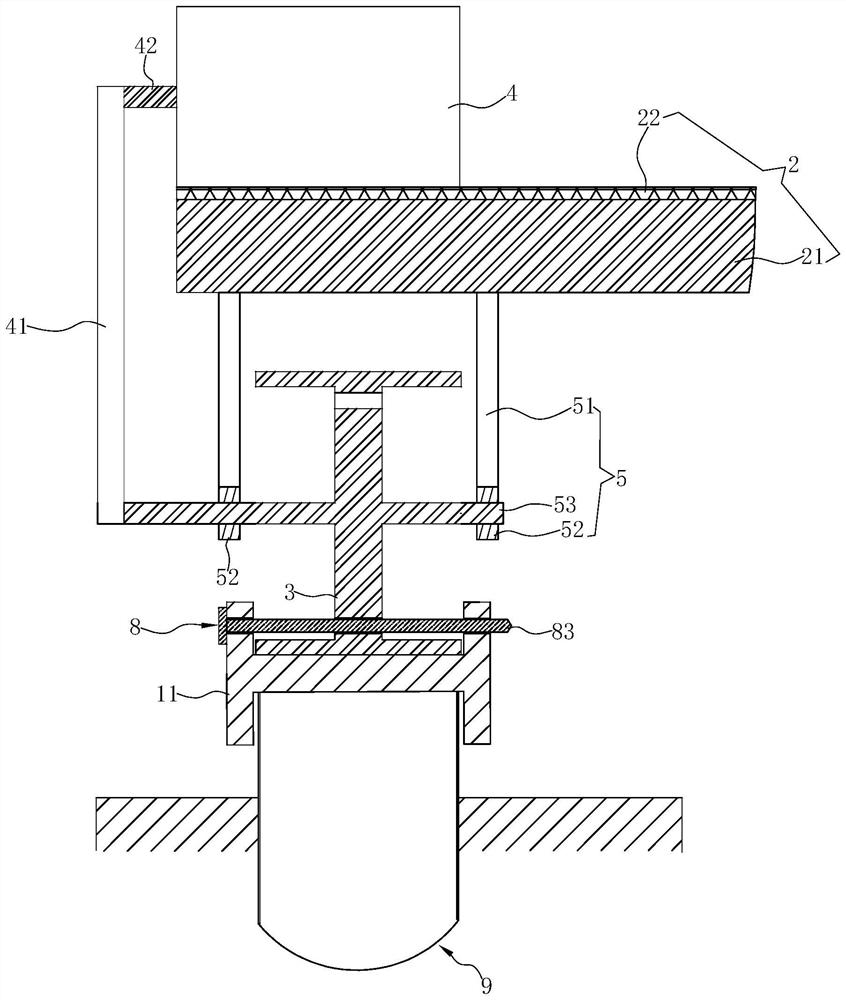

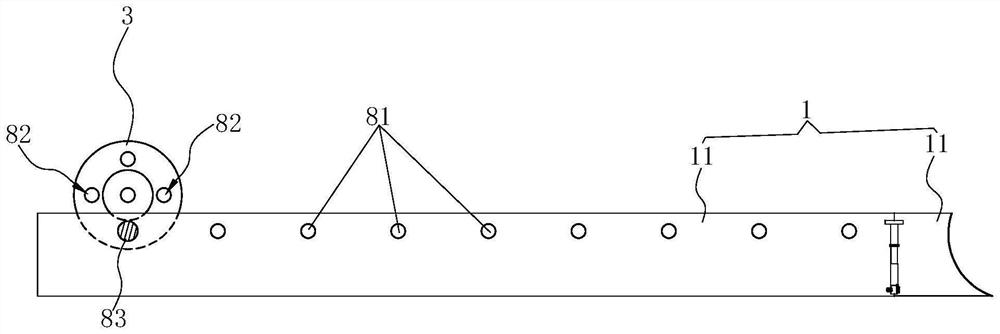

Polaroid stripping machine

InactiveCN104875472ANot easy to deform and damageReduce damage and deformationLamination ancillary operationsLaminationBiochemical engineering

The invention discloses a polaroid stripping machine which comprises a base cabinet, a support frame, a workbench unit, a rotating shaft unit, a heating device, a destaticizing device, a first control cabinet unit and a second control cabinet. The support frame is fixedly arranged on the base cabinet. The workbench unit is arranged on the support frame. The rotating shaft unit is fixedly disposed on the top of the base cabinet and positioned below the workbench unit. The heating device is fixedly arranged on the top of the base cabinet and positioned at one side of the rotating shaft unit. The destaticizing device is fixedly arranged at one side of the workbench unit. The first control cabinet unit is mounted on the base cabinet. The second control cabinet is movably arranged on the base cabinet. The polaroid stripping machine has advantages of good polaroid stripping effect and high work efficiency.

Owner:佑仁电子科技(苏州)有限公司

A new type of automobile wheel hub

The invention discloses a novel automobile hub. The novel automobile hub comprises a rim, an axle hub and a spoke set, wherein the wheel edge on the edge of the rim is provided with a plurality of clamping bars which are evenly distributed along the outer circumference of the wheel edge and used for clamping a tire, the axle hub is arranged on the axis of the rim, the spoke set comprises a plurality of first spokes and a plurality of second spokes, the first spokes and the second spokes are evenly distributed along the outer circumference of the axle hub in a radial shape, connected to the two sides of the rim respectively and used for supporting the rim, the width of the two side ends of each first spoke is larger than the width of the center position of the first spoke, first inclination angles opposite in direction are formed at the two side ends of each first spoke and are opposite to the outer surface of the first spoke, the two side ends of each first spoke are each provided with a cavity, and reinforcing ribs connected to the rim and the axle hub are further arranged on the outer surfaces of the first spokes; the rim and the axle hub are connected through the spoke set so that an automobile hub body can be formed. The novel automobile hub has the advantages of being good in stability, light in weight, fast in heat dissipation and high in safety coefficient.

Owner:SICHUAN XUNJI TECH CO LTD

Layout design method of large underground caverns

ActiveCN103291316BReduce damage and deformationReduce the cost of reinforcement supportTunnelsUnderground cavernPrincipal stress

The invention discloses a large-scale underground cavern group arrangement design method applied to hydraulic and hydroelectric engineering and underground storage cavern engineering. According to the arrangement design method, principal factors, especially the essential factor of the rock strength-stress ratio, influencing underground cavern surrounding rock stability can be comprehensively taken into account, the designing scheme for large-scale underground cavern group arrangement can be more scientific, and considered factors are more comprehensive. The position of a main cave is determined at first, the orientation of an axis of the main cave is determined, then the thickness of a rock pillar in the main cave is determined, and at last the shape of the main cave is determined. When the orientation of the axis of the main cave is determined, the trend of a rock mass main structural surface on a construction site and the orientation of the maximum principal stress are measured at first, the orientation of the axis of the main cave is determined according to an included angle between the axis of the main cave and the trend of the rock mass main structural surface and an included angle between the axis of the main cave and the orientation of the maximum principal stress, the included angle between the axis of the main cave and the trend of the rock mass main structural surface is not less than 40 degrees, and the included angle between the axis of the main cave and the orientation of the maximum principal stress is 0-40 degrees.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

