A fine drawing degreasing cleaning device

A technology of degreasing cleaning and fine drawing, which is applied in the direction of metal extrusion cleaning equipment, metal extrusion, manufacturing tools, etc., can solve the problems of overheating and deformation of the take-up I-shaped wheel, and achieve improved surface cleanliness, low failure rate, Mitigate the effect of reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

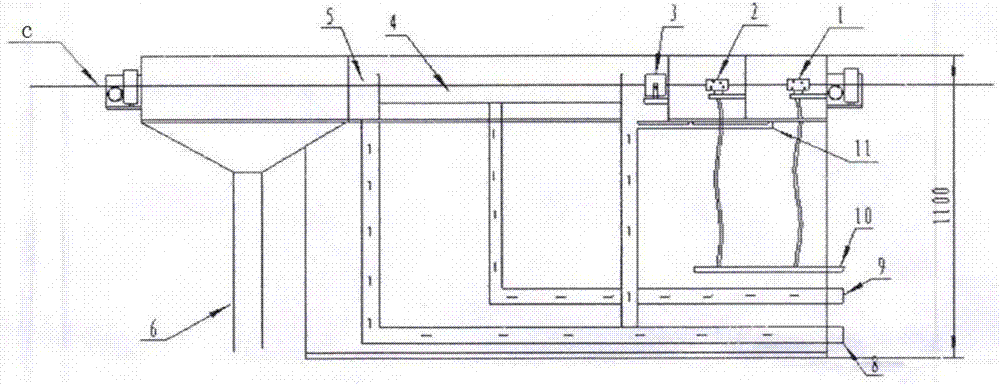

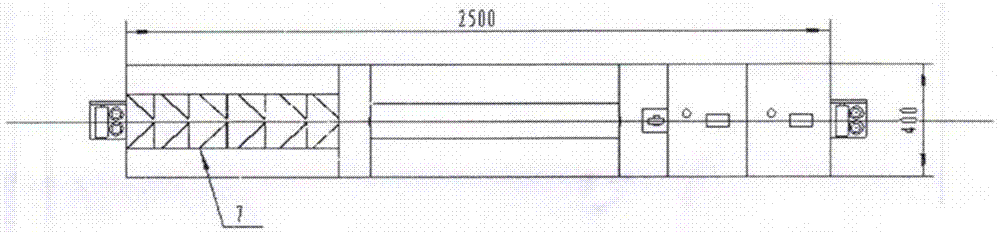

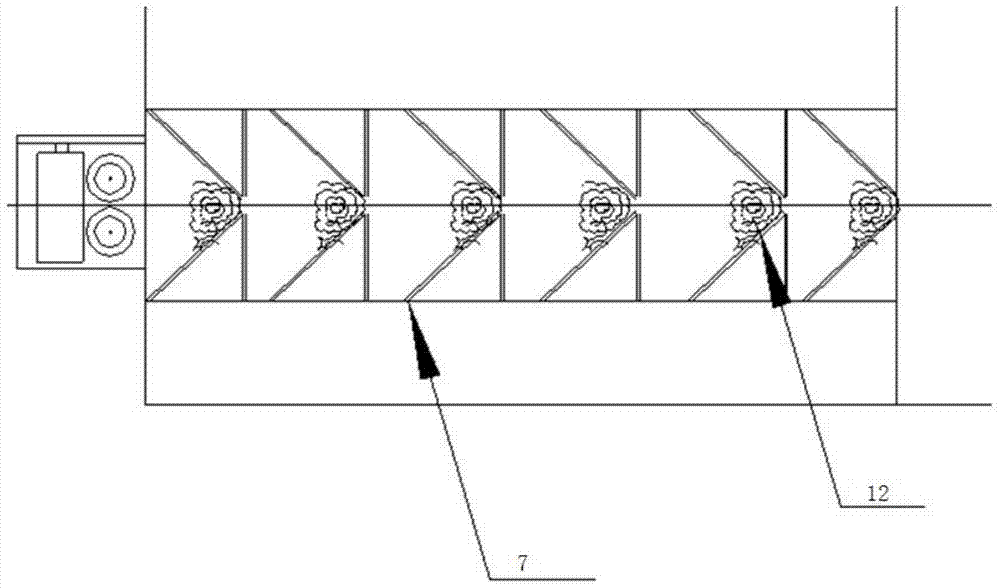

[0042] A fine wire drawing degreasing cleaning device, including a frame, on which a dust removal unit 7, an overflow tank 5, a cooling water tank 4, a water filter plate 3, and two high-pressure air blowing valve blocks 1 are sequentially arranged along the fine wire drawing movement direction , 2; the bottom of the dust removal unit 7 is connected to the dust suction pipeline 6, and the dust removal unit is built with a wiping body, and the dust removal unit is composed of a coarse dust removal device, a fine dust removal device, and a fine dust removal device; the coarse dust removal device The device, the fine dust removal device, and the fine dust removal device are all conical barrels, and the three have the same horizontal height, and are arranged in sequence along the direction of fine wire drawing; 1 / 2 of the main body of the high-pressure air blowing valve block is divided into a thick end and a thin end. , the center of the main body is provided with a through hole f...

Embodiment 2

[0045] The difference from Embodiment 1 is that the lower part of the overflow tank 5 is connected to the return pipe 8 . The waste water is recycled after treatment, realizing the recycling of reclaimed water and the purpose of saving water resources.

Embodiment 3

[0047] The difference from Embodiment 1 is that the lower part of the cooling water tank 4 is connected with the water supply pipe 9 of the cold water tank. Provide enough cooling water to ensure the cooling efficiency of fine wire drawing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com