Patents

Literature

128results about How to "The process is closely connected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

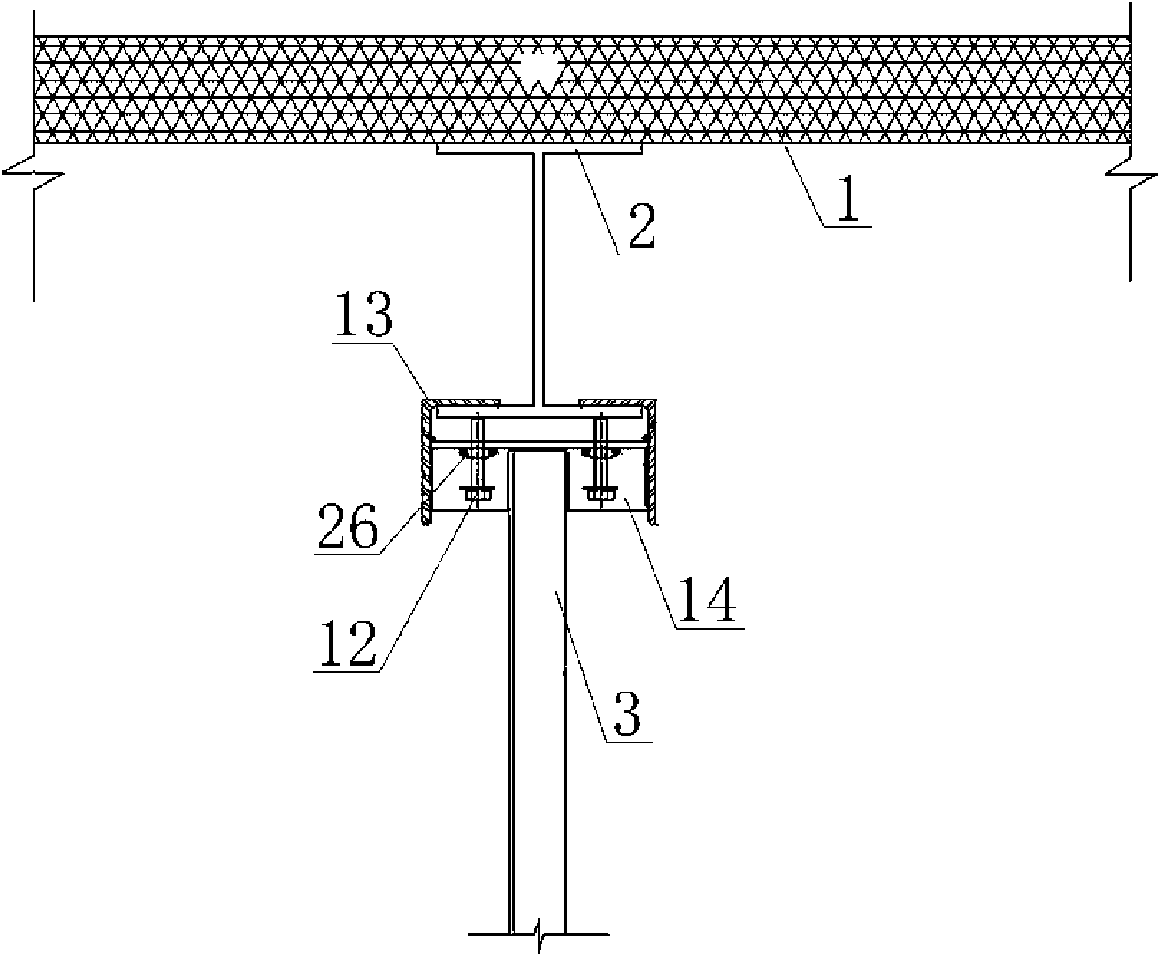

