A kind of self-adaptive regulation method, device, and electronic equipment for blade machining process

A technology of self-adaptive regulation and processing procedures, applied in metal processing equipment, automatic control devices, metal processing and other directions, can solve the problems affecting the quality and accuracy of processing, and achieve the effect of improving processing quality and accuracy, reducing damage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

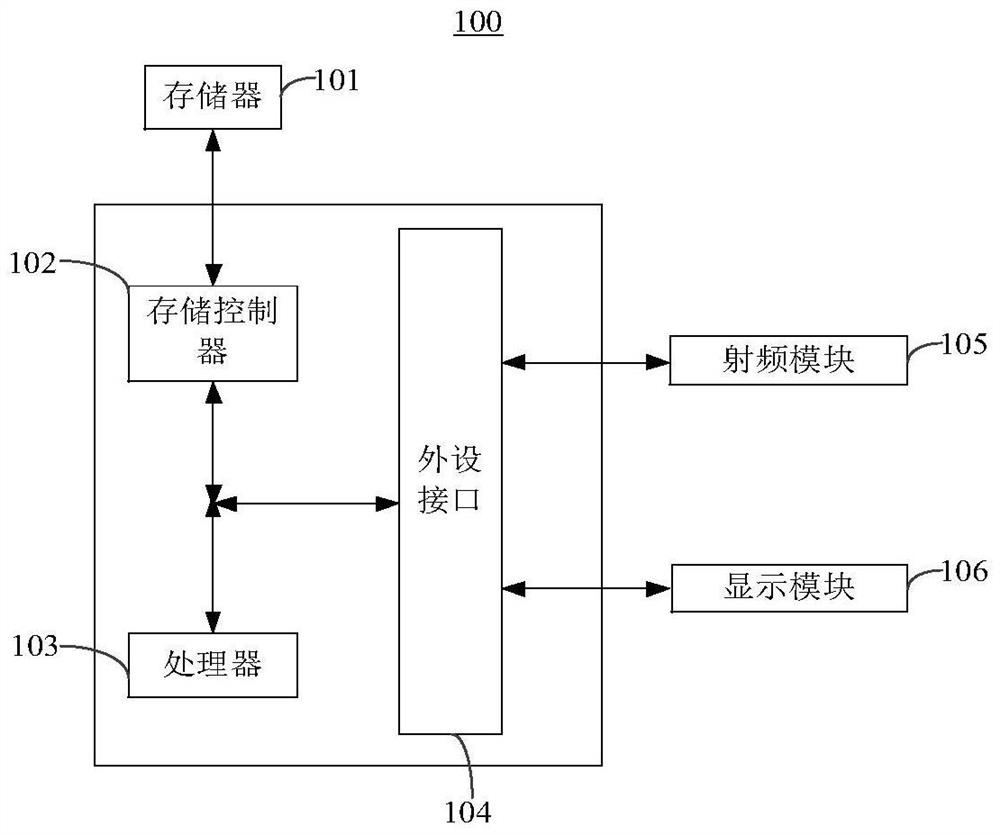

[0031] figure 2 A structural block diagram of an electronic device 100 that can be applied to the adaptive control method and device for the blade machining process provided by the embodiment of the present invention is shown. like figure 1As shown, the electronic device 100 includes a memory 101, a memory controller 102, one or more (only one is shown in the figure) processor 103, a peripheral interface 104, a radio frequency module 105, a display unit 106, and the like. These components communicate with each other via one or more communication bus / signal lines 107 .

[0032] The memory 101 can be used to store software programs and modules, such as the adaptive control method of the blade machining process in the embodiment of the present invention, the program instructions / modules corresponding to the device, and the processor 103 runs the software programs and modules stored in the memory 101, Thereby, various functional applications and data processing are performed, s...