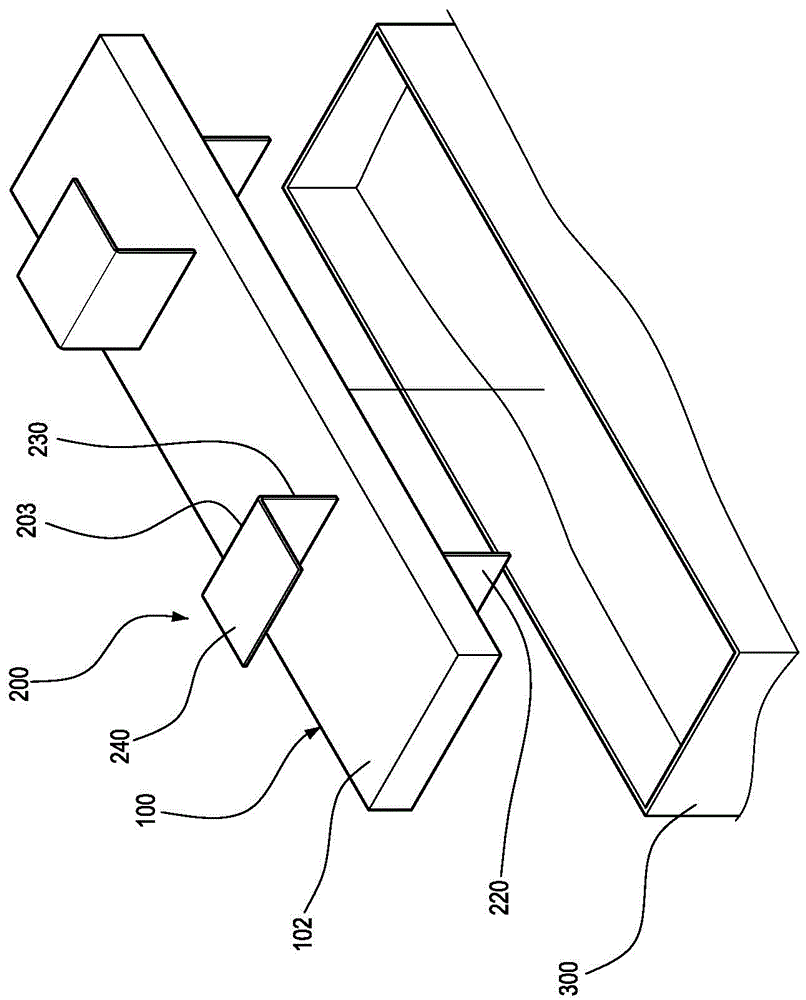

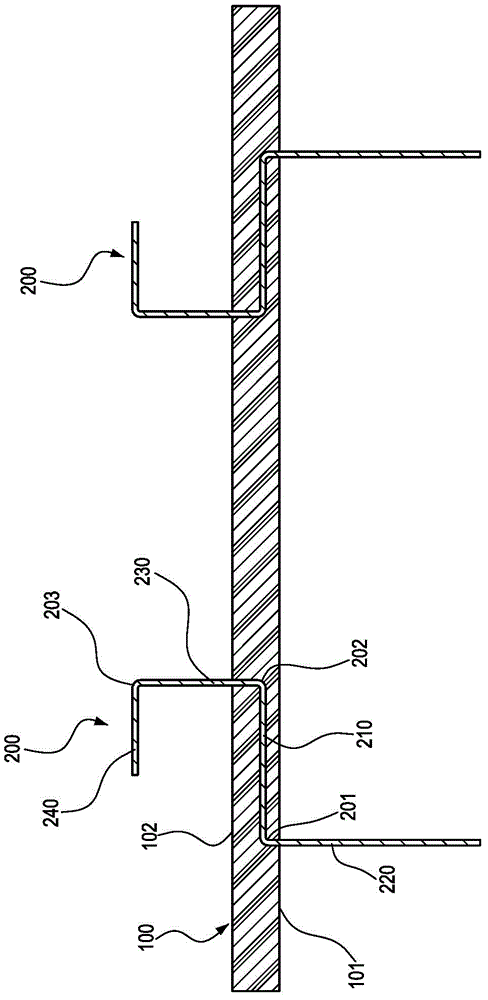

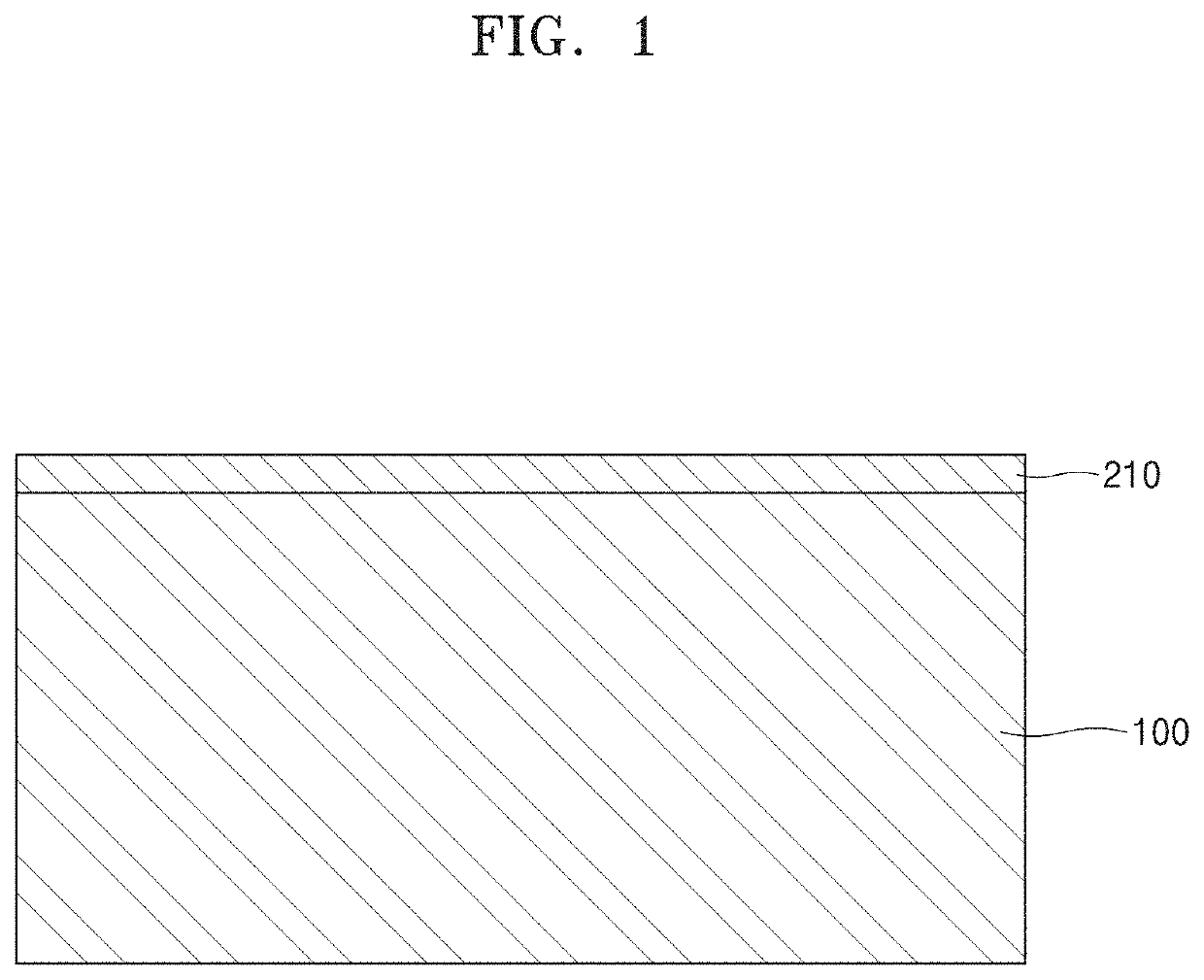

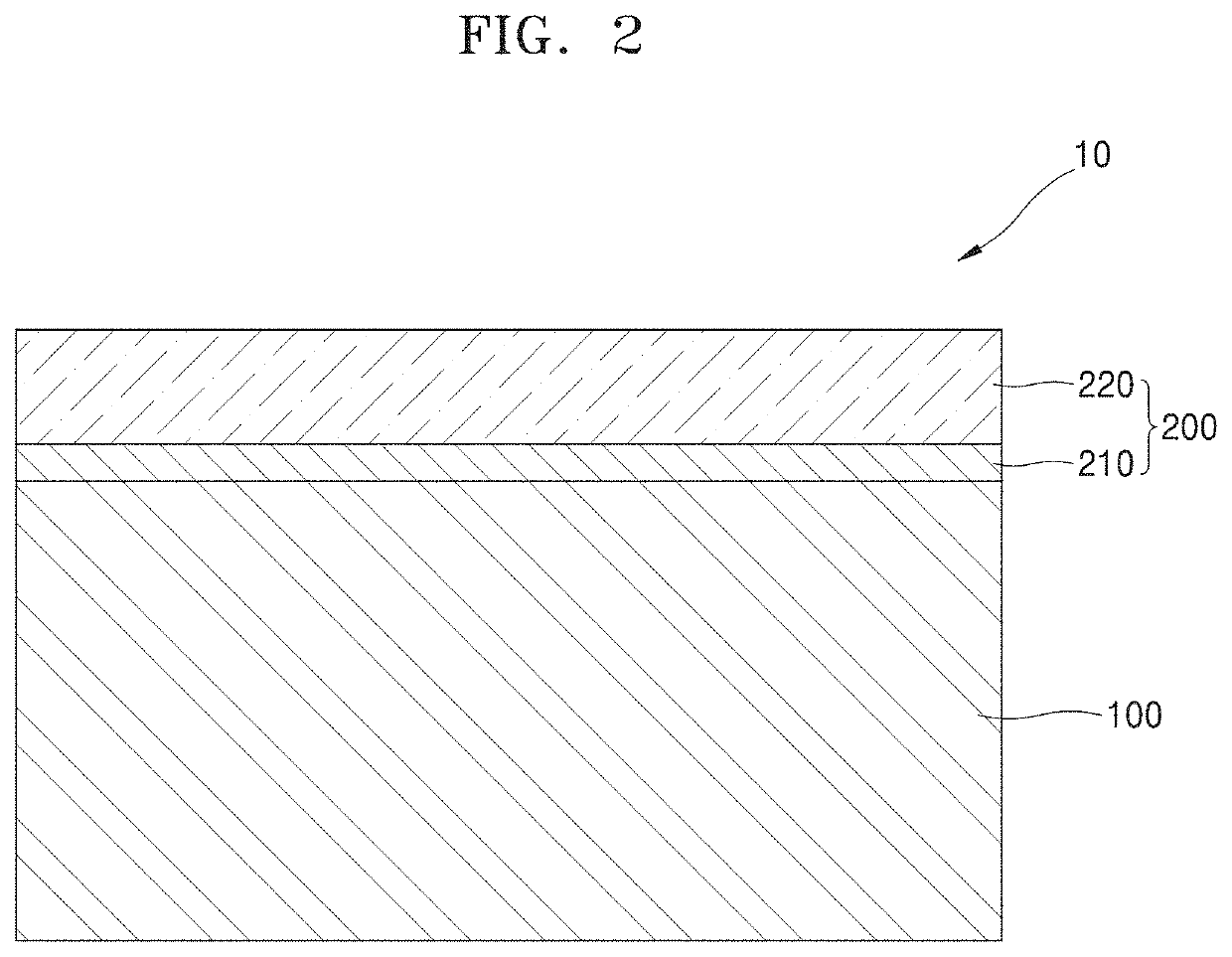

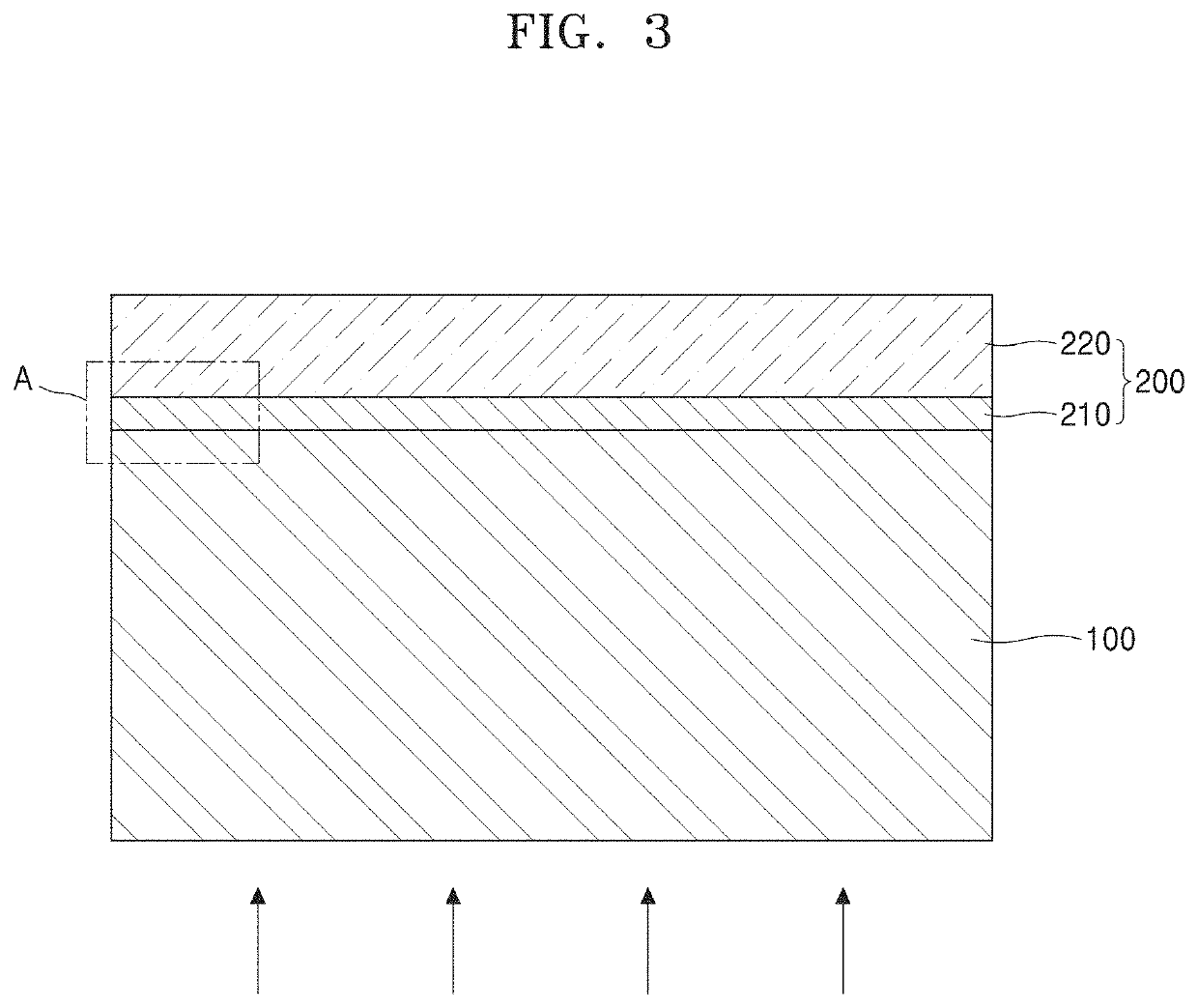