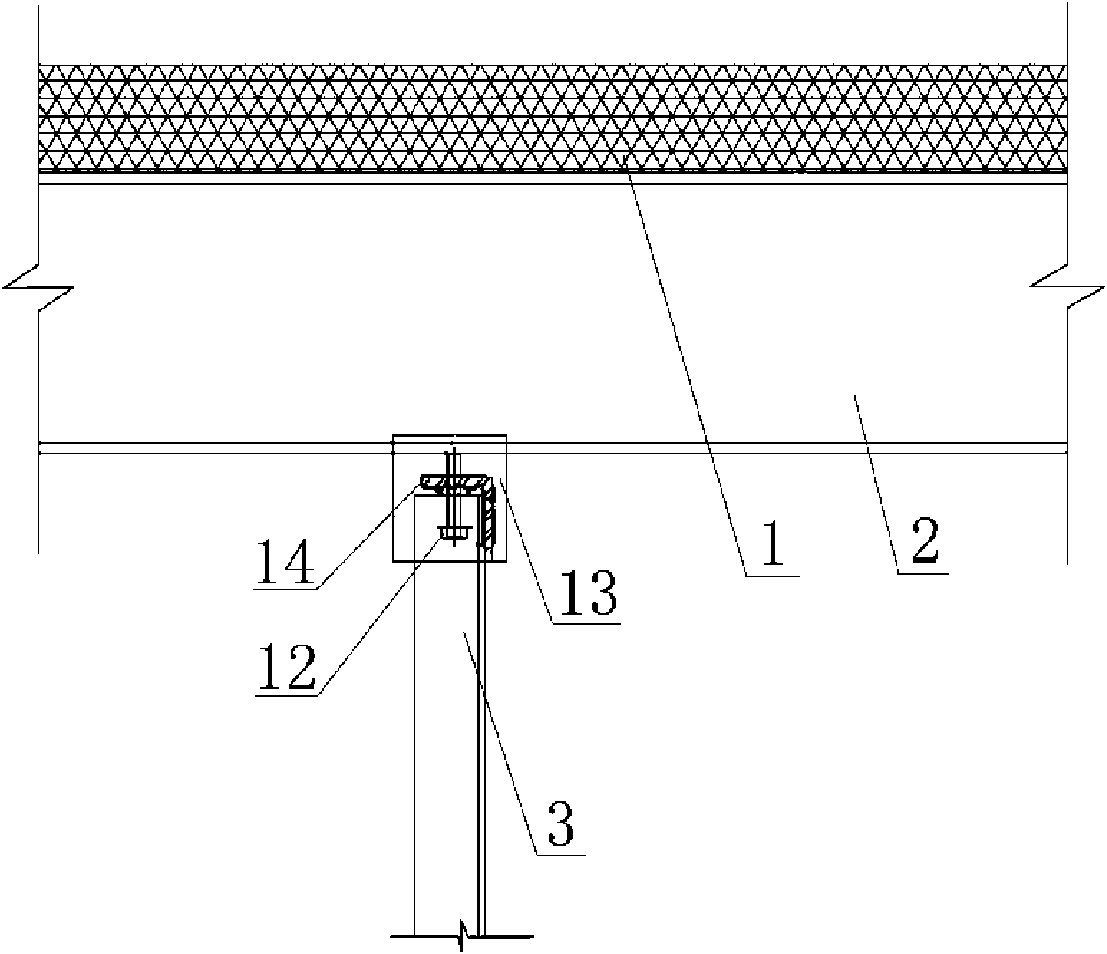

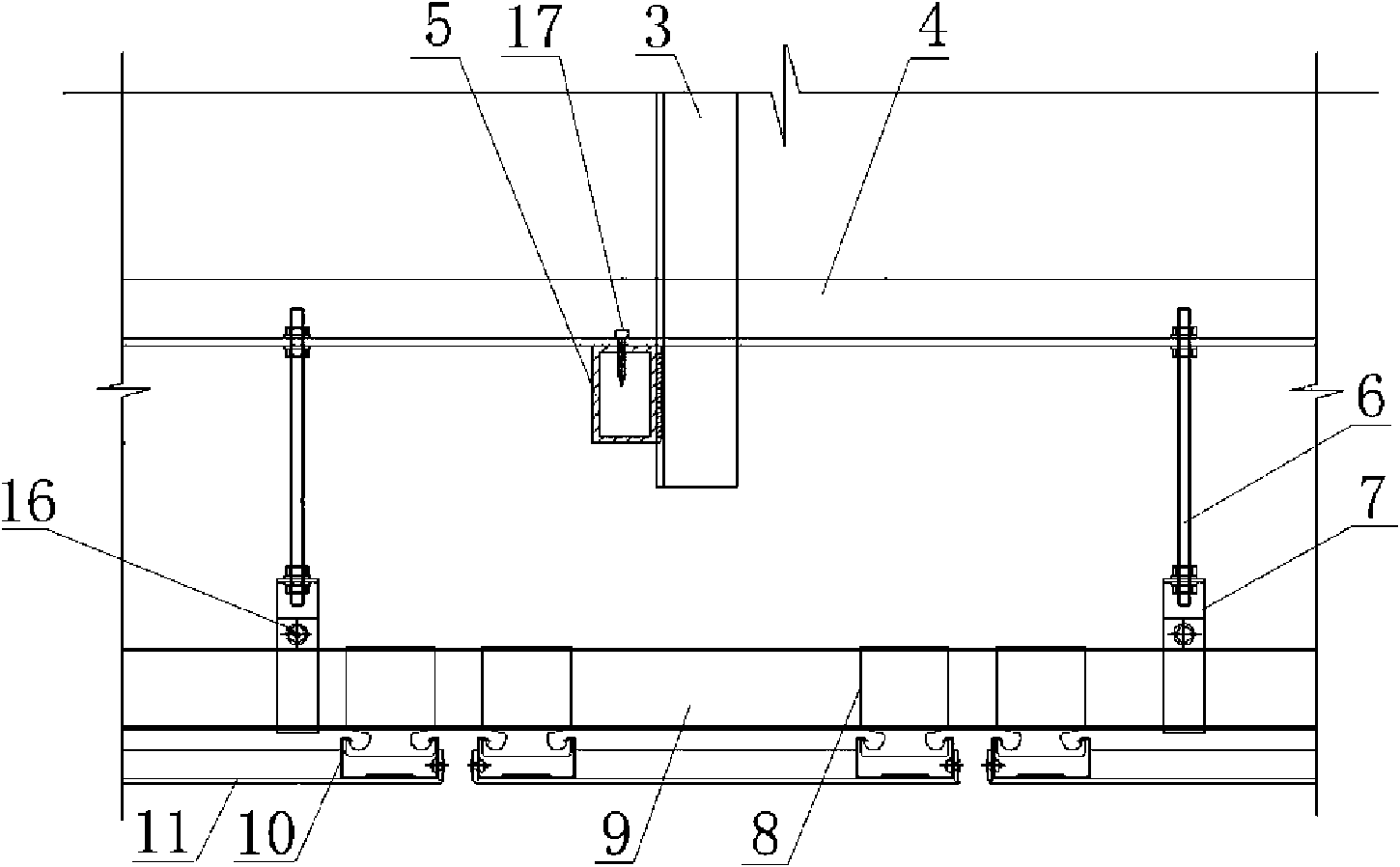

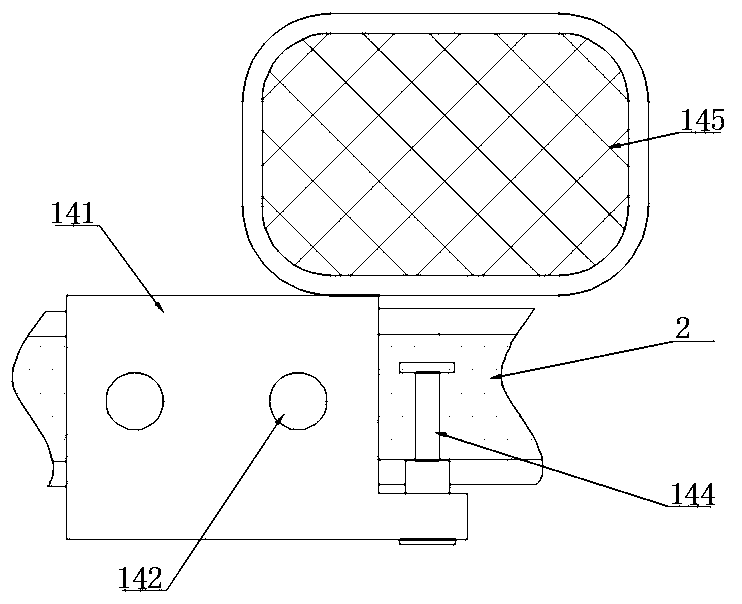

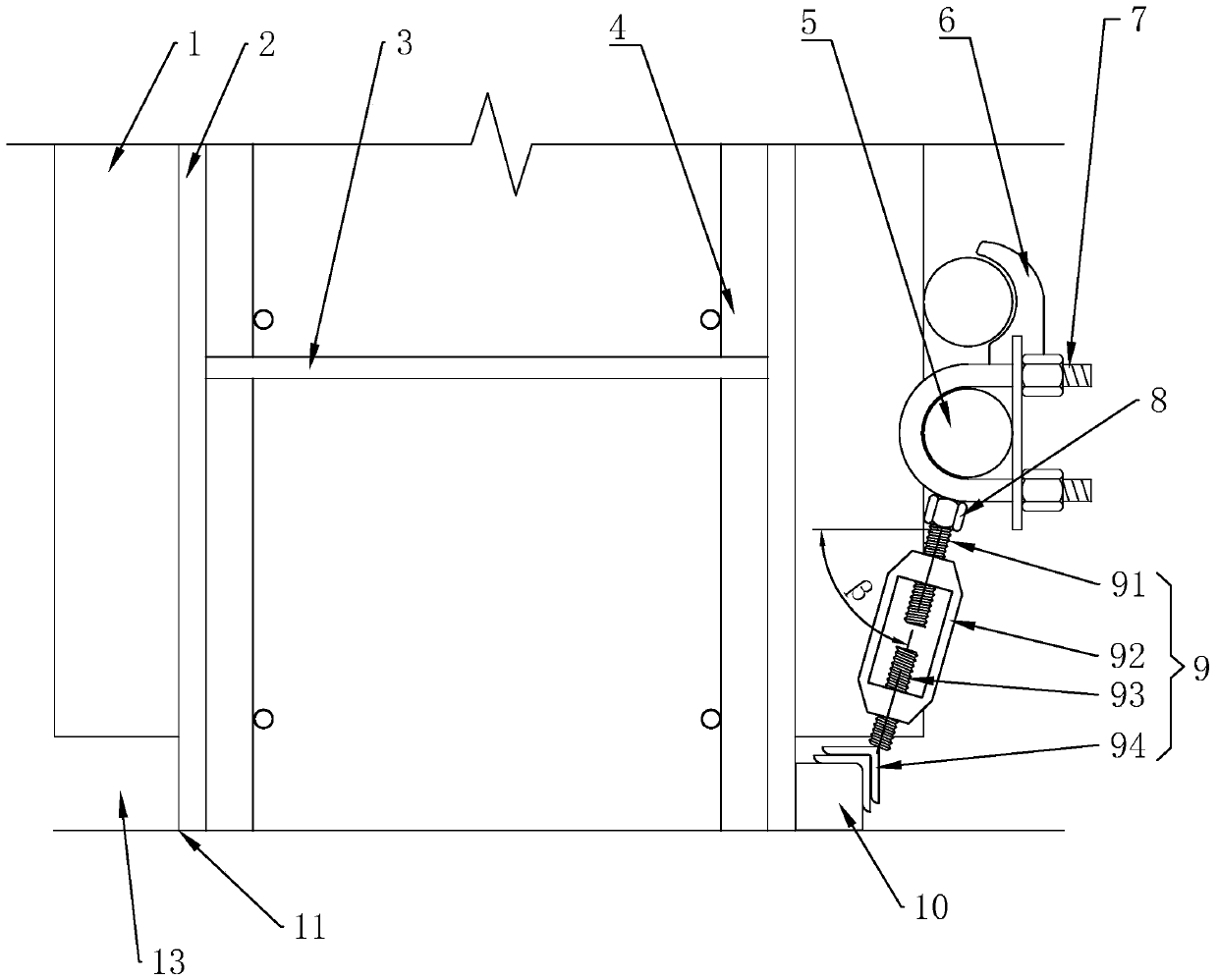

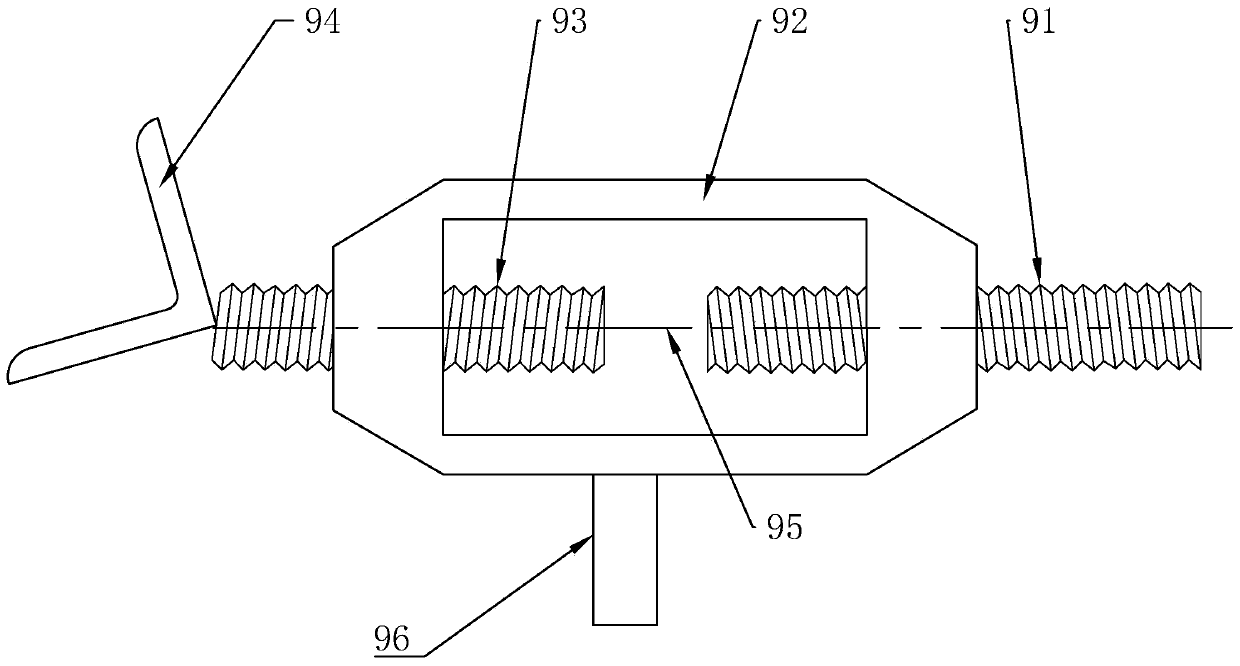

