High volume fraction aluminum-based silicon carbide composite grinding fluid based on elid and preparation method thereof

A technology of aluminum-based silicon carbide and high volume fraction, applied in lubricating compositions, petroleum industry, etc., can solve problems such as inability to achieve mirror-level ultra-precision machining, uneven surface quality of processed parts, and inability to meet practical application requirements, etc. Achieve the effects of reducing scratches, good cooling effect, and high processing quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of special grinding fluid, concrete steps are as follows:

[0037] ②Heat engine oil and lard to 60°C to melt and mix for later use;

[0038] ② Add benzotriazole, chlorinated fatty acid, and emulsified silicone oil to some distilled water, heat to 50°C, stir and fuse, and cool for later use;

[0039] ③At room temperature, add fatty acid diethanolamide, sodium naphthenate, calcium molybdate, ethylpropanol, orthophenol, sodium edetate, and sodium chloride into the remaining distilled water, stir evenly, and dissolve;

[0040] ④ Mix the liquids obtained in steps ①, ②, and ③, heat to 80°C, stir evenly, and cool;

[0041] ⑤ Mix the liquid obtained in ④ with distilled water in proportion and stir until uniform, and obtain a special grinding fluid for aluminum-based silicon carbide composite materials with a high volume fraction.

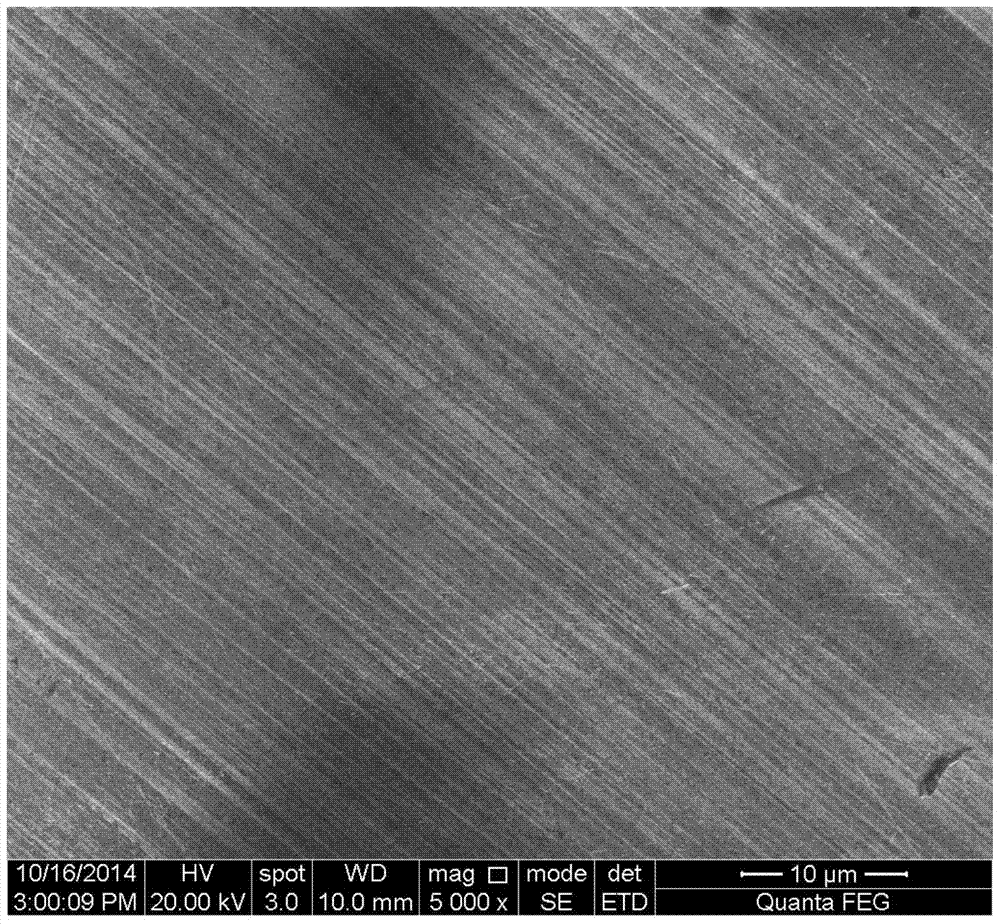

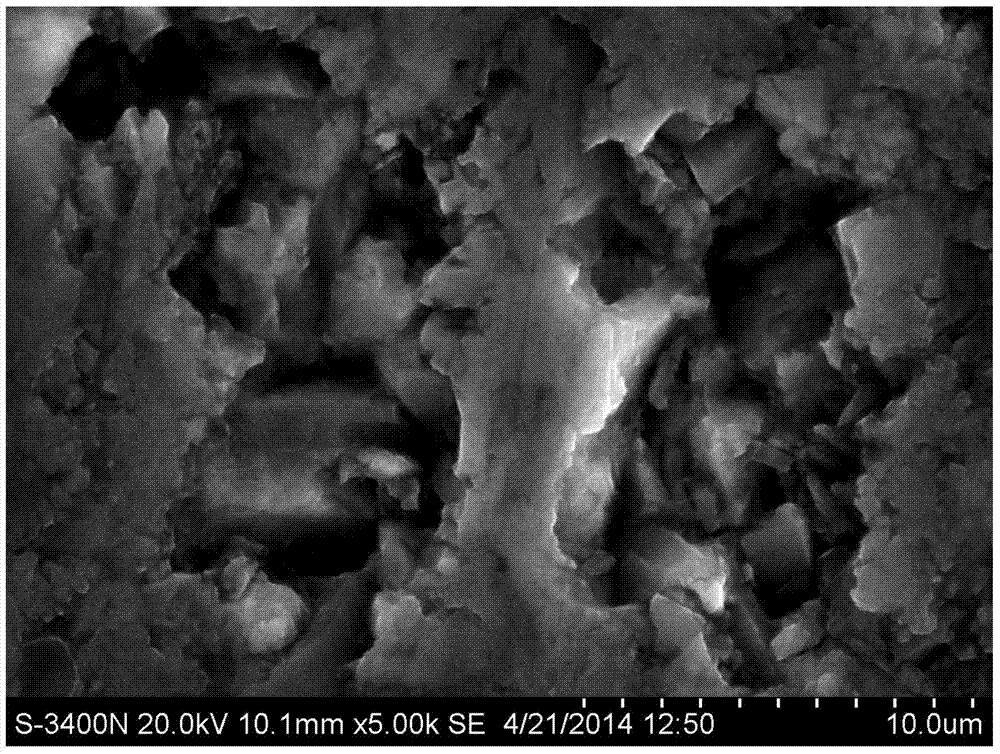

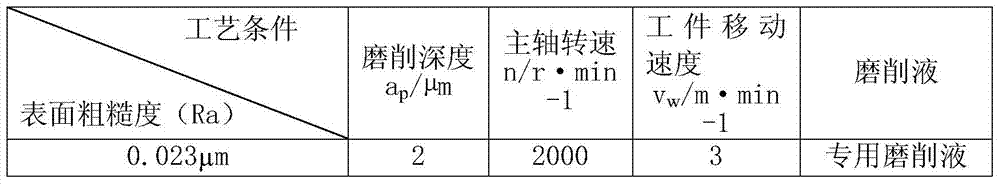

[0042] The grinding effect of this experiment is shown in attached table 1, attached figure 1 shown.

[0043] 2. Comparat...

Embodiment 2

