Patents

Literature

50results about How to "Speed up work progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

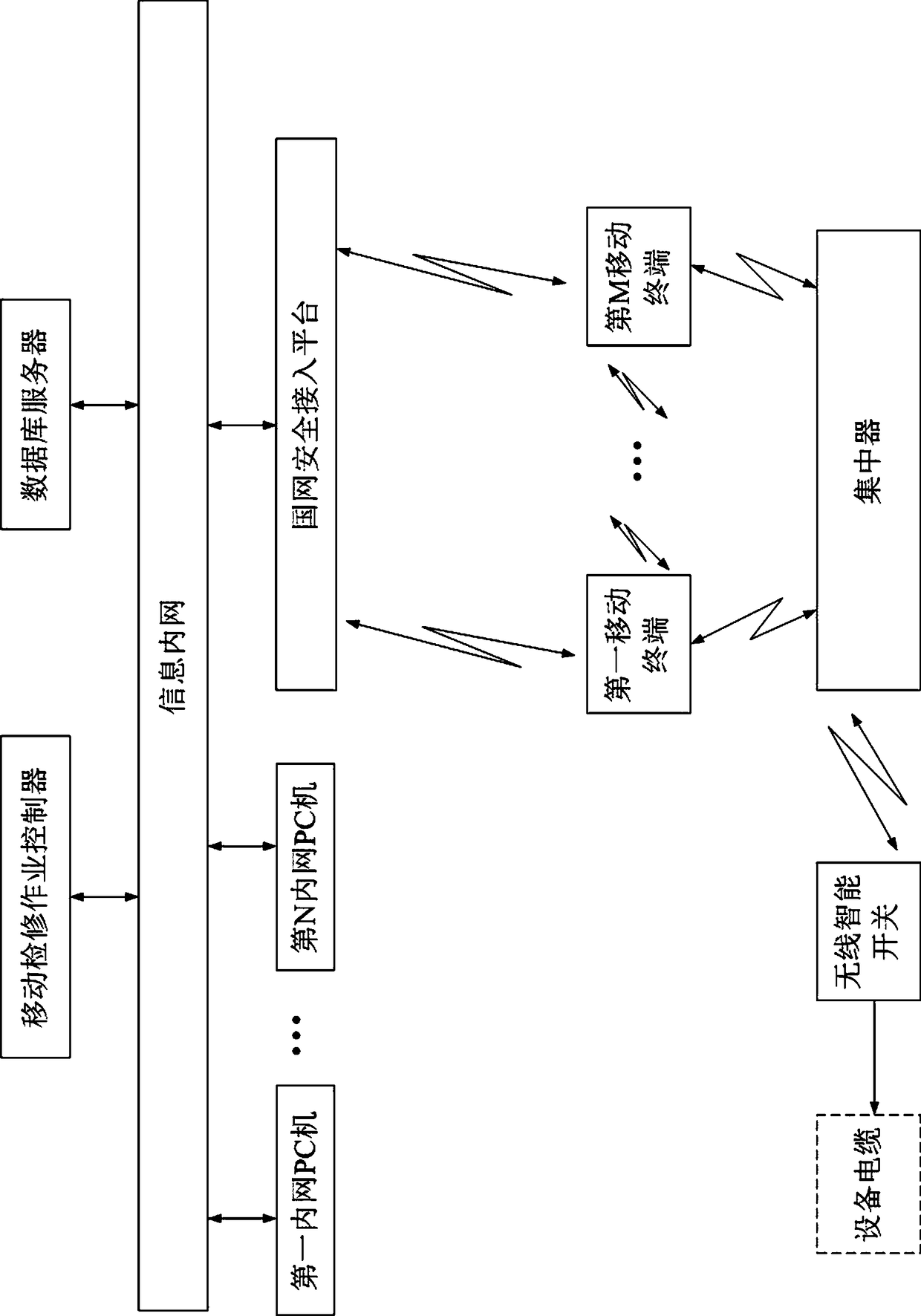

Overhauling operation control method based on mobile terminal

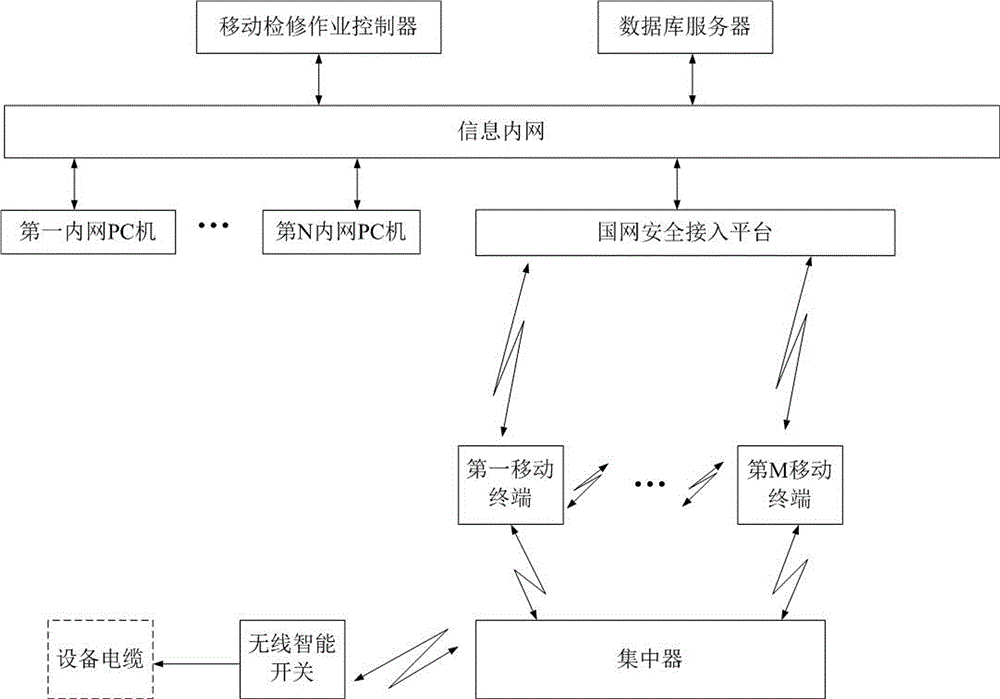

ActiveCN104902011AFacilitate communicationReduce riskResourcesTransmissionTime informationComputer terminal

The invention discloses an overhauling operation control method based on a mobile terminal. The method comprises the following steps: constructing an overhauling operation control platform based on the mobile terminal; constructing a software platform; and the software platform formulating a corresponding operation task according to the overhauling operation task, setting an instruction template and transmitting the task instruction to the corresponding first to Mth mobile terminals, the mobile terminal locking other mobile terminals and viewing the operation progress in real time and the like. The method has the advantages: real-time information communication is performed on the site operation condition by the mobile terminal, so that low efficiency caused by multiple calls or repeated communication with paper is avoided; and an operator uses the mobile terminal to remotely control an intelligent socket to achieve the purposes of intelligent power disconnection and power connection, so that intelligent early warning of potential safety hazards is realized, information can fed back to the mobile terminal and a mobile overhauling operation controller in real time, and the safety of site operation is ensured.

Owner:STATE GRID CORP OF CHINA +1

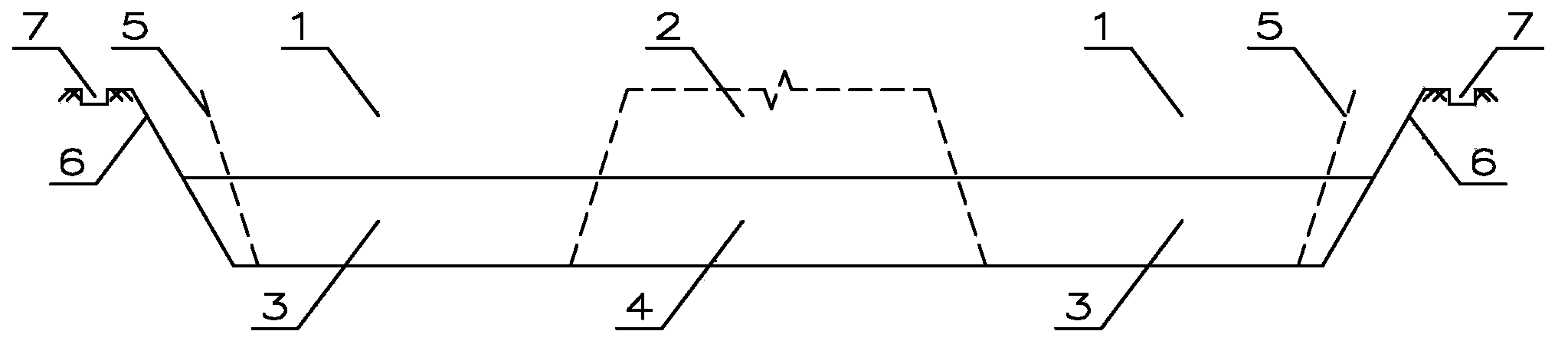

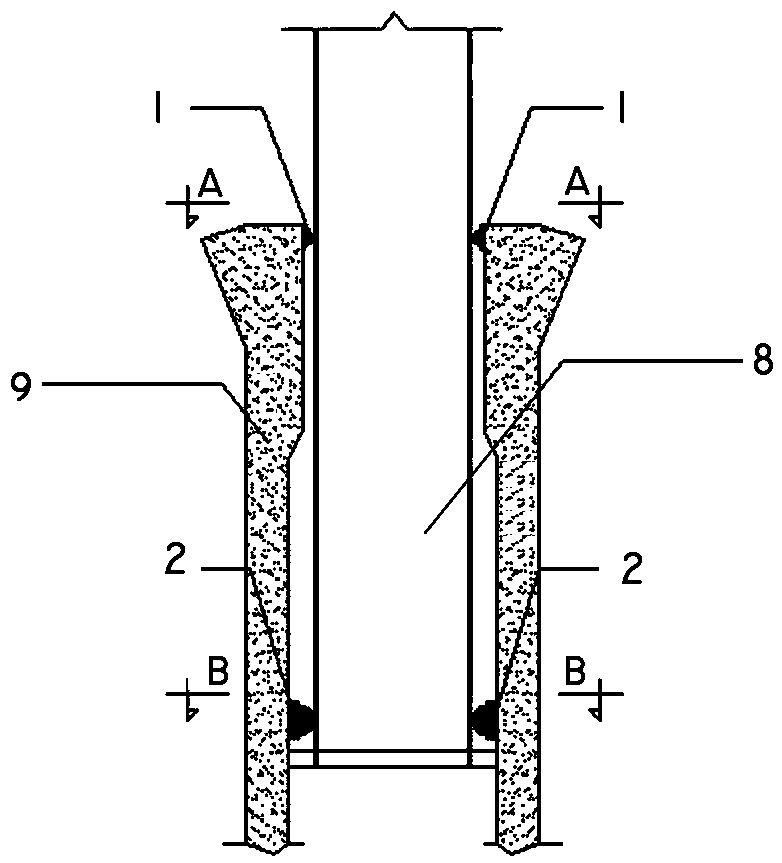

Double-channel underground chamber construction method

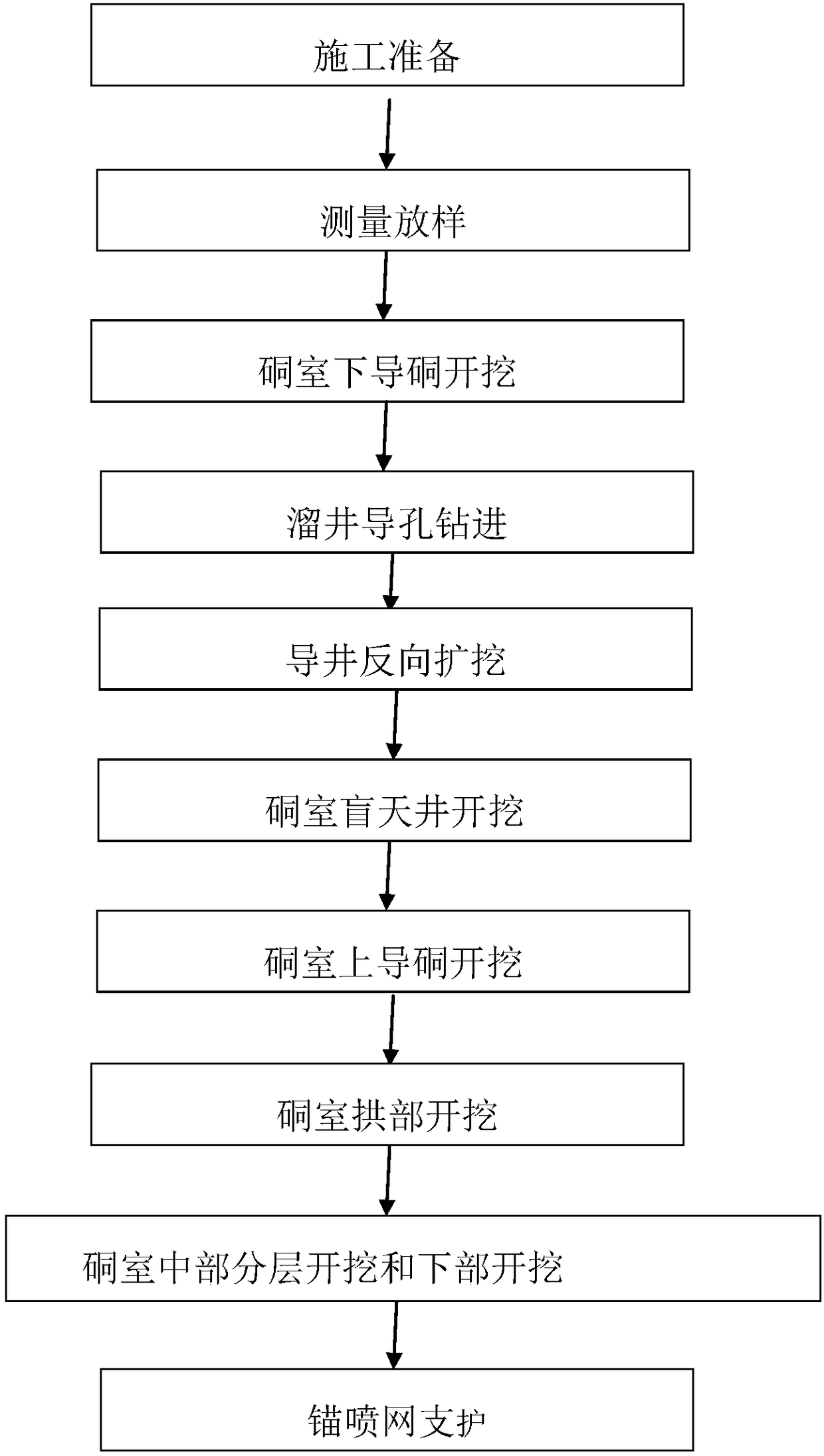

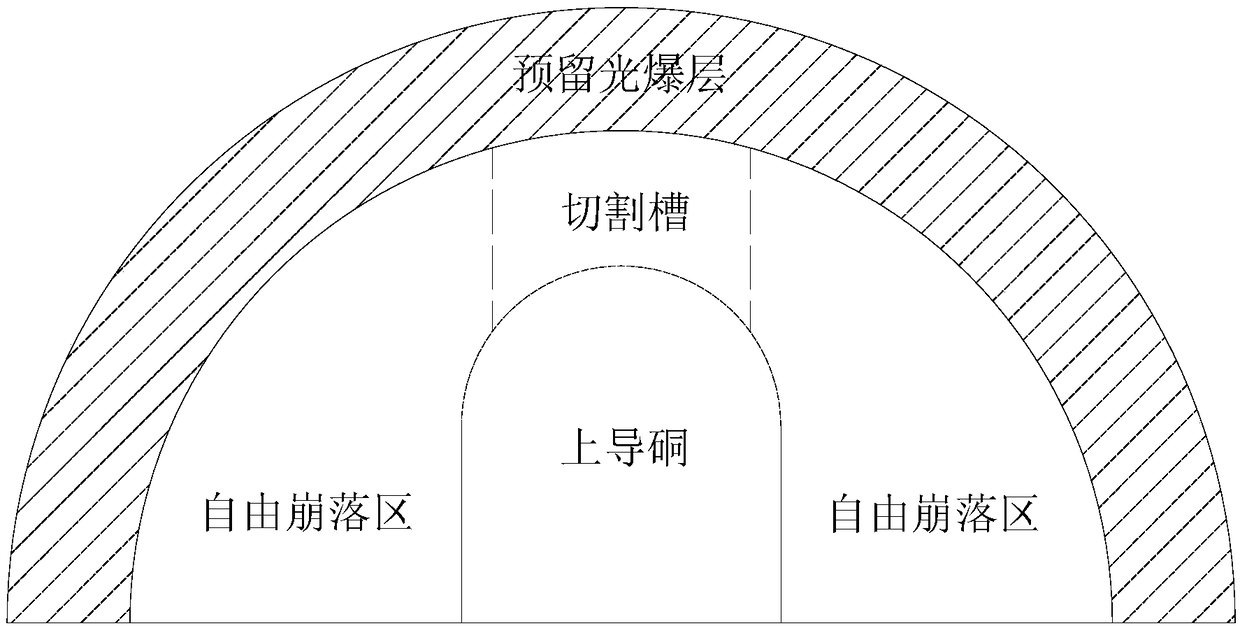

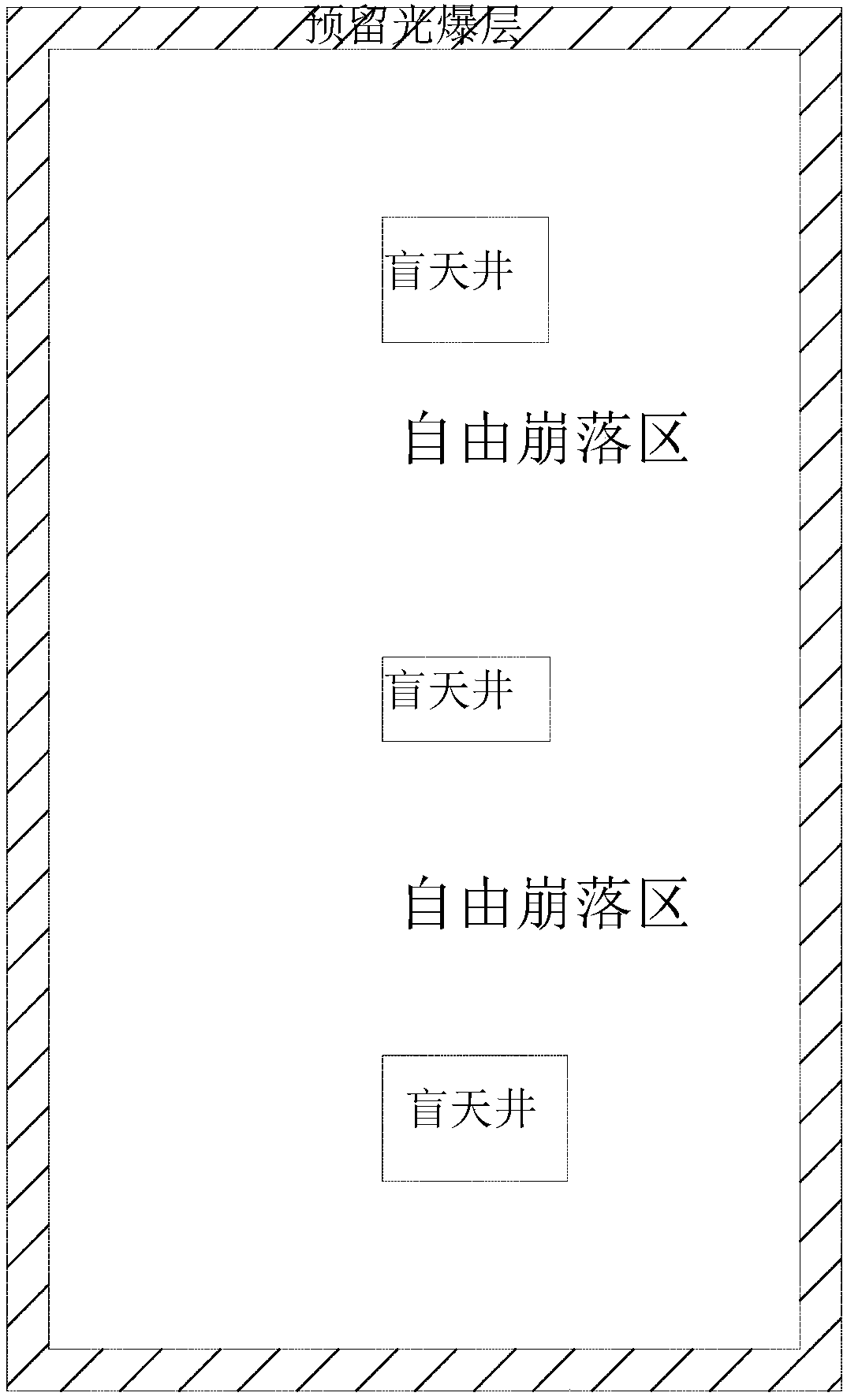

InactiveCN108343455AImprove blasting efficiencySpeed up work progressUnderground chambersSmooth surfaceBuilding construction

The invention relates to the field of engineering construction and discloses a double-channel underground chamber construction method. The double-channel underground chamber construction method comprises the following steps that (1) construction preparation is conducted; (2) measuring and setting out are conducted; (3) a chamber lower guiding chamber is excavated, specifically, the lower guiding chamber communicating with a chute is excavated along the center axis of the chamber from a chamber inlet-outlet gate way channel, and the excavation section of the guiding chamber is the same as the section of the chamber inlet-outlet channel in size; (4) chute guiding holes are drilled; (5) a guiding well is excavated for expansion in the reverse direction; (6) chamber blind raises are excavated;(7) a chamber upper guiding chamber is excavated, specifically, with a chamber arching line as a bottom plate, an upper guiding chamber communicating with the three blind raises are tunneled along the axis of a crushing chamber; and (8) a chamber arched part is excavated, specifically, through the upper guiding chamber, an arched part cutting groove is excavated above the blind raise in the middle of the chamber, the through the constructed arched part cutting groove, tunneling is conducted from the middle to the two ends of the chamber, and smooth surface blasting is conducted to form an arched part. The double-channel underground chamber construction method has the effects that the total excavation cost of the chamber is recued, and the construction period is shortened.

