Manufacturing method of forced centering bracket for existing pre-buried slide groove and T-shaped bolts

A technology of forced centering and manufacturing method, applied in the field of shield tunnel measurement, can solve the problems of long operation time of mounting bracket, low cycle utilization rate of the bracket, inconvenient carrying of the bracket, etc., saving manpower and installation time. , The effect of simple and convenient installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

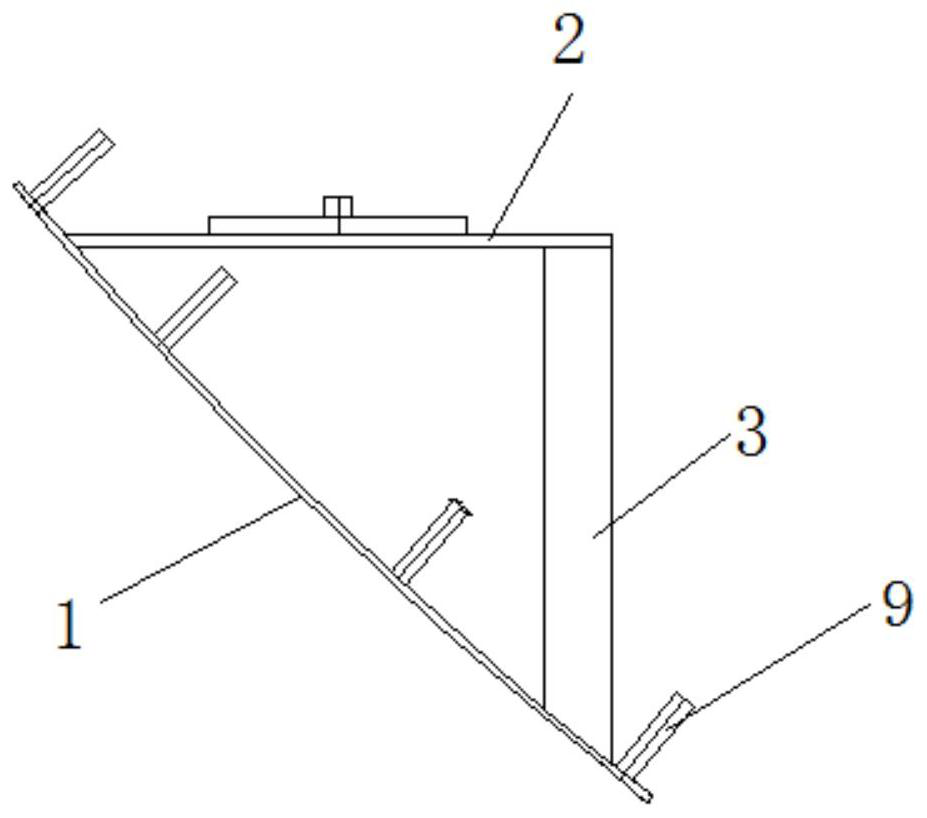

[0053] Specific implementation mode one: see Figure 1-Figure 3 This embodiment will be described. A method for manufacturing a forced centering bracket with pre-embedded chute and T-shaped bolts described in this embodiment specifically includes the following steps:

