a valve

A valve and valve port technology, applied in the field of valves, can solve problems such as threaded connection structure damage, threaded connection structure extrusion deformation, slipping, etc., to achieve the effect of reducing damage and deformation, ensuring reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

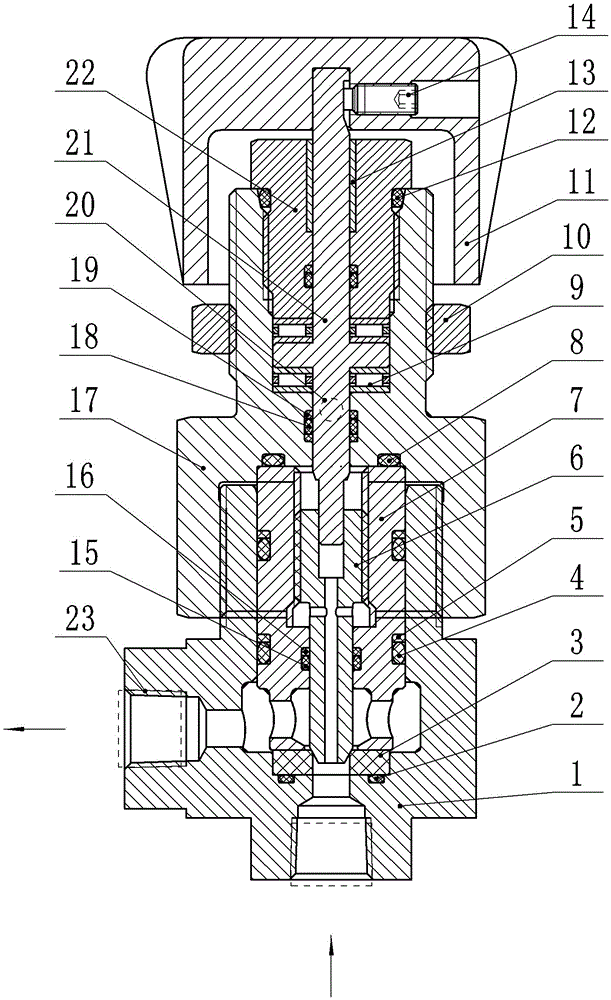

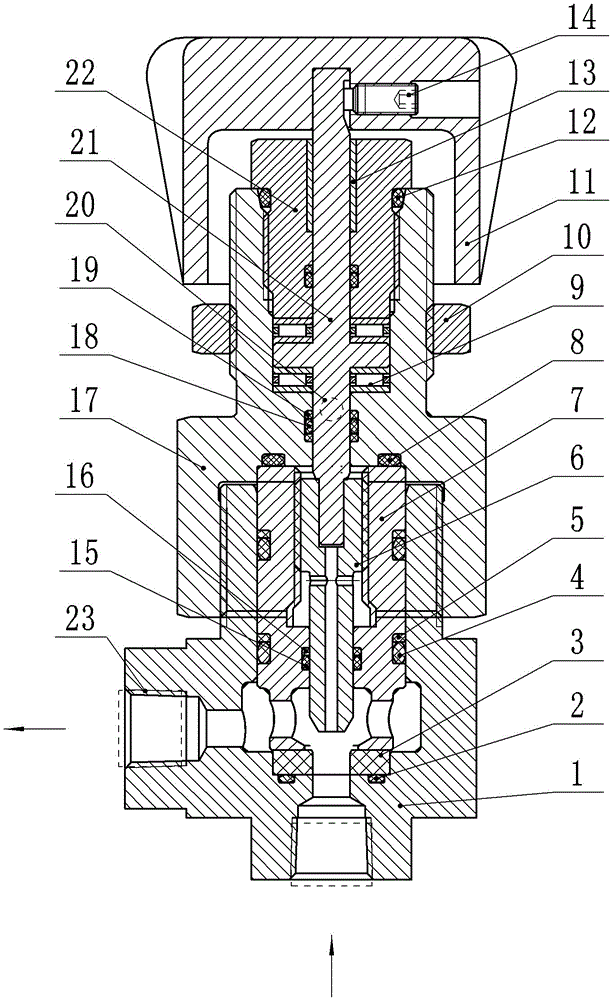

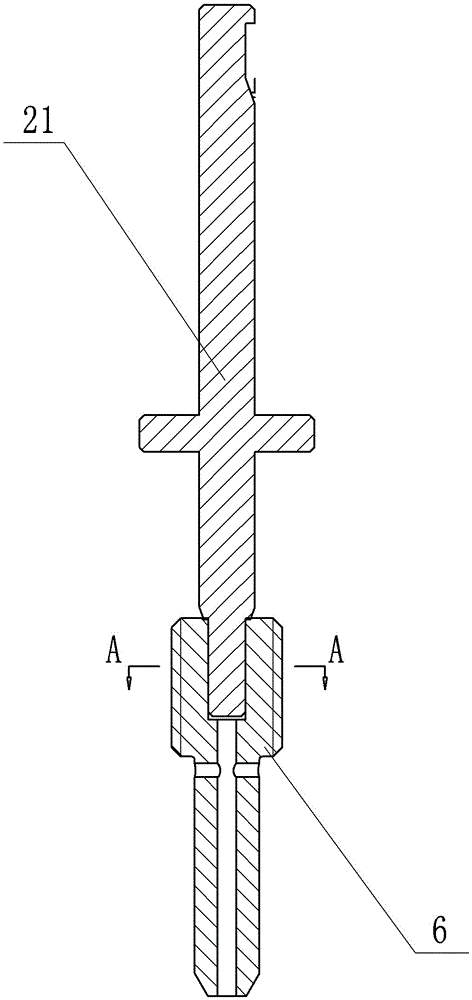

[0021] Embodiments of the valve of the present invention: as Figure 1 to Figure 6 As shown, the valve is a manually controlled dark-rod high-pressure balanced globe valve used in high-pressure and large-flow air, nitrogen, natural gas, petrochemical and other systems, including valve seat 1, valve sleeve 7, valve cover 17, handle 11, Bonnet plug 22, valve stem 21, and valve disc 6, wherein valve seat 1 is provided with a valve cavity, the upper end of valve seat 1 is the opening end of the valve cavity, and the lower end of valve seat 1 is provided with an inlet and a left side communicating with the valve cavity. There is an outlet connected to the valve cavity, and a valve port for controlling the on-off state between the inlet and the outlet is provided at the part where the inlet and the valve cavity communicate; the valve cover 17 is coaxially threaded on the top periphery of the valve seat 1, and the The plug 22 is coaxially threaded on the top periphery of the valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com