Owner:浙江省隧道工程集团有限公司

Earth excavation technology for ultra-large type deep foundation pit

ActiveCN104164878AFlexible deployment of excavating machinerySpeed up work progressExcavationsStructure of the EarthEngineering

The invention relates to an earth excavation technology for an ultra-large type deep foundation pit. The earth excavation technology for the ultra-large type deep foundation pit comprises the following steps that (1) after measurement, a plurality of regions are divided, and earth slope roads are arranged between the regions; (2) a basin-type excavation technology is adopted in the foundation pit boundary regions, wherein construction is conducted on middle earth at first, then construction is conducted on ring-edge earth, and a slope supporting structure is constructed in time; (3) an island-type excavation technology is adopted in the foundation pit middle regions, construction is conducted on earth of the adjacent boundary regions, then construction is conducted on middle earth, and stable transition with the adjacent regions is considered comprehensively; (4) the regions are excavated and supported layer by layer, overexcavation is strictly prohibited, mechanical excavation is primary, manual construction and excavation are secondary, and it is guaranteed that undisturbed earth is not damaged; (5) a reverse-type excavation technology is adopted in the earth slope roads, and excavation is conducted from bottom to top step by step. Intercepting ditches are formed in the periphery of the foundation pit, drainage ditches and water-collecting wells are formed in the construction regions, and accumulated water is discharged in a concentrated mode. The earth excavation technology for the ultra-large type deep foundation pit has the advantages that the advantages of the island-type excavation technology and the advantages of the basin-type excavation technology are brought into full play, the construction procedures are linked effectively, the progress of operation is rapid, the time effect is reduced effectively, and safety is high.

Owner:CCCC HIGHWAY MAINTENANCE ENG TECH

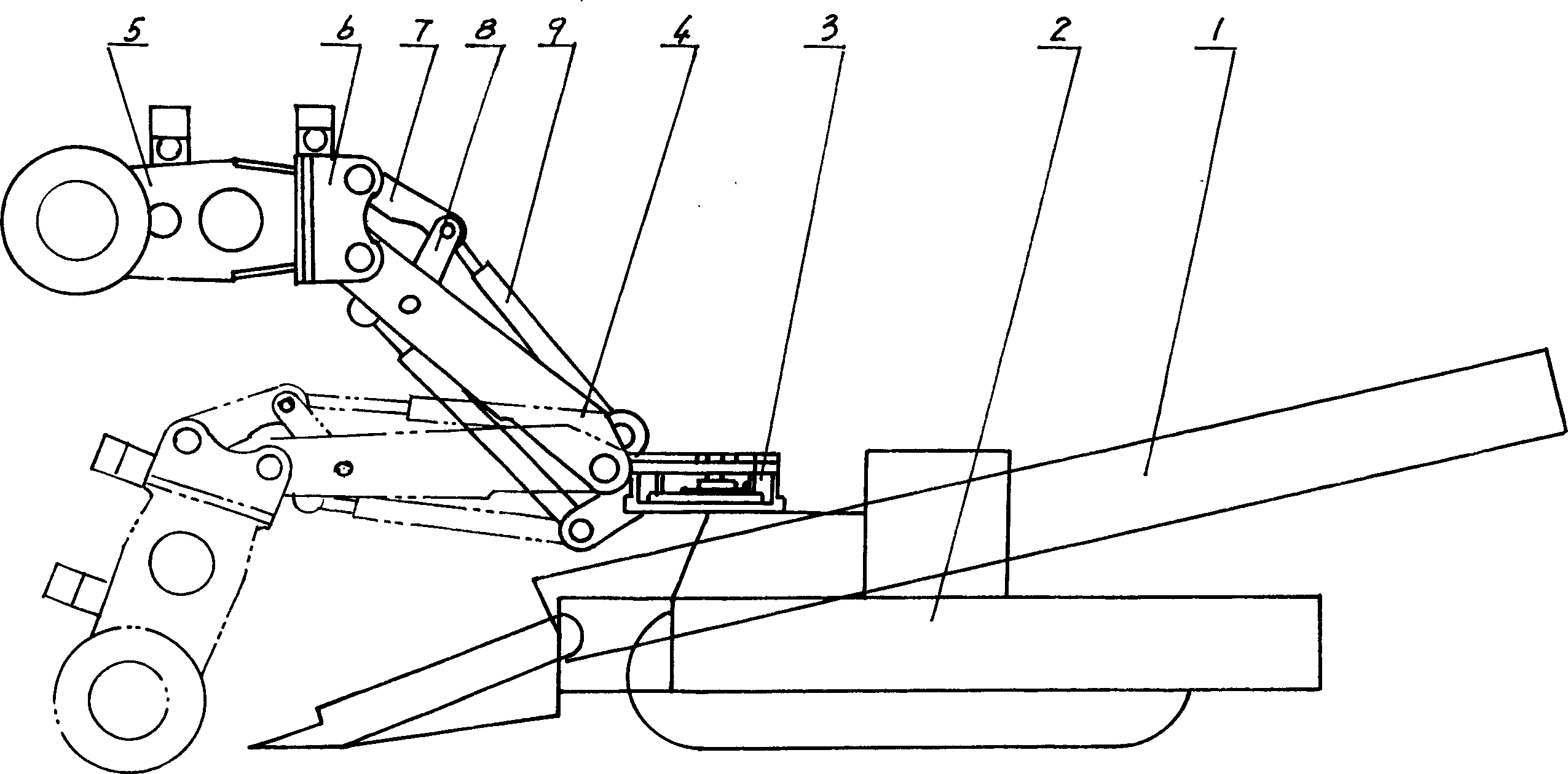

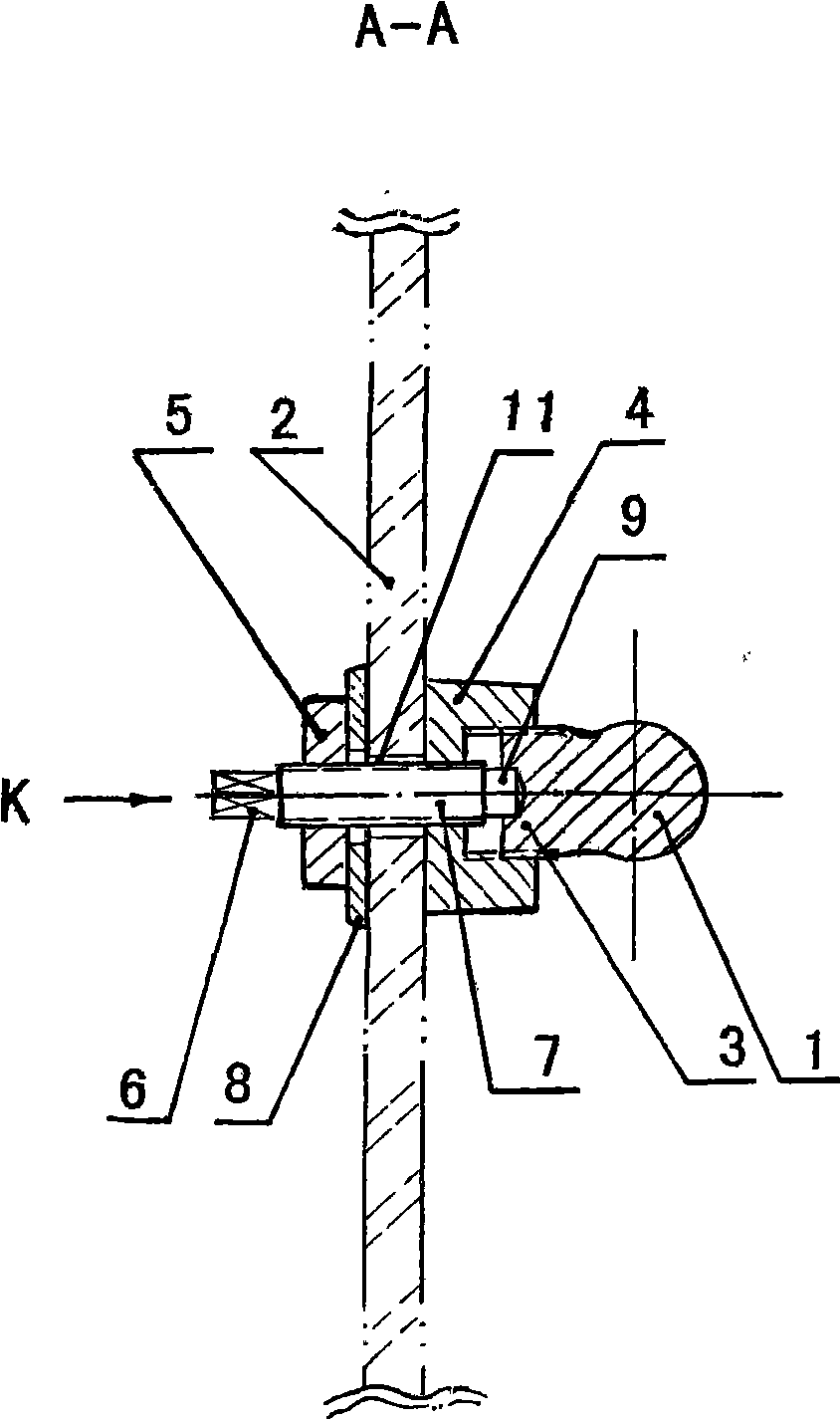

Small size multifunction heading machine

The present invention relates to a small multifunctional development machine for mining coal and repairing roadway. It includes self-propelled crawler body on which a hoeing machine and a cutting arm connecting device are mounted, said cutting arm connecting device is hinged with cutting arm, hinged swinging device and cutting head device whose cutting head can be leftwards and rightwards moved. Said cutting head device is hinge-connected with cutting arm by means of hinged swinging device, and can be removably connected. Said development machine can be matched with breaking hammer and percussion drill, so that it has several different functions.

Owner:SHANDONG JINTIANNIU MINING MACHINERY

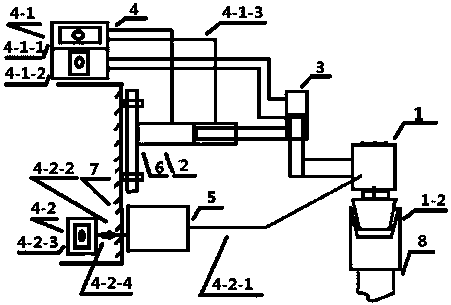

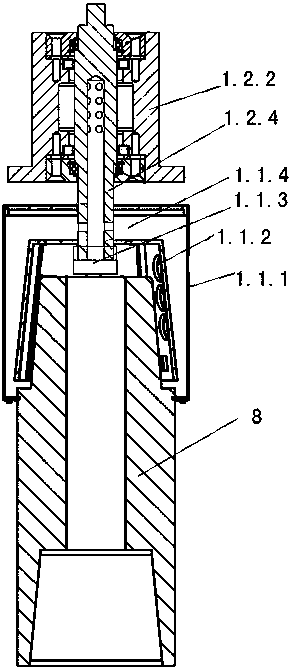

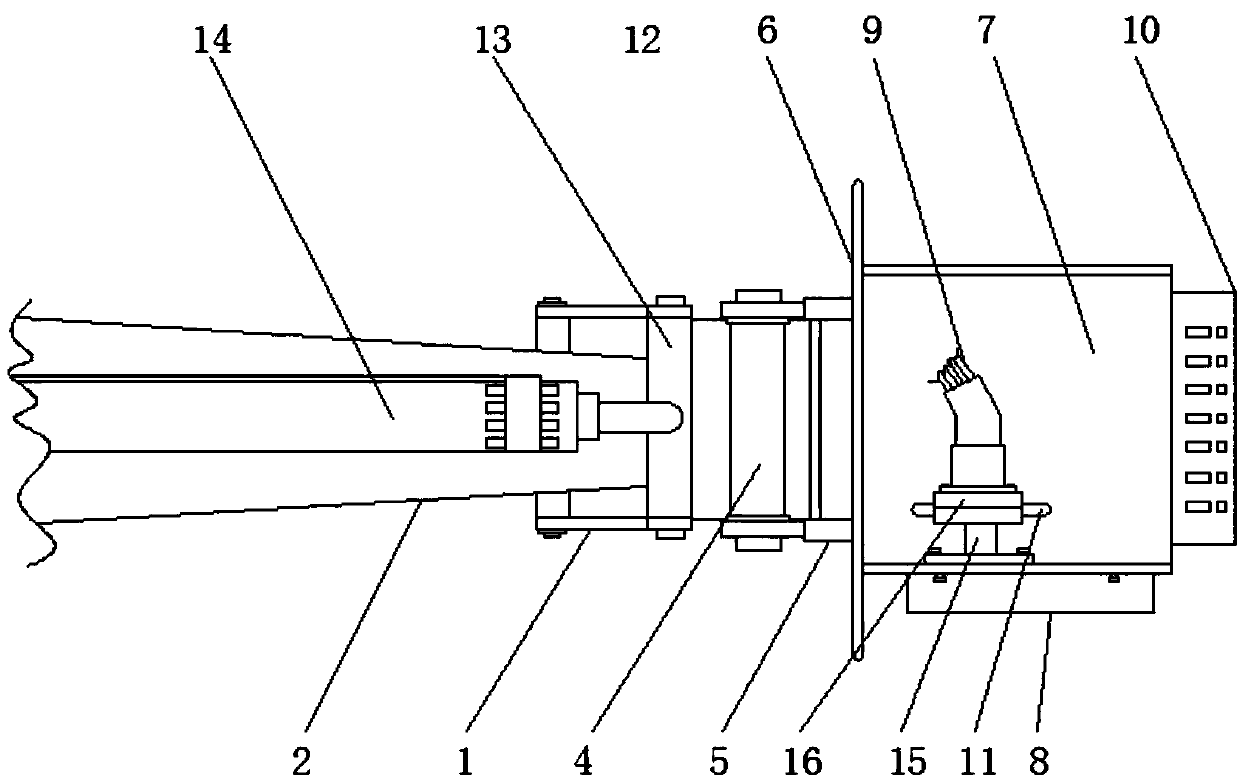

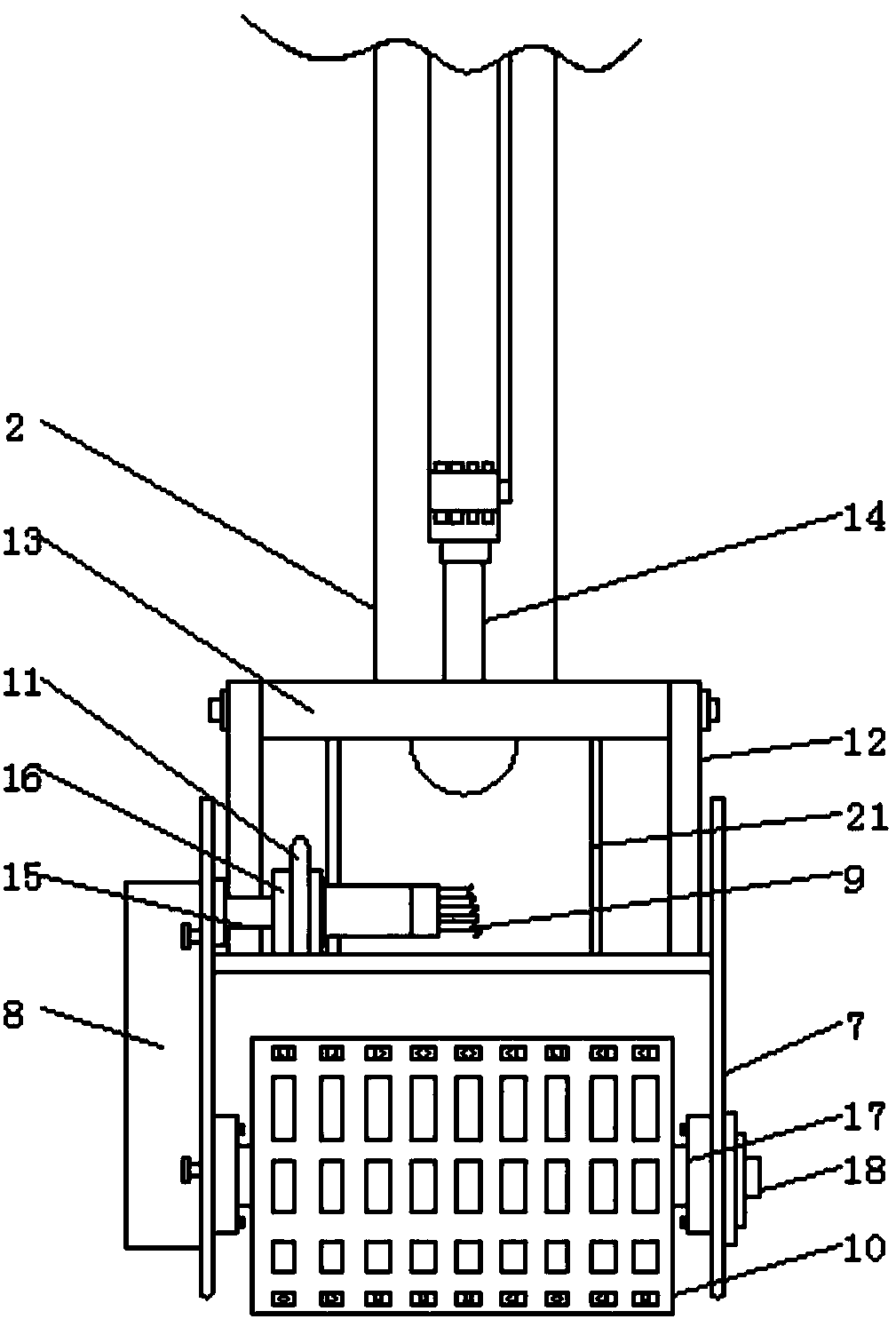

Automatic drilling rod screw thread sealing grease spraying device and method

PendingCN107812638AThe operation process is convenientSpray evenlySpraying apparatusTransfer mechanismControl level

The invention relates to an automatic drilling rod screw thread sealing grease spraying device and a method. According to the technical scheme, the automatic drilling rod screw thread sealing grease spraying device is characterized in that a spraying mechanism is connected to the outer end of a vertical hydraulic lifting transfer mechanism; the vertical hydraulic lifting transfer mechanism is connected to the outer end of a horizontal hydraulic transfer mechanism; a control mechanism, together with the horizontal hydraulic transfer mechanism, the vertical hydraulic lifting transfer mechanism and a sealing grease pneumatic control mechanism, is fixed to a hydraulic power tongs suspension arm; and by controlling the movement of the horizontal hydraulic transfer mechanism and the vertical hydraulic lifting transfer mechanism through the control mechanism, the spraying mechanism is transferred to a to-be-sprayed drilling rod male button or female button for locating, and a sealing grease of a sealing grease storage tank is sprayed to the drilling rod male button or female button through the sealing grease pneumatic control mechanism. The operation process is quick and convenient, the spraying is timely and uniform, and the spraying quality of drilling rod sealing grease can be improved, so that the drilling rod screw thread can be sealed effectively, the labor intensity of workerscan be reduced, the operation progress and effectiveness can be improved, and potential safety hazards are eliminated.