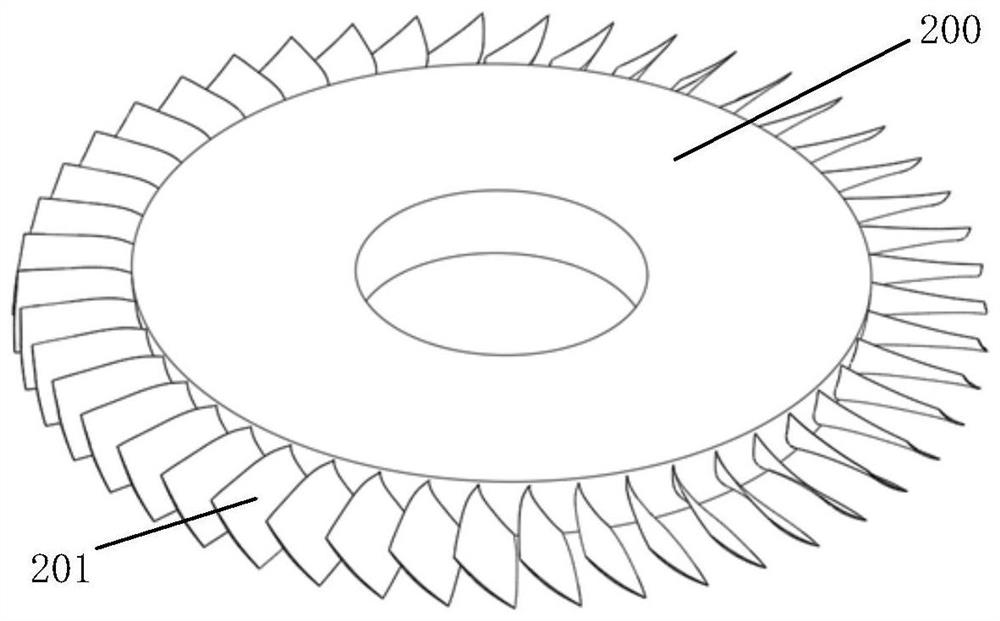

Electrode structure of lithium battery

ActiveCN102986061BLower resistanceReduce damage and deformationSmall-sized cells cases/jacketsLi-accumulatorsEngineeringMetal