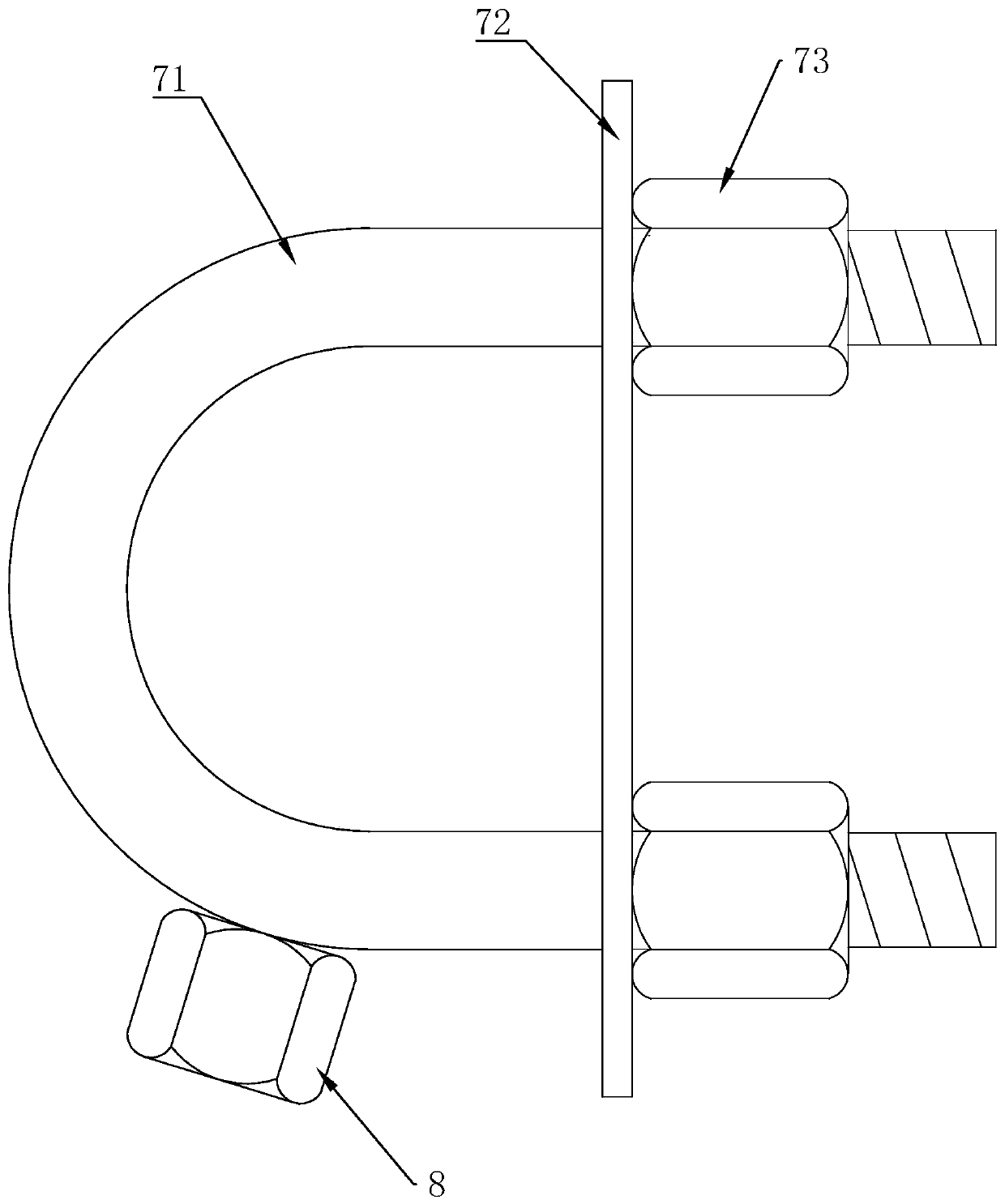

Large-area lower edge nested aluminum plate curved hung ceiling with high punching rate and construction method thereof

