Method for lifting railway roadbed with settlement diseases

A railway roadbed and roadbed technology, applied in roads, tracks, buildings, etc., can solve the problems of high polymer grouting construction level, limited adjustment range of fasteners, and insufficient control of roadbed settlement, etc., to improve The efficiency of working space utilization, reducing the amount of on-line work, and the effect of outstanding cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

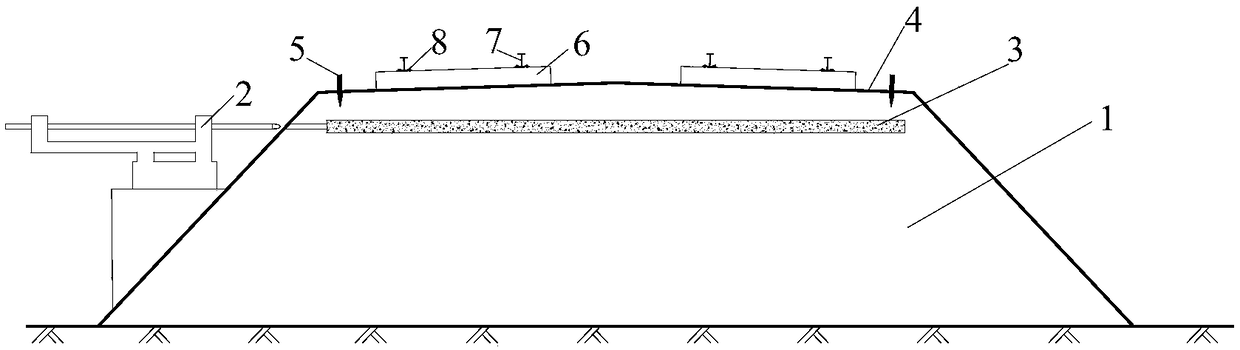

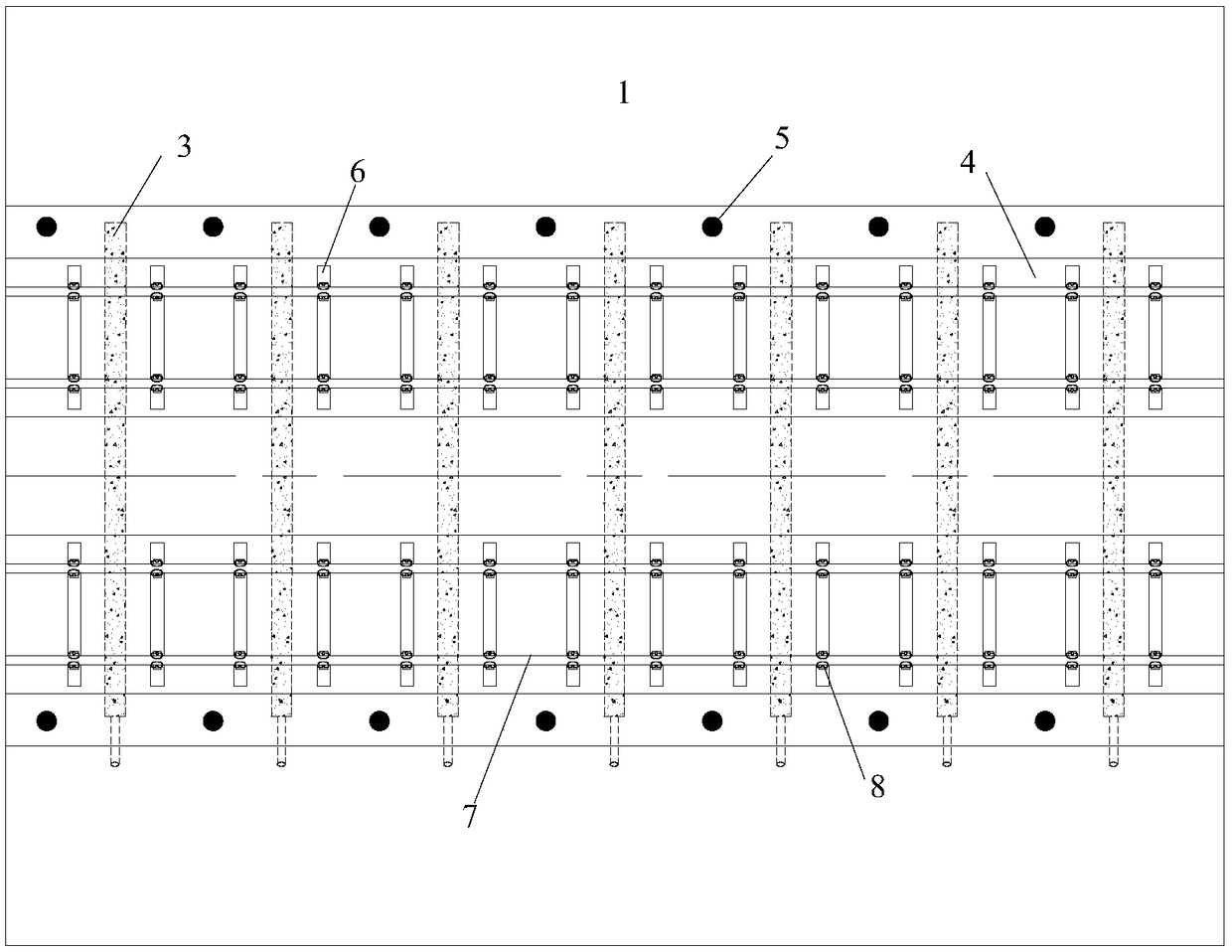

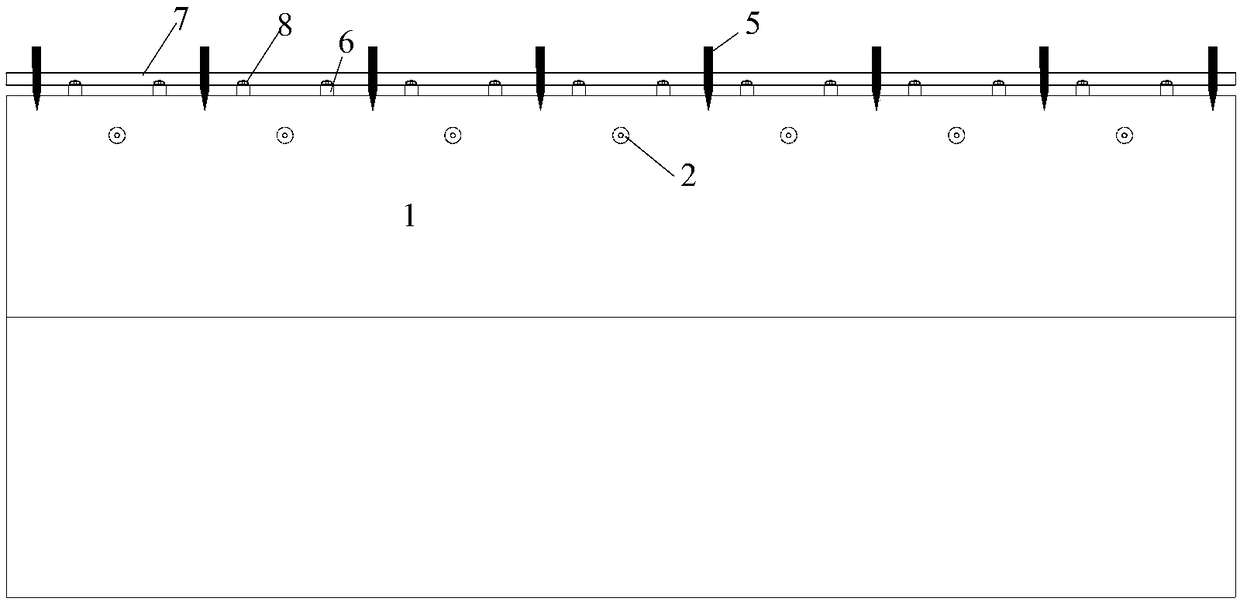

[0031] see Figure 1-Figure 3 , a kind of method for raising the subgrade of subsidence disease railway, comprises the following steps:

[0032] S1. Drilling positioning: First, determine the area where the settlement disease occurs on the ballastless track of the high-speed railway, and take the position with the most serious line settlement as the starting position for the settlement disease treatment; One side erects the fixed bracket of the horizontal jet grouting equipment 2, installs the horizontal jet grouting equipment 2 and determines the drilling position of the horizontal jet grouting pile 3 to be made.

[0033] The above-mentioned drilling positions are generally located 1-2 m below the surface 4 of the subgrade bed.

[0034] S2. Fastener unlocking: During the lifting process of the ballastless track of the high-speed railway, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com