An electrode structure of a lithium battery, an electrode structure in which the positive electrode and the negative electrode of the battery in the tank of the lithium battery are electrically connected to the outside, comprising: a cover plate body (100); an electrode body (200) made of at least a sheet metal material, The covered part is arranged in the cover body (100), and the two ends of the covered part (210) are respectively formed with bent parts (201, 202), and the bent parts (201, 202) are respectively extended to form a connection The part (220) and the output part (230) are exposed from the surface of the cover body (100). Through coating and non-direct penetration, the conductive electrode structure of the lithium battery is formed to achieve the sealing effect of the conductive part of the electrode.

Owner:CHANGS ASCENDING ENTERPRISES CO LTD

A fine drawing degreasing cleaning device

The invention provides a fine drawing degreasing cleaning device, which is sequentially provided with a dust removal unit, an overflow tank, a cooling water tank, a water filter plate, and multiple sets of high-pressure air blowing valve blocks along the horizontal movement direction of the fine drawing; the lower part of the dust removal unit is connected to a dust suction pipeline , the dust removal unit has a built-in wiping body, and the dust removal unit includes a coarse dust removal device, a fine dust removal device, and a fine dust removal device; There is a through opening for the wire rod to pass through. It can simultaneously realize vacuum treatment, water circulation treatment, and high-pressure air drying. The equipment has a simple structure, high efficiency, and strong practicability, which effectively improves the cleanliness of the silk surface; avoids the problem of overheating and deformation of the take-up wheel.

Owner:DEZHOU HENGYUAN WELDING MATERIAL

a smart cabinet

ActiveCN110169664BPrevent deformationAvoid dripping onto the inner bulkheadFurniture partsKitchen cabinetsStructural engineeringCupboard

Owner:广东亿科不锈钢制品有限公司

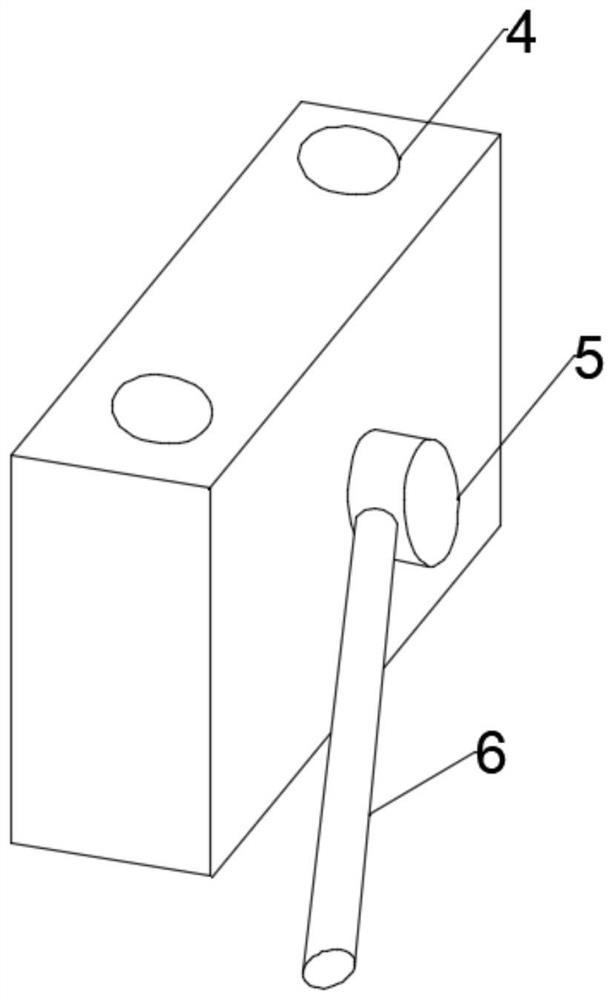

Device for inserting computer memory bank into slot

InactiveCN107263388AImprove work efficiencyEasy to operateMetal-working hand toolsMemory bankEngineering

The invention discloses a device for inserting a computer memory bank into a slot. The device for inserting the computer memory bank into the slot comprises a pressing plate and a positioning block which comprises a first positioning plate and a second positioning plate; the upper ends of the first positioning plate and the second positioning plate are connected with the inner end face of the pressing plate; the inner end face of the pressing plate is matched with the upper end portion of the memory bank; the inner side end faces of the first positioning plate and the second positioning plate are planes, and are arranged in parallel; and the distance between the two inner side end faces is matched with the width of the memory bank. The device for inserting the computer memory bank into the slot is compact in structure, small in weight, convenient to hold and capable of saving labor, reducing the labor intensity of an operator and improving the work efficiency of the operator.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Method of manufacturing electronic device

ActiveUS20210090932A1Reduce damage and deformationComplex shapeAdhesive processesLamination ancillary operationsThermal shockSi substrate

A method of manufacturing an electronic device is provided. The method includes forming a stack structure by placing a to-be-peeled layer on a substrate, applying thermal shock to the stack structure, detaching the to-be-peeled layer from the substrate, and transferring the detached to-be-peeled layer to a target substrate.

Owner:DAEGU GYEONGBUK INST OF SCI & TECH

Tent supporting rod

The invention discloses a tent supporting rod which comprises an aluminum alloy base rod and a coating outside the aluminum alloy base rod. The tent supporting rod is characterized in that the aluminum alloy base rod consists of the following components in parts by weight: 2-3 parts of Cu, 4-6 parts of Ti, 0.2-1 part of Fe, 6-8 parts of Zn, 4-7 parts of Mg, 1-2 parts of Ni, 0.2-0.5 part of Zr, 1-2 parts of Si, and 65-72 parts of Al; and the coating comprises the following materials: epoxy resin, pigment, a plasticizer and a flame retardant. The supporting rod has high strength, high elastic modulus, relatively good wear resistance and a relatively long service life.

Owner:YANCHENG CHANGHUA OUTDOOR PROD CO LTD

Method for excavating foundation pit in soft soil stratum

PendingCN114718074AEasy to excavateReduce damage and deformationBridge applicationsSoil-shifting machines/dredgersPurlinExcavator

The invention discloses a soft soil stratum foundation pit excavation method which is characterized by comprising the following steps: 1) foundation pit support pile construction: measuring the driving position of a support pile according to the size of a foundation pit, firstly driving vertical columnar piles according to the measuring position, driving vertical sheet piles among the columnar piles, and driving the vertical sheet piles into a certain height above the ground, the sinking height of the sheet piles is consistent with the sinking elevation of the columnar piles, and enclosing purlins are arranged on the outer sides of the supporting piles. The trestle bridge in the width direction of the foundation pit is erected on the supporting piles, the trestle bridge can move relative to the foundation pit in the length direction of the foundation pit, the excavator is hoisted to the trestle bridge through a crane, the foundation pit is excavated, advancing and retreating of the excavator are achieved through moving of the trestle bridge, deep sinking of the excavator is avoided due to the fact that the excavator does not make direct contact with the soft soil stratum, and the construction efficiency is improved. A traditional excavation-drying-excavation technology is not needed, the construction period is shortened, the utilization rate of equipment is improved, the operation space of the excavator located on the trestle is increased, and excavation of the foundation pit is better facilitated.