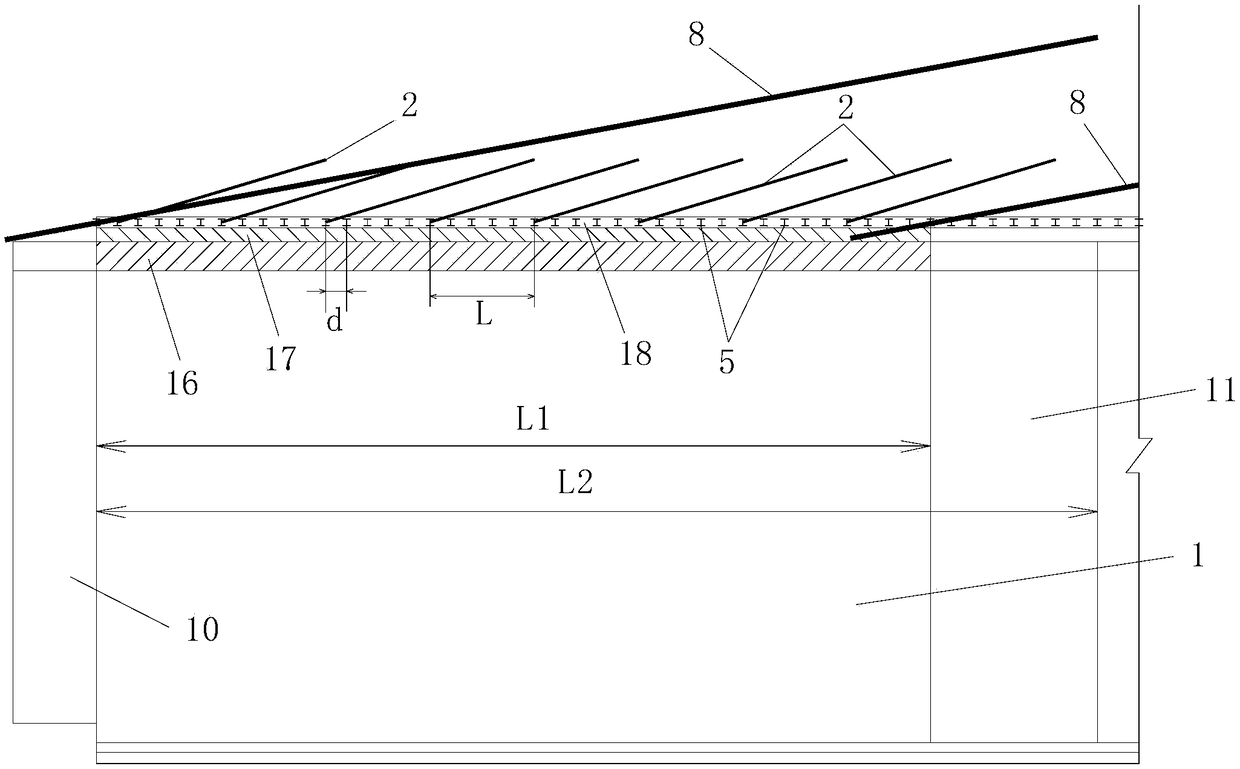

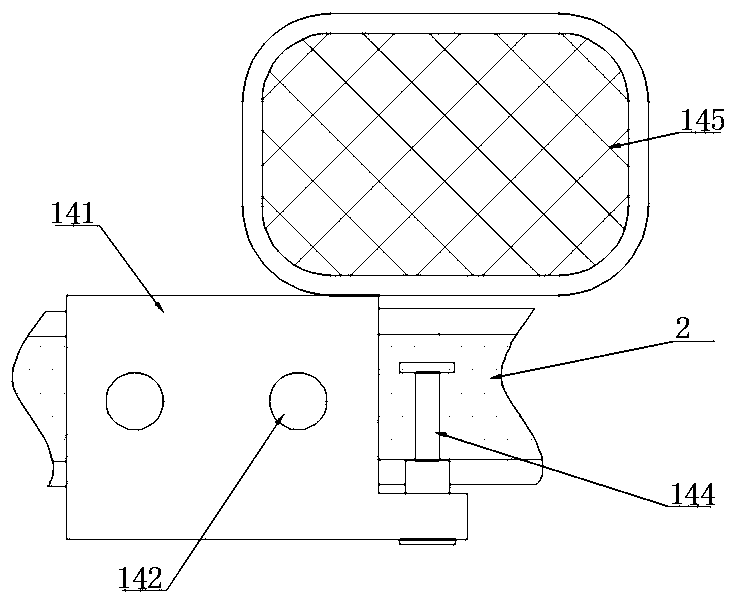

The invention provides a large-area lower edge nested aluminum plate curved hung ceiling with high punching rate and a construction method thereof. The bottom flange of an I-shaped steel beam is suspended and connected with a U-shaped fastener. The U-shaped fastener comprises a pair of main suspending angle steel and a piece of transverse angle steel connected between the two pieces of main suspending angle steel. The transverse angle steel is connected with an angle steel suspender in a T shape. The two pieces of main suspending angle steel of the U-shaped fastener are nested and connected to the upper surface of the bottom flange of the steel beam. The horizontal flange of the transverse angle steel thereon is provided with two circular holes. The lower end of each circular hole is welded with a nut. The upper end of a jackscrew passes through the nut and the circular holes and is pressed on the lower surface of the bottom flange of the steel beam. The lower end of the angle steel suspender is connected with a conversion layer steel frame, and the conversion layer steel frame is connected with a primary steel keel and a secondary steel keel in the shape of meshes and connected with a lightweight steel suspender, the lower end of the lightweight steel suspender is connected with a lightweight steel keel system by a hanger and a connecting bolt. The lightweight steel keel system is fixedly connected with a metal ceiling plate. The invention solves the technical problem of ceiling ultra-large space curved steel structure roof.

