Dam body prepressing inverted filling construction method for ultra-high concrete panel rock-fill dam

A technology of concrete face and construction method, which is applied in the direction of dams, barrages, barrages, etc., can solve the problems of unsafe operation of rockfill dam body, cracks in concrete face plate, unbalanced settlement and deformation of rockfill body of dam body, etc. Achieve the effects of improving uneven deformation of the dam body, reducing differential deformation, and improving displacement distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

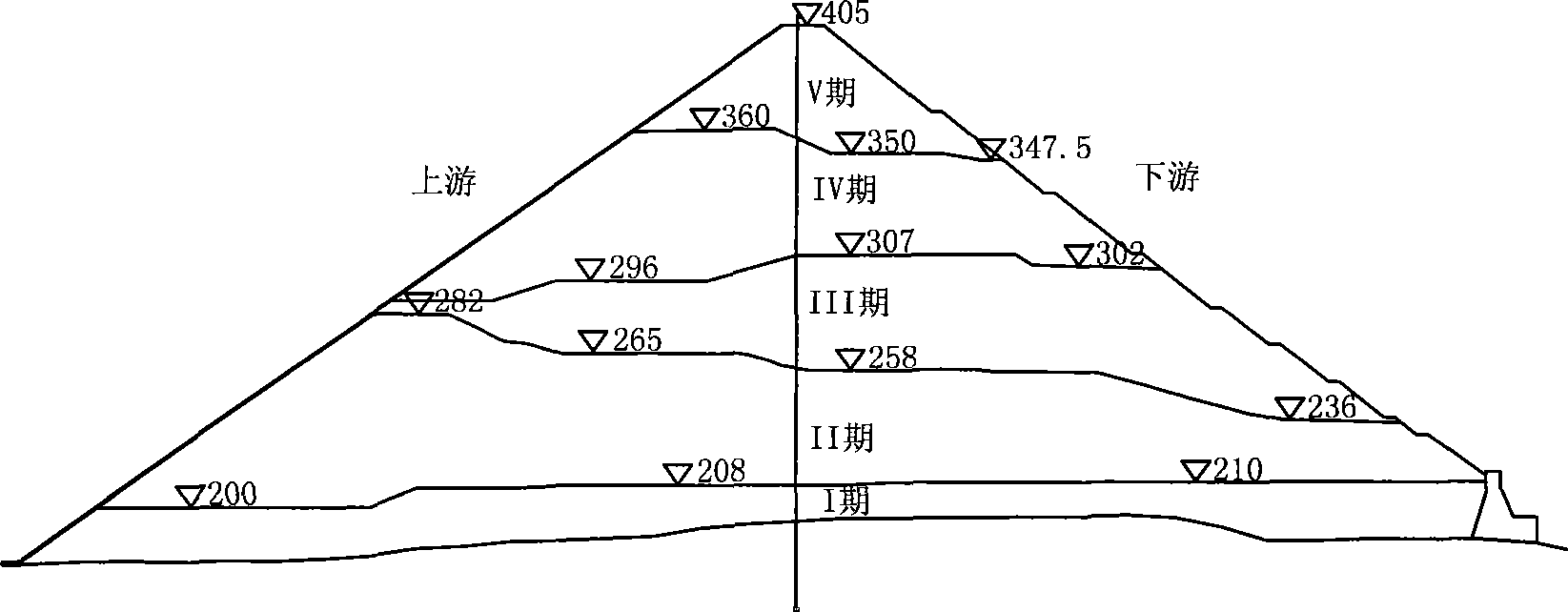

[0010] The main construction steps of reverse filling: such as figure 1 Shown:

[0011] Firstly, the first-stage dam body cushion, base and rockfill are filled to form the first-stage 200- 208- 210 dam body;

[0012] In order to ensure that the dam body can be filled to the flood control section in a dry season, the second phase of filling of the dam body was carried out according to the shape of positive steps with high upstream and low downstream, forming 282- 265- 258- 236 economic section for crossing the flood; after the dam body crosses the flood, continue to use rockfill material for the third stage of filling, so that the downstream of the section after the third stage of filling is higher than the upstream, and the obtained 296- 307- 302 anti-platform section, the rockfill dam in the downstream area of the dam body can obtain a settlement period of 2-3 months during the construction period, and then complete the fourth phase of the rockfill dam bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com