Method of treating lining after collapse of underground cavern crown

A technology for underground caverns and treatment methods, which is applied to underground caverns, shaft linings, tunnel linings, etc., can solve the problem of poor concrete arch ring pouring conditions, large differences in physical and mechanical properties between reinforced concrete structures and surrounding surrounding rocks, and increased Lower concrete arch ring load and other issues, to achieve the effect of improving construction quality and safety control conditions, significant promotion and practical value, and reducing engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

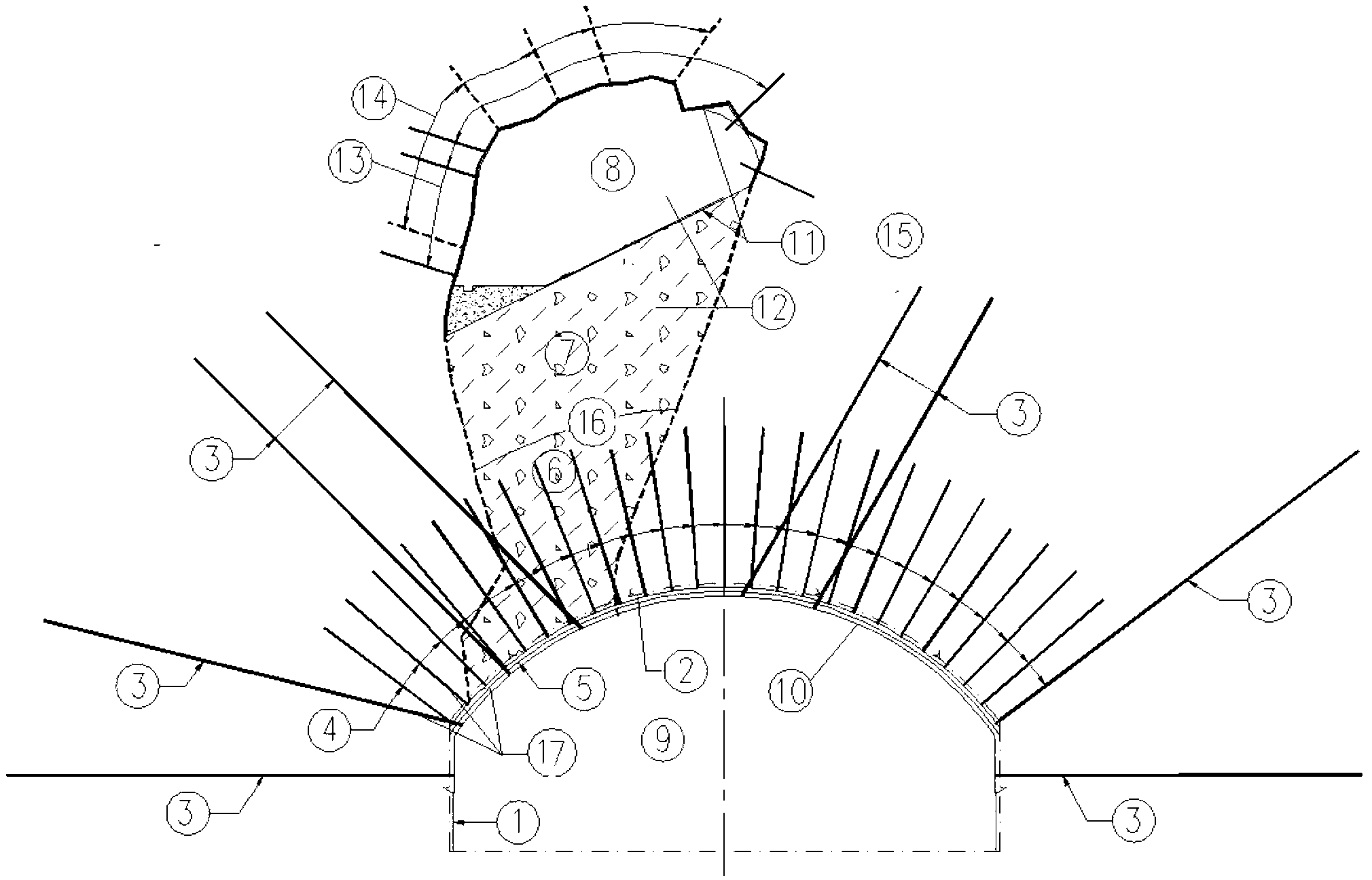

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] In order to provide a lining treatment method after the collapse of the vault of the underground cavern with a small workload, low cost and good anti-collapse effect, the lining treatment method after the vault of the underground cavern collapses is characterized in that it includes the following steps:

