Ring excavation construction method for underground large-span spherical-cap-shaped dome under weak surrounding rock

A construction method and circular excavation technology, which is applied to underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems of inability to guarantee the safety of excavation construction workers and equipment, difficulty in controlling the quality of spherical crown domes, and surrounding weak surroundings. The problems such as large rock disturbance can be solved, and the effect of shortening the exposure time, saving investment, and avoiding the cost of construction measures can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

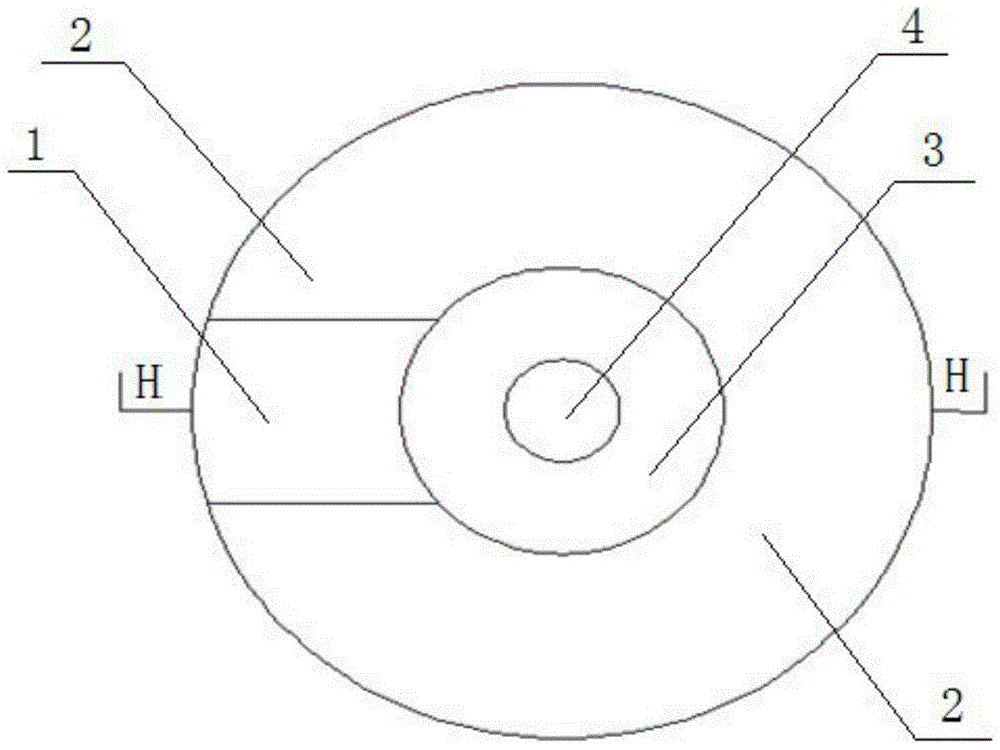

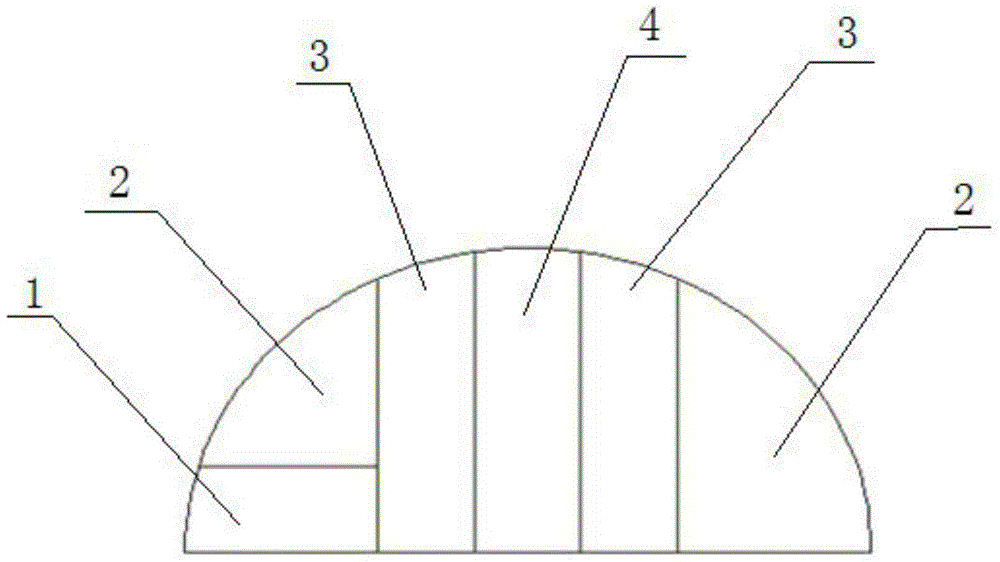

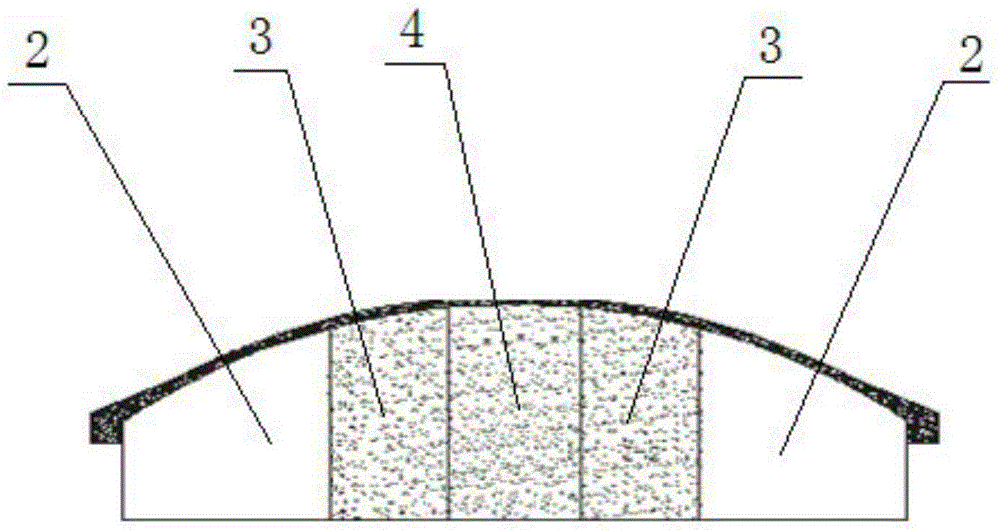

[0086] Embodiment 1: A circular excavation construction method for a spherical crown dome tank cap of a large-span oil storage under weak surrounding rock, comprising the following steps,

[0087] Step 1. Determine the Slope-Span Ratio of the Dome Tank Cap

[0088] The dome tank cap is in the shape of a spherical crown. According to the span of the dome tank cap, adjust the design sag height of the dome tank cap, so that the dome tank cap sag ratio is 1:4.7, ensuring that the dome tank cap is in the best stable state;

[0089] Step 2: From the upper lead hole directly into the bottom of the tank cap to form A section 1

[0090] Directly enter the bottom of the tank cap from the upper lead hole at a distance of 6m from the outer circumference of the tank cap, and extend 3m to both sides on the circular section of the bottom of the tank cap at the same time, forming section A 1;

[0091] Step 3: Excavation support for the first ring of the dome tank cap

[0092] Taking Section...

Embodiment 2

[0111] Embodiment 2: A circular excavation construction method for a spherical crown dome of a large-span underground storage room under weak surrounding rock, comprising the following steps,