Owner:北京市建筑工程装饰集团有限公司

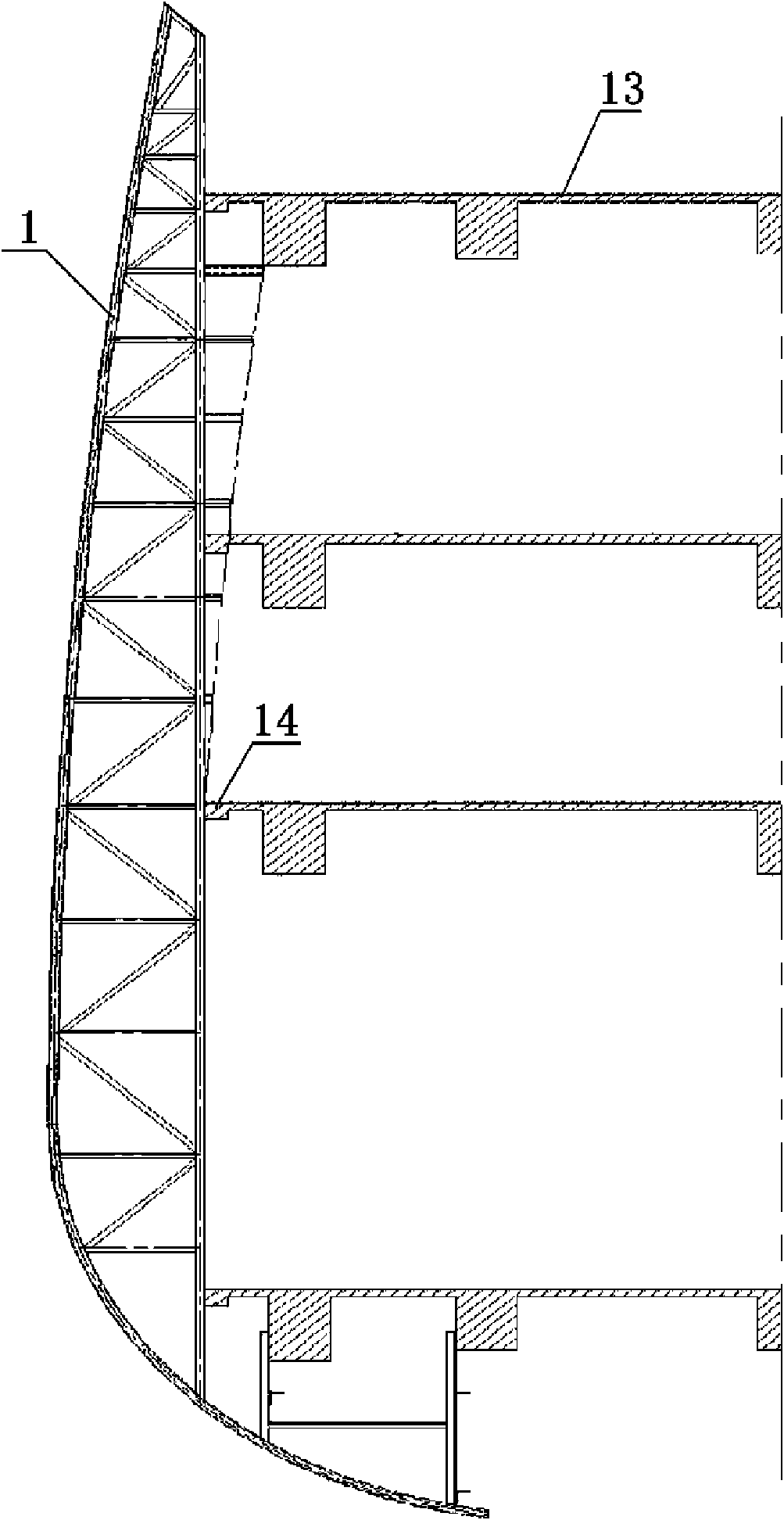

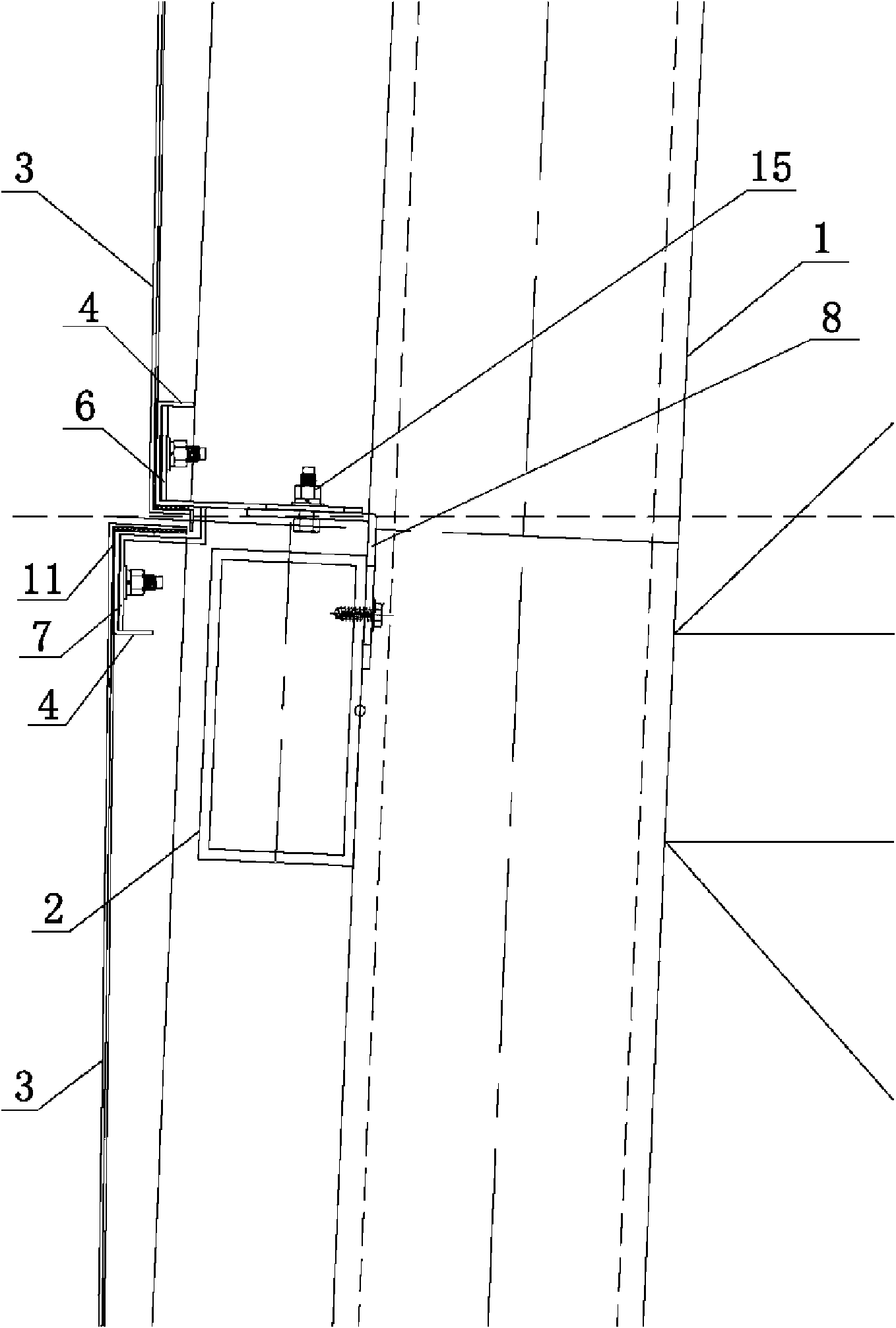

