Flexible transmission type built-in miniature multi-point displacement test system used for model experiment

A technology of model test and test system, applied in the direction of using optical device, measuring force, measuring device, etc., can solve the problems of low degree of visualization of data acquisition and processing, difficult to reduce the friction resistance between casing and steel wire, strong rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

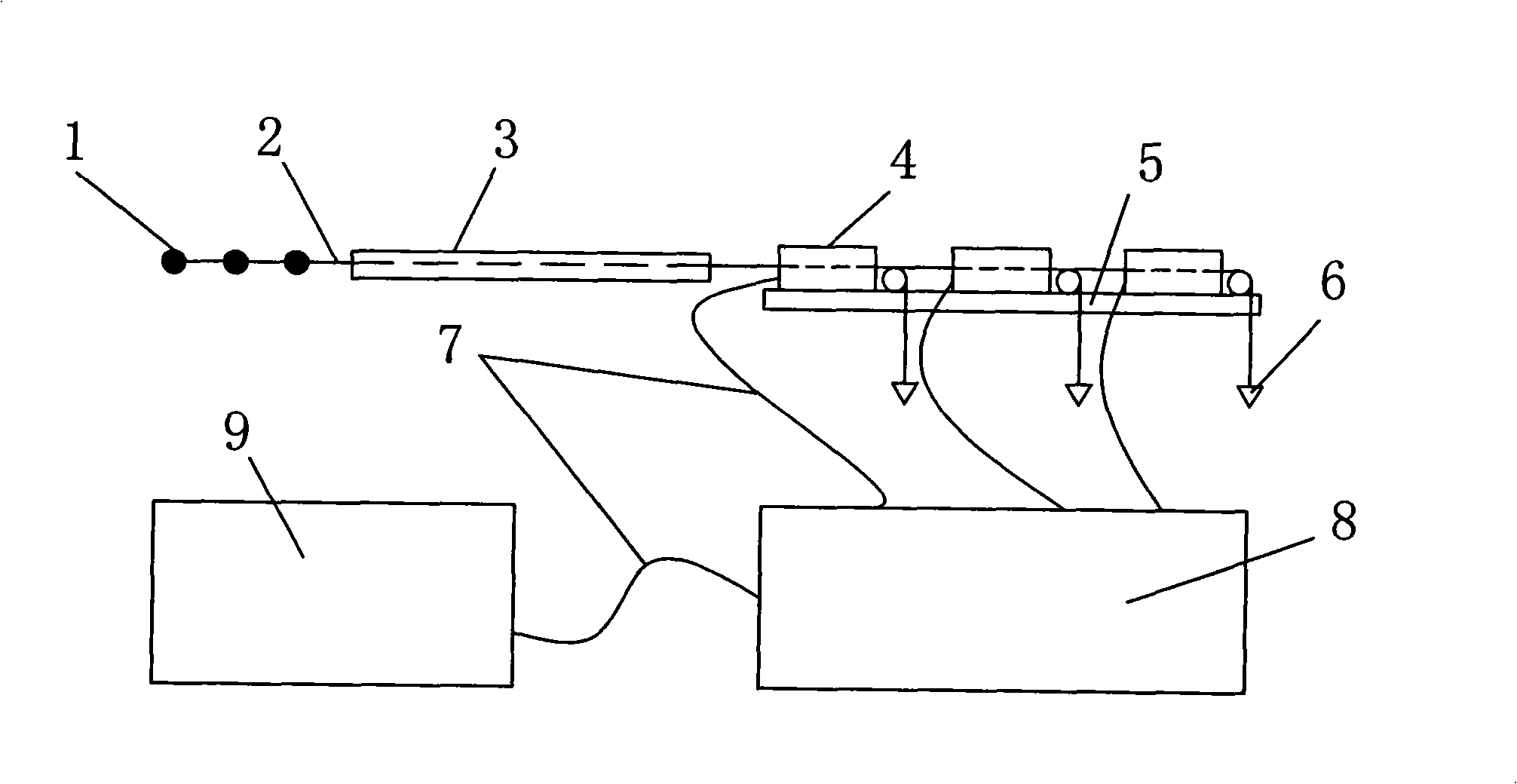

[0020] As shown in the figure, the flexible transmission type built-in miniature multi-point displacement test system for model testing has a structure including a bench 5, a grating ruler 4, a steel wire rope 2, a signal conversion system 8, and a data acquisition system 9. The steel wire rope 2 After the test fixed end 1 is drawn out, it passes through the grating ruler 4 fixed on the bench 5 and finally connects with the weight 6. The grating ruler 4 is connected to the signal conversion system through the wire 7, and the signal conversion system 8 is connected through the wire Data Acquisition System9.

[0021] The steel wire rope 2 drawn out from the test fixed end 1 should be put in the casing 3 and pass through the grating scale 4, and several positioning disks are also arranged in the casing 3.

[0022] The flexible sleeve is a flexible sleeve with a diameter of 10mm.

[0023] The steel wire rope 2 adopts a steel strand with a diameter of 0.5 mm without deformation in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com