Method for enhancing slotting blasting efficiency of roadway (tunnel) tunneling

A tunneling and efficient technology, applied in blasting, tunneling, earth-moving drilling, etc., can solve the problems of underutilized blastholes, small blasthole diameters, and large rock clamping, so as to ensure the effect of cutting and blasting, excellent The effect of blasting compensation space and preventing explosives from rushing out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

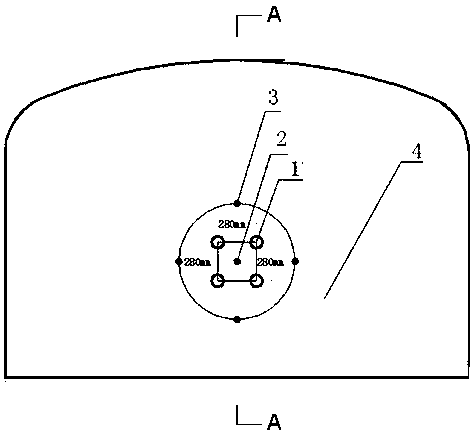

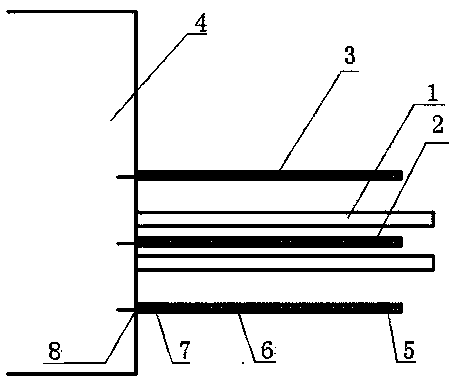

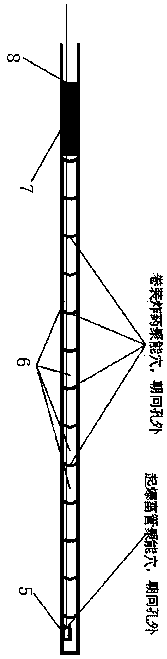

[0018] Embodiment 1: see figure 1 , figure 2 , a method for enhancing the efficiency of cutting blasting in roadway (tunnel) excavation, said method comprising the following steps: 1) Drilling four 78mm-diameter holes perpendicular to the work surface in the middle and lower part of the roadway (tunnel) excavation work surface Empty hole 1, a charging hole 2 with a diameter of 50mm is arranged in the center of the empty hole connection line, as the first hole for detonation, and 4 holes evenly distributed on a circle with a radius of 40cm are drilled with the center of the empty hole connection line as the center of the circle. Charging hole 3 with a diameter of 50mm, four charging holes are used as the second stage detonation;

[0019] 2) The four 78mm empty holes 1 are 20cm-30cm deeper than the surrounding 50mm charging holes 3, the depth of the four 78mm empty holes in the middle is equal, the depth of the central charging hole is equal to that of the surrounding charging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com