Owner:SINOPEC SSC +2

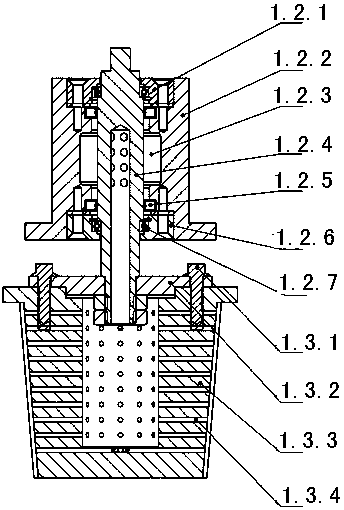

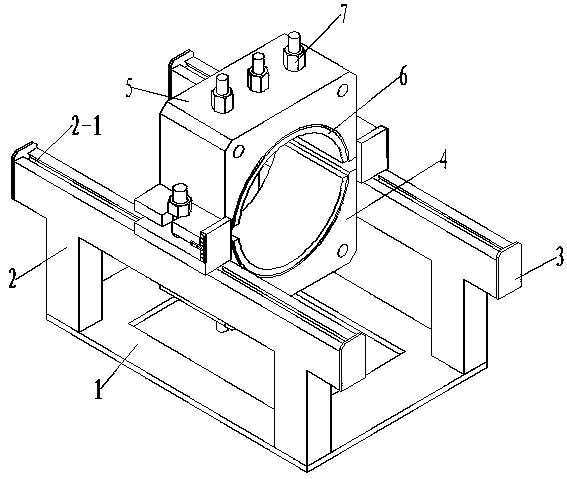

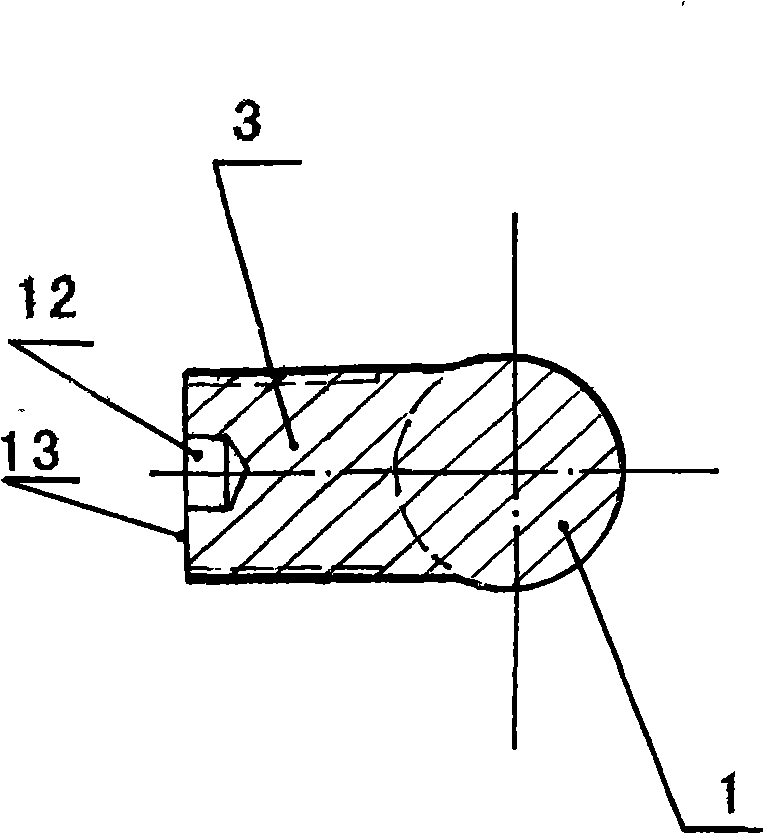

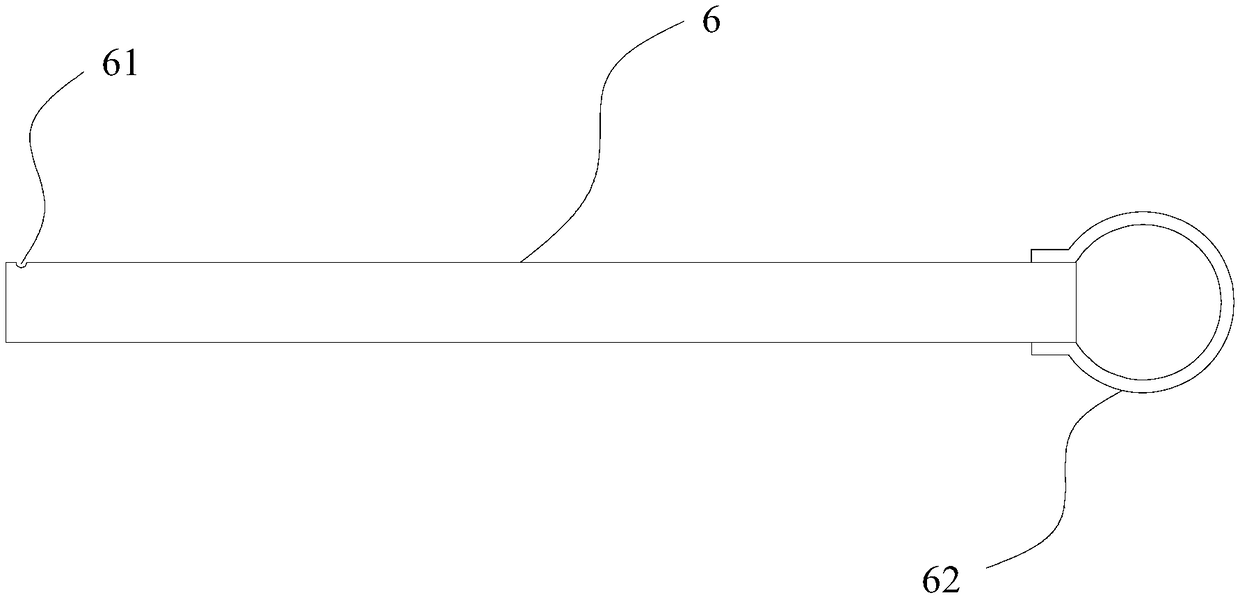

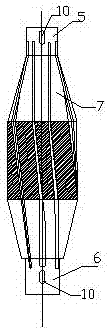

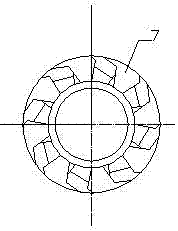

Pipe opening rounding shaping and butt connecting device

PendingCN111215483AImproved rounding effectSpeed up work progressWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe

The invention relates to the technical field of pipe butt welding construction auxiliary devices, in particular to a pipe opening rounding shaping and butt connecting device. The device comprises a shaping assembly. The shaping assembly comprises a rounding base, a rounding upper cover and shaping linings. The rounding base and the rounding upper cover are same in body structure and are each provided with a rectangular block where a through circular arc groove is formed, wherein flanges are arranged on the left and right side surfaces of each rectangular block correspondingly. An opening of the circular arc groove of the rounding base faces upwards. The rounding upper cover is arranged on the rounding base, and an opening of the circular arc groove of the rounding upper cover faces downwards. Guide holes in the two sides of the rounding upper cover sleeve positioning guide columns of the rounding base correspondingly. The shaping linings are contained in the circular arc grooves of therounding base and the rounding upper cover correspondingly. The length of threaded rods is greater than the depth of through holes, and nuts are connected to the threaded rods correspondingly. The rounding effect is obviously improved when compared with a traditional manual striking mode; and rounding is performed by screwing up the nuts on the threaded rods, the operating pace is quickened, andthe time cost is saved.

Owner:CHINA 22MCC GROUP CORP

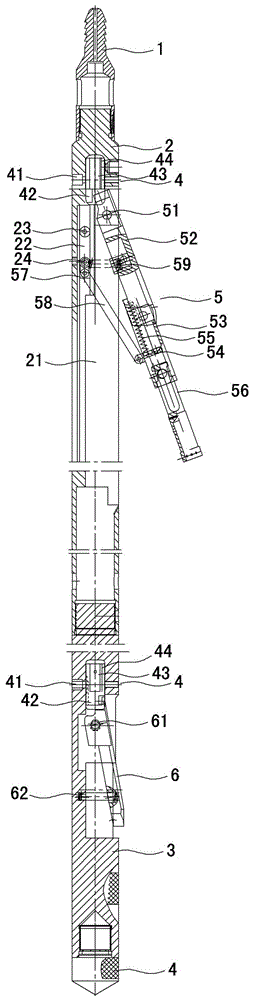

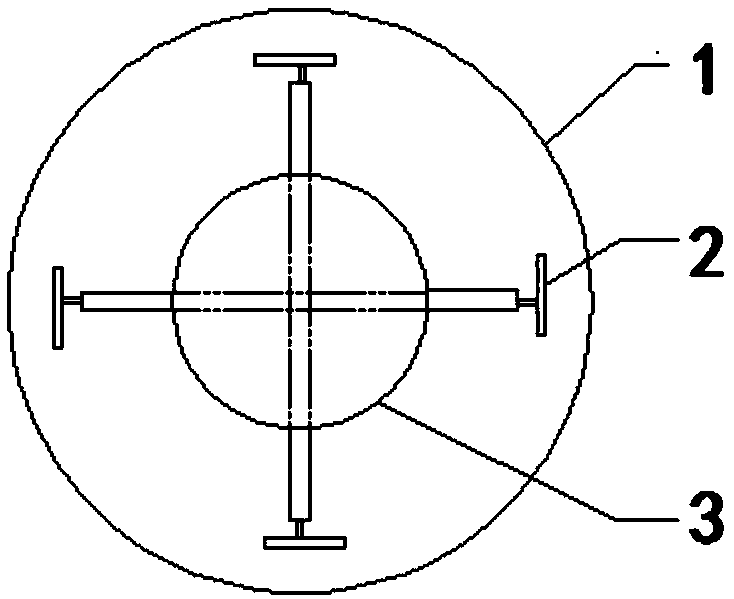

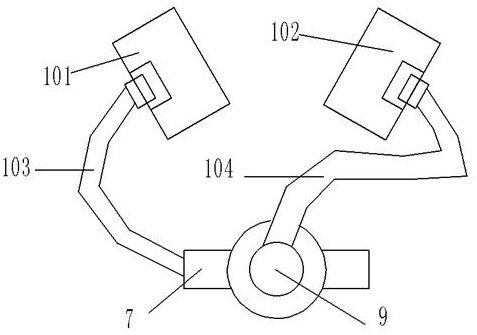

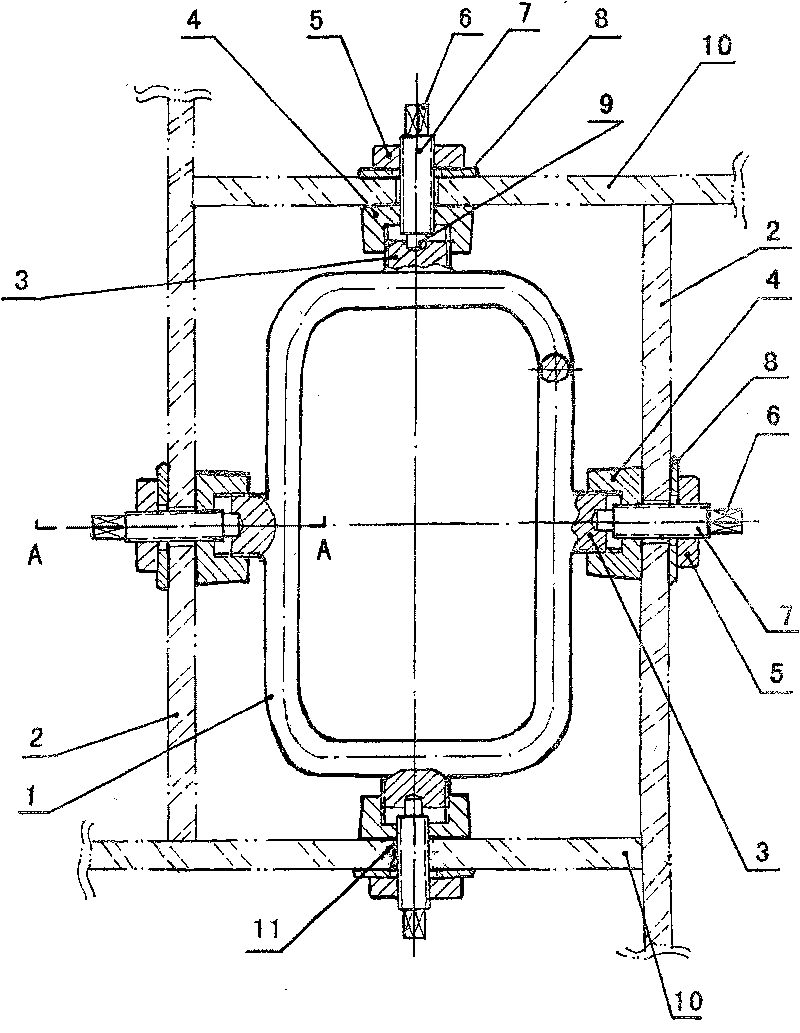

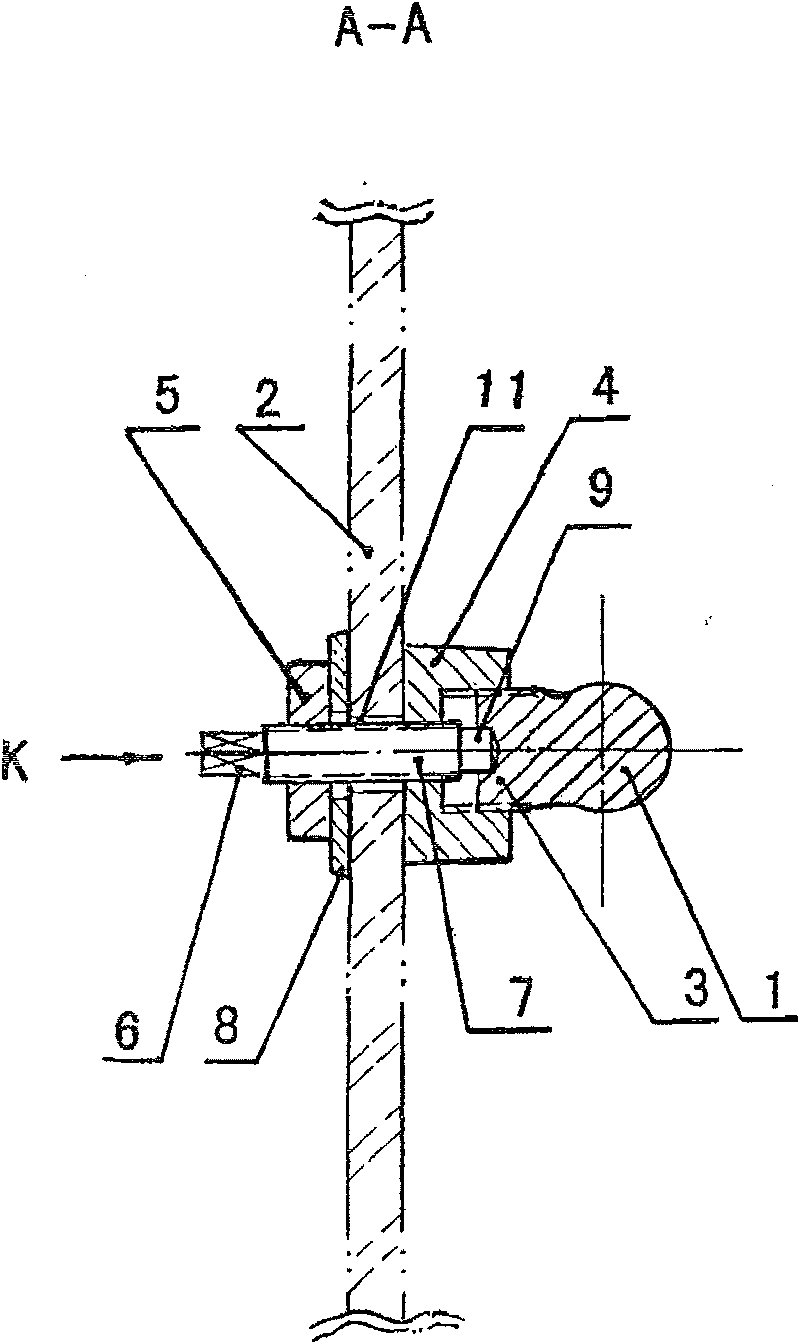

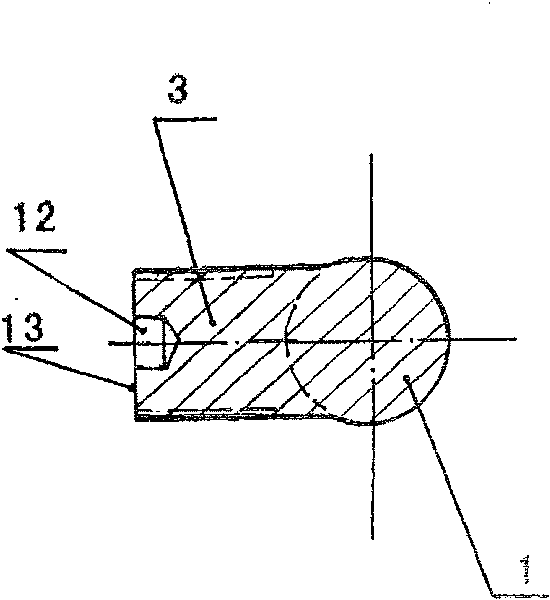

Automatic arm retraction type putting and fishing device

ActiveCN106437595ASpeed up work progressIncrease productivityBorehole/well accessoriesPush pullDual purpose

The invention relates to an automatic arm retraction type putting and fishing device. A putting and fishing claw (5) is composed of an upper putting and fishing claw (52), a lower putting and fishing claw (53), a pup joint (54), a pressure spring (55) and a pressure feed head or a fishing head (56). The automatic arm retraction type putting and fishing device further comprises a sliding block (57), a push-pull rod (58) and a tension-pressure dual-purpose spring (59). The sliding block (57) is installed on a sliding track (22) of an upper body 2 in a sliding mode, a sliding block stop mechanism (7) is arranged on the sliding block (57), an upper locking groove (23) and a lower locking groove (24) are formed in the upper end and the lower end of the sliding track (22) respectively, one end of the push-pull rod (58) is hinged to the pup joint (54), the other end of the push-pull rod (58) is hinged to the sliding block (57), one end of the tension-pressure dual-purpose spring (59) is connected to the middle of the upper putting and fishing claw (52), and the other end of the tension-pressure dual-purpose spring (59) is connected with the sliding block (57). The putting and fishing claw of the automatic arm retraction type putting and fishing device is spread under a well and can be automatically retracted into the upper body after the putting and fishing process is finished, the putting and fishing claw can continue to be put into the position below a water distributor, and the overall working progress of an oil field can be easily accelerated.

