Method for excavating foundation pit in soft soil stratum

A foundation pit and stratum technology, which is applied in the engineering field, can solve the problems of difficulty in excavation, damage and deformation of the foundation pit envelope, and instability of the foundation pit, so as to improve the utilization rate of equipment, shorten the construction period and increase the working space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

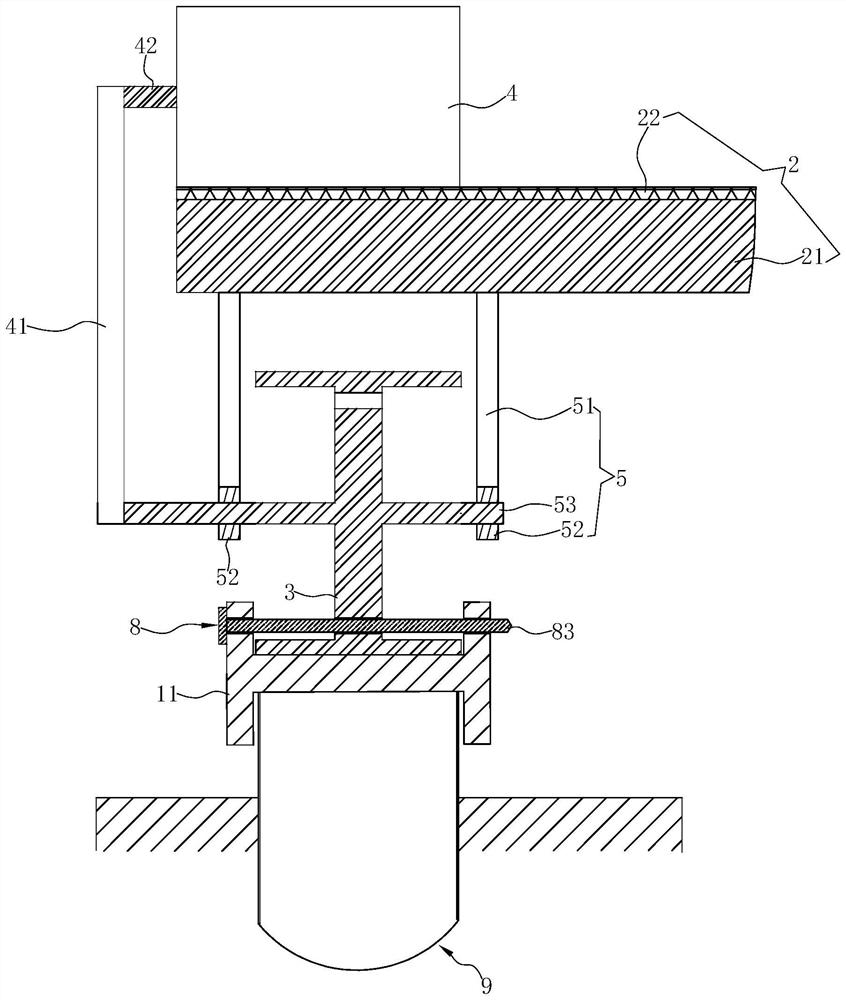

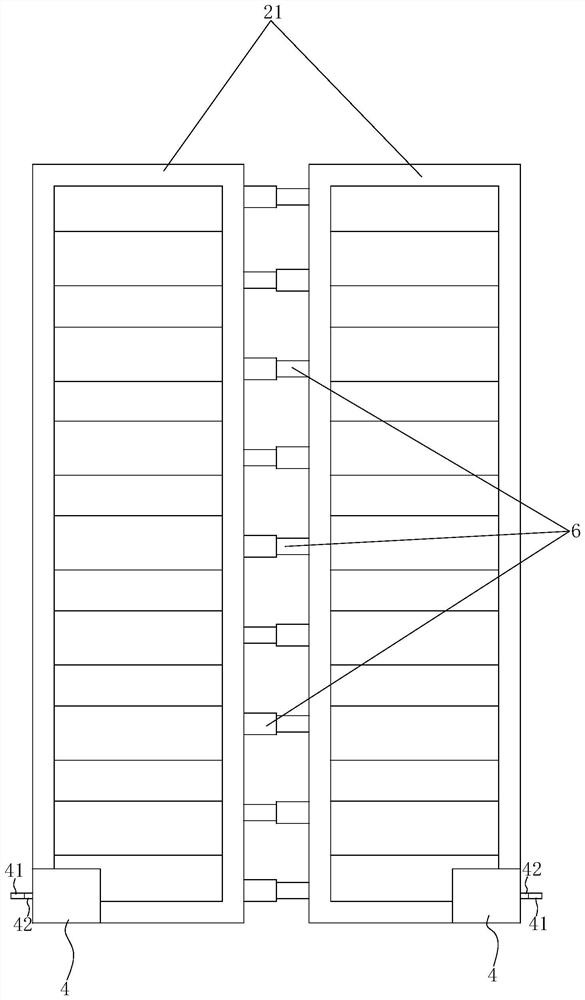

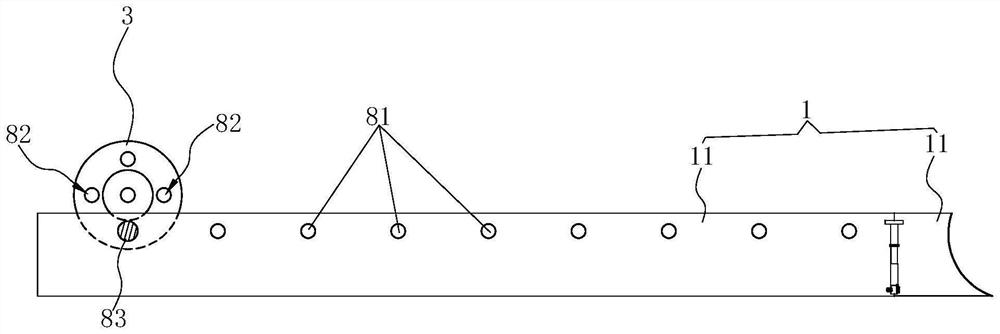

[0039] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0040] The method for excavating a foundation pit in a soft soil layer in this embodiment includes the following steps:

[0041] 1) Construction of foundation pit supporting pile 9: According to the size of the foundation pit, measure the driving position of the supporting pile 9. According to the measurement position, first drive the vertical columnar pile 91. The columnar pile 91 exceeds a certain height on the ground. Vertical sheet piles 92 are driven between 91 , and the subsidence height of the sheet piles 92 is consistent with the subsidence elevation of the columnar piles 91 . see Figure 7 In this embodiment, the supporting pile 9 adopts the PC construction method combined pile, and the construction method adopts the combined connection of the steel pipe pile (column pile 91) and the Larsen steel sheet pile (sheet pile 93) to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com