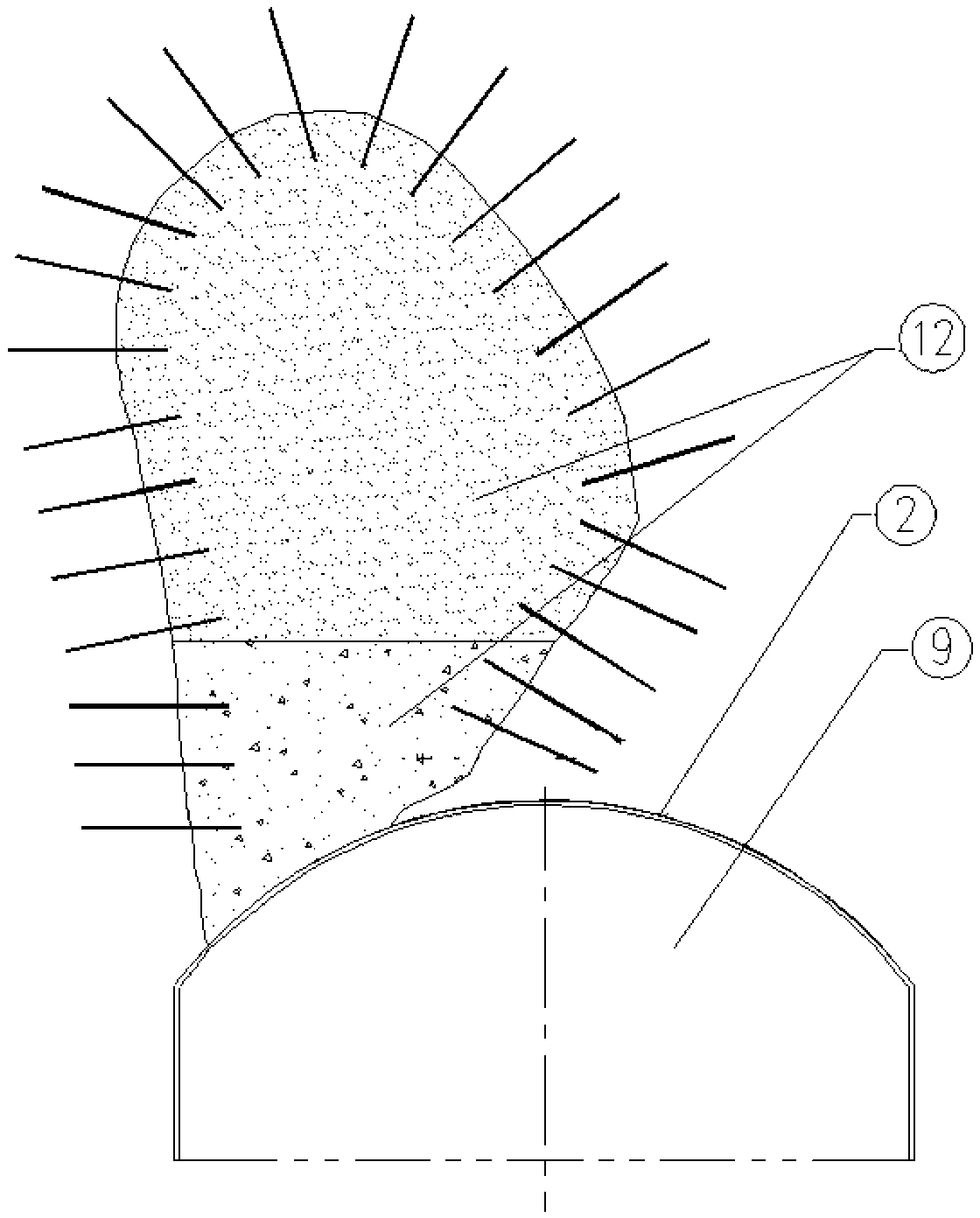

[0024] a. Clean up the collapse slag in the cavern 9, and the cleaning amount shall be based on the ability to avoid the remaining collapse slag 16 from falling;

[0025] b. Insert reinforced anchor rods 4 into the surrounding rocks 15 on both sides of the remaining collapse slag 16 and the remaining collapse slag 16. The end of each reinforced anchor rod 4 close to the top arch 2 of the cavern is located in the same cross section of the cavern 9, and the remaining collapse slag 16 Insert at least one reinforced anchor rod 4 in the surr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com