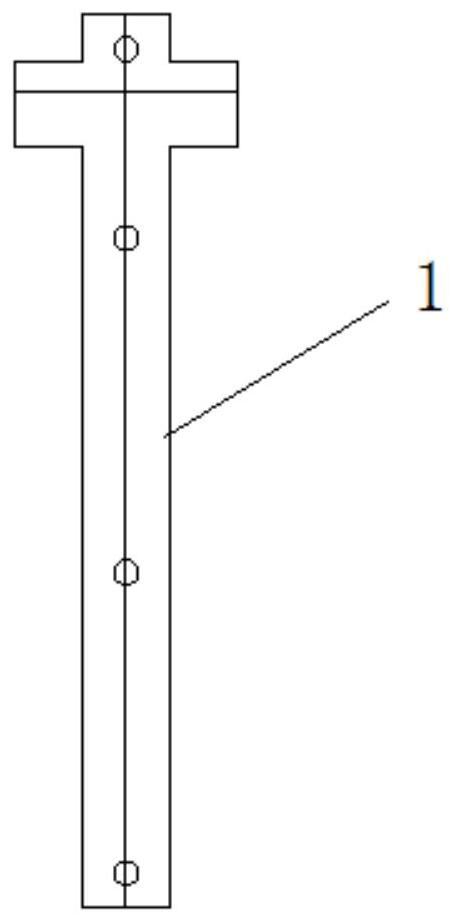

[0054] (1) Make No. 1 arc-shaped steel plate 1 installed on the pre-embedded chute of the segment, and the No. 1 arc-shaped steel plate 1 is fixed on the existing pre-embedded chute inside the segment by T-bolt 9, so The No. 1 arc-shaped steel plate 1 is provided with several circular holes corresponding to the positions of the existing embedded chute, and is used for passing through the T-shaped bolts 9;

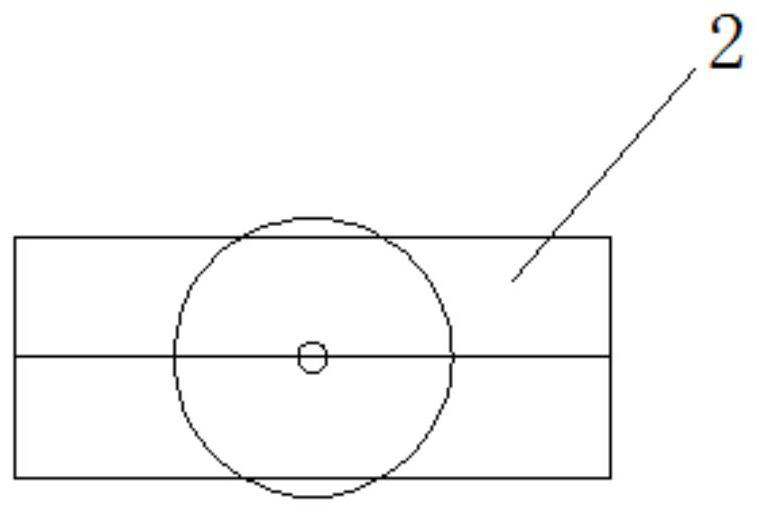

[0055] (2) make and place No. 1 square steel plate 2 of forced centering dish, described No. 1 square steel plate 2 is installed on the top of the head end of No. 1 curved steel plate 1;

[0056] (3) making No. 1 angle steel 3 that is connected with No. 1 curved steel plate and No. 1 square steel plate resp...

specific Embodiment approach 2

[0064] Specific implementation mode two: see Figure 4-Figure 5 This embodiment will be described. A method for manufacturing a forced centering bracket with pre-embedded chute and T-shaped bolts described in this embodiment specifically includes the following steps:

[0065] (1) Make No. 1 arc-shaped steel plate 1 installed on the pre-embedded chute of the segment, and the No. 1 arc-shaped steel plate 1 is fixed on the existing pre-embedded chute inside the segment by T-bolt 9, so The No. 1 arc-shaped steel plate 1 is provided with several circular holes corresponding to the positions of the existing embedded chute, and is used for passing through the T-shaped bolts 9;

[0066] (2) make and place No. two square steel plates 4 of forced centering dish, described No. two square steel plates 4 are installed on the top of the head end of No. one curved steel plate 1;

[0067] (3) making No. 2 angle steel 5 that is connected with No. 1 curved steel plate and No. 2 square steel p...

specific Embodiment approach 3

[0072] Specific implementation mode three: see Figure 6-Figure 8 This embodiment will be described. A method for manufacturing a forced centering bracket with pre-embedded chute and T-shaped bolts described in this embodiment specifically includes the following steps:

[0073] (1) Make two No. 2 arc-shaped steel plates 6 installed on the segment pre-embedded chute, each arc-shaped steel plate 6 is provided with a circular hole;

[0074] (2) make No. 3 square steel plates 7 that place the forced centering dish, and described No. 3 square steel plates 7 are positioned at the below of two No. 2 curved steel plates 6;

[0075] (3) make two square steel pipes 8 that are connected with No. two curved steel plates 6 and No. three square steel plates 7 respectively, and two square steel tubes 8 are perpendicular to No. three square steel plates 7;

[0076] (4) The lower ends of the two square steel pipes 8 are welded vertically to the upper right starting end of the No. 3 square st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com