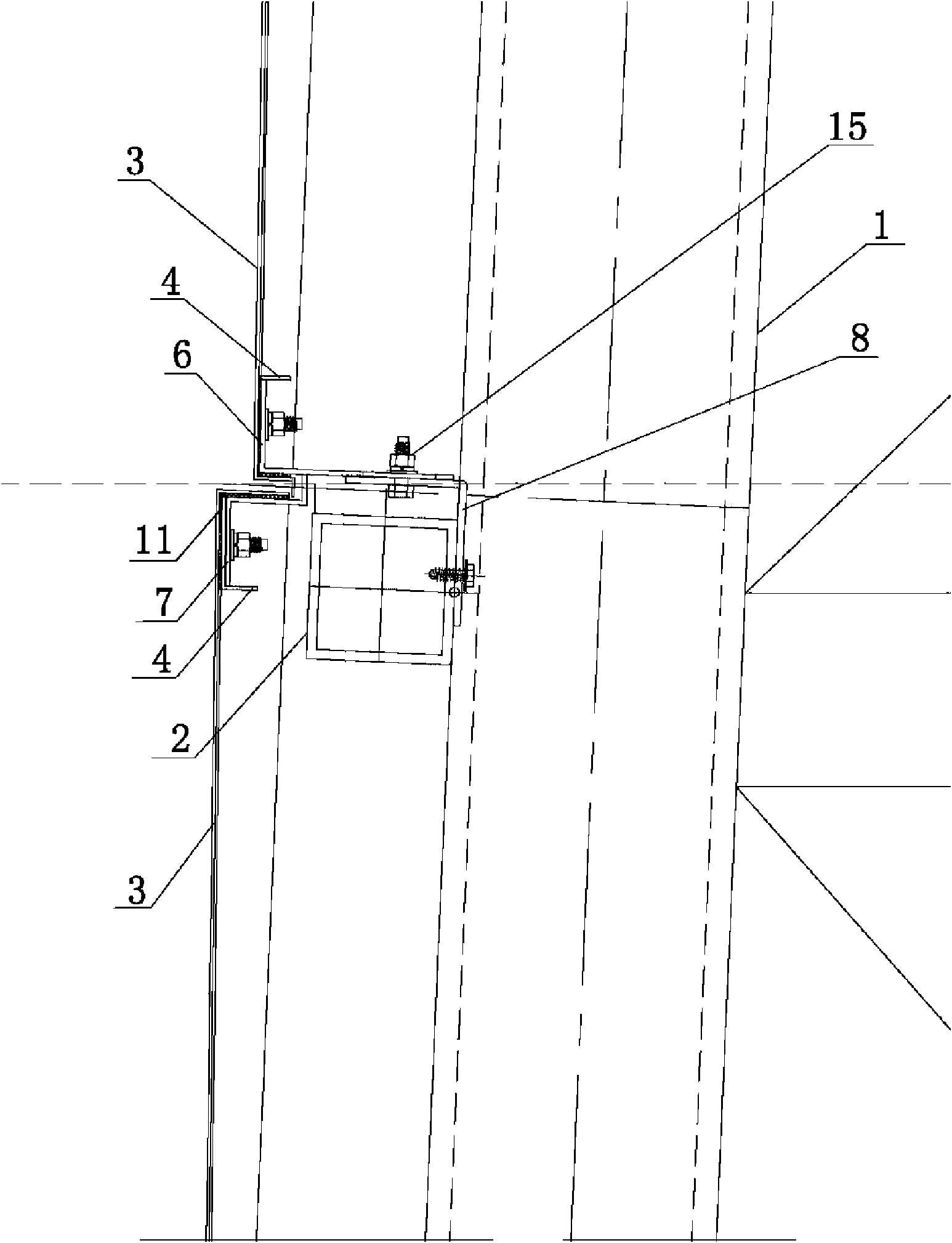

Multi-curved surface overhung copper plate curtain wall and construction method thereof

