Face slab dam rolling and slope fixing device and face slab dam rolling and slope fixing construction method

A face dam and formwork technology, applied in the direction of dams, barrages, barrages, etc., can solve the problems of adverse impact of face plate force, construction progress limitation, uneven face plate, etc., to achieve crack prevention of face plate, construction cost reduction, The effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

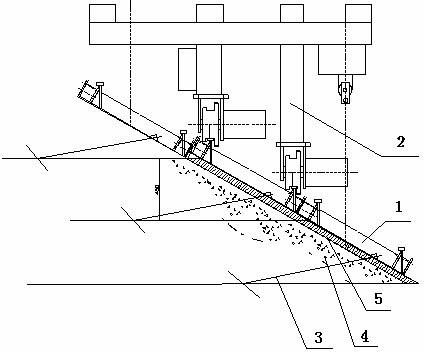

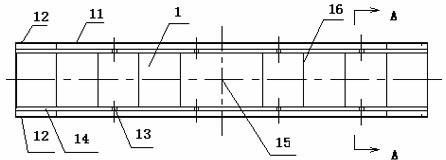

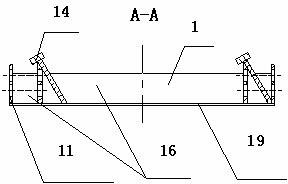

[0025] As an embodiment of the present invention, such as Figure 1 to Figure 7 As shown, a face dam rolling slope consolidation device includes a special formwork 1, and the special formwork 1 includes a rectangular bottom plate 19, and the length and width of the bottom plate 19 are adjusted according to different construction conditions. Positioning connecting plate 11 is arranged symmetrically along the width direction of base plate 19, and positioning connecting plate 11 is provided with positioning hole 12, and positioning hole 12 is used for the positioning when connecting between multi-layer special templates 1. Partition plates 16 are uniformly arranged on the bottom plate 19 along its length direction. Connecting pin holes 13 are evenly opened on the positioning connecting plate 11 , and the multi-layer special templates 1 are connected through the connecting pin holes 13 and connecting bolts 17 . Base plate 19 is provided with moving track 14 along its length direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com