Multi-piece valve disk

A multi-piece, valve disc technology, used in multi-way valves, lift valves, valve devices, etc., to achieve the effects of simple assembly, easy disassembly, and high functional reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

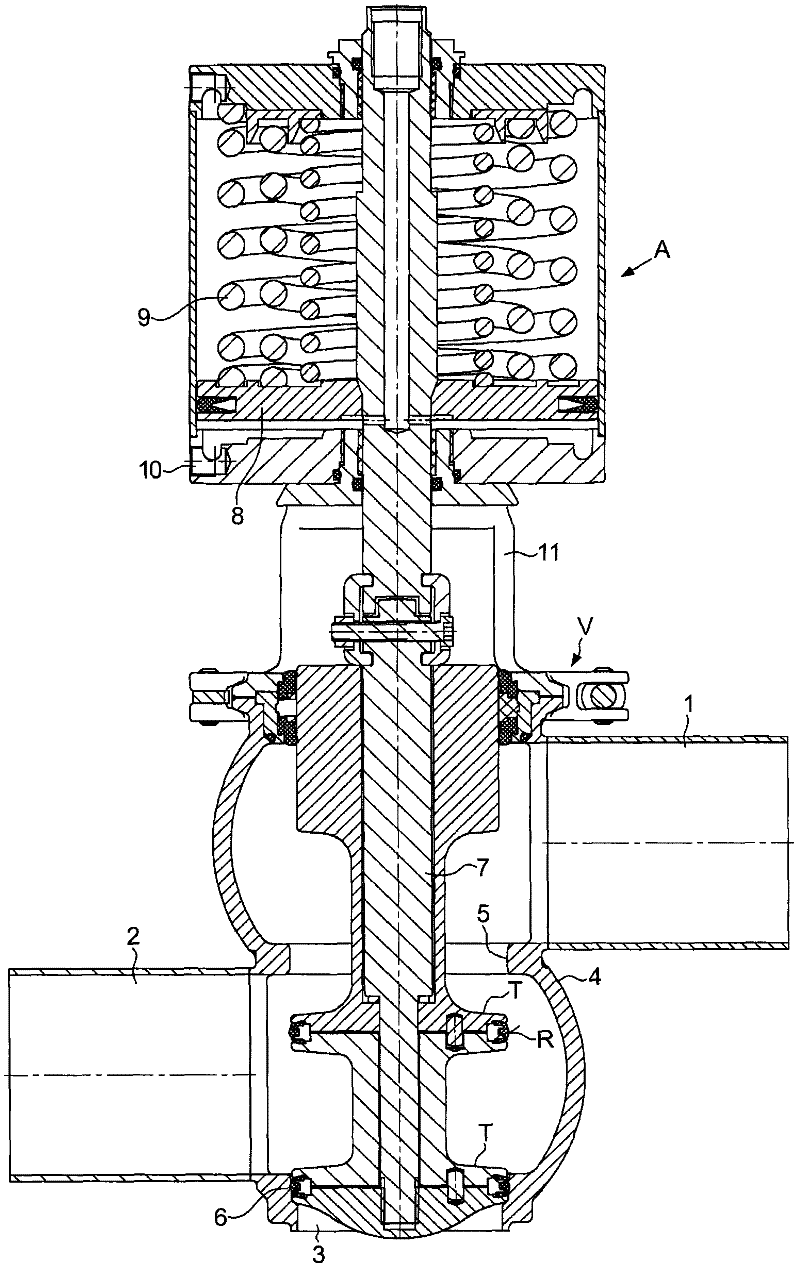

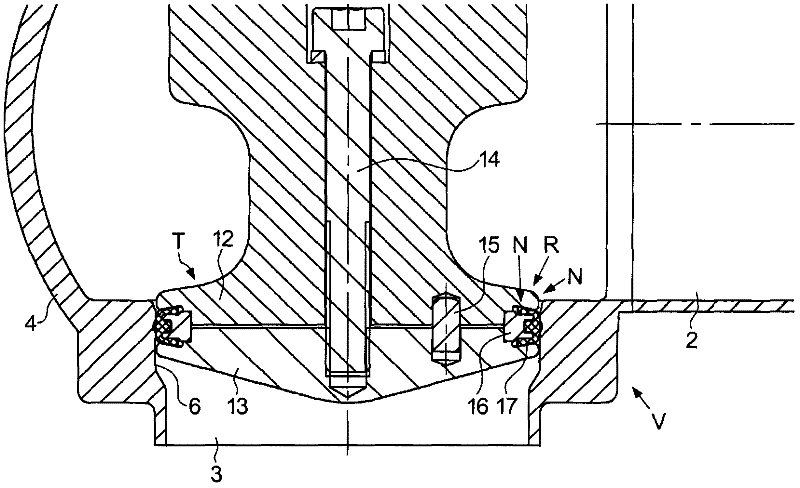

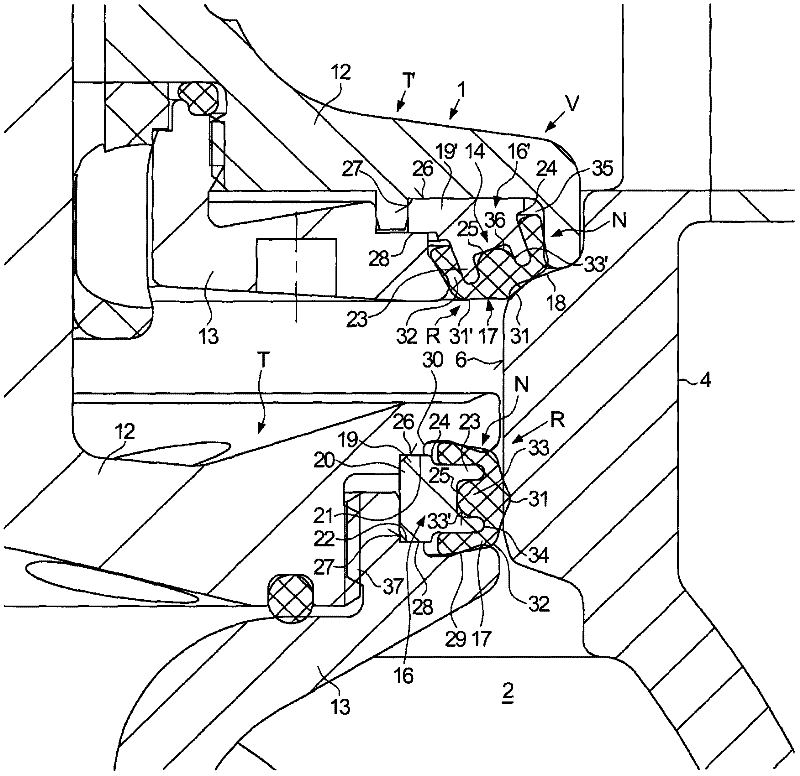

[0026] The invention relates to a multi-part valve disk T having at least one sealing ring arrangement R and also to this sealing ring arrangement R itself. Valve discs T with at least one sealing ring arrangement R are used, for example, in valves with only one or two valve discs in sliding and / or seat valves (single sliding or seat valves); or in valves with two and one seat In the double-seat valve of the disc T that works together. Double seat valves can work which exhibit a combination of seat and slide valve functions, or a combination of both seat valve functions or two slide valve functions. Such double-seat valves are used, for example, for the flow control of beverage products, food, pharmaceuticals or biotechnological products, they must be selectively cleanable in a specific way, must reliably isolate the individual flow paths from each other in the closed position and have a Leakage between flow media is selectively avoided, and they must prevent media exchange b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com