Method applicable to pouring of concrete for artificial excavating pile body

A technology for artificially digging hole piles and concrete, which is applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of pipe lifting and backflow, low construction efficiency, high safety risk, etc., to avoid safety accidents and process conversion. Less and less security risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] Step 1: Mixing of concrete: The concrete used in the anhydrous underwater concrete pouring method has specific requirements. The concrete mix ratio should adopt the mix ratio of underwater concrete. The mix ratio of C30 concrete is: water (164kg): cement (320kg ): gravel (1047kg): sand (790kg): water reducing agent (3.6kg): fly ash (80kg). The design slump of concrete is 180~220mm.

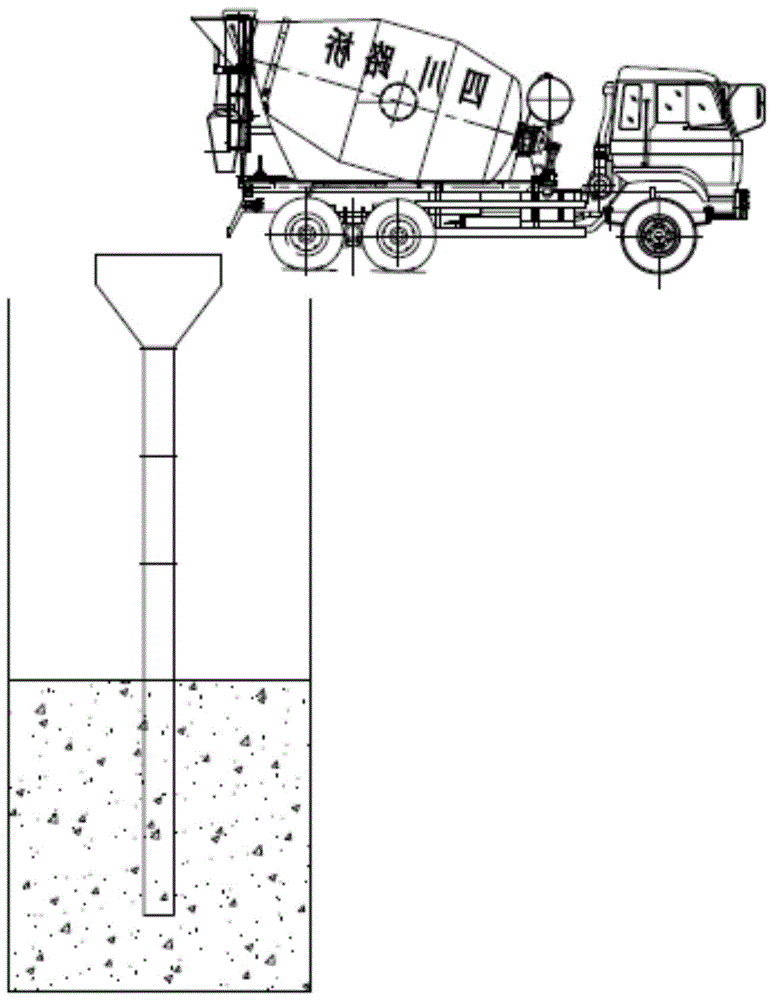

[0019] Step 2: Kick-off: When the first set of concrete is poured, the distance between the conduit opening and the bottom of the hole is 40~50cm. The kick-off does not need to consider the buried depth of the conduit. It only requires continuous supply of concrete to ensure that the surface concrete is not in the initial setting state, such as figure 1 shown.

[0020] Step 3: Pouring buried depth control: The pile body concrete of the anhydrous underwater concrete pouring method is mainly achieved through the self-weight and downward force of the concrete to achieve compaction. The buried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com