A kind of valve processing equipment and its processing technology

A technology for processing equipment and valve bodies, applied in metal processing equipment, turning equipment, turning equipment, etc., can solve the problems of low processing efficiency and inability to meet the needs of rapid processing, achieve high processing efficiency, improve processing quality accuracy, and improve The effect of the crumb effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

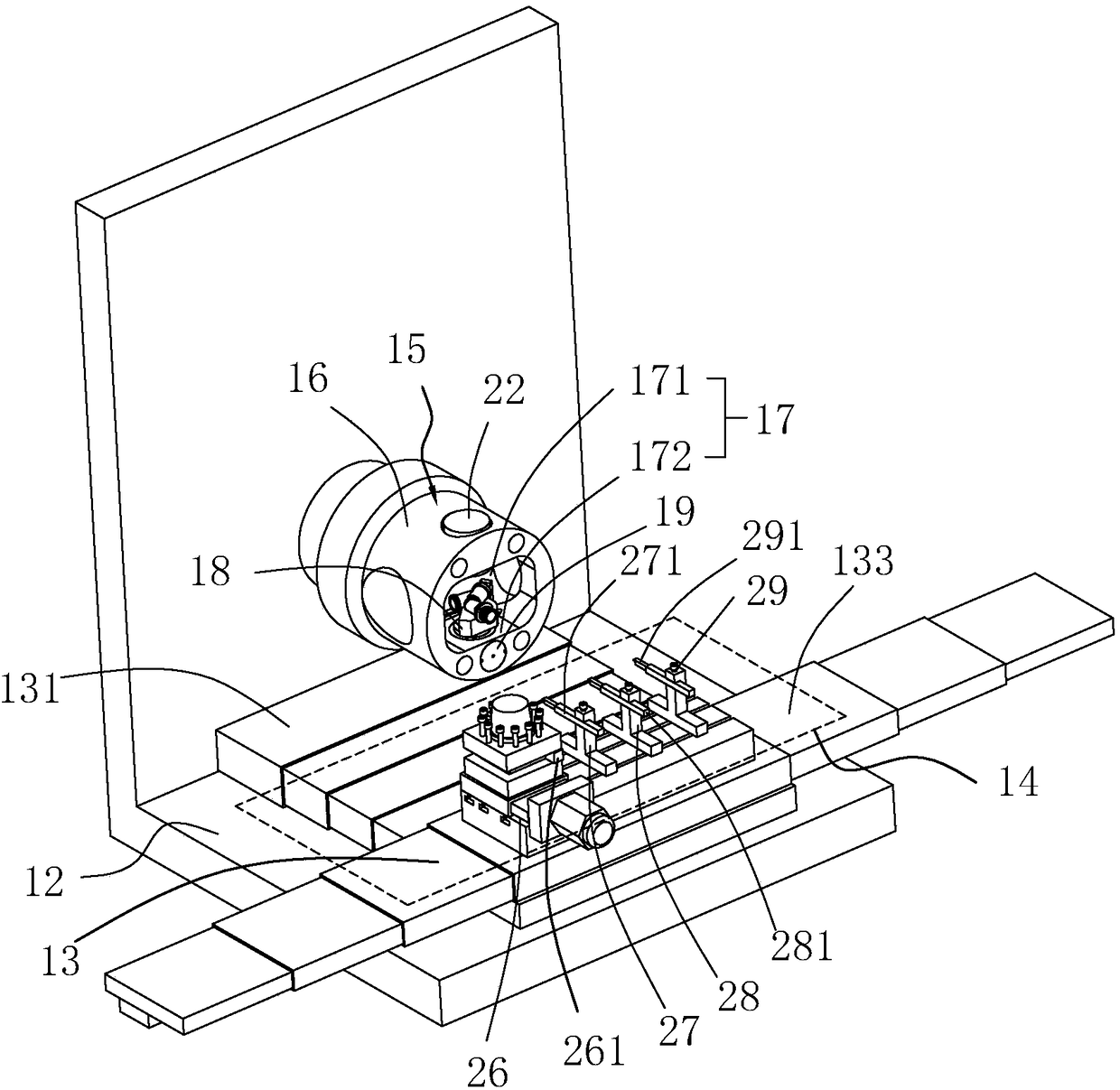

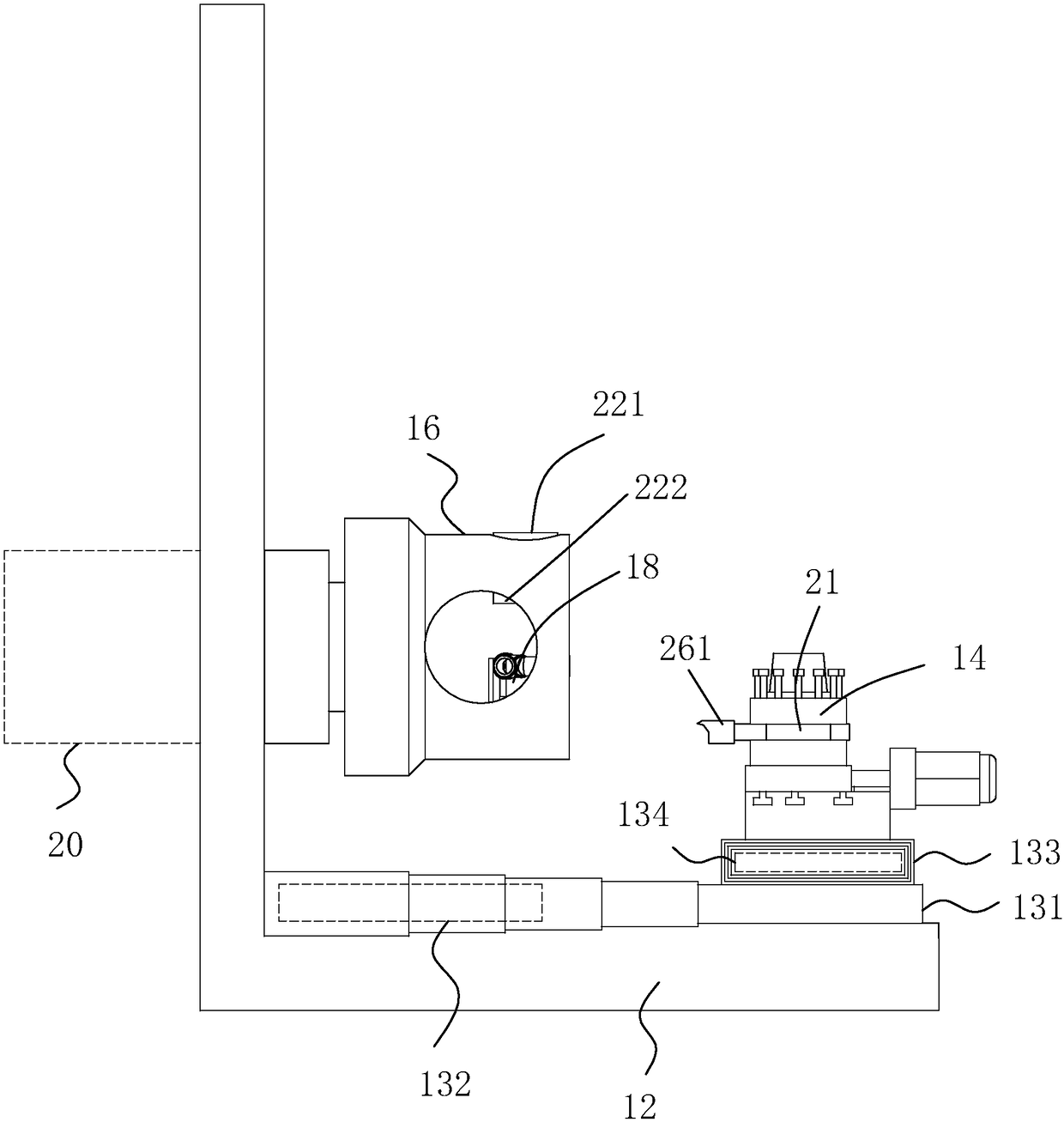

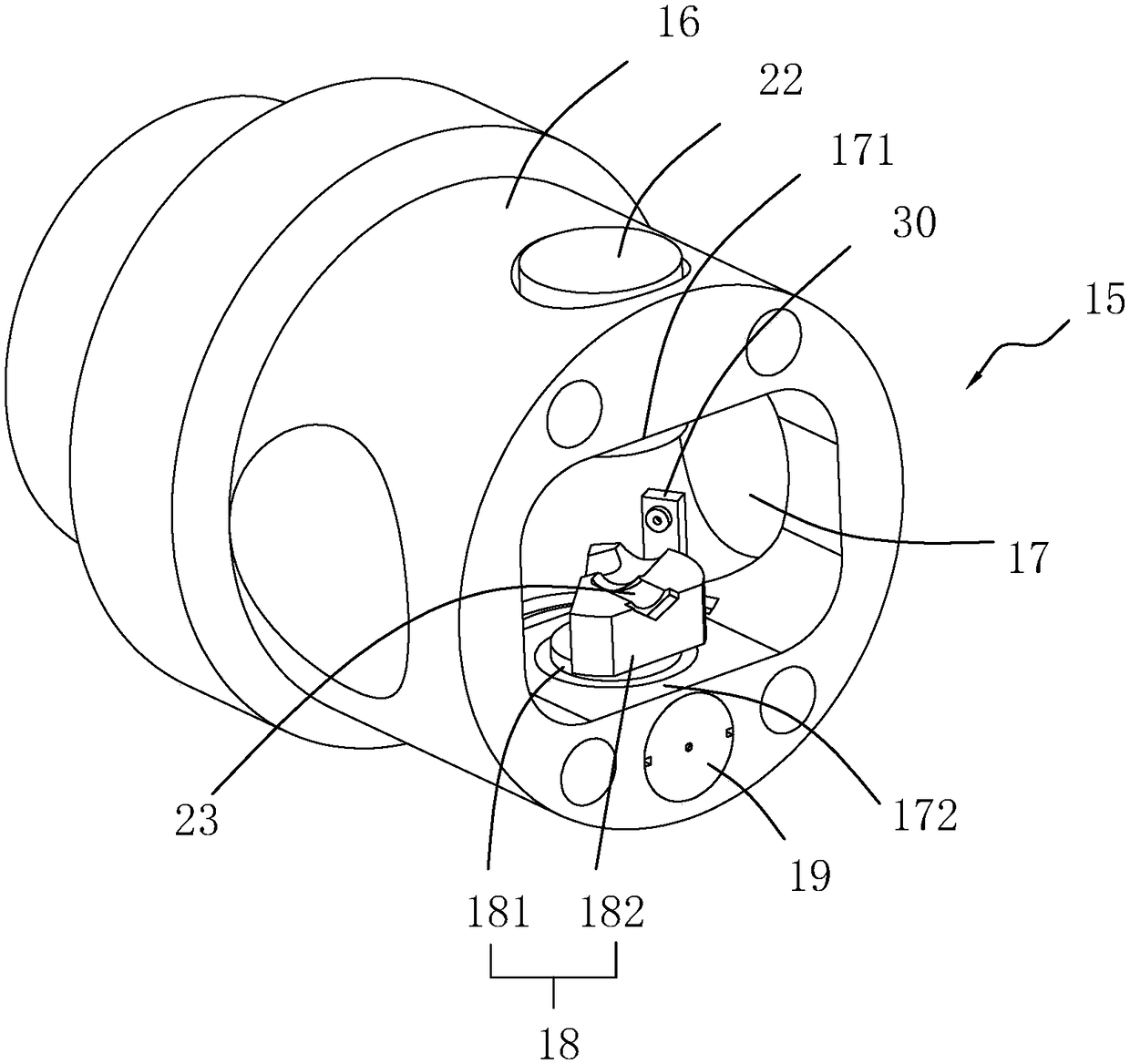

[0054] A kind of valve processing equipment, see figure 1 as well as figure 2 As shown, the bed body 12 is included, the bed body 12 includes a horizontal plane and a vertical plane, and a mobile platform group 13 is installed on the horizontal plane of the bed body 12, and the mobile platform group 13 can realize horizontal and vertical two-way sliding actions ,, and on the upper end surface of the longitudinal moving table 133, a tool holder group 14 is provided, on which a processing tool 21 is installed; on the vertical surface of the bed body 12, a clamping part 15 and a driving part 20 , the