Owner:牡丹江金恒石油机械科技有限公司

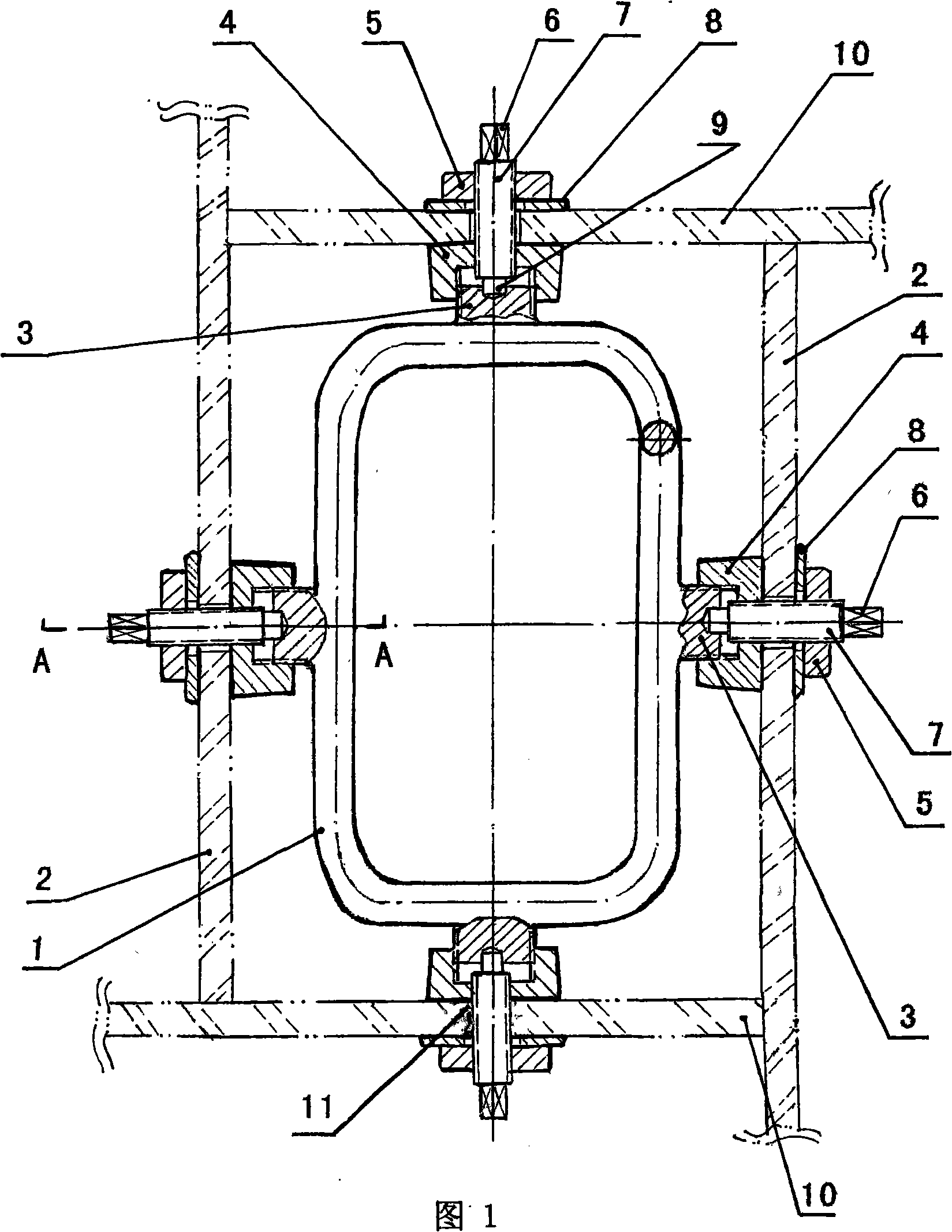

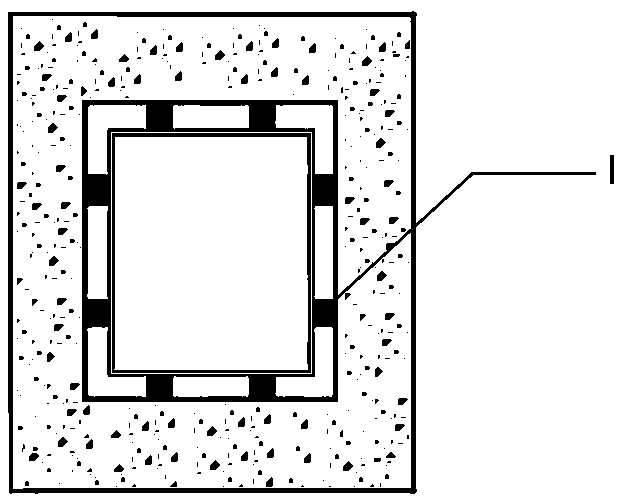

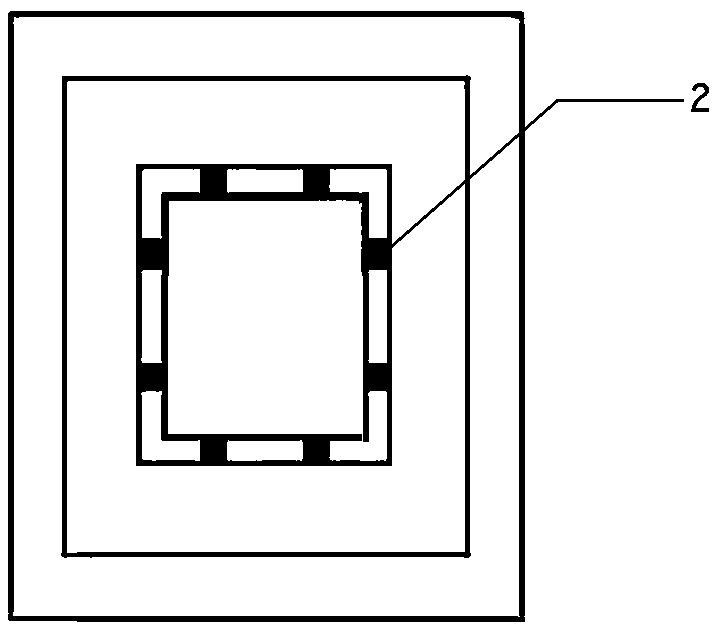

Bidirectional regulation positioning buckle device for building construction cast-in-situ concrete combined template

InactiveCN101270611AEasy to produceImprove interchangeabilityAuxillary members of forms/shuttering/falseworksArchitectural engineeringMaterial consumption

The invention discloses a double adjusting location locking device used for a cast-in-place compound template of building construction, which mainly consists of a pre-burying annular shelf provided with a convex column, an adjustable location fastener connected with the convex column in thread and an adjusting screw rod; the pre-burying annular shelf is arranged in a cast-in-place cavity formed by the template and leads the adjusting screw rod to extend out of the wall of the template to reveal an adjusting square head; adjustable location fastener can be driven to rotate and move the template to a needed position by turning the adjusting screw rod, then a locking nut is used to lock the template; the invention can simultaneously carry out double direction adjustment location to fix the compound template to form the cast-in-place cavity along the transverse and the longitudinal direction for the use of construction, has the advantages of precious adjusting location, convenient construction operation and saving construction material consumption, etc., besides, the invention has remarkable effects on improving the construction efficiency and the building engineering quality.

Owner:邹尧 +2

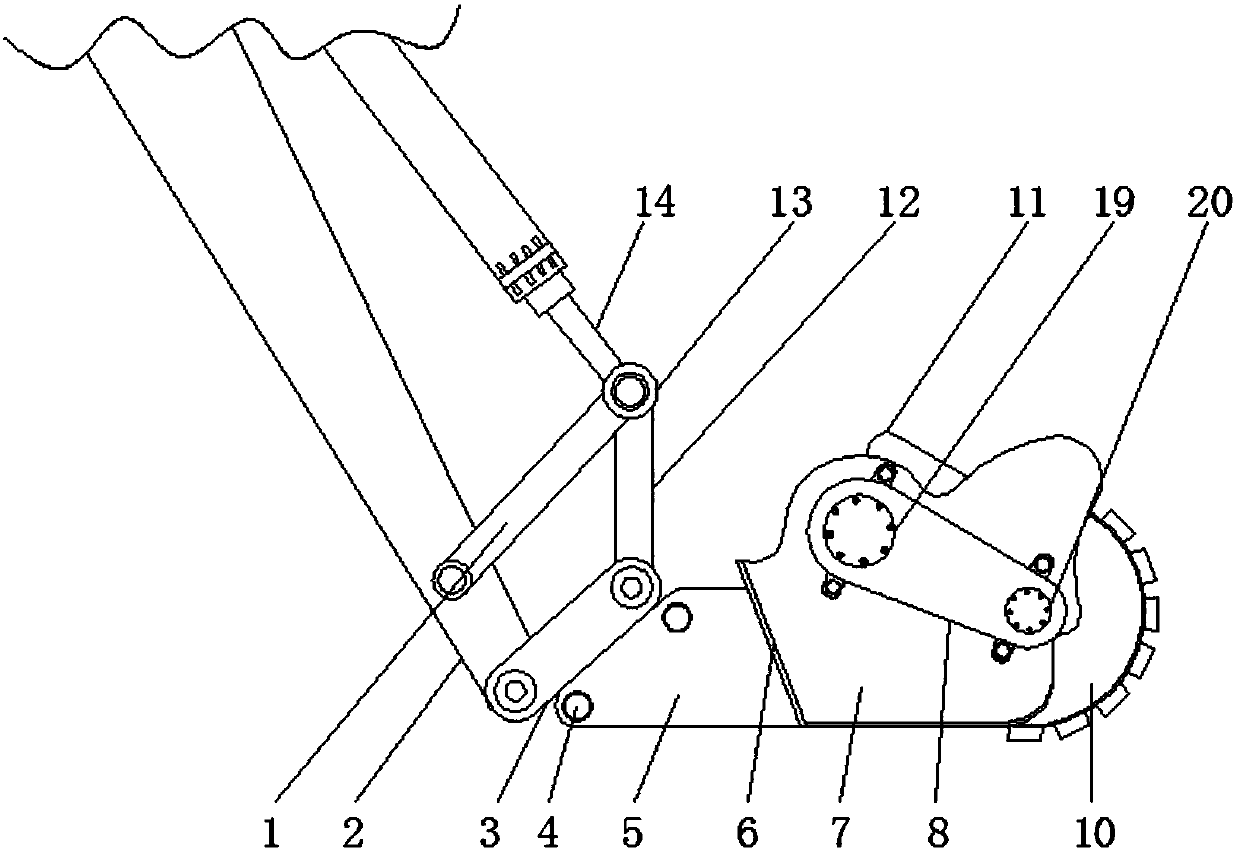

Standing type high-voltage cable operation device

ActiveCN112271632AStable operation maintenanceSpeed up work progressClimate change adaptationApparatus for overhead lines/cablesHigh-voltage cableStructural engineering

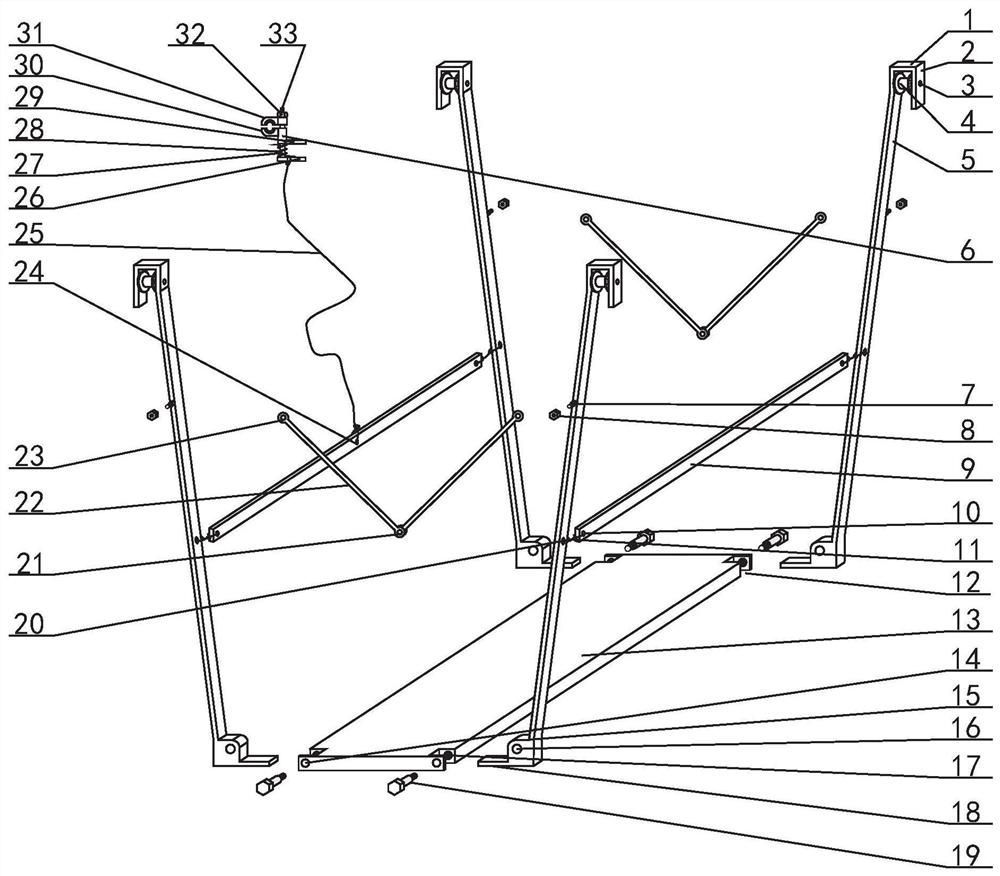

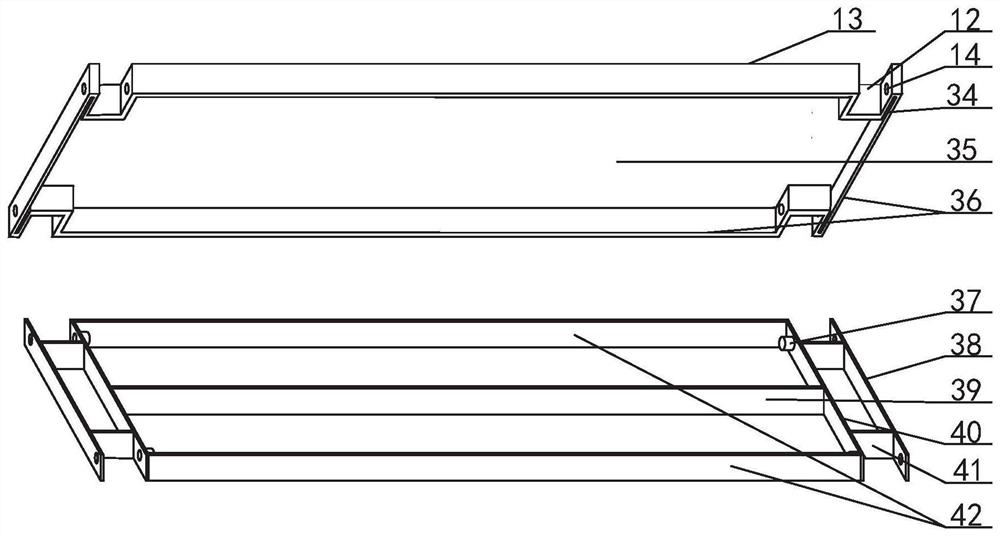

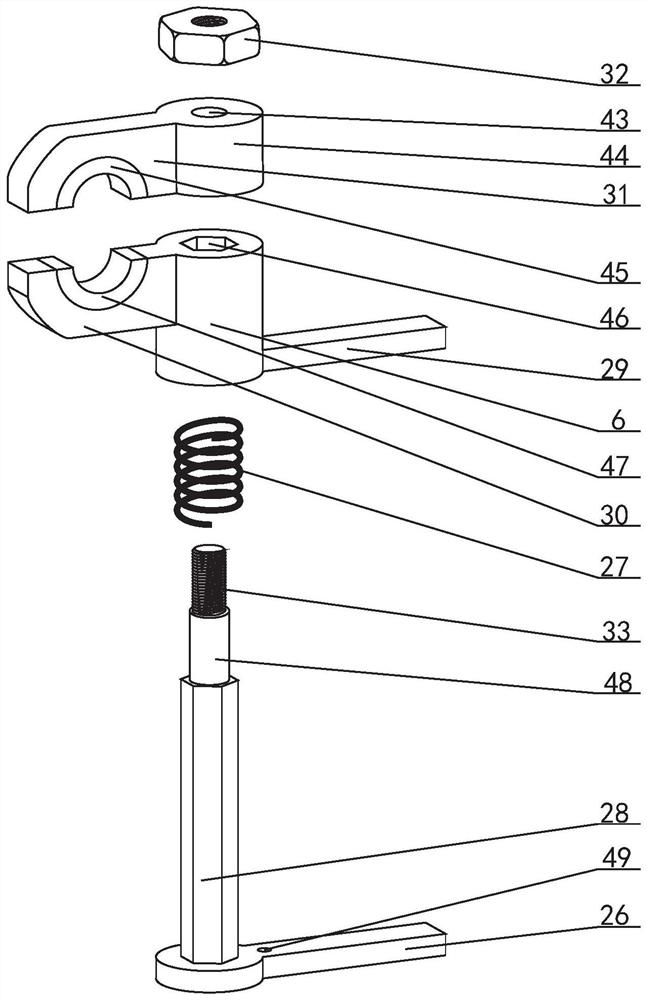

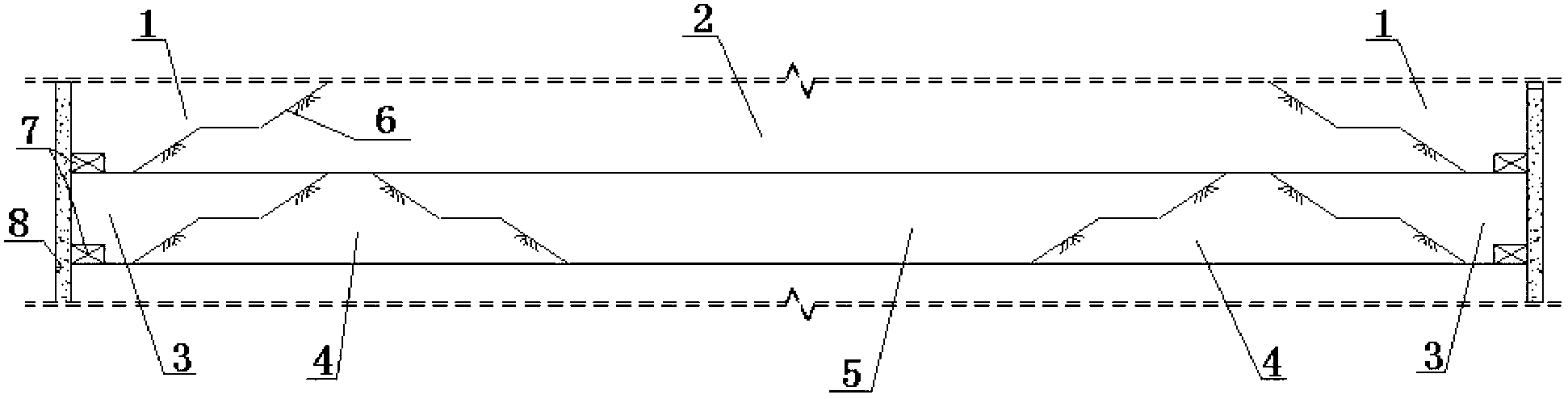

The invention discloses a standing type high-voltage cable operation device and relates to a high-voltage cable maintenance device. Two sides of a standing plate (13) are respectively hinged with thelower ends of four vertical rods (5) close to the front end and the rear end, grooved wheels (4) are respectively arranged on the outer sides of the upper ends of the four vertical rods, and telescopic rods (22) are respectively arranged between the vertical rods on two sides of the front part of the standing plate and the rear part; a stop lever (9) is arranged between the middles of every two vertical rods on the two sides of the standing plate respectively, and the cable locking device is connected with any vertical rod or any stop lever or any telescopic rod through a pull rope (25). According to the invention, the four vertical rods arranged on the standing plate are respectively hung on a high-voltage cable, and the high-voltage cable is braked by the cable locking device, so stableoperation maintenance on the high-voltage cable is obtained.

