Electrode structure of lithium battery

An electrode structure, lithium battery technology, applied in the direction of lithium batteries, structural parts, small-sized batteries/batteries, etc., can solve the problems of high manufacturing difficulty and cost, shortening battery life, reducing charging and discharging efficiency, etc. Low difficulty and cost, increase service life, reduce the effect of damage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The detailed content and technical description of the present invention will be further described with examples, but it should be understood that these examples are for illustrative purposes only, and should not be construed as limitations on the implementation of the present invention.

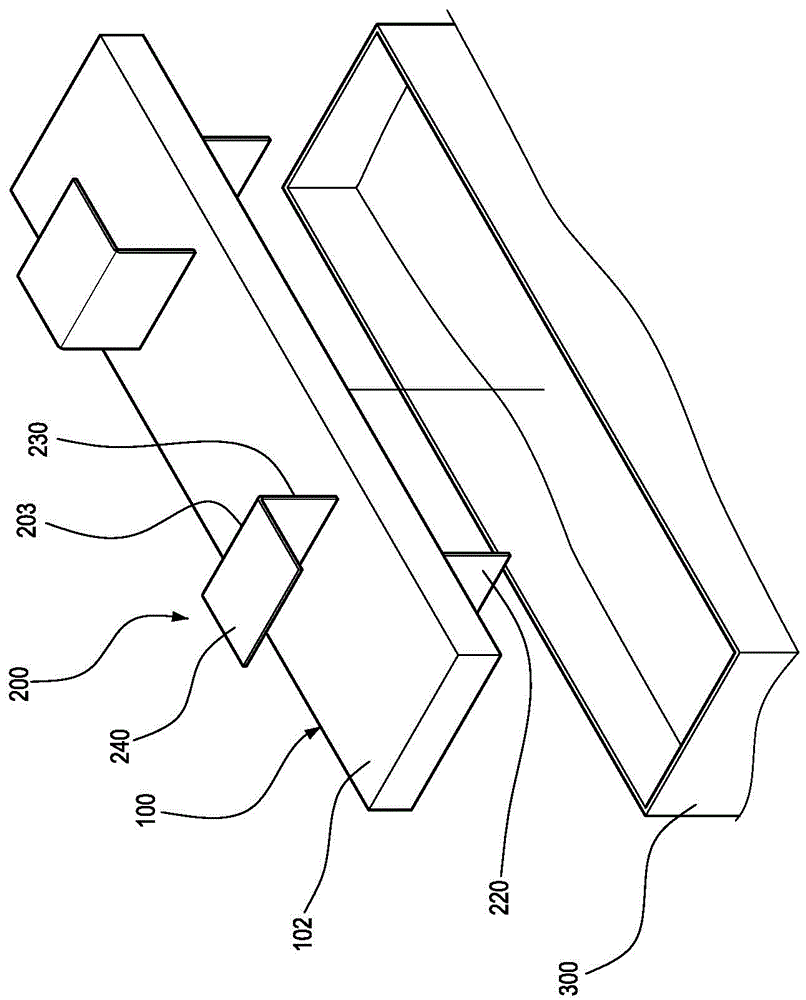

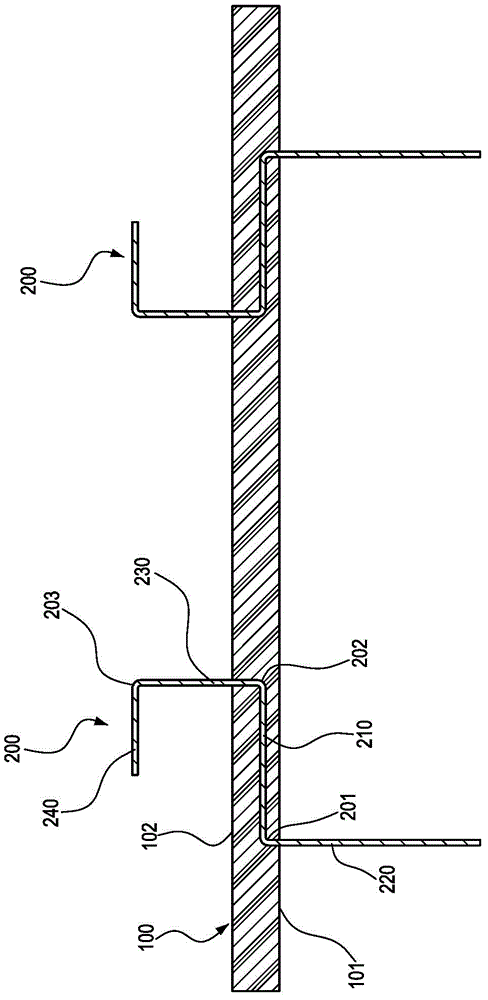

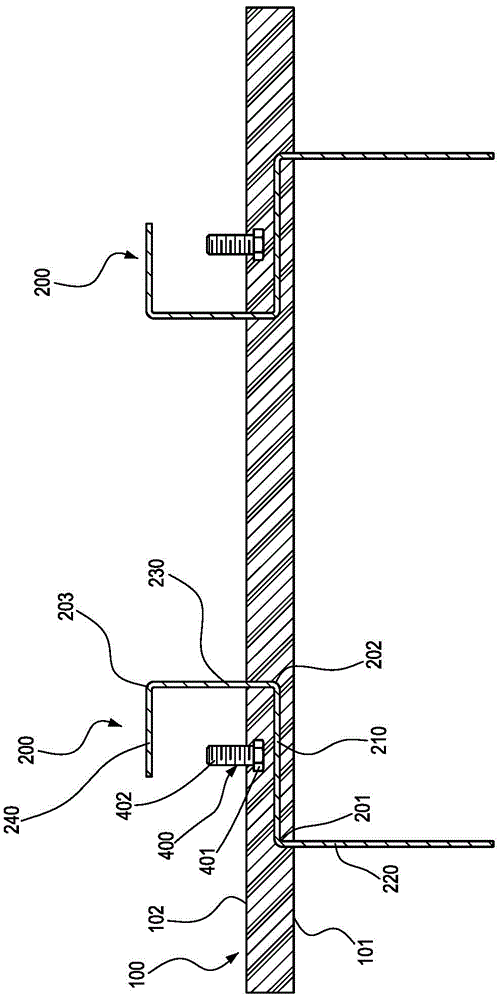

[0034] see figure 1 and figure 2 , is a perspective view and a schematic cross-sectional view of the first embodiment of the present invention. Taking a square lithium battery as an example, it is necessary to electrically connect the positive pole and the negative pole of the battery in the tank body 300 of the lithium battery to the outside. Generally, the square lithium battery has two sheet metal electrode bodies 200 on the cover body 100. They are respectively used to electrically connect the positive pole and the negative pole of the battery in the tank body 300 (not shown in the figure). The middle section of each electrode body 200 is a covered part 210, and the covered part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com