Embodiment 2

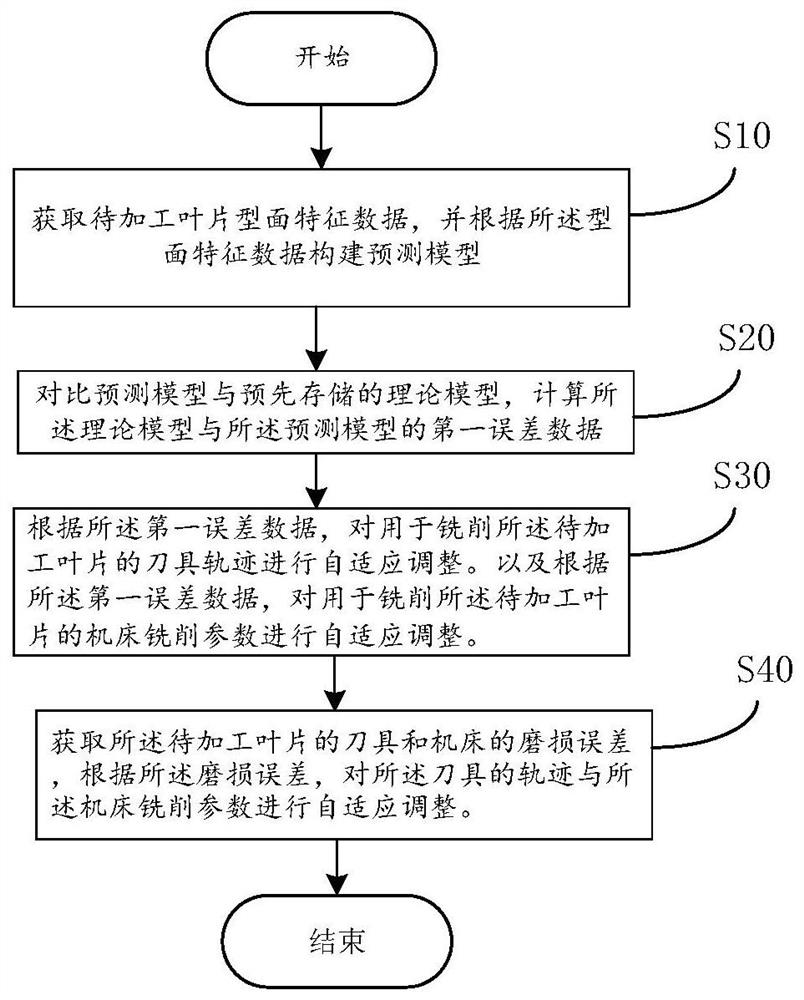

[0039] like image 3 As shown, it is an adaptive adjustment method for a blade machining process provided by an embodiment of the present invention, and the method includes the following steps:

[0040] S10: Acquire profile feature data of the blade to be processed, and construct a prediction model according to the profile feature data.

[0041] In one embodiment, the step includes:

[0042] The attitude adjustment is performed on the blade to be processed, so that the blade to be processed reaches the optimal measurement position.

[0043] Three-dimensional coordinate measurement is performed on the profile of the blade to be processed to obtain the profile feature data of the blade to be processed.

[0044] According to the profile feature data, three-dimensional reconstruction is performed on the blade to be processed to obtain the prediction model.

[0045] Specifically, a measuring probe is positioned and installed on the blade, and the attitude of the blade is adjuste...

Embodiment 3

[0061] like Figure 4 As shown, it is a structural block diagram of an adaptive control device 300 for a blade machining process provided by an embodiment of the present invention, and the device includes:

[0062] The first acquisition module 301 is used to acquire the profile feature data of the blade to be processed.

[0063] The first building module 302 is configured to build a prediction model according to the profile feature data.

[0064] The first calculation module 303 is configured to compare the prediction model with the pre-stored theoretical model, and calculate the first error data of the theoretical model and the prediction model.

[0065] The adjustment module 304 is configured to adaptively adjust the tool path for milling the blade to be machined and the machine tool milling parameters for milling the blade to be machined according to the first error data.

[0066] Further, the device also includes:

[0067] The attitude adjustment module 305 is used to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com