Owner:LANGFANG POWER SUPPLY COMPANY STATE GRID JIBEI ELECTRIC POWER COMPANY +1

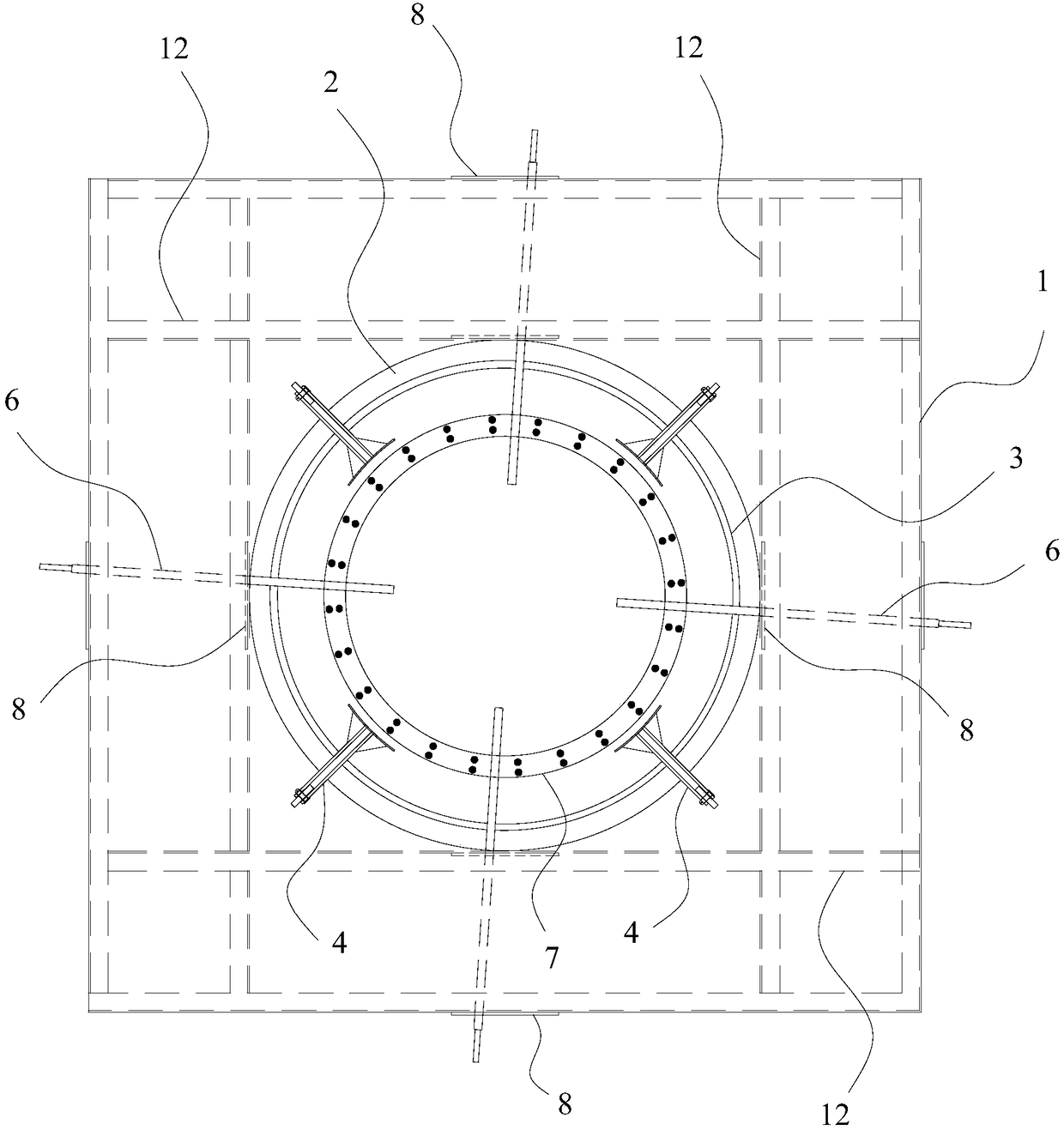

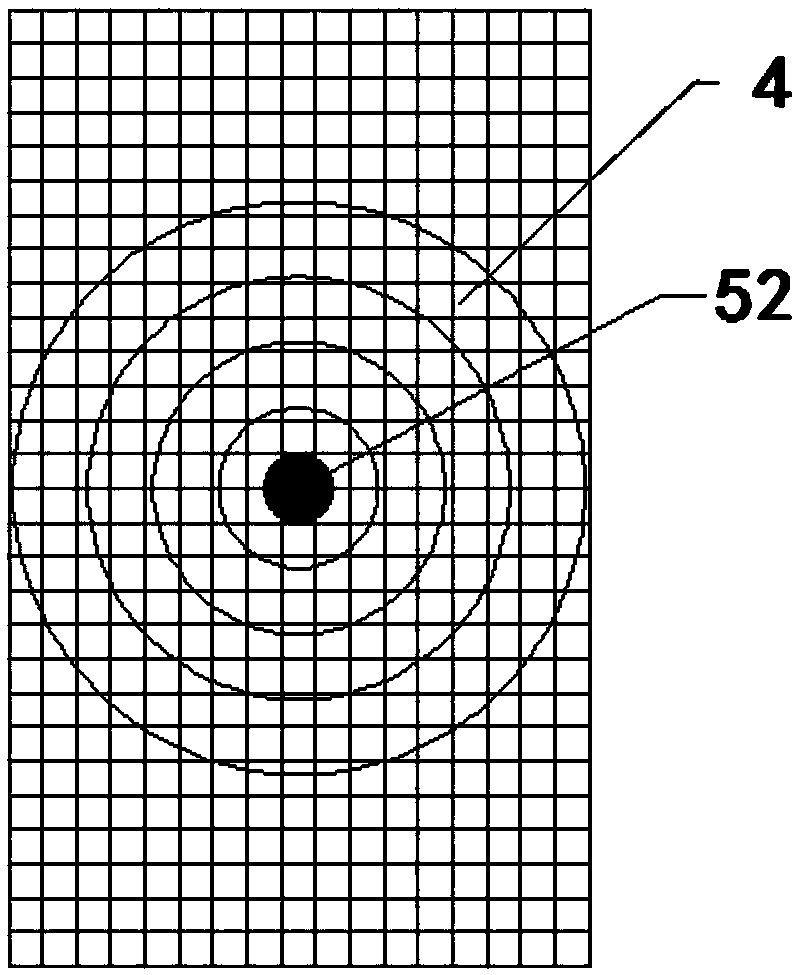

Island-basin combination excavation method for consequent operation of a major-diameter round no-inner support deep foundation pit

InactiveCN102704495AAccelerate the progress of excavationReduce exposure timeExcavationsResidual soilsDeformation control

The invention discloses an island-basin combination excavation method for consequent operation of a major-diameter round no-inner support deep foundation pit. The island-basin combination excavation method comprises the following steps: firstly processing a top soil mass by island type excavation, constructing a top round soil mass, and then excavating a middle soil mass and timely constructing a round purlin of the top layer; if the round purlin of the top layer achieves the design strength, firstly excavating a lower round soil mass, timely constructing a lower round purlin and then excavating a lower middle soil mass; if the round purlin of the top layer is not formed or does not achieve the design strength, on the premise of satisfying the foundation pit deformation control requirement, firstly excavating the lower middle soil mass, and then excavating the round soil mass; and finally excavating the residual soil mass of the layer. The island-basin combination construction method is used and then the island-basin combination excavating operation way closely joined with enclosing structure construction is formed. The excavation progress of the foundation pit is quickened, the exposure time of the foundation pit is reduced and the deformation control of the enclosing structure and the ambient environment protection are facilitated.

Owner:SHANGHAI CONSTRUCTION GROUP +1

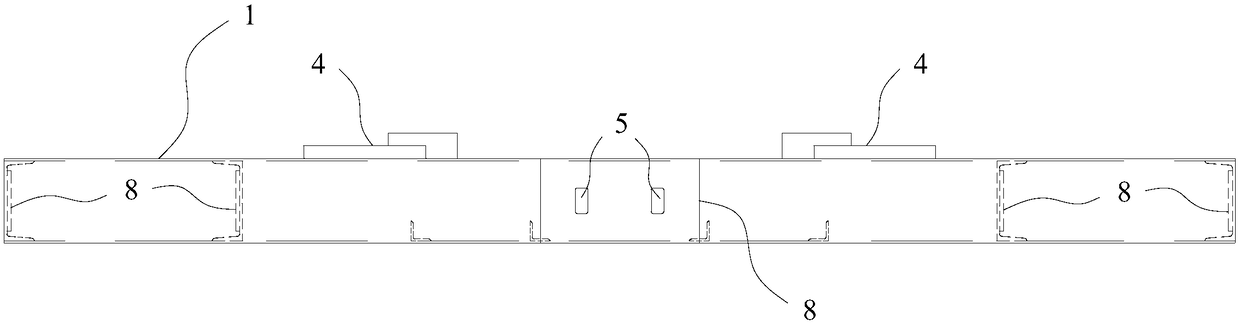

Installation platform of reinforcement cage and using method thereof

The invention discloses an installation platform of a reinforcement cage and a using method thereof. The installation platform comprises a body which contains a cuboid, the body is provided with a through hole, the diameter of the through hole is matched with the diameter of a protective cylinder, the height of the lower surface of the body is larger than the height of the top face of the protective cylinder, at least two limiting parts are arranged on the upper surface of the body, and the front ends of all the limiting parts extend into the through hole; the front ends of all the limiting parts are concentric, all the front ends are concentric with the protection cylinder, and at least one communicating hole channel is formed in each side face of the body; and the sizes of the hole channels are adaptive in the sizes of bolts, and all the bolts are used for being connected with the body and the reinforcement cage. By the adoption of the device, the operation platform can be provided when the reinforcement cage is installed and concrete is poured, so that the installation stability of the reinforcement cage is ensured, the construction difficulty of workers is lowered, the construction efficiency is improved, the operation progress is accelerated, the positioning of the reinforcement cage is effectively realized, and the installation quality of the reinforcement cage is improved.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

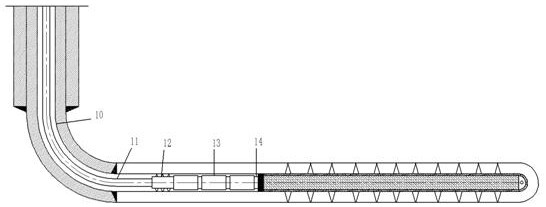

Casing scraper

InactiveCN107201889ACompact and reasonable structureEasy to useCleaning apparatusEngineeringScrew thread

The invention discloses a casing scraper. The casing scraper is characterized in that the middle of the inner side of an upper connector is fixedly connected with the upper end of the outer side of a body; the middle of the inner side of a lower connector is fixedly connected with the lower end of the outer side of the body; a radially retractable scraping pipe sleeves the body and is positioned between the upper connector and the lower connector, and scraping teeth are arranged on the scraping pipe; the scraping pipe comprises an upper connecting head, a lower connecting head and at least two elastic scraping sheets; the axially retractable elastic scraping sheets which are circumferentially distributed are arranged between the upper connecting head and the lower connecting head in a fixedly connected manner, and each elastic scraping sheet is in the shape of an arch with a high middle and two low sides. The casing scraper has the advantages that the casing scraper comprises a drop-proof connector, the upper portion of the casing scraper is mounted on the lower portion of the lower connector in a threaded manner when the casing scraper is used, a first lower connector with the casing scraper can idle when strings reversely rotate in repeated scraping and string tripping procedures, threaded connection between the first lower connector and the casing scraper can be prevented from being loosened, the casing scraper can be prevented from dropping in service procedures, and the problem of downhole accidents due to the fact that existing scrapers are released and fall into wells can be solved.

Owner:YANCHENG DONGRONG PETROLEUM MACHINERY CO LTD

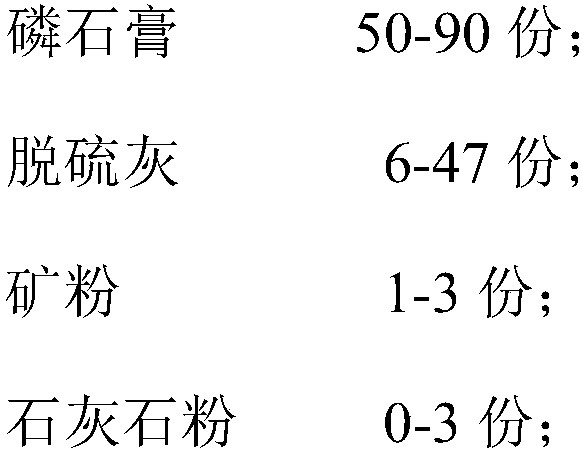

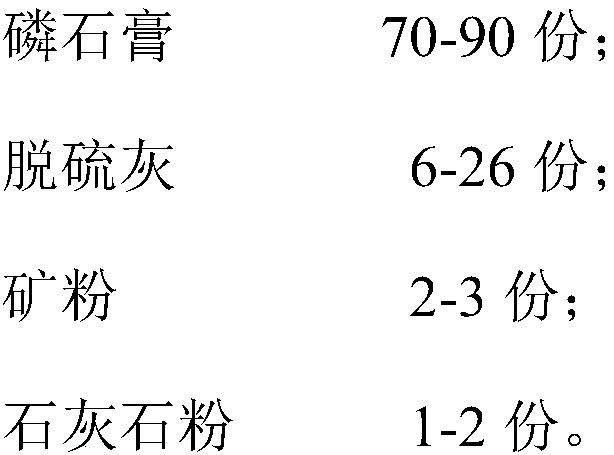

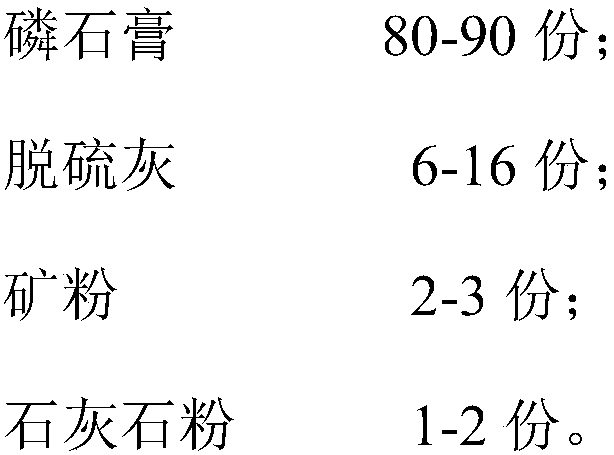

Cement retarder as well as preparation method and application thereof

The invention relates to a cement retarder which is prepared from the following raw materials in parts by weight: 50 to 90 parts of ardealite, 6 to 47 parts of desulfurized fly ash, 1 to 3 parts of mineral powder and 0 to 3 parts of limestone flour, wherein the specific surface area of the mineral powder is more than or equal to 500 m<2> / Kg. The cement retarder realizes comprehensive treatment ofthe desulfurized fly ash and the ardealite through simple measures, so that wastes are turned into treasures, energy is saved, and the environment is protected; furthermore, the cement retarder is economical, practical and low in cost. The dilemma problem of occupation and environmental pollution which are caused by low utilization rate of the desulfurized fly ash and the ardealite for an enterprise is relieved, and a qualified cement retarder is provided for a cement production enterprise; therefore, the cement retarder has a very wide application prospect.

Owner:华润水泥技术研发(广西)有限公司

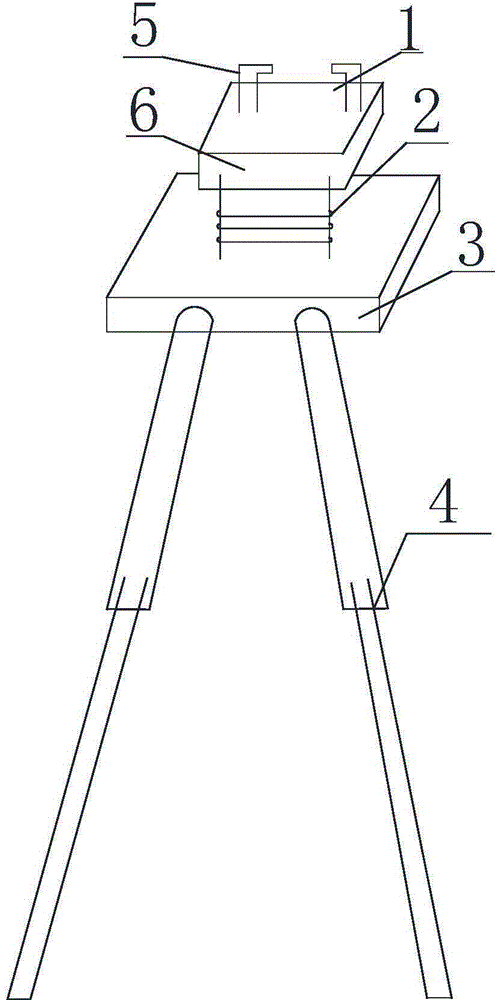

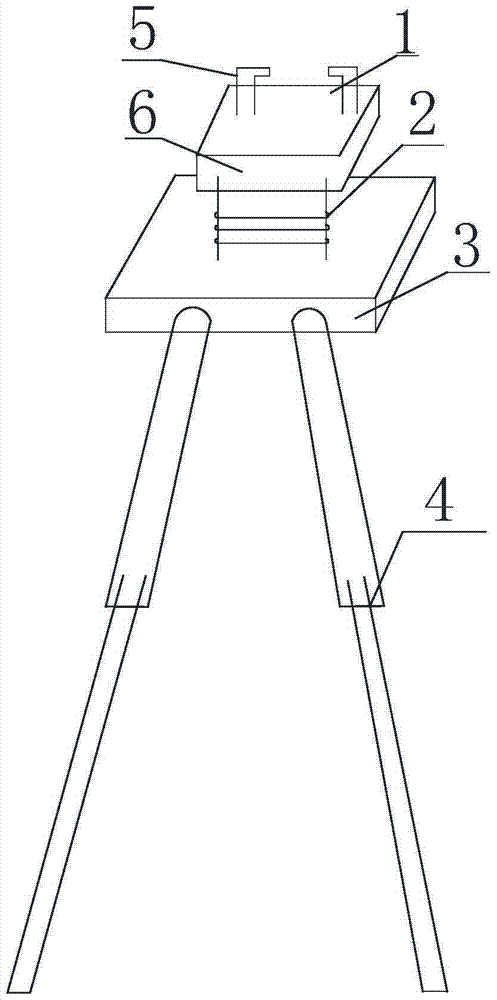

Light portable rock drill shock absorption support

InactiveCN104481415AReduce labor intensitySave human resourcesDerricks/mastsWork benchesEngineeringUltimate tensile strength

The invention provides a light portable rock drill shock absorption support, and belongs to the shock absorption support device field. The light portable rock drill shock absorption support solves the defects that an existing portable rock drill is low in work efficiency, large in action intensity and poor in automation degree. The light portable rock drill shock absorption support comprises a bottom seat, wherein a shock absorber is connected with the upper portion of the bottom seat, the upper portion of the shock absorber is connected with a clamp groove, the lower portion of the bottom seat is connected with frame legs, and the frame legs are designed in a telescopic type. The frame legs are connected with the bottom seat through a spherical pair, and the number of the frame legs is two. The light portable rock drill shock absorption support can achieve single person and single machine operation for the portable rock drill, reduces labor intensity, improves work efficiency, averagely saves four or five persons for one work face, and not only achieves the effects of saving manpower resources and reducing labor intensity of workers, but also accelerates operation progress.

