Battery pack and method of manufacturing battery pack

A battery pack and battery technology, applied in battery pack components, electrolyte storage battery manufacturing, secondary batteries, etc., can solve problems such as difficulty in meeting use requirements, short cycle life, reduced battery safety, etc., to meet use requirements, improve Reserves, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The embodiment of the present invention also provides a method for preparing a battery pack. The preparation method of the battery pack comprises:

[0049] Provide multiple batteries;

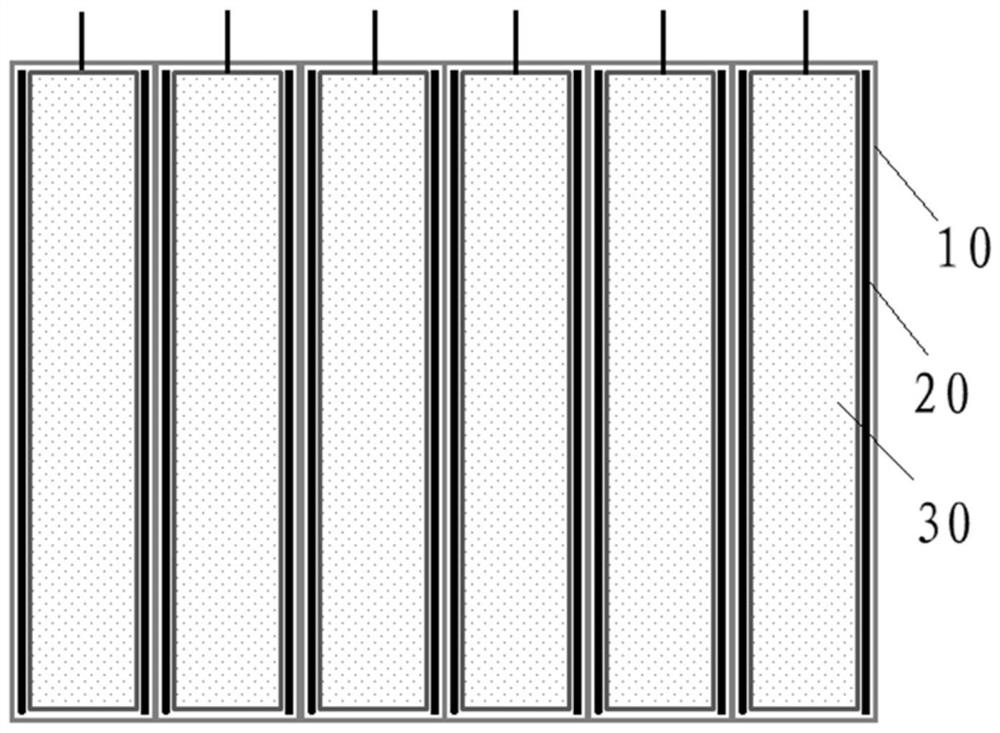

[0050] A plurality of batteries are arranged in sequence; wherein, each battery includes a casing 10 and a battery cell 30 arranged in the casing 10, the battery cell 30 is filled with electrolyte, and the first side of the battery cell 30 in at least one battery A functional layer 20 is provided. The first side of the cell 30 is the side of the cell 30 facing the arrangement direction of the batteries. The functional layer 20 has a porous structure. In the battery pack prepared by the above method, a functional layer 20 is provided on the first side of the cell 30 in at least one battery, the electrolyte can be stored through the pore structure in the functional layer 20, and the storage capacity of the electrolyte in the battery can be increased. The electrolyte can be released durin...

