Screw anchor and method for producing a screw anchor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

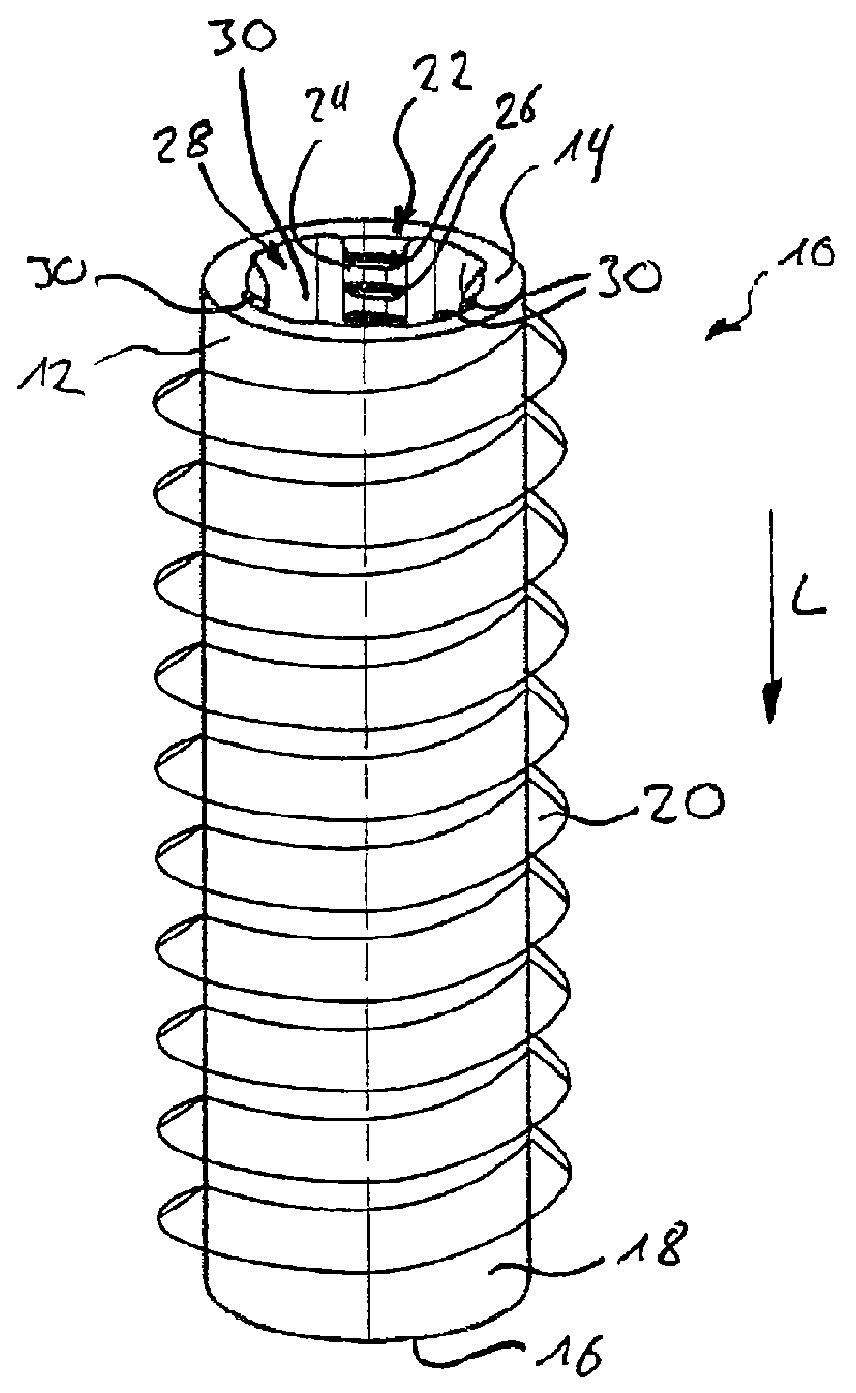

[0033]In FIG. 1 depicts a screw anchor 10 for screwing into concrete. The screw anchor may be screwed into a borehole of the concrete base body for fastening a component on a concrete base body. Then a component to be fastened on the concrete part may be mounted on the screw anchor 10 for example with an additional fastening element and therewith be fastened on the concrete part.

