Floating tugboat used for steel beam installation, and system and method for bridge erection

A technology of steel girders and floating towing, which is applied in the direction of bridge construction, erection/assembly of bridges, bridges, etc. It can solve the problems of cumbersome positioning, difficulties in structures and erection, and large erection tonnage, so as to achieve small reinforcement of steel girders and construction interference Small, beneficial effect on control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

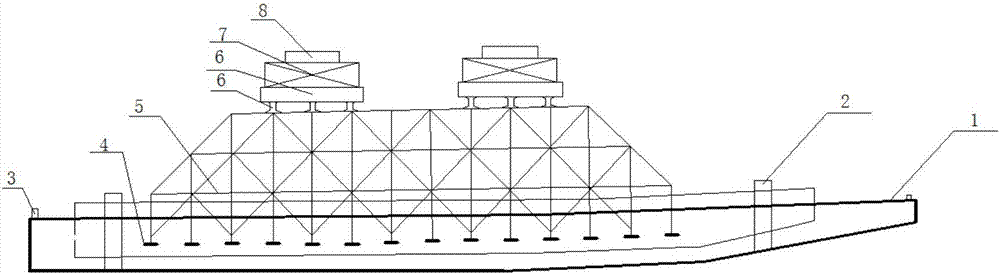

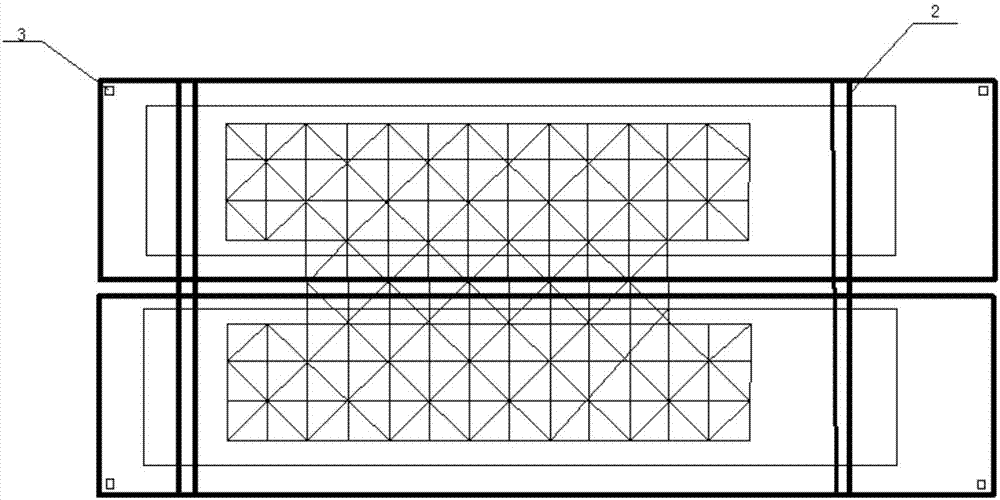

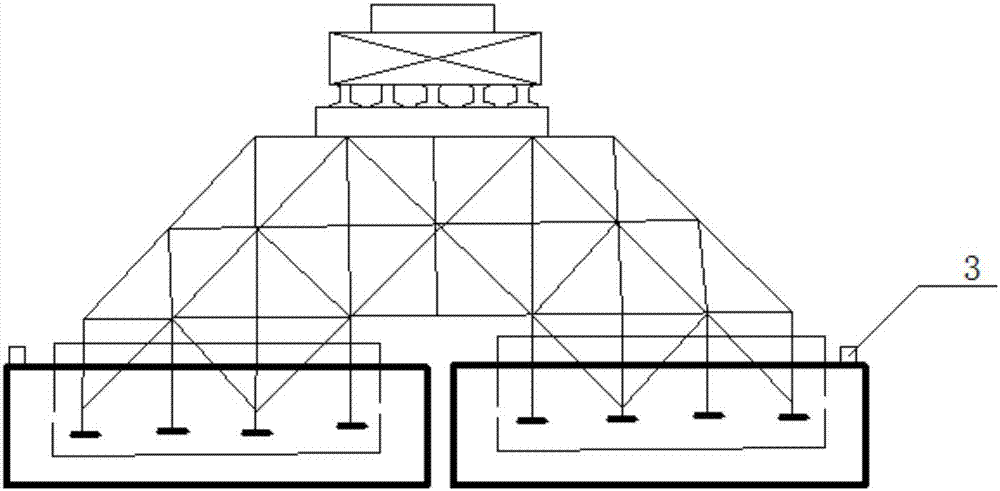

[0043] like Figure 1 ~ Figure 3 As shown, the present embodiment provides a floating tugboat 9 for installing steel girders, the floating tugboat 9 can carry the steel girders used for erecting bridges in water, and the steel girders assembled from the assembled platform of the assembled position, Accurate delivery to the target position, thereby avoiding the construction of structure foundations and false frames in the water, and ensuring that the construction interference during the water construction period is small.

[0044]Specifically, the floating tugboat 9 mainly includes a barge group and a guide mechanism, wherein the barge group is used to carry steel beams for erecting bridges, and the barge group drives the steel beams to move from the assembled position to the target position on the water by moving, and is a steel girder. The beams provide support for water movement; the guide mechanisms are respectively connected to the front and rear ends of the barge group, a...

Embodiment 2

[0053] On the basis of Example 1, this Example 2 proposes a bridge erection system. The implementation of this system has the advantages of small construction interference during the time period of water construction closure, parallel construction, small reinforcement of steel beams, and no need for guide beams. Compared with the existing frame method, there is no need to set frame in the bridge hole, less interference to shipping during the construction period, saving construction costs; compared with the dragging method, there is no need to set guide beams and connecting rods , The amount of steel beam reinforcement is small, saving installation costs.

[0054] The system includes an assembly platform, a slide rail mechanism, a pushing mechanism and a floating tugboat 9 as in Embodiment 1. Among them, the assembly platform is set at the assembling position of the steel beam, and is used to assemble the steel beam section by section; the slide rail mechanism is set on the car...

Embodiment 3

[0061] On the basis of Embodiment 1 and Embodiment 2, Embodiment 3 proposes a bridge erection method, thereby forming an efficient construction process of segment-by-section assembly and dragging. The implementation of this method can avoid the construction of structure foundations and false frames in the water, and has the advantages of small construction interference during the time period of water construction closure, parallel construction, small reinforcement of steel beams, and no need for guide beams. Compared with some scaffolding methods, there is no need to set scaffolding in the bridge hole, the construction period has less interference with shipping, and construction costs are saved; compared with the dragging method, there is no need to set guide beams and connecting rods, and the reinforcement of steel beams is small. Save installation costs.

[0062] The method includes the following steps:

[0063] S1. Respectively preset target positions of steel girder secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com