The invention provides a multi-curved surface overhung copper plate curtain wall and a construction method thereof. The primary keel thereof is a steel truss. The outer side of the main keel steel truss is connected with a transverse secondary keel. The four sides of the curtain wall panel are provided with hems. The screw of the curtain wall panel is connected with the secondary keel by a combined adjustable hanger and a bolt. The combined adjustable hanger is formed by connecting any two or three of following hangers end to end: the first hanger that is an L-shaped folded plate structure with the horizontal plate surface provided with an oblong hole along a central line and a vertical plate surface provided with a circular hole, the second hanger that is a folded plate structure with two platforms folded plate for three times with an angle of 90 degrees and an upper platform plate surface provided with an oblong hole along the central line and the vertical plate surface provided with a circular hole, and the third hanger that is an L-shaped folded plate structure with the horizontal plate surface provided with one to two oblong holes along the plate width and the vertical plate surface provided with an oblong hole along the central line. The construction error caused in the process of mounting the plates can be eliminated by the combined adjustable hanger and the variation of multi-curved surface plates in continuous curved space is satisfied. The invention solves the technical problem of mounting the multi-curved surface copper plate curtain wall.

Owner:北京市建筑工程装饰集团有限公司

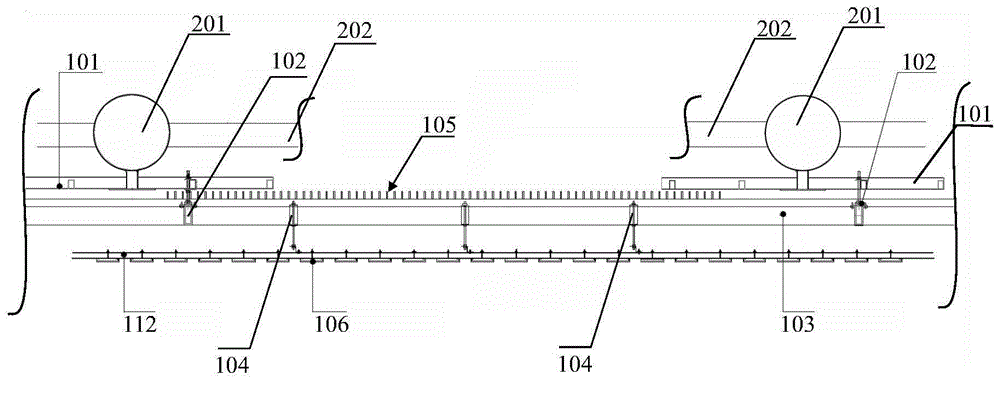

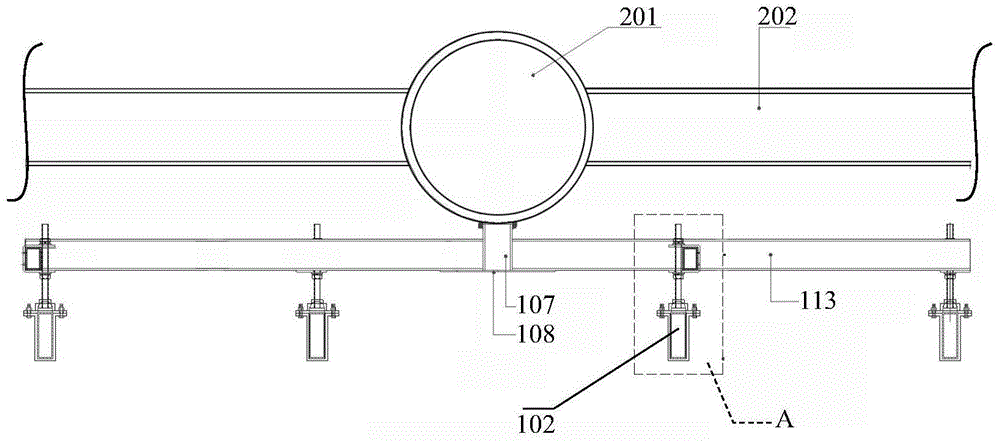

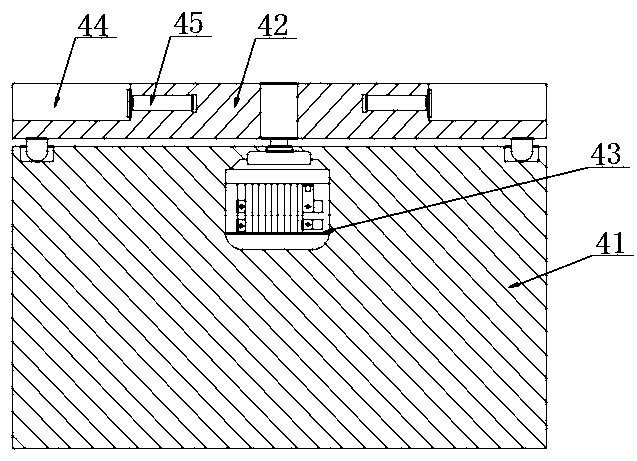

Suspended ceiling system and construction method thereof

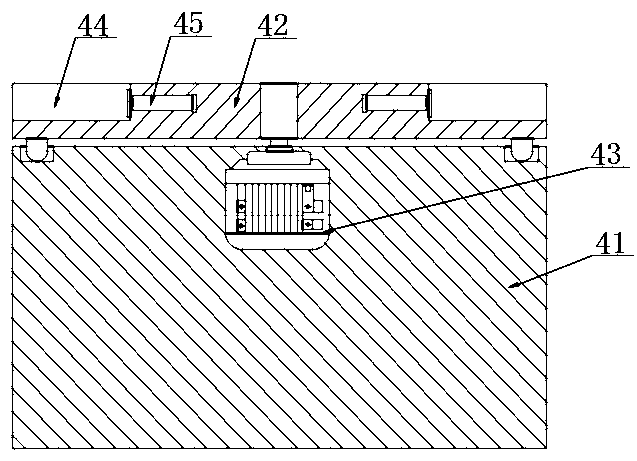

ActiveCN104612307AEven by forceStable structureCeilingsBuilding material handlingEngineeringCantilever

The invention provides a suspended ceiling system which is suspended on spherical nodal points of steel structure on a roof. The suspended ceiling system is characterized by comprising a suspended system connected with the spherical nodal points; a diamond unit frame structure system arranged on the lower side of the suspended system; a ribbon board system arranged on the lower side of the diamond unit frame structure system in a lifting mode. The suspended ceiling system is characterized in that the diamond unit frame structure system comprises multiple diamond unit frames which are connected with each other in a splicing mode, the suspended system comprises multiple multi-direction movable cantilever beams which are connected with multiple spherical nodal points respectively, each multi-direction movable cantilever beam is provided with at least two extended frames, and the extended frames are connected with the diamond unit frame arranged on the lower side of the corresponding spherical nodal point in a lifting mode. The suspended ceiling system is forced uniformly in whole, and is firm in structure, good in steady performance, and excellent in displaying the suspended effect.