Owner:SHANDONG UNIV OF SCI & TECH

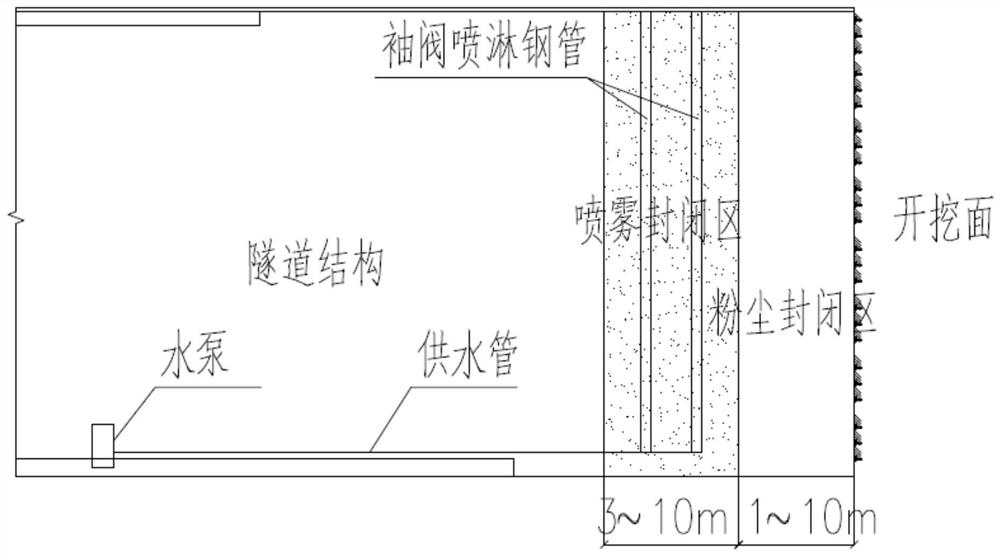

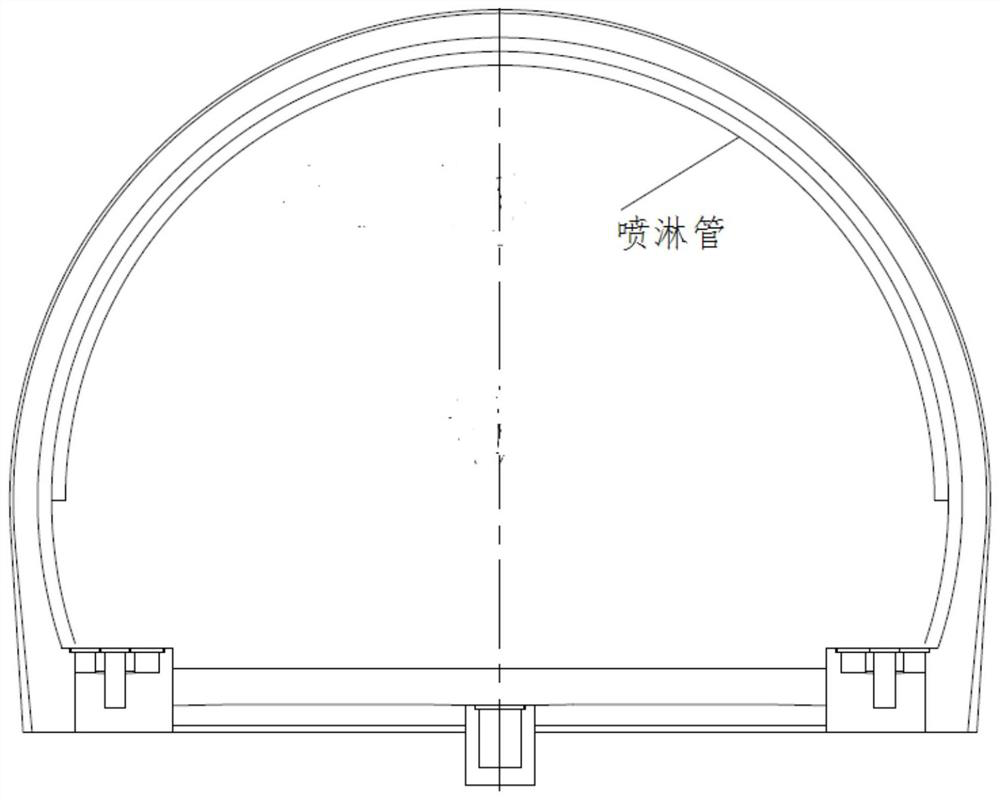

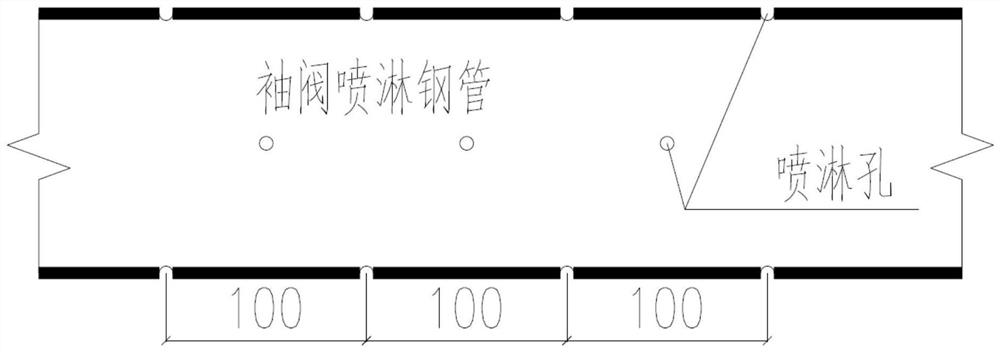

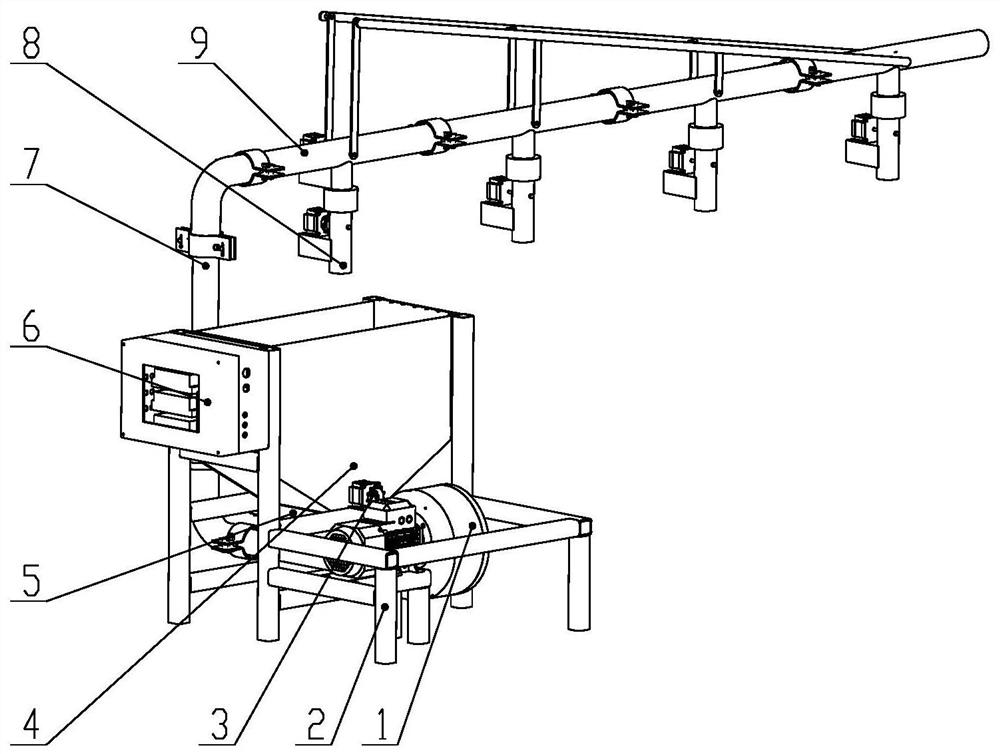

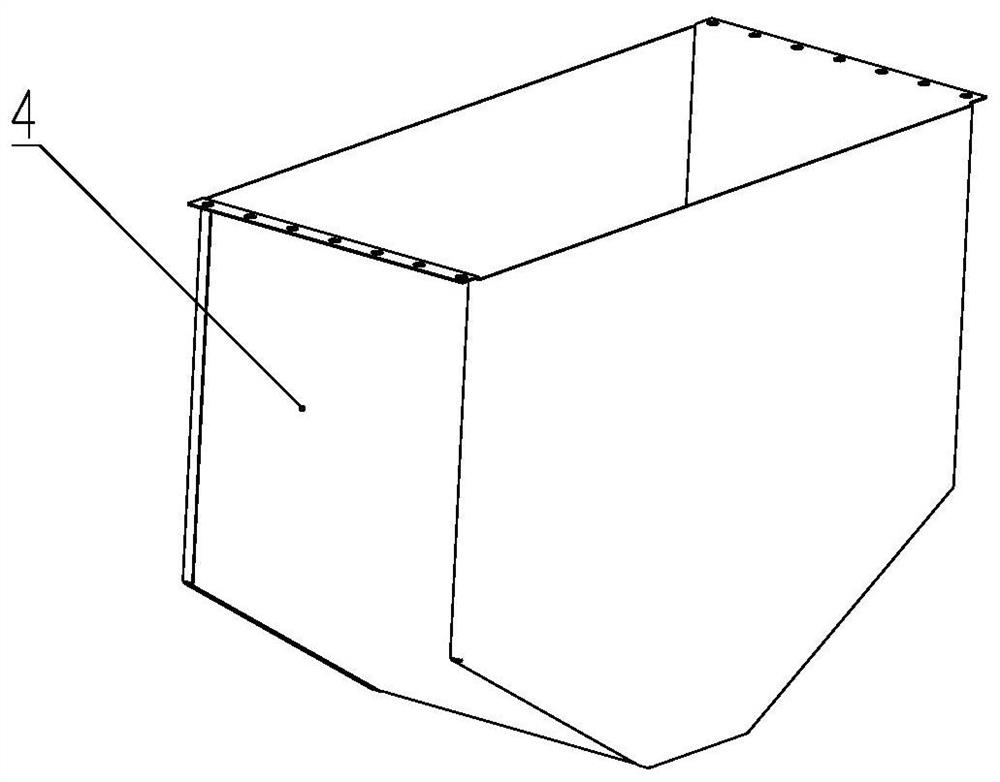

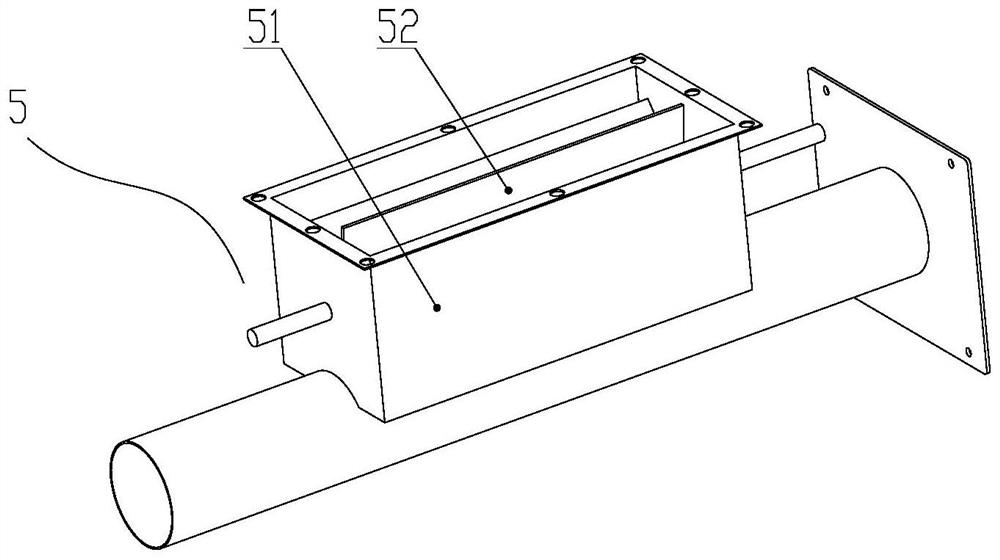

Tunnel engineering mining method excavation blasting instantaneous dust fall process

InactiveCN112709593AShorten the lockout periodSolve problems that are difficult to eliminate quicklyDust removalFire preventionDetonatorDetonation

The invention discloses a tunnel engineering mining method excavation blasting instantaneous dust fall process. The tunnel engineering mining method excavation blasting instantaneous dust fall process is used for effectively utilizing blasting shock waves to form a high-density water mist closed area at the front end of a tunnel excavation face during mining method excavation blasting. The tunnel engineering mining method excavation blasting instantaneous dust fall process comprises the steps that after waterproof explosives and waterproof detonating detonators are installed on the tunnel excavation face, simple sleeve valve steel pipe mist spraying equipment is adopted in the range away from a dust dense area of a blasting face, spraying is carried out for more than 5 minutes, the water mist closed area is formed, then detonation blasting is carried out, high-speed vibration impact is carried out through the blasting shock waves, dust molecules and high-density water molecules move relatively at a high speed in the water mist closed area, mixed and dried dust particles rapidly absorb the water molecules in the water mist, the weight of the water molecules is sharply increased, the water molecules rapidly fall onto the ground, and the purpose of instantaneous dust removal is achieved. The tunnel engineering mining method excavation blasting instantaneous dust fall process effectively solves the problem that dust in tunnel engineering mining method excavation blasting is difficult to quickly eliminate.

Owner:张俊

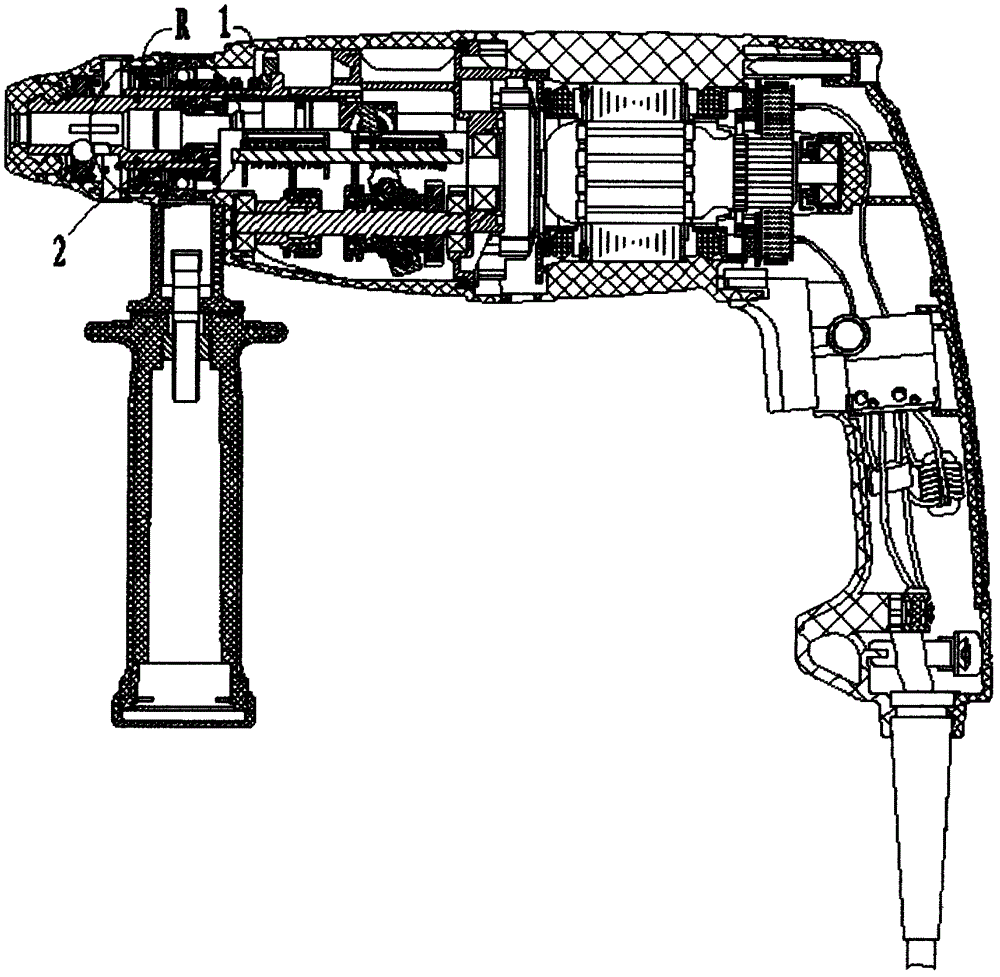

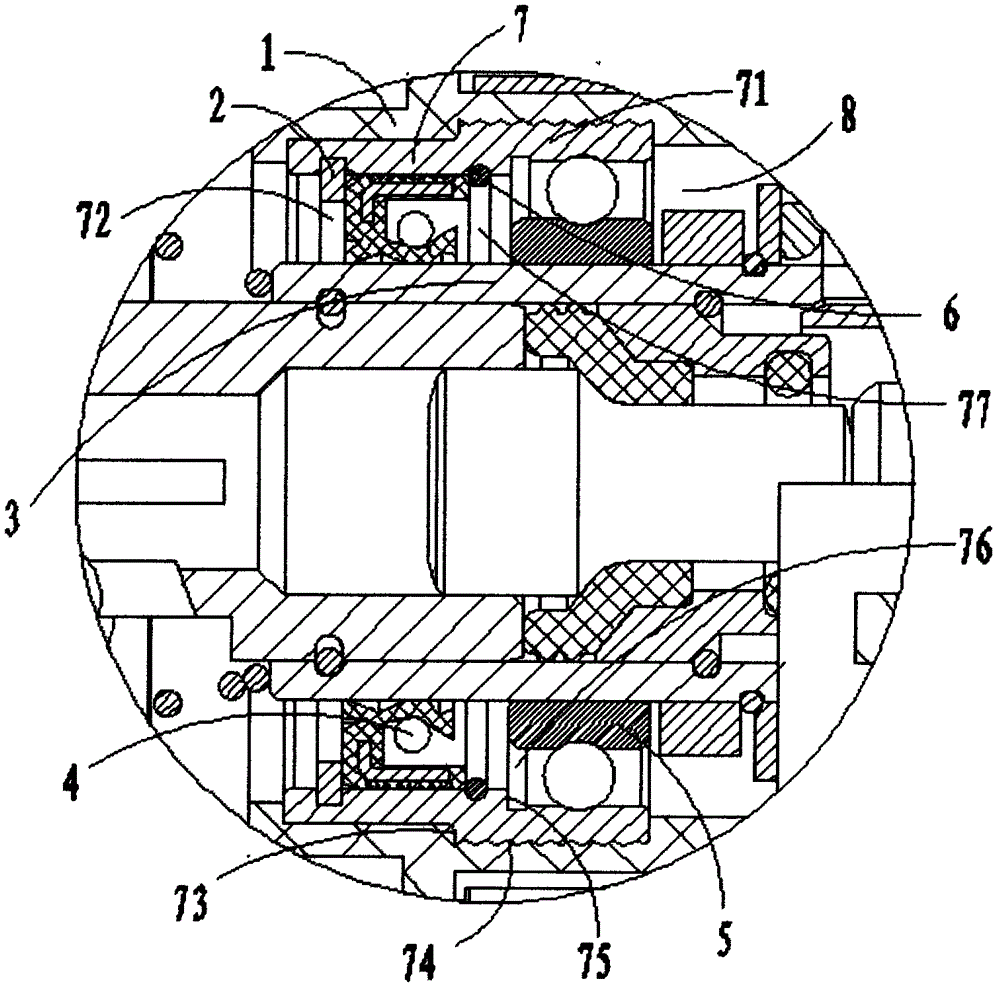

electric hammer

ActiveCN102501223BPlay a sealing roleImprove coaxialityPortable percussive toolsLow noiseMechanical engineering

The invention discloses an electric hammer which comprises a head shell and a rotary sleeve. A through hole is arranged in the head shell. The rotary sleeve is positioned in the through hole. A bearing and a sealing ring are respectively arranged between the head shell and the rotary sleeve. The sealing ring is positioned at one side of the bearing. The rotary sleeve can rotate relative to the head shell. An outer ring of the bearing extends towards the side of the sealing ring to form a supporting ring. The width of the supporting ring is greater than the width of an inner ring of the bearing. The outer peripheral surface of the sealing ring is abutted against and connected with the inner peripheral surface of the supporting ring. The inner peripheral surface of the sealing ring is abutted against and connected with the outer peripheral surface of the rotary sleeve. The supporting ring is fixedly connected with the inner wall of the through hole of the head shell. The electric hammer has the beneficial effects that the problem of oil leakage is fundamentally solved; the operating efficiency and the working accuracy can also be improved; and the service life of the electric hammer is prolonged; and the electric hammer is energy-saving and has low cost and low noise.

Owner:ZHEJIANG BENYU TOOLS

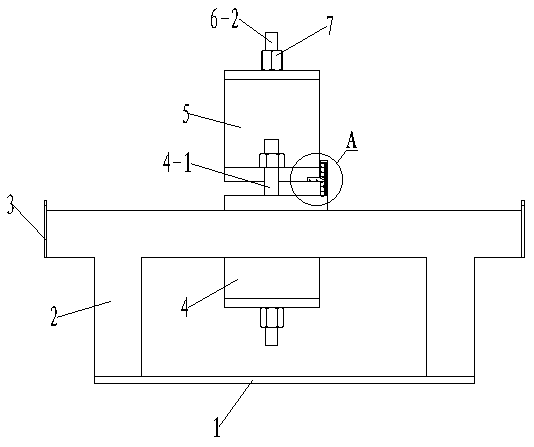

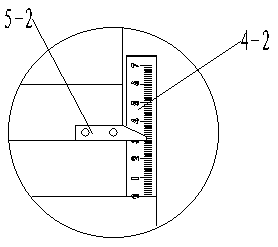

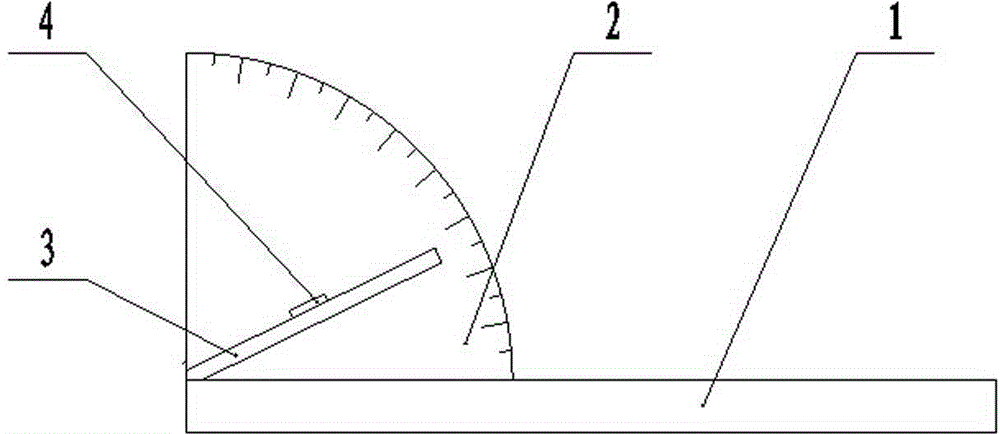

Photovoltaic battery panel mounting positioner

InactiveCN104702201AEasy to adjustReasonable and reliable structural designPhotovoltaic supportsPhotovoltaic energy generationProtractorPhotovoltaic power station

The invention relates to solar photovoltaic power station mounting positioning devices, particularly to a photovoltaic battery panel mounting positioner. The photovoltaic battery panel mounting positioner solves the problem that existing battery panel positioning is poor in precision and low in efficiency. The photovoltaic battery panel mounting positioner comprises a stripe base, and the top of either the left or the right of the stripe base is fixedly and perpendicularly provided with a right-angle fan-shaped protractor; one right-angle side of the fan-shaped protractor coincides with the stripe base, the other right-angle side of the fan-shaped protractor is perpendicular to the stripe base, the fan-shaped protractor is provided with a pointer rotating around the axis of the fan-shaped protractor, and the middle of the pointer is provided with a gradienter. The photovoltaic battery panel mounting positioner is reasonable and reliable in structural design and can rapidly and precisely adjusting a battery panel to be perpendicular to sunlight no matter the battery panel is placed onto a horizontal ground or an inclined roof surface, thereby maximizing the photoelectric conversion efficiency and improving the positioning precision, and meanwhile, accelerating the operation progress. The photovoltaic battery panel mounting positioner has the advantages of being simple in structure, convenient to process and low in cost.

