Built-in refuse incineration feed device

A waste incineration and feeding device technology, which is applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of reducing feeding efficiency, increasing the load of push carts, and energy waste, so as to improve feeding efficiency and avoid energy consumption. Waste and eliminate the effect of pushing material dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

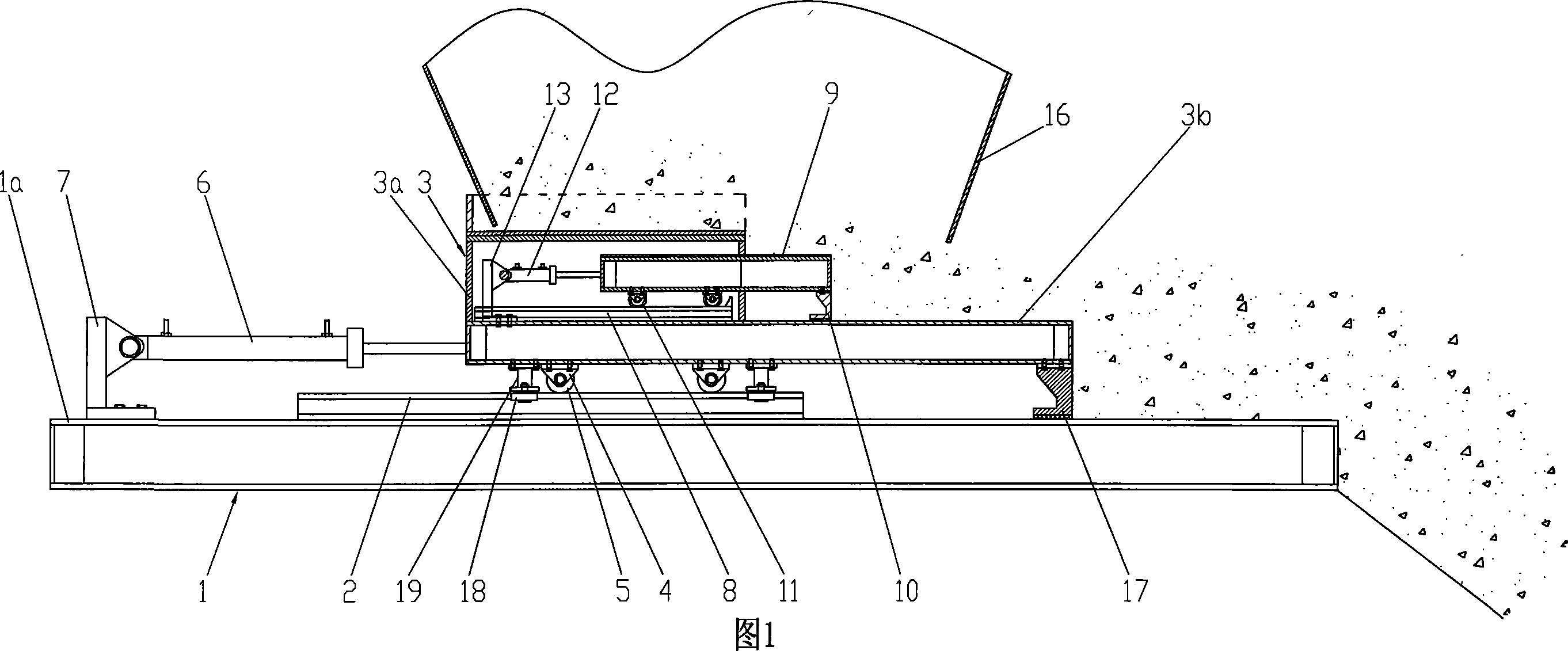

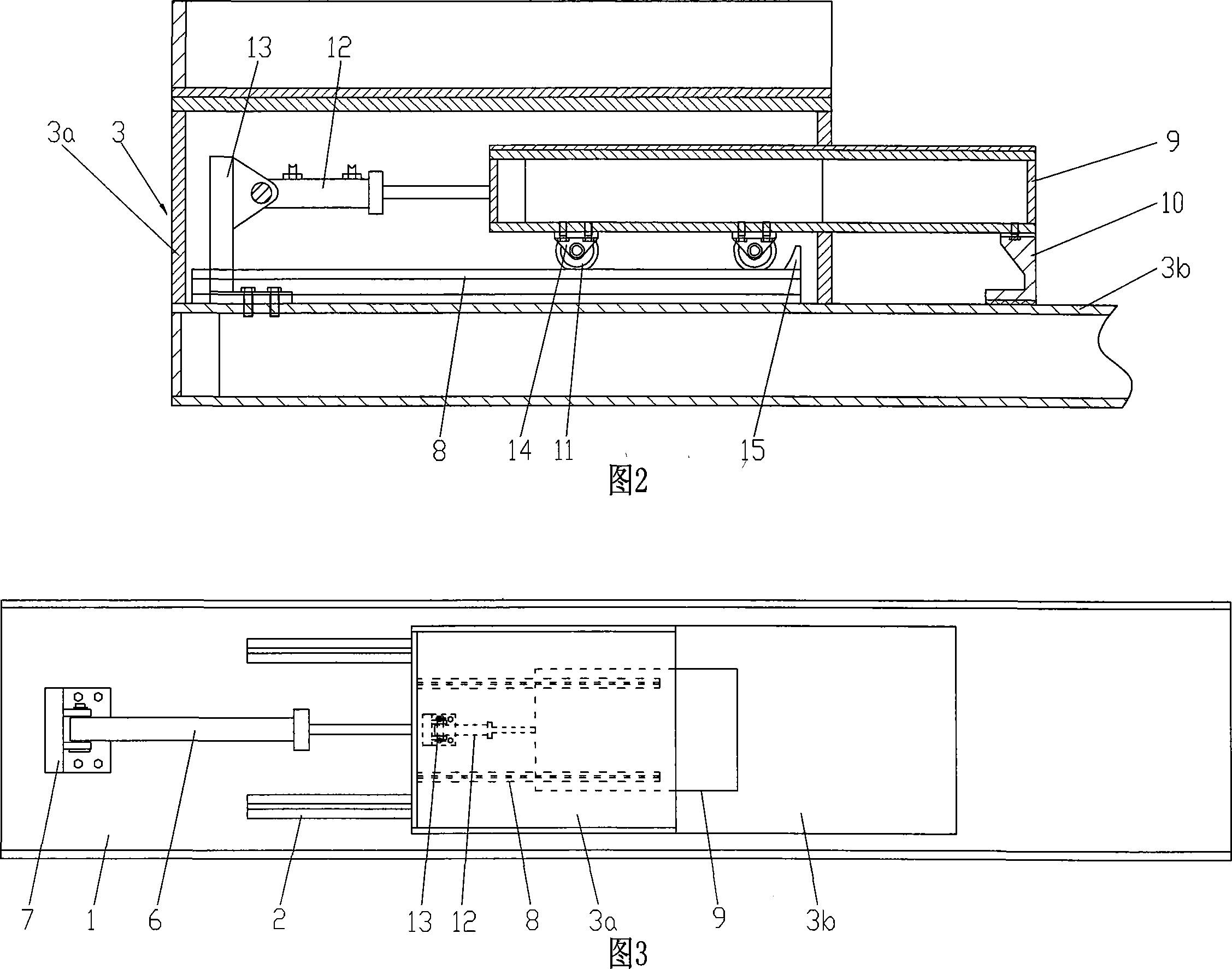

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0014] As shown in Figure 1, Figure 2 and Figure 3, the top plate 1a of the fixed chassis 1 is a flat plate structure parallel to the horizontal plane, and two rails 2 are arranged in parallel at the position behind the middle part of the top plate 1a of the fixed chassis 1, and the fixed chassis 1 1 The middle part of the rear end of the top plate 1a is bolted to the support 7, and the tail end of the hydraulic cylinder 6 parallel to the track 2 is connected to the support 7, and its piston rod protrudes forward and is fixedly connected to the rear end of the push cart 3. Pushing cart 3 is positioned at the below of feed bin 16, has the car body of upper and lower deck length unequal, wherein the rear end of upper strata car body 3a is aligned with the rear end of lower deck car body 3b, and the upper surface of upper strata car body 3a is positioned at upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com