Owner:CCCC SHANGHAI DREDGING

Layout method of underground caverns

ActiveCN103291331BReduce damage and deformationReduce the cost of reinforcement supportUnderground chambersUnderground cavernStress ratio

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

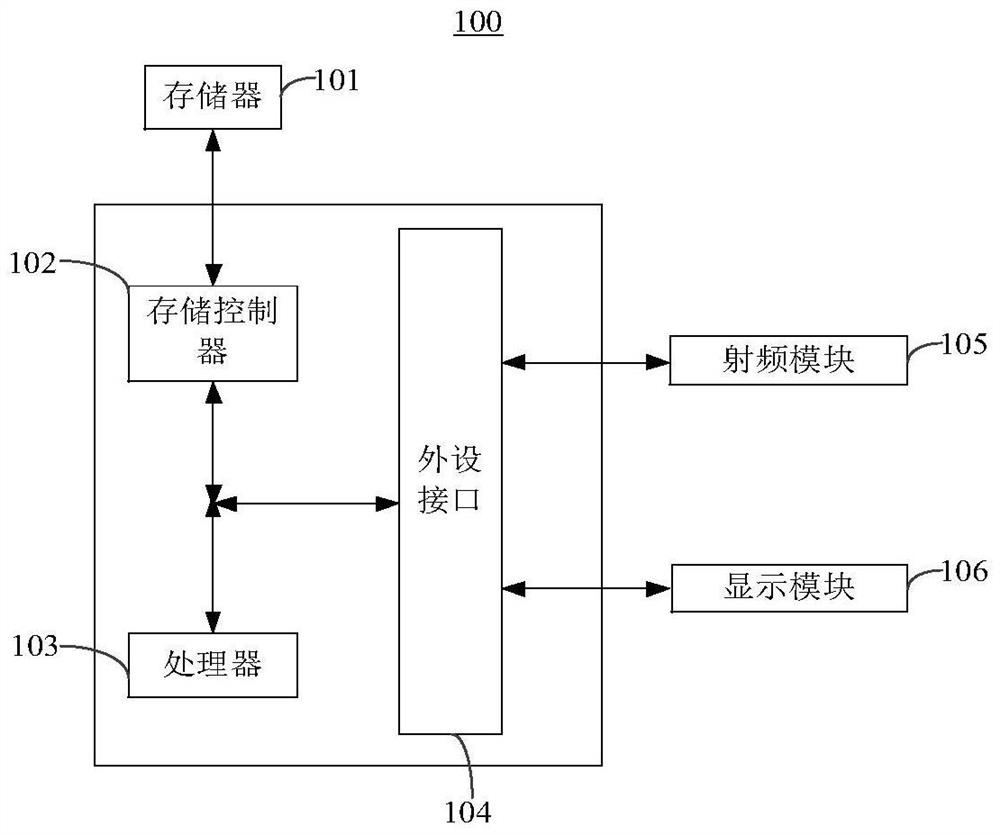

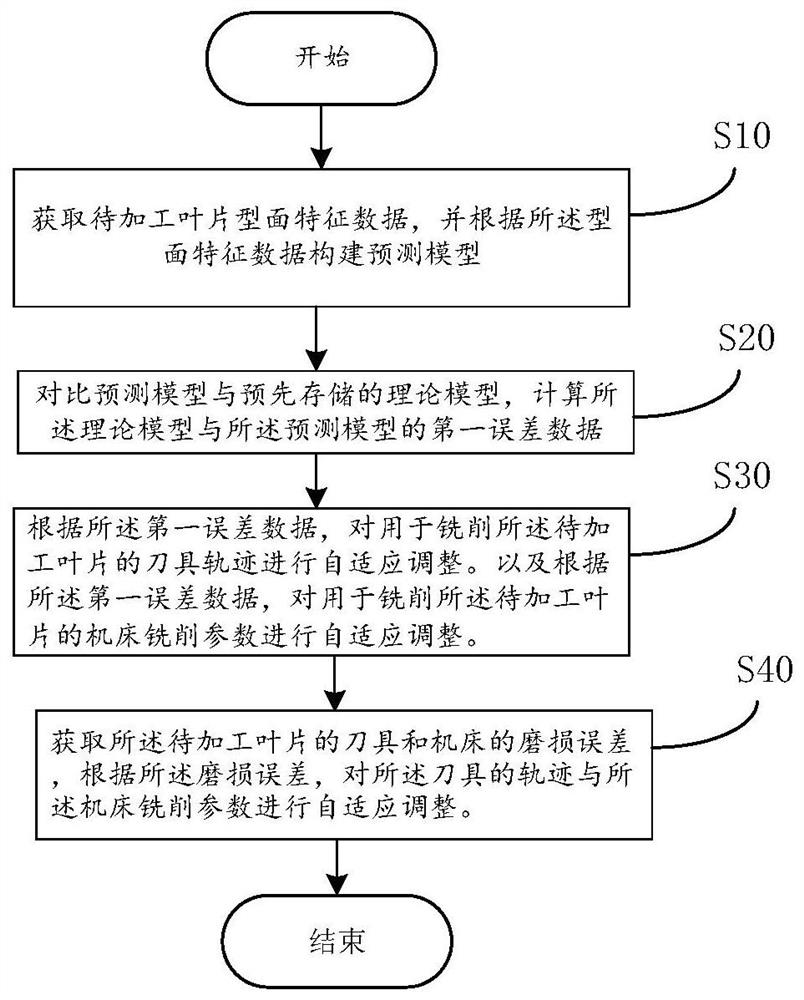

A kind of self-adaptive regulation method, device, and electronic equipment for blade machining process

ActiveCN111618654BImprove processing quality and precisionReduce damage and deformationAutomatic control devicesFeeding apparatusSelf adaptiveMachining process

The invention provides a self-adaptive regulation method, device and electronic equipment for blade machining process, belonging to the technical field of aero-engine milling. The provided self-adaptive control method for a blade machining process includes: acquiring profile feature data of a blade to be processed, and constructing a prediction model according to the profile feature data. The prediction model is compared with the pre-stored theoretical model, and the first error data of the theoretical model and the prediction model is calculated. Through the obtained first error data, the tool path of the blade to be processed and the milling parameters of the machine tool are adaptively adjusted, which improves the processing quality and accuracy of the blade and reduces the damage and deformation of the parts.

Owner:TSINGHUA UNIV

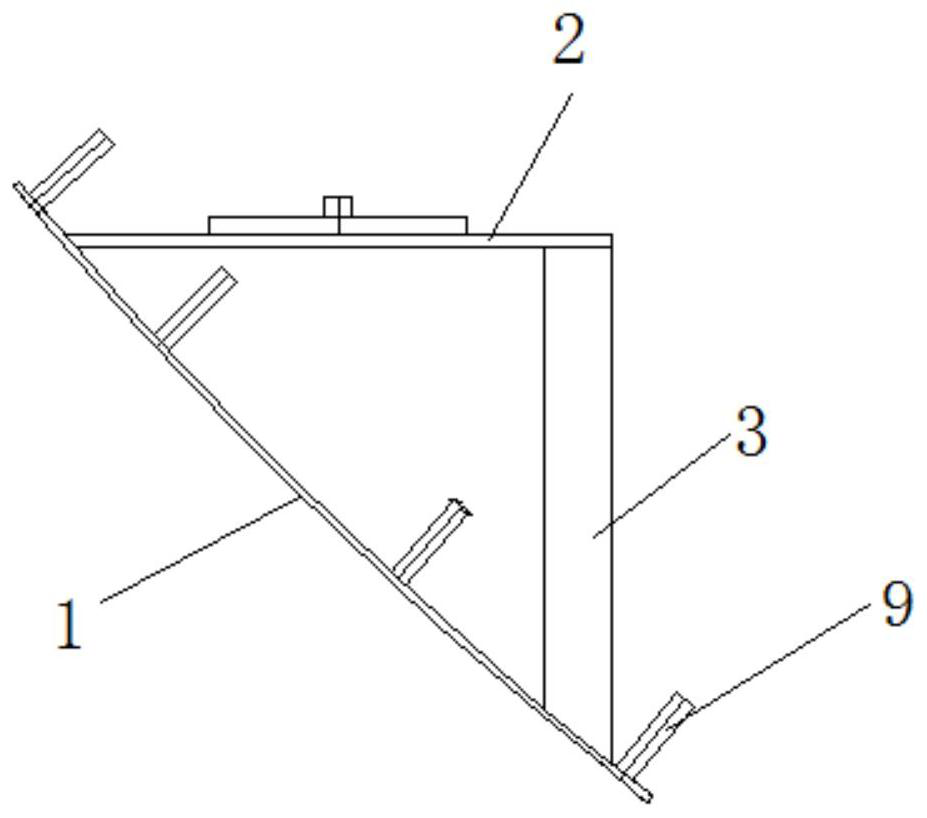

Manufacturing method of forced centering bracket for existing pre-buried slide groove and T-shaped bolts