Owner:STATE GRID CORP OF CHINA +1

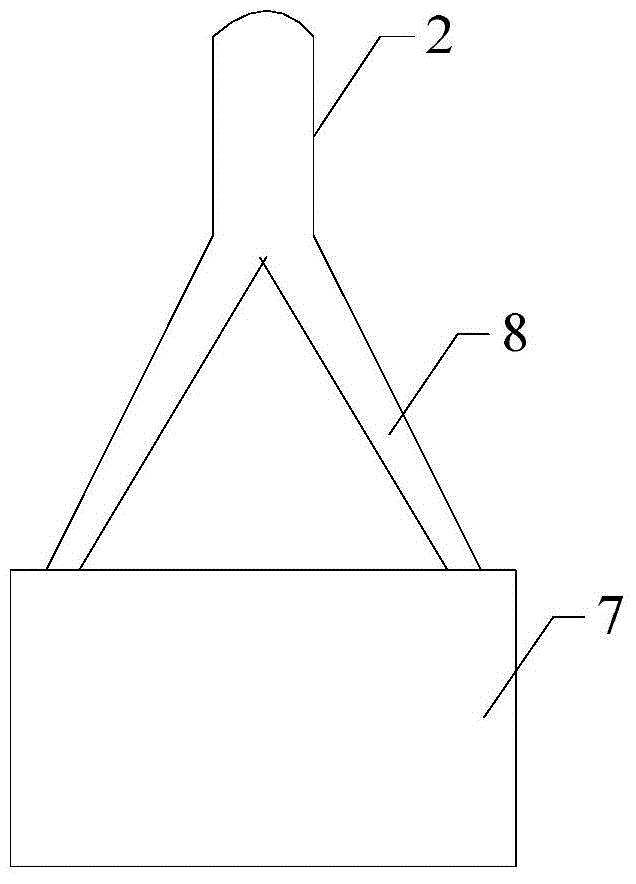

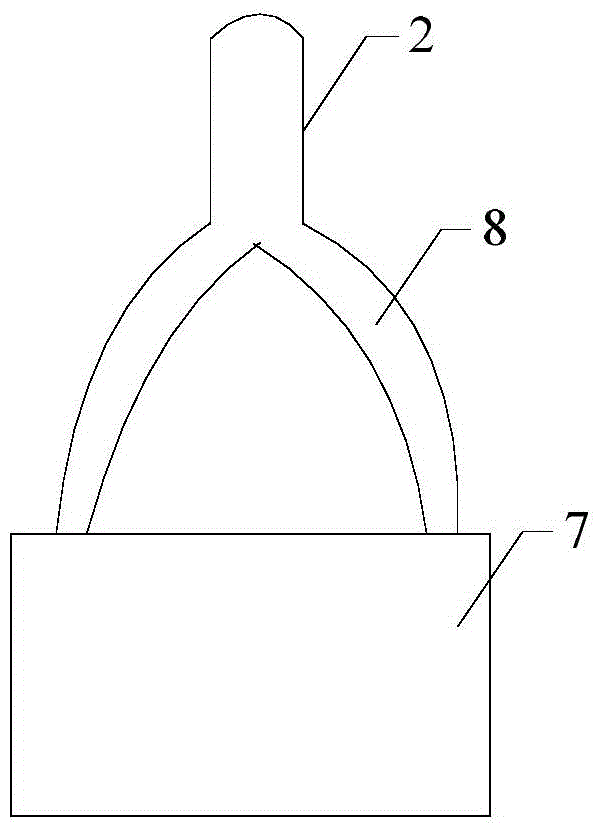

Embedded-type overturn-preventing limiting device for mast hoisting construction and construction method of device

PendingCN109057507ASimple structureIngenious designTowersArchitectural engineeringEngineering plastic

The invention discloses an embedded-type overturn-preventing limiting device for mast hoisting construction and a construction method of the device. The limiting device comprises a square bottom plate, arc plates, a covering layer and a protection layer; the arc plates are arranged on a pair of opposite sides of the upper surface of the square bottom plate, and the two ends of the arc plate are fixedly connected with the bottom plate; the covering layer is arranged on the outer side face of the arc plate, and the outer side face of the covering layer is coated with the protection layer. The arc plates are first arc plates or second arc plates; the first arc plates are in an arc shape, and the arc center angle is 0-180 degrees; the second arc plates are in a U shape. The covering layer is an engineering plastic alloy plate. The device is simple in structure, novel in design, easy to manufacture and universal. Through the arrangement of the embedded-type overturn-preventing limiting device, the construction safety and construction quality are effectively guaranteed, and the construction cost is also reduced. By means of the construction method, the situation can be avoided that sincean inverted-installation hoisting construction technology is usually adopted for existing construction of an television tower towering steel mast, the gravity center of the steel mast is above the hoisting suspension point.

Owner:CHINA CONSTR SECOND BUREAU INSTALLATION ENG

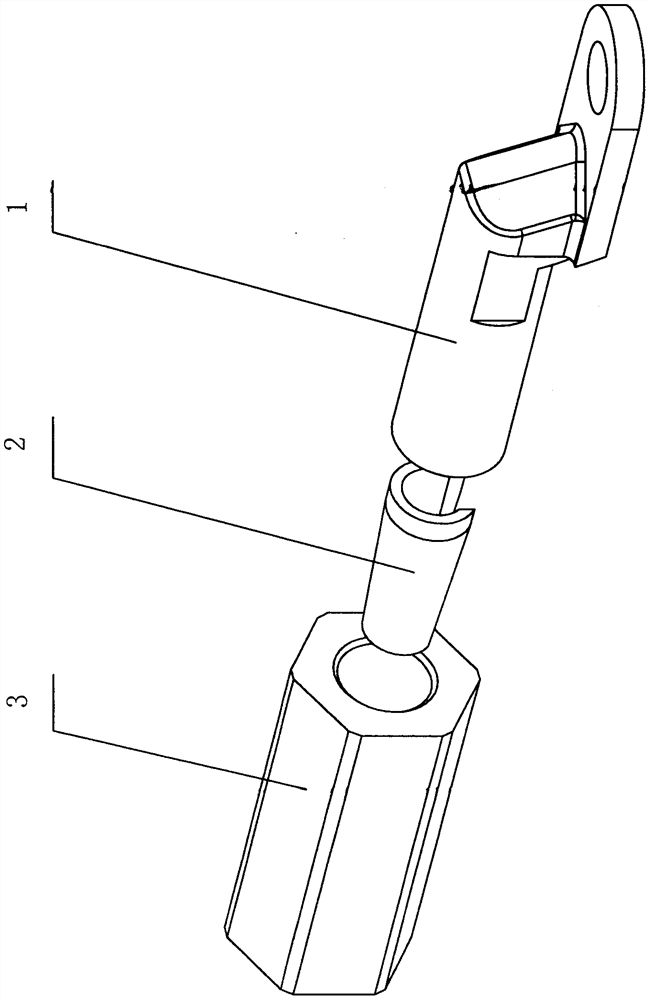

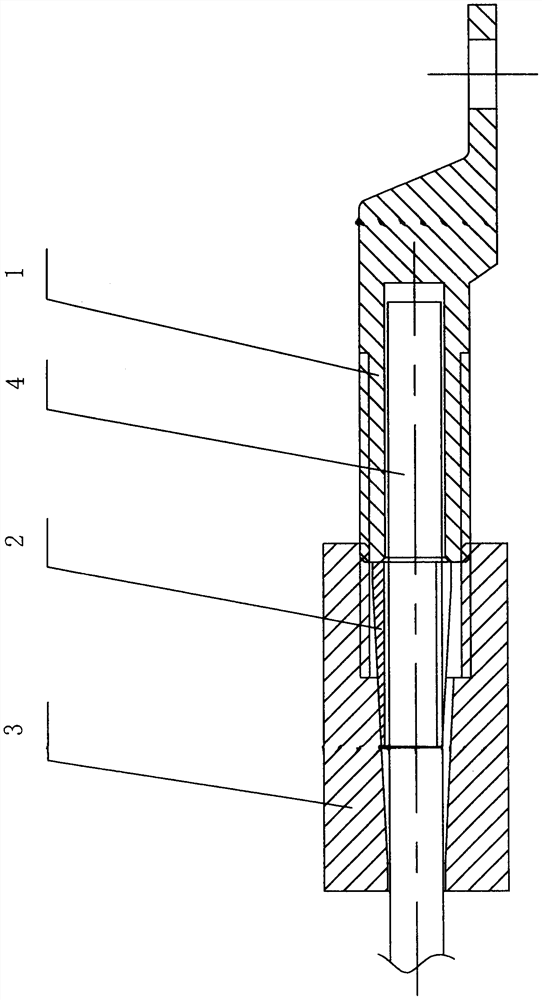

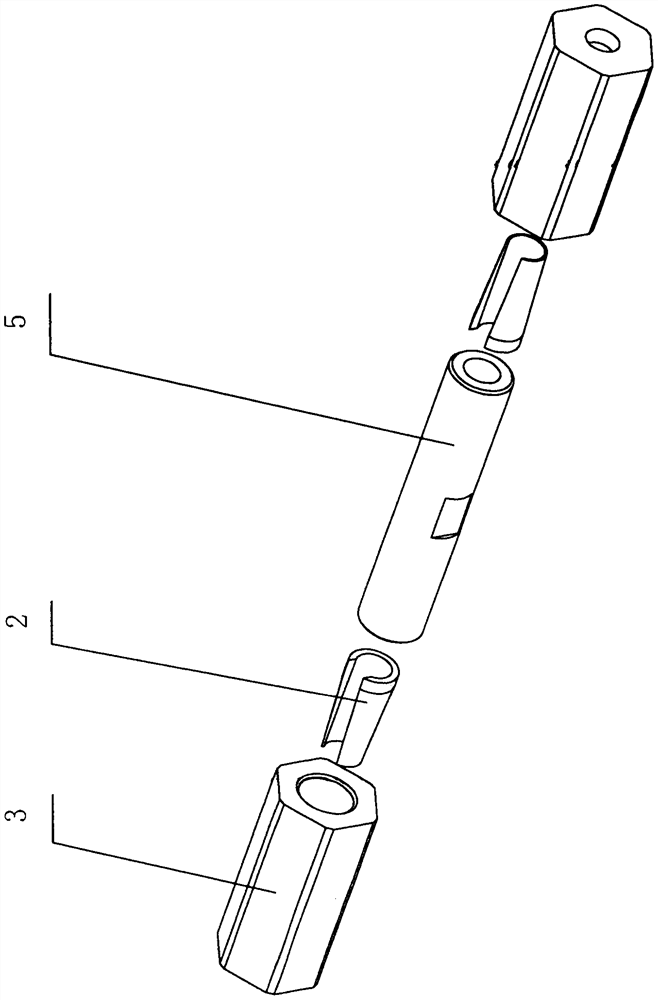

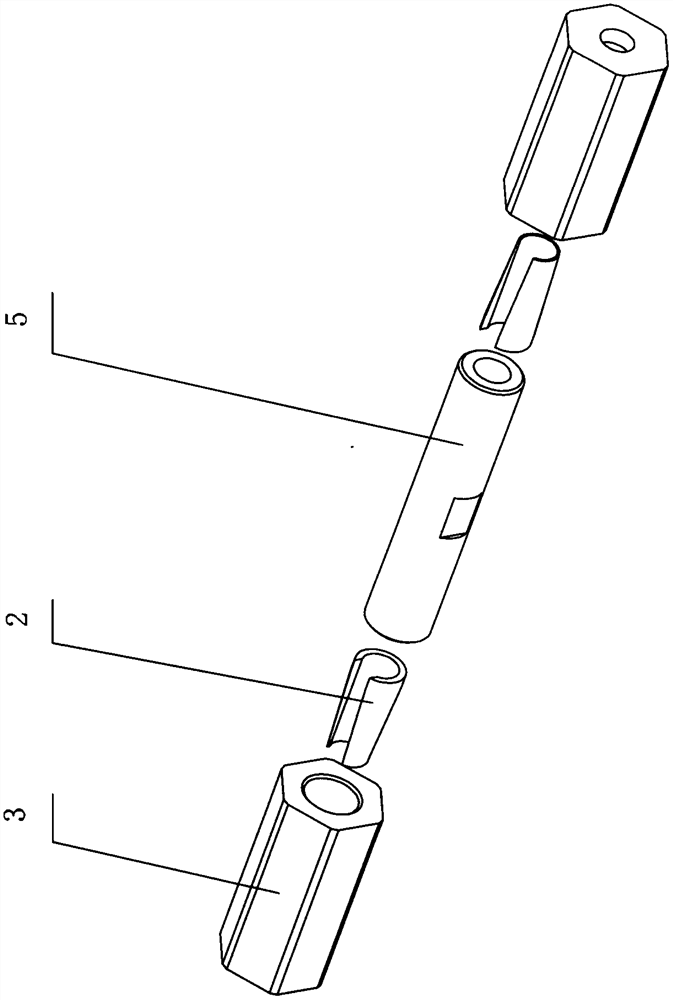

External conductive cable connector

InactiveCN112382866AFirmly connectedAvoid deep processingClamped/spring connectionsMulticonductor cable end piecesMechanical engineeringElectrical and Electronics engineering

The invention discloses an external conductive cable connector, and the connector comprises a clamping piece, a conductive wiring lug and a locking threaded sleeve; the sleeve head of the conductive wiring lug is provided with an external thread, the clamping piece is a conductive conical shrinkage sleeve provided with an axial shrinkage groove, and the sleeve hole of the locking threaded sleeve is an internal threaded hole and a conical hole which are coaxial. A cable core of the conductive cable penetrates through a sleeve hole of the locking threaded sleeve and is arranged in a sleeve holein the head end of the conductive wiring lug sleeve, the conductive conical contraction sleeve is sleeved on the cable core and is arranged in a sleeve hole of the locking threaded sleeve, and the locking threaded sleeve is screwed on a sleeve head of the conductive wiring lug. The screwed-in locking screw sleeve enables the conductive conical contraction sleeve to axially abut against the sleevehead end of the conductive wiring lug and then radially contracts the conductive conical contraction sleeve so as to clamp the wire core. According to the invention, deep processing of the conductivewiring lug is avoided, and the operation progress is accelerated.

Owner:南京市高靠线路器材制造有限公司

Tree digging machine

The invention discloses a tree digging machine which comprises a second fixing plate, a mounting plate, a casing and a rotating wheel. A belt box is mounted on the front face of the casing, a large belt pulley and a small belt pulley are mounted in the belt box, a hydraulic motor is mounted at the top of the casing through a fixing component, the output end of the hydraulic motor is connected withthe large belt pulley on the belt box, the rotating wheel is mounted in the casing through a second rotating shaft, the large belt pulley is connected with the second rotating shaft through the smallbelt pulley, an oil pipe is mounted at the input end of the hydraulic motor, and the mounting plate is mounted on one side of the casing. Through a series of structure compositions of the second fixing plate, the mounting plate, the casing and the rotating wheel and the like, compared with a conventional tree digging machine, the tree digging machine is more convenient to use and is simplified onthe whole, so that workers operate and control the tree digging machine more conveniently during operation, the tree digging machine control difficulty is lowered, the tree digging fault occurrence rate is reduced, and the tree digging machine is high in practicality and worth popularizing and using.

Owner:钟山县高新果业发展有限公司

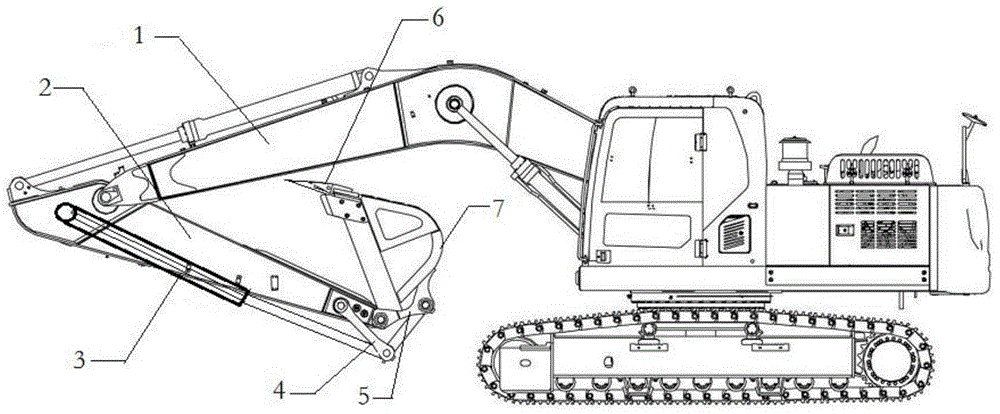

Small excavator with double support arms

InactiveCN104975625AImprove job stabilityStable supportMechanical machines/dredgersExcavatorDouble support

The invention discloses a small excavator with double support arms, which comprises a bucket rod, two hinged seats, two support arm oil cylinders and a bucket, wherein the bucket rod is arranged between a moving arm and the bucket, and comprises a first bucket rod and a second bucket rod which are hinged with each other from the head to the tail, the front part of the second bucket rod is divided into two support arms which are equal in length, the front ends of the two support arms are pin-jointed with the bucket, the two hinged seats are respectively arranged on pin-jointed positions of the front ends of the two support arms and the bucket, the two support arm oil cylinders are respectively arranged on the outer sides of the two support arms, the bucket comprises a bucket main body, a bucket seat and a bucket tooth, the bucket seat is pin-jointed with the front ends of the two support arms, the bucket tooth is of an isosceles triangle, and sawteeth are uniformly distributed on the two equal sides of the isosceles triangle. The small excavator with the double support arms is reasonable in design, improves excavating strength, stabilizes excavating operation performance, can not cause mechanical injury to the bucket rod during the excavating operation, and prolongs service life.