Embodiment 1

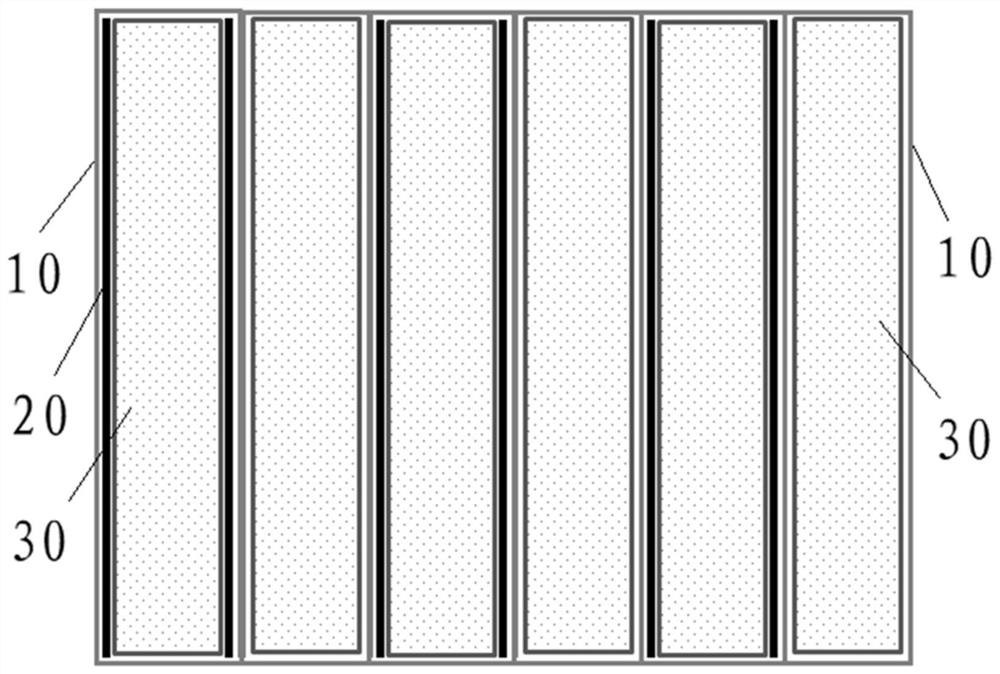

[0060] The selected functional layer has a compressive deformation rate of 10%, a porosity of 20%, and a thickness of 2.5mm;

[0061] After fully mixing the positive electrode material, conductive agent, binder, and solvent, coat and dry to prepare the positive electrode sheet; after fully mixing the negative electrode material, conductive agent, binder, additive, and solvent, coat and dry to prepare the negative electrode pole piece; and prepare the positive pole piece, the negative pole piece, and the diaphragm into a lithium-ion battery cell;

[0062] The functional layer is placed on the first side and the second side of the battery cell, sealed with aluminum-plastic packaging film, after baking, the battery cell is injected with electrolyte, hot-pressed to form a package, and a lithium-ion battery with a functional layer is obtained.

[0063] Six single cells with functional layers are connected in parallel or in series to form a battery pack.

Embodiment 2

[0065] The selected functional layer has a compressive deformation rate of 10%, a porosity of 20%, and a thickness of 1mm;

[0066] After fully mixing the positive electrode material, conductive agent, binder, and solvent, coat and dry to prepare the positive electrode sheet; after fully mixing the negative electrode material, conductive agent, binder, additive, and solvent, coat and dry to prepare the negative electrode Pole piece;

[0067] And prepare the positive pole piece, the negative pole piece, and the diaphragm into a lithium-ion battery cell;

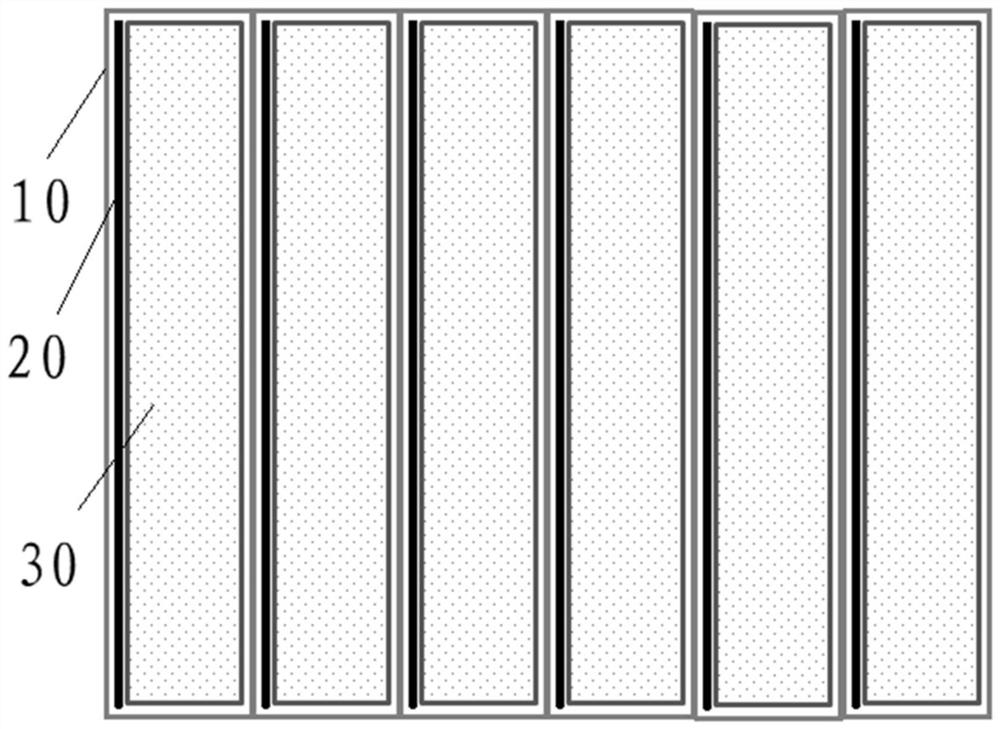

[0068] Put the functional layer on the first side of the battery cell, seal it with aluminum-plastic packaging film, inject liquid into the battery cell after baking, heat-press and seal it, and obtain a lithium-ion battery with a functional layer;

[0069] Arrange six single cells with functional layers in sequence, with the first side of the functional layers facing the same direction, and form a battery pack by connecting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com