[0069] 3% motor oil, 0.5% lard, 2% fatty acid diethanolamide, 3.5% sodium naphthenate, 1.3% calcium molybdate, 1.1% benzotriazole, 0.8% chlorinated fatty acid, 2.4% ethylene propanol, 0.7% o-phenol, 0.5% emulsified silicone oil, 0.2% sodium edetate, 0.5% sodium chloride, and 83.5% distilled water.

[0070] The configuration steps are as follows:

[0071] ①Heat the mixture of engine oil and lard to 100°C, stir evenly, and cool down;

[0072] ② The fatty acid diethanolamide, sodium naphthenate, calcium molybdate, benzotriazole, chlorinated fatty acid, ethylene propanol, catechol, emulsified silicone oil, sodium ethylenediaminetetraacetic acid, and sodium chloride are mixed in proportion to Mix with distilled water, heat to 30°C, stir evenly, and cool;

[0073] ③ Mix the liquid obtained in steps ① and ② with distilled water in proportion to obtain a grinding fluid.

[0074] Table 5 Surface roughness after grinding

[0075]

Embodiment 3

[0077] 1.7% motor oil, 0.7% lard, 2.3% fatty acid diethanolamide, 2.4% sodium naphthenate, 2% calcium molybdate, 1.2% benzotriazole, 0.9% chlorinated fatty acid, 2.3% of ethylene propanol, 0.8% of catechol, 0.5% of emulsified silicone oil, 0.2% of sodium edetate, 0.7% of sodium chloride, and 84.3% of distilled water.

[0078] The configuration steps are as follows:

[0079] ① Mix engine oil, lard, fatty acid diethanolamide, sodium naphthenate, calcium molybdate, benzotriazole, chlorinated fatty acid, ethylpropanol, orthophenol, emulsified silicone oil, sodium edetate, chlorine Sodium chloride was mixed and heated to 100°C, stirred evenly, and cooled;

[0080] ② Mix the liquid obtained in step ① with distilled water in proportion to obtain the grinding fluid.

[0081] Table 6 Surface roughness after grinding

[0082]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com