connection relationship between the clamping part 15 and the vertical surface of the bed body 12 is a rotary connection, the driving part 20 can be a rotary motor, and the driving part 20 can directly drive the clamping part 15 to rotate in a circumferential direction, and the clamping part 15 The axis of rotation of the center of rotation is in the horizontal direction. The clamp...

Embodiment 2

[0063] Embodiment 2: The difference from Embodiment 1 is that, see Figure 8 As shown, the telescopic power part 22 uses a push rod linear motor 223 instead, and the connection mode between the motor housing of the push rod linear motor 223 and the upper groove wall 171 is a rotary connection, and the push rod end of the push rod linear motor 223 is also the same There is a pressing block 222 for contact with the valve body to be processed, and the rotation axis of the push rod linear motor 223 is consistent with the rotation axis of the installation table 18; the push rod linear motor 223 can drive the push rod end to perform up and down telescopic movement , the pressing block 222 at the end presses the valve body to be processed on the installation platform 18, when the installation platform 18 rotates, because the push rod linear motor 223 is connected to the upper groove wall 171 in rotation, the push rod linear motor 223 Smooth rotation occurs.

Embodiment 3

[0064] Embodiment three: a kind of processing technology, comprises the following steps:

[0065] S1: Preliminary clamping and alignment. The valve body to be processed is placed on the installation platform 18 and pressed by the telescopic power part 22. The symmetrical point 7 in the valve body is located on the rotation axis of the installation platform 18, and the second branch pipe of the valve body The pipe end of 5 is facing the opening of the clamping groove 17;

[0066] S2: The polished turning tool 261 on the first tool seat 26 is close to the end of the second branch pipe 5, and the outer side of the end of the second branch pipe 5 is polished, thereby effectively reducing the roughness of the outer wall of the second branch pipe 5 end ;

[0067] S3: the external thread turning tool 271 on the second tool seat 27 processes the external thread section 11 at the end of the second branch pipe 5 with a relatively low roughness;

[0068] S4: secondary clamping and alig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com