InactiveCN111636877ASmall form factorSave materialMining devicesTunnelsStructural engineeringMaterial resources

The invention provides a manufacturing method of a forced centering bracket for an existing pre-buried slide groove and T-shaped bolts. The implementation method comprises the steps that an arc-shapedsteel plate installed on a segment pre-buried slide groove is manufactured at first, the arc-shaped steel plate is fixed to the existing pre-buried slide groove on the inner side of a segment throughthe T-shaped bolts, a square steel plate for placing a forced centering disc is manufactured, and then, angle steel connected with the arc-shaped steel plate and the square steel plate is manufactured; and the arc-shaped steel plate, the square steel plate and the angle steel are welded together to form a bracket, and the bracket is fixed to the existing pre-buried slide groove on the inner sideof the segment through the T-shaped bolts. The problems that a bracket is inconvenient to carry, long in installing operation time, large in damage deformation and low in recycling rate, and a segmentneeds to be repaired after the bracket is disassembled are solved. According to the manufacturing method, an existing forced centering bracket is transformed to be in a non-drilling installation mode, the tunneling speed of a shield tunnel is effectively ensured, and manpower, material resources and operation time are saved.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 3RD ENG

Slot-assembled steel pipe column and steel beam connection node and its construction method

ActiveCN105350658BReduce damage and deformationHigh degree of factoryBuilding constructionsArchitectural engineeringEngineering

The invention discloses a clamping groove assembling type steel pipe column and steel beam connecting joint and a construction method thereof. A plurality of H-shaped steel beams are horizontally connected to the side wall of the periphery of a steel pipe column. A steel beam end plate extending in the beam height direction of the steel pipe column is fixedly welded to the end face of each H-shaped steel beam. A U-shaped clamping groove is welded to the lower side of the steel pipe column. The lower sides of the steel beam end plates are inserted into the U-shaped clamping groove. An annular movable steel hoop is installed on the upper side of the steel pipe column. The upper ends of the steel beam end plates are hooped and connected through the movable steel hoop or hooped and connected in the mode that a reinforcing plate is matched with the movable steel hoop. Insertion plates for fastening are inserted into gaps between the U-shaped clamping groove and the steel beam end plates. An annular reinforcing plate is welded to the portion, matched with the movable steel hoop, of the middle of the inner wall of the reinforcing plate. An end plate reinforcing plate is fixedly arranged at the joint of an upper wing edge and the middle of the upper end of each steel beam end plate. A notch is formed in the middle of the annular reinforcing plate on each side. The clamping groove assembling type steel pipe column and steel beam connecting joint has the advantages that the industrial degree is high, no welding or bolt connection is needed on a construction site, and the construction speed is high, and has better technical benefits.

