Grouting-type micro steel pipe pile and grouting reinforcement method

A technology of steel pipe piles and steel pipes, which is applied in excavation, sheet pile walls, construction, etc., can solve the problems of repeated waste, single reinforcement means, and long reinforcement cycle, etc., and achieves small construction interference, simple construction technology, and increased compactness The effect of degree and carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

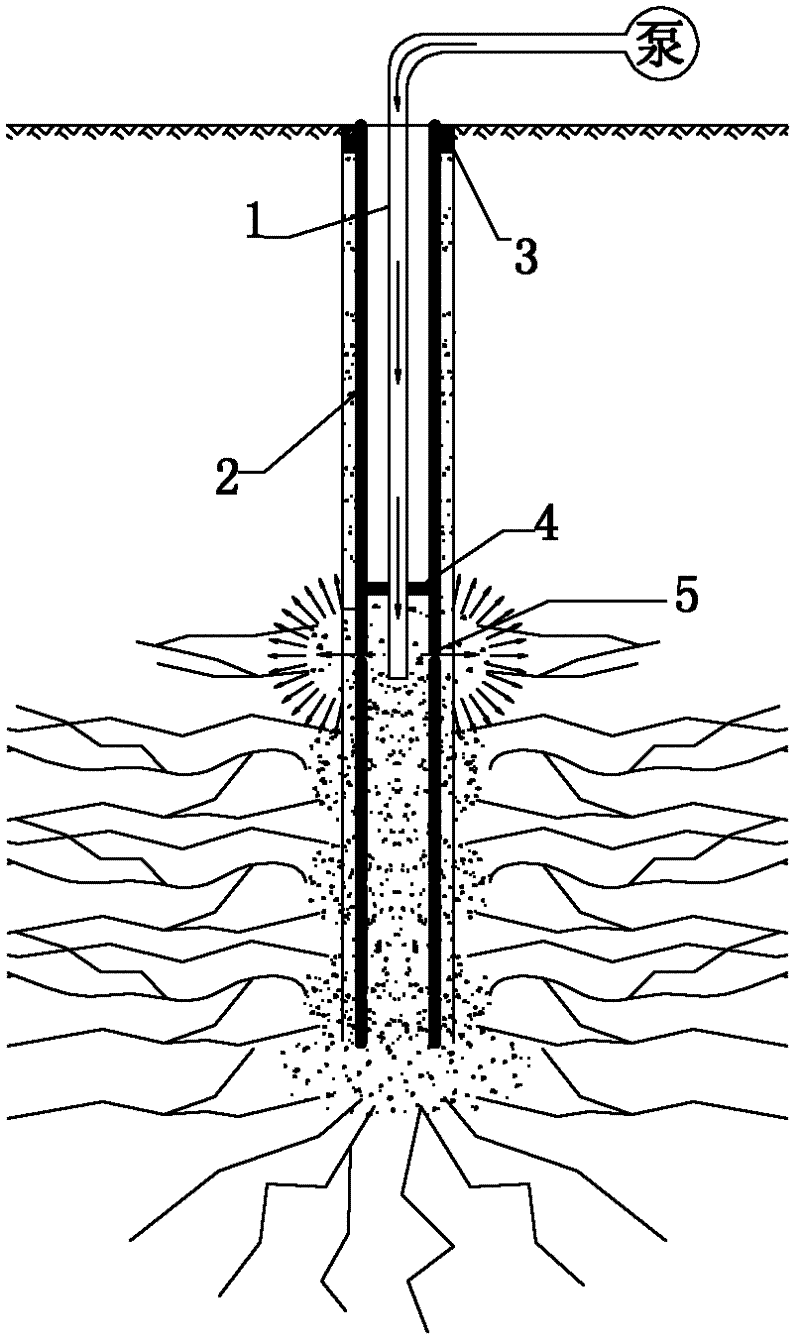

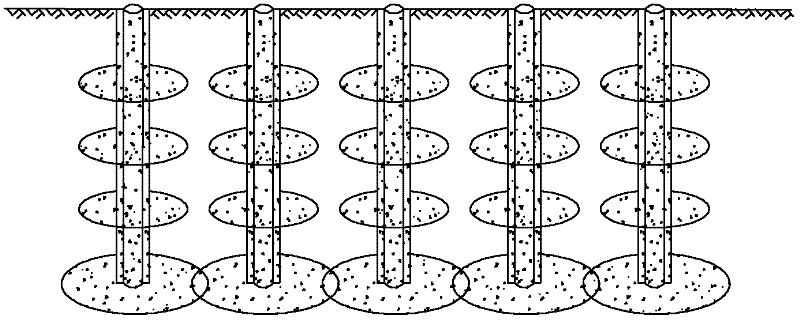

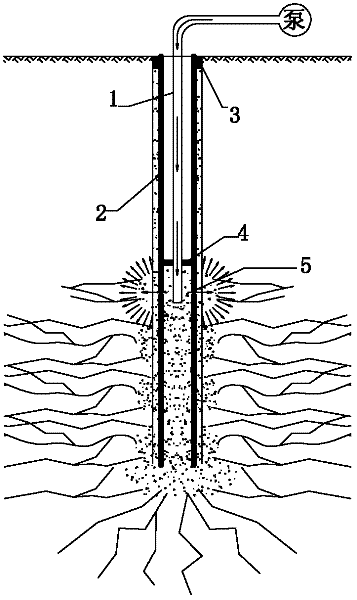

[0038] Such as Figure 1-2 As shown, a kind of grouting type micro-steel pipe pile, comprises steel pipe 2, and the side wall of described steel pipe 2 is provided with multiple sets of grouting hole groups with intervals along the axial direction, and the outside of each group of grouting hole groups is covered with Rubber sealing ring 4. Each of the pulp outlet groups is composed of four uniformly distributed pulp outlet holes 5 on the same horizontal plane.

[0039] The grouting reinforcement method of the grouting micro-steel pipe pile is as follows:

[0040] (1) Micro steel pipe pile technology

[0041] 1) Technical points:

[0042] ①Drilling

[0043] Drill to the depth required by the design, the hole diameter is 75-127mm, determined according to the diameter of the steel pipe 2 used in the design, the drilling is required to be vertical, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com