[0112] Step 1. Determine the Slope-Span Ratio of the Spherical Crown Dome

[0113] According to the span of the spherical dome, adjust the design height of the dome so that the sag ratio of the spherical dome is 1:4.3 to ensure that the spherical dome is in the best stable state;

[0114] Step 2: Form A section 1 by directly entering the bottom of the spherical crown dome from the upper lead hole

[0115] Directly enter the bottom of the spherical crown dome from the upper entrance hole 6m away from the outer circumference of the dome, and expand 2.5m to both sides on the circular section at the bottom of the dome at the same time, forming section A 1;

[0116] Step 3: Excavation support for the first ring of the spherical crown dome

[0117] With Section A 1 as the starting point and...

Embodiment 3

[0134] Embodiment 3: A circular excavation construction method for the spherical crown dome of the national defense underground large-span machinery storehouse under weak surrounding rocks, including the following steps,

[0135] Step 1. Determine the Slope-Span Ratio of the Spherical Crown Dome

[0136] According to the span of the spherical crown dome, adjust the design sag of the dome tank cap, so that the sag ratio of the spherical crown dome is 1:6.6, and ensure that the spherical crown dome is in the best stable state;

[0137] Step 2: Form A section 1 by directly entering the bottom of the spherical crown dome from the upper lead hole

[0138] Directly enter the bottom of the spherical crown dome from the upper lead hole at a distance of 6m from the outer circumference of the tank cap, and expand 3m to both sides on the circular section at the bottom of the dome at the same time, forming section A 1;

[0139] Step 3: Excavation support for the first ring of the spheric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com