Owner:HANGZHOU TONGMSK DESIGN CO LTD

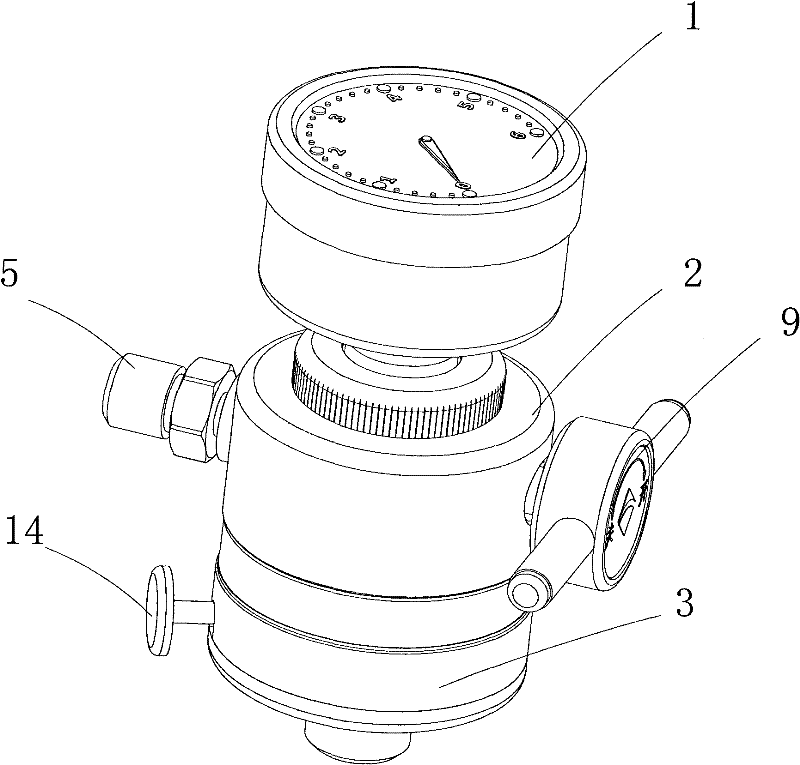

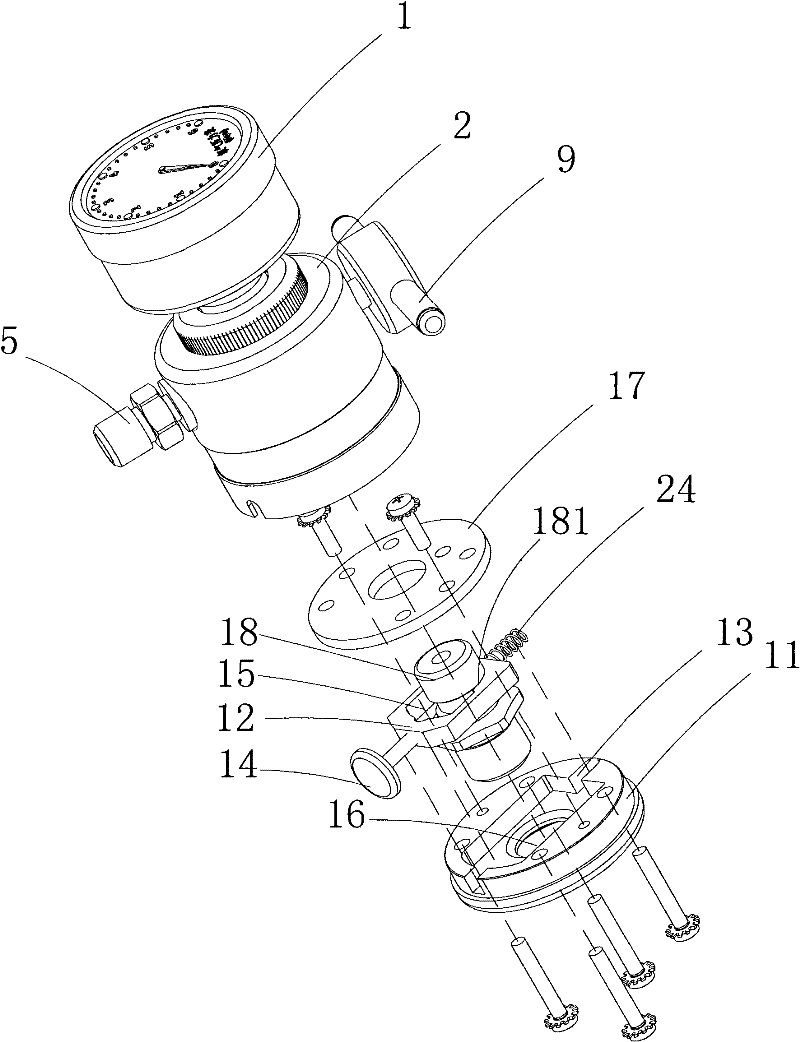

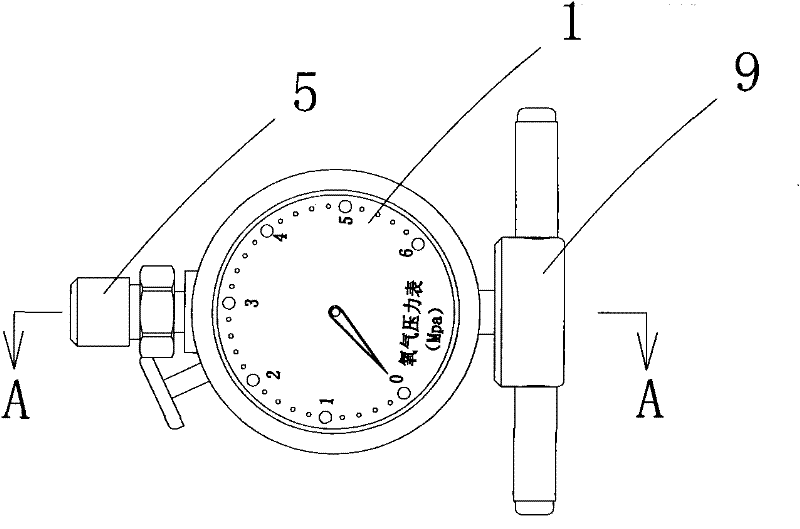

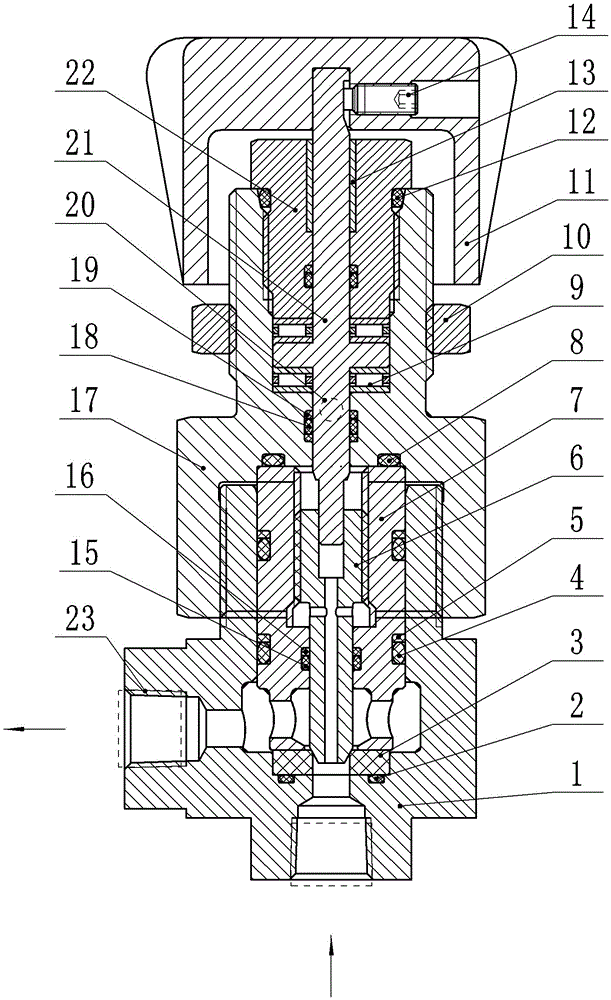

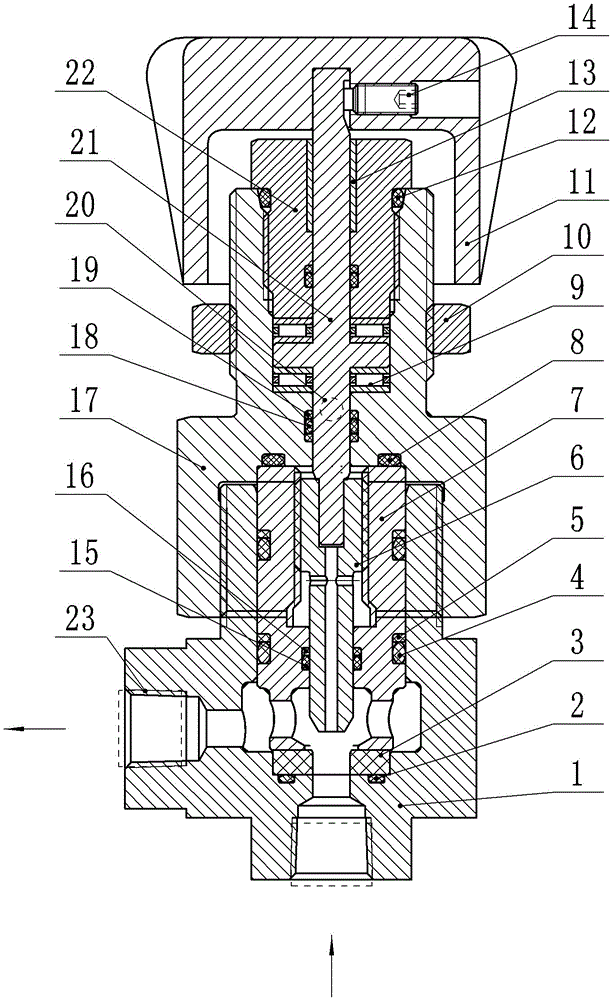

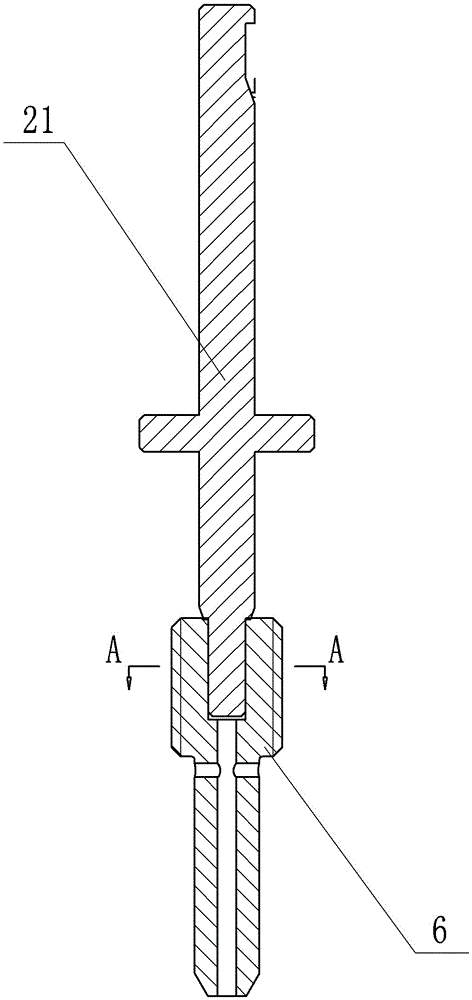

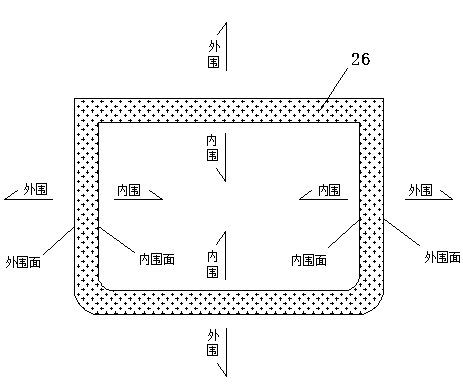

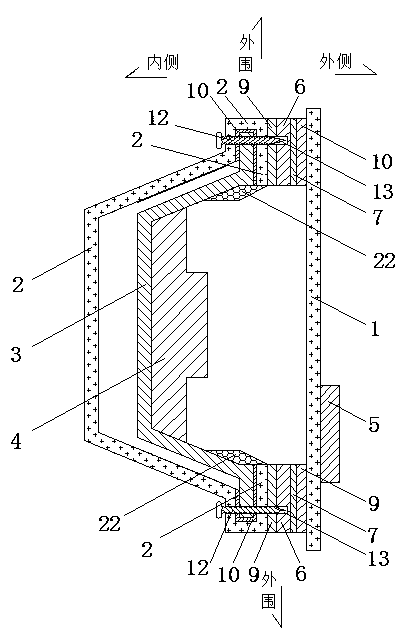

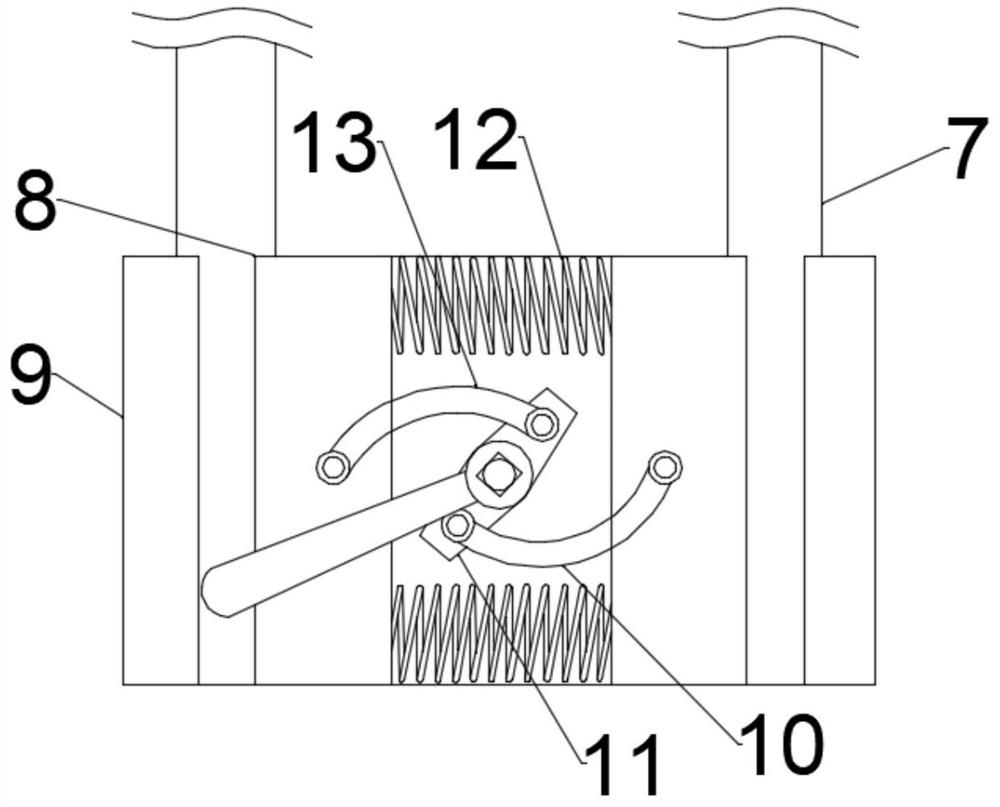

Miniature oxygenator with self-locking oxygen bullet connecting component

ActiveCN101806394BCompact structureLow costContainer filling methodsContainer discharging methodsOxygenatorsSelf locking

The invention discloses a miniature oxygenator with a self-locking oxygen bullet connecting component, which comprises an oxygen pressure gauge, a body and an oxygen bullet connecting component used for connecting an oxygen bullet. The oxygen pressure gauge is fixed on the top end of the body; the oxygen bullet connecting component is arranged at the bottom end of the body and comprises a connecting cover and a self-locking sheet; the connecting cover is connected to the bottom of the body, and is provided with a self-locking sheet accommodating part; the self-locking sheet is sleeved in the self-locking sheet accommodating part which is provided with a sleeving hole for the oxygen bullet to pass through; the self-locking sheet is provided with a lock hole which is clamped with the oxygenbullet; and a self-locking sheet spring is arranged between one end of the self-locking sheet and the inner wall of the self-locking sheet accommodating part. The miniature oxygenator with the self-locking oxygen bullet connecting component has the advantages of simple and compact structure, low cost, convenient operation, high safety and high reliability.

Owner:HUNAN SUNDY SCI & TECH DEV

a valve

ActiveCN103498942BGuaranteed reliabilityGuaranteed stabilityOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringMechanical engineering

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

Large-scale underground cavern group arrangement method

ActiveCN103291332BReduce damage and deformationReduce the cost of reinforcement supportUnderground chambersUnderground cavernStress ratio

The invention discloses a large-scale underground cavern group arrangement method applied to hydraulic and hydroelectric engineering and underground storage cavern engineering. According to the arrangement method, principal factors, especially the essential factor of the rock strength-stress ratio, influencing underground cavern surrounding rock stability can be comprehensively taken into account, the designing scheme for large-scale underground cavern group arrangement can be more scientific, and considered factors are more comprehensive. The position of a main cave is determined at first, the orientation of an axis of the main cave is determined, then the thickness of a rock pillar in the main cave is determined, and at last the shape of the main cave is determined. When the position of the main cave is determined, the rock strength-stress ratio on a construction site is firstly measured, and when the rock strength-stress ratio is 2.0-4.0, the thickness from the outer edge of the main cave to a rock of a valley slope surface should be larger than 400m; when the rock strength-stress ratio is 4.0-7.0, the thickness from the outer edge of the main cave to the rock of the valley slope surface is 200-400m; when the rock strength-stress ratio is larger than 7.0, the thickness from the outer edge of the main cave to a rock of the valley slope surface is 150-200m.