Owner:中建八局装饰工程有限公司

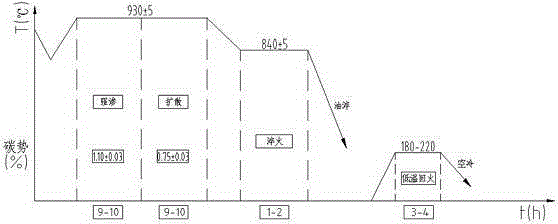

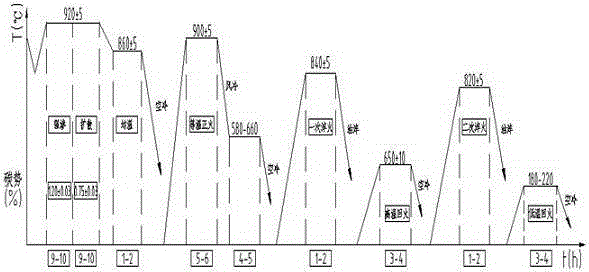

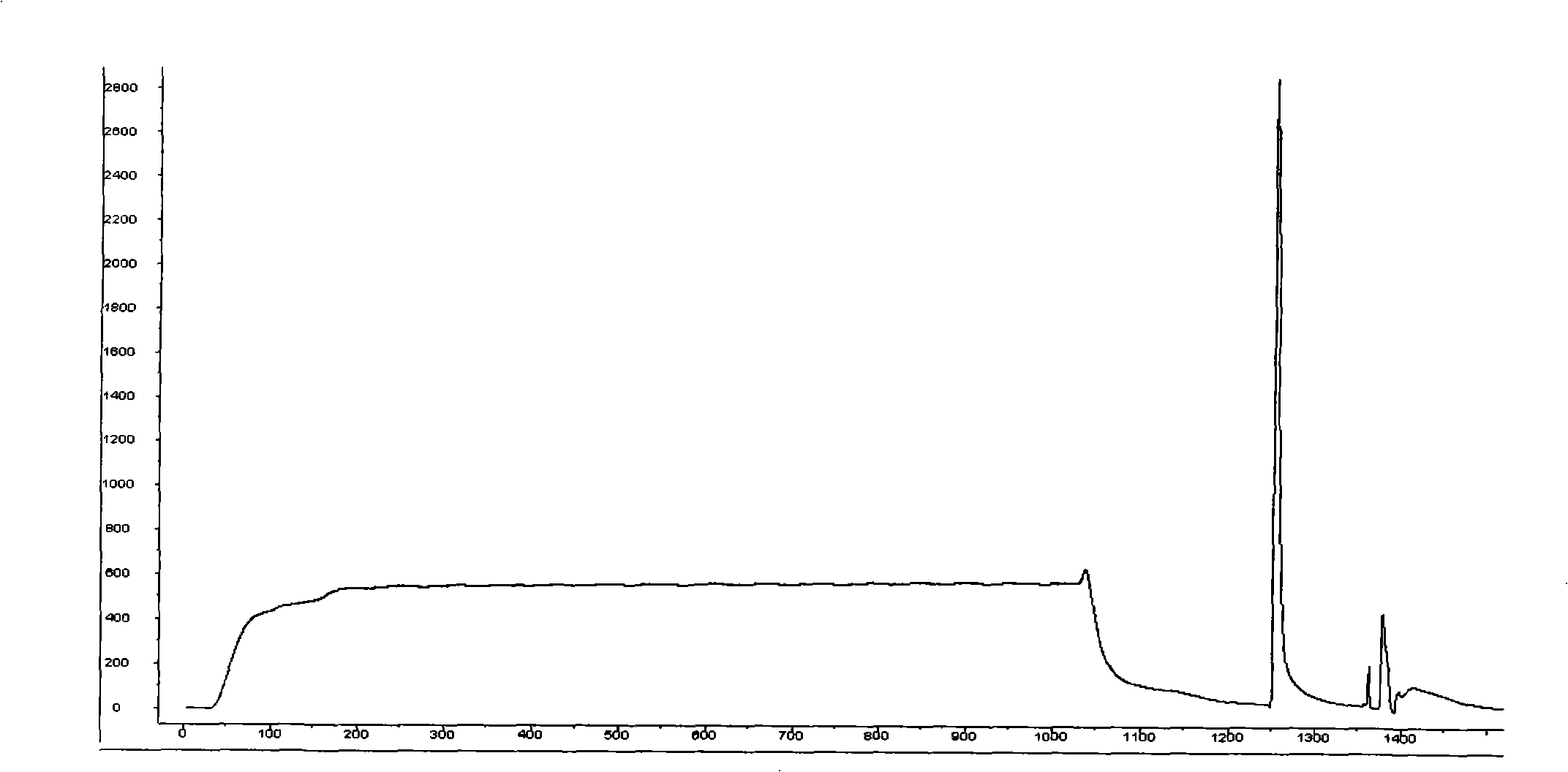

Steel grain refining heat treatment method for heavy-load locomotive gear

ActiveCN105238911AImprove wear resistanceImprove fatigue strengthSolid state diffusion coatingRoom temperatureHeavy load

The invention discloses a steel grain refining heat treatment method for a heavy-load locomotive gear. The method comprises the steps of S1, carburization, wherein steel for the gear is placed into a carburizing furnace, after the temperature rises to the first temperature, carburization is carried out, and after the temperature drops to 860 DEG C+ / -5 DEG C and is constant, the steel is cooled to the room temperature; S2, isothermal normalizing, wherein the steel is subjected to heat preservation for a hour at the temperature being 900 DEG C + / -5 DEG C, and after the steel is subjected to air cooling to be at the second temperature, heat preservation is carried out for b hour, and the steel is subjected to air cooling to be at the room temperature; S3, one-time quenching, wherein after the steel is heated to 840 DEG C+ / -5 DEG C and subjected to heat preservation, the steel is discharged out of the furnace, and oil quenching is carried out; S4, high-temperature tempering, wherein after the steel is heated to the third temperature and subjected to heat preservation for c hour, the steel is subjected to air cooling to be at the room temperature; S5, secondary quenching, wherein after the steel is heated to 820 DEG C+ / -5 DEG C and subjected to heat preservation, the steel is discharged out of the furnace, and oil quenching is carried out; and S6, low-temperature tempering, wherein after the steel is subjected to heat preservation for d hour at the fourth temperature, the steel is subjected to air cooling to be at the room temperature. The grain refining heat treatment method is adopted, the material structure is improved, the toughness, the impact toughness, the wear-resisting property, the fatigue strength and the anti-corrosion property of materials can be improved, and the comprehensive mechanical property of the product is good.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