Owner:吴爱群

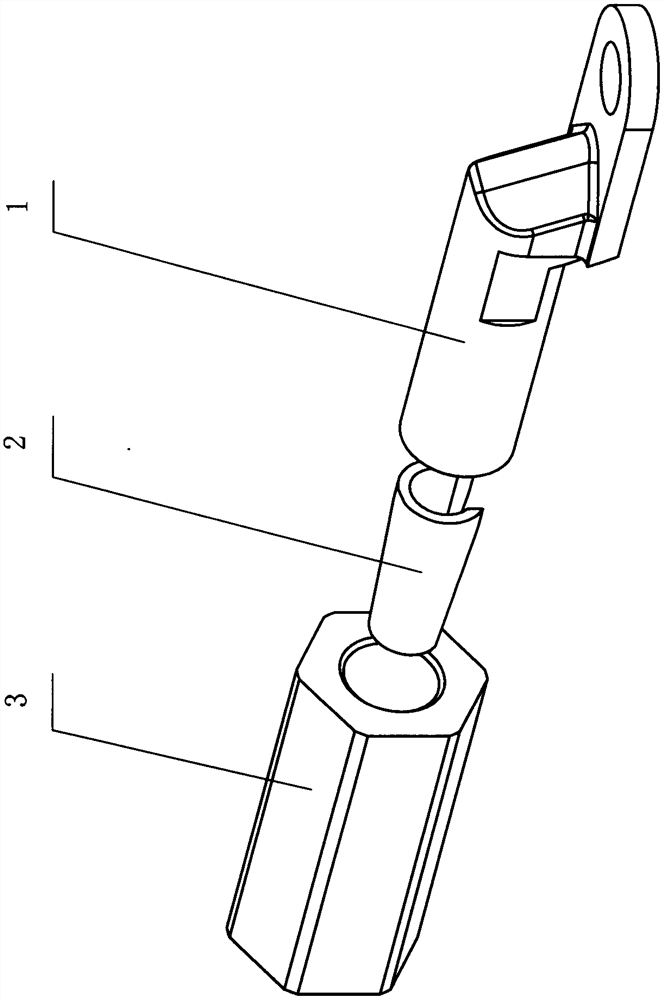

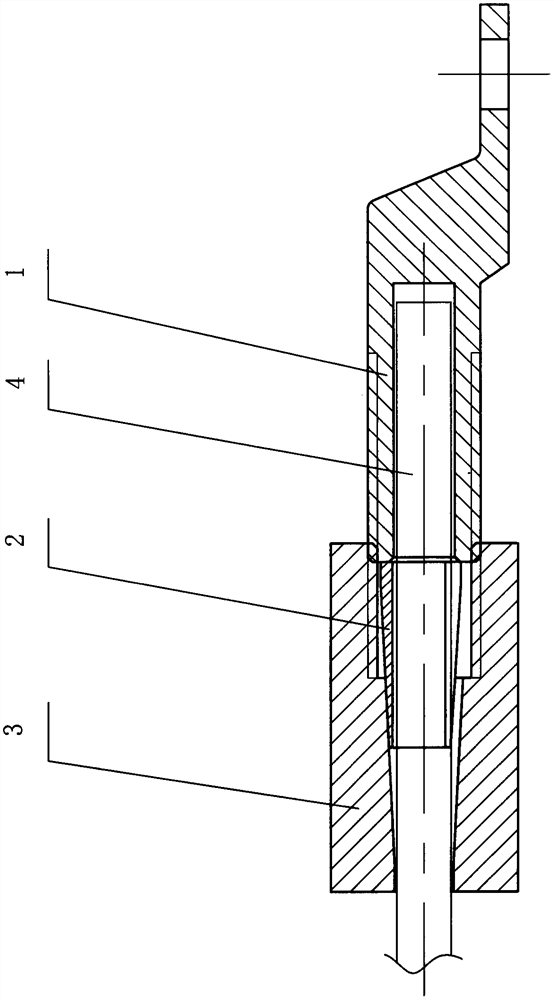

External conductive cable connector

PendingCN113161770AFirmly connectedAvoid deep processingClamped/spring connectionsMulticonductor cable end piecesEngineeringMechanical engineering

An external conductive cable connector disclosed by the invention comprises a clamping piece, a conductive wiring lug and a locking screw sleeve. The sleeve head of the conductive wiring lug is provided with an external thread, the clamping piece is a conductive conical shrinkage sleeve provided with an axial shrinkage groove, the sleeve hole of the locking screw sleeve is an internal threaded hole and a conical hole which are coaxial, a cable core of the conductive cable penetrates through the sleeve hole of the locking screw sleeve and is arranged in a sleeve hole in the head end of the conductive wiring lug sleeve, the conductive conical shrinkage sleeve is arranged on the cable core in a sleeved mode and is arranged in the sleeve hole of the locking screw sleeve, and the locking screw sleeve is screwed to a sleeve head of the conductive wiring lug. The screwed-in locking screw sleeve axially abuts the conductive conical shrinkage sleeve against the sleeve head end of the conductive wiring lug and then radially contracts the conductive conical shrinkage sleeve so as to clamp the wire core. According to the invention, deep processing of the conductive wiring lug is avoided, and the operation progress is accelerated.

Owner:南京市高靠线路器材制造有限公司

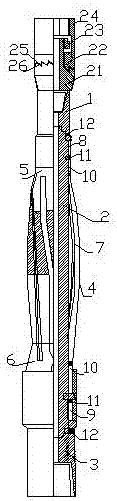

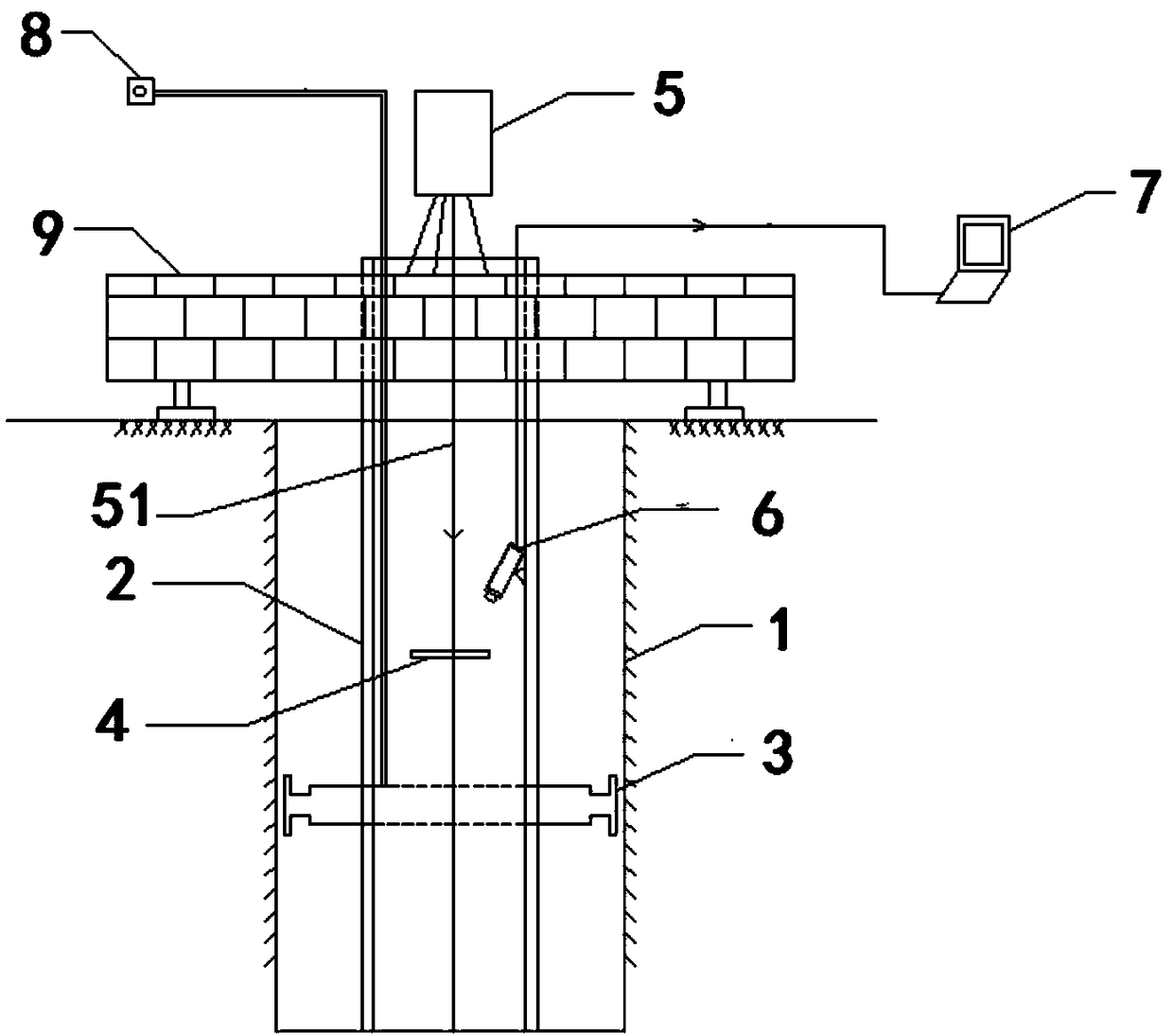

Installation and positioning method of super-deep and large-diameter steel pipe columns

ActiveCN106958244BEasy to adjustSpeed up work progressBulkheads/pilesStructural engineeringLaser beams

The invention discloses a mounting positioning method of an ultra-deep large-diameter steel pipe column. The method comprises the following steps: step 1, calculating water filling height in the steel pipe column; step 2, arranging four jacks at the lower part of the steel pipe column, and horizontally mounting a positioning plate in the steel pipe column; step 3, vertically hoisting the steel pipe column to a designed position in a cast-in--situ pile, wherein water is gradually added to the steel pipe column during the hoisting until the water filling height calculated in step 1; and arranging a laser plummet of which laser beams are overlapped with a designed axis of a cast-in-situ bored pile on the top part of the steel pipe column; and step 4, determining the offset of the steel pipe column according to the position relation of the laser beams and a positioning plate; calibrating the position of the steel pipe column through the four jacks; and then enabling telescoping rods of the four jacks to be against the inner wall of a bored hole of the cast-in-situ bored pile after calibrating, thus finishing the positioning of the steel pipe column. The method is simple to operate, low in safety risk, and high in mounting and positioning accuracy; in addition, the visualized mounting and positioning construction of the steel pipe column is achieved.

Owner:中铁隧道局集团建设有限公司

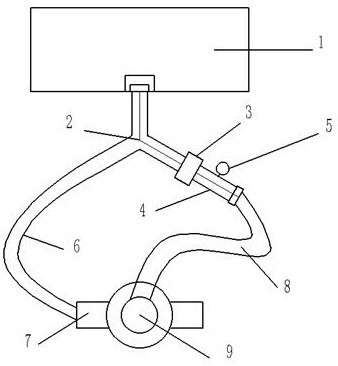

A fishing device and method for a sand-buried pipe string in an oil-water well

ActiveCN109252824BImprove timelinessIncrease success rateBorehole/well accessoriesLine tubingOil water

The invention discloses a fishing device and method for an underground sand-buried pipe string in an oil-water well. The device includes a ground pressure pipeline and an underground fishing pipe string. The starting ends of the high-pressure pipeline and the second high-pressure pipeline are respectively connected to two branch ports of the same tee, the main inlet of the tee is connected to the pump truck, and the end of the first high-pressure pipeline is connected to the oil pipe joint at the upper port of the downhole fishing string, The end of the second high-pressure pipeline is connected to the casing joint of the wellhead. A pressure test cylinder and a valve are arranged between the first high-pressure pipeline and the tee, and a pressure gauge is installed on the pressure test cylinder. The invention solves the difficult problem of insufficient salvage force due to serious sand burial in the salvage operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

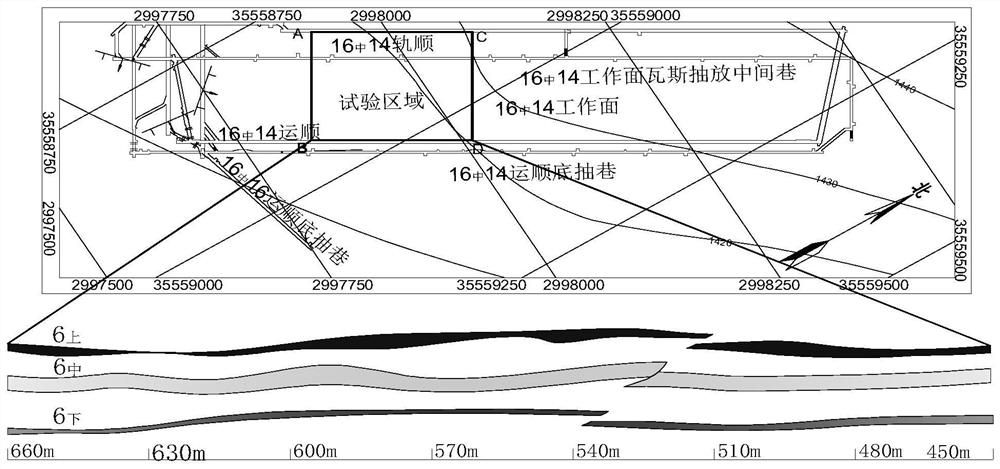

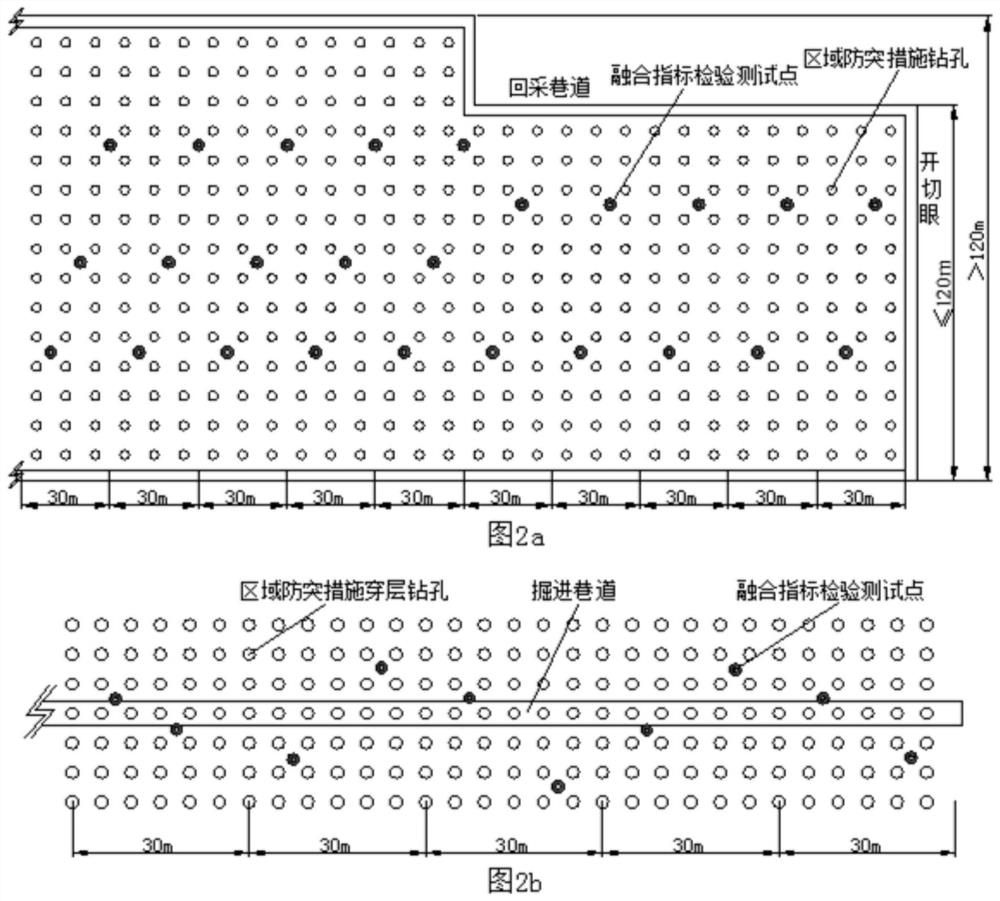

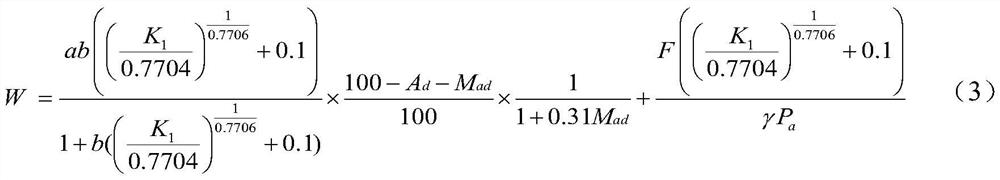

Close-range adjacent outburst coal seam fusion index area verifying method

PendingCN113446063AImprove verification work efficiencySpeed up work progressMining devicesSafety equipmentsClose rangeChemistry

The invention relates to a close-range adjacent outburst coal seam fusion index area verifying method, belongs to the technical field of coal mine safety, and mainly aims at achieving the aims that when a close-range outburst coal seam group is mined and area outburst prevention measure effect inspection is performed on an adjacent outburst coal seam with the normal distance of less than 5 m from the coal seam and the average thickness of more than 0.3 m, measuring points are arranged in key areas with coal seam thickening and geologic structure occurrence, and area verification is carried out by measuring area and working face fusion indexes. The close-range adjacent outburst coal seam fusion index area verifying method comprises the implementation steps of advanced detection, fusion index testing, critical value determination and risk comprehensive judgment. The close-range adjacent outburst coal seam fusion index area verifying method improves the verification work efficiency of the adjacent outburst coal seam area, improves the operation progress of an outburst coal seam mining working face, realizes safe and efficient production of the outburst coal seam mining working face, provides a basis for adjacent outburst coal seam area verification under similar occurrence conditions, and provides thoughts and scientific practical experience for formulating related industry specification terms for adjacent outburst coal seam area verification.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST +1

Method for randomly adjusting blast-furnace tuyere air inlet area

InactiveCN111378800AAdjust the operating system in timeShorten working timeTuyeresBlast furnace detailsEngineeringBlast furnace

The invention discloses a method for randomly adjusting blast-furnace tuyere air inlet area. The method comprises the following steps that 1) a tuyere sleeve is manufactured in advance for standby, wherein the inner diameter of the small port end of the tuyere sleeve is phi 100 mm; 2) during blast furnace production, a tuyere small sleeve with the inner diameter of phi 125 mm or phi 120 mm is generally arranged, if the air inlet area needs to be reduced during blast furnace operation, the tuyere sleeve with the inner diameter of phi 100 mm is additionally arranged; 3) if the air inlet area ofthe blast furnace needs to be continued to be adjusted to be 0.259 square meter, before the tuyere sleeve is additionally arranged, a brick cutting machine is used for cutting off the small end of thetuyere sleeve by 10 mm, and then the inner diameter of the tuyere sleeve is changed from phi 100 mm to phi 105 mm; and 4) according to the different requirements of the air inlet area of the blast furnace, the brick cutting machine is used for sequentially cutting off the small end of the tuyere sleeve by the length of 10 mm so that the tuyere sleeve can be changed into tuyere small sleeves withdifferent inner diameter such as phi 105 mm, phi 110 mm, phi 115 mm, phi 120 mm and phi 125 mm, the different requirements of blast furnace operation are met, and the requirement of blast furnace production is met.

Owner:XINJIANG BAYI IRON & STEEL

A Lightweight Handheld Rock Drill Shock Absorbing Bracket

InactiveCN104481415BReduce labor intensitySave human resourcesDerricks/mastsWork benchesHand heldEngineering

Owner:SHANDONG UNIV OF SCI & TECH

A method and device for dynamic tracking and reseeding of small seeds

ActiveCN113196915BReduce damage rateEffectively match job progressSeed depositing seeder partsSeederAgricultural science

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Bidirectional regulation positioning buckle device for building construction cast-in-situ concrete combined template

InactiveCN101270611BReduce manufacturing costSimple structureAuxillary members of forms/shuttering/falseworksMaterial consumptionScrew thread

The invention discloses a double adjusting location locking device used for a cast-in-place compound template of building construction, which mainly consists of a pre-burying annular shelf provided with a convex column, an adjustable location fastener connected with the convex column in thread and an adjusting screw rod; the pre-burying annular shelf is arranged in a cast-in-place cavity formed bythe template and leads the adjusting screw rod to extend out of the wall of the template to reveal an adjusting square head; adjustable location fastener can be driven to rotate and move the templateto a needed position by turning the adjusting screw rod, then a locking nut is used to lock the template; the invention can simultaneously carry out double direction adjustment location to fix the compound template to form the cast-in-place cavity along the transverse and the longitudinal direction for the use of construction, has the advantages of precious adjusting location, convenient construction operation and saving construction material consumption, etc., besides, the invention has remarkable effects on improving the construction efficiency and the building engineering quality.

Owner:邹尧 +2

Maintenance operation control method based on mobile terminal

ActiveCN104902011BFacilitate communicationReduce riskResourcesTransmissionTime informationComputer terminal

The invention discloses an overhauling operation control method based on a mobile terminal. The method comprises the following steps: constructing an overhauling operation control platform based on the mobile terminal; constructing a software platform; and the software platform formulating a corresponding operation task according to the overhauling operation task, setting an instruction template and transmitting the task instruction to the corresponding first to Mth mobile terminals, the mobile terminal locking other mobile terminals and viewing the operation progress in real time and the like. The method has the advantages: real-time information communication is performed on the site operation condition by the mobile terminal, so that low efficiency caused by multiple calls or repeated communication with paper is avoided; and an operator uses the mobile terminal to remotely control an intelligent socket to achieve the purposes of intelligent power disconnection and power connection, so that intelligent early warning of potential safety hazards is realized, information can fed back to the mobile terminal and a mobile overhauling operation controller in real time, and the safety of site operation is ensured.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com