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Layout design method of underground cavern group

ActiveCN103266902BReduce damage and deformationReduce the cost of reinforcement supportUnderground chambersDesign planUnderground cavern

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Automobile back door three-dimensional shell sharing outer shell

InactiveCN103523095AInaccessibleFirmly connectedSuperstructure subunitsBack doorElectrical and Electronics engineering

According to the technical scheme, an automobile back door three-dimensional shell sharing an outer shell is characterized in that the edge of the outer shell bends towards the inner side, is turned over for form a J shape and completely covers the edge of an inner shell, a medium material layer, an adhering material layer, a color layer and a detachable connection fixing devices are disposed at the connection of an outer transparent material layer and the shell, and the detachable connection fixing devices can be a plurality of screw holes, screws, nuts, through holes and / or bolts. By the automobile back door three-dimensional shell, connection between the outer shell of the automobile back door three-dimensional shell sharing the outer shell and inner shell and connection between the shell and the edge of the outer transparent material layer can be tight, seamless, firm, anti-impact and invisible, and color of the connection can be corresponded to that of three-dimensional decoration.

Owner:张清华

A construction reinforcement cage hoisting reinforcement structure

ActiveCN113638548BIncrease stiffnessAvoid deformationBuilding reinforcementsArchitectural engineeringRebar

The present invention is applicable to the field of building construction, and provides a hoisting and strengthening structure of a steel cage for building construction, and further includes: a fixing structure, the fixing structure includes several fixing components, and a plurality of fixing components are arranged at the bottom of the fixing structure Inside, the fixed assembly includes a clamping piece, a rotating piece, a pushing piece, and a control head, and the fixing assembly is used to change the angle between the control head and the pushing piece by using the tightness of the rotating piece and the control head, and then drive the clip The fastener clamps and fixes the main reinforcement of the reinforcement cage; the reinforcement structure is fixedly connected with the reinforcement cage, and the reinforcement structure is used to improve the rigidity of the reinforcement cage itself, and the reinforcement structure and the fixed structure are detachably connected.

Owner:CHINA RAILWAY 24TH BUREAU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com