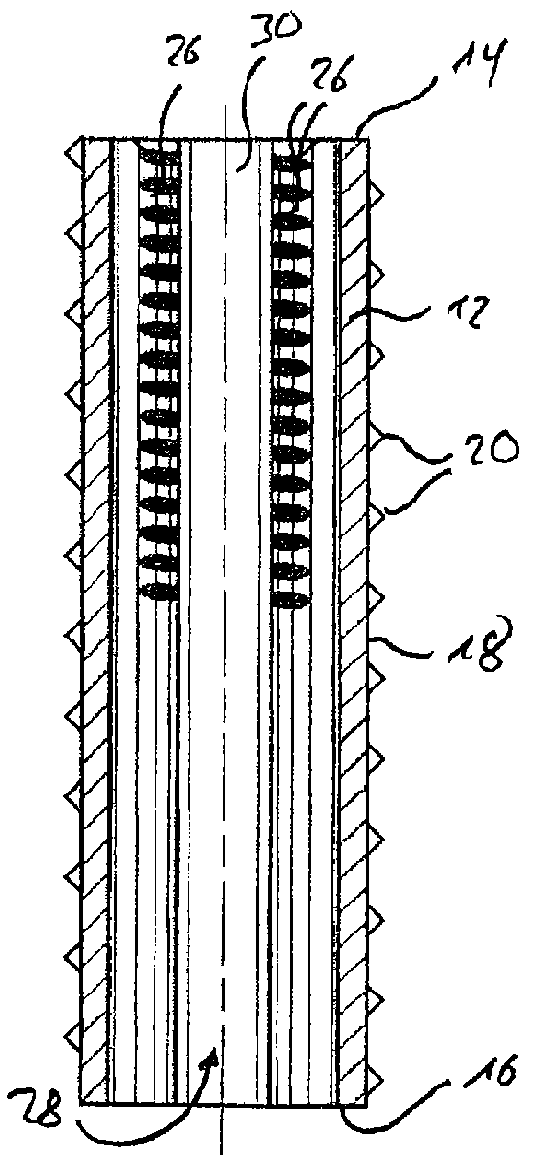

[0034]The screw anchor 10 has a cylindrical base body 12 having a first axial end face 14, a second axial end face 16 as well as a lateral surface 18. An external thread 20 is provided on the lateral surface 18 of the base body 12, with which the screw anchor 10 may be screwed into a borehole in a concrete body and thereby be fixed on the concrete body.

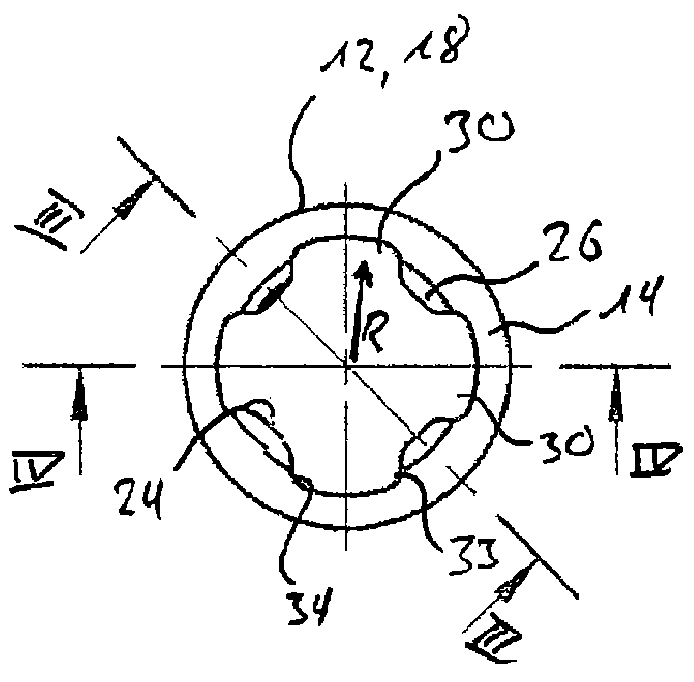

[0035]The base body 12 also has a receptacle 22, which, as FIGS. 3 and 4 show, extends from the first end face 14 over the entire length of the base body 12 to the second axial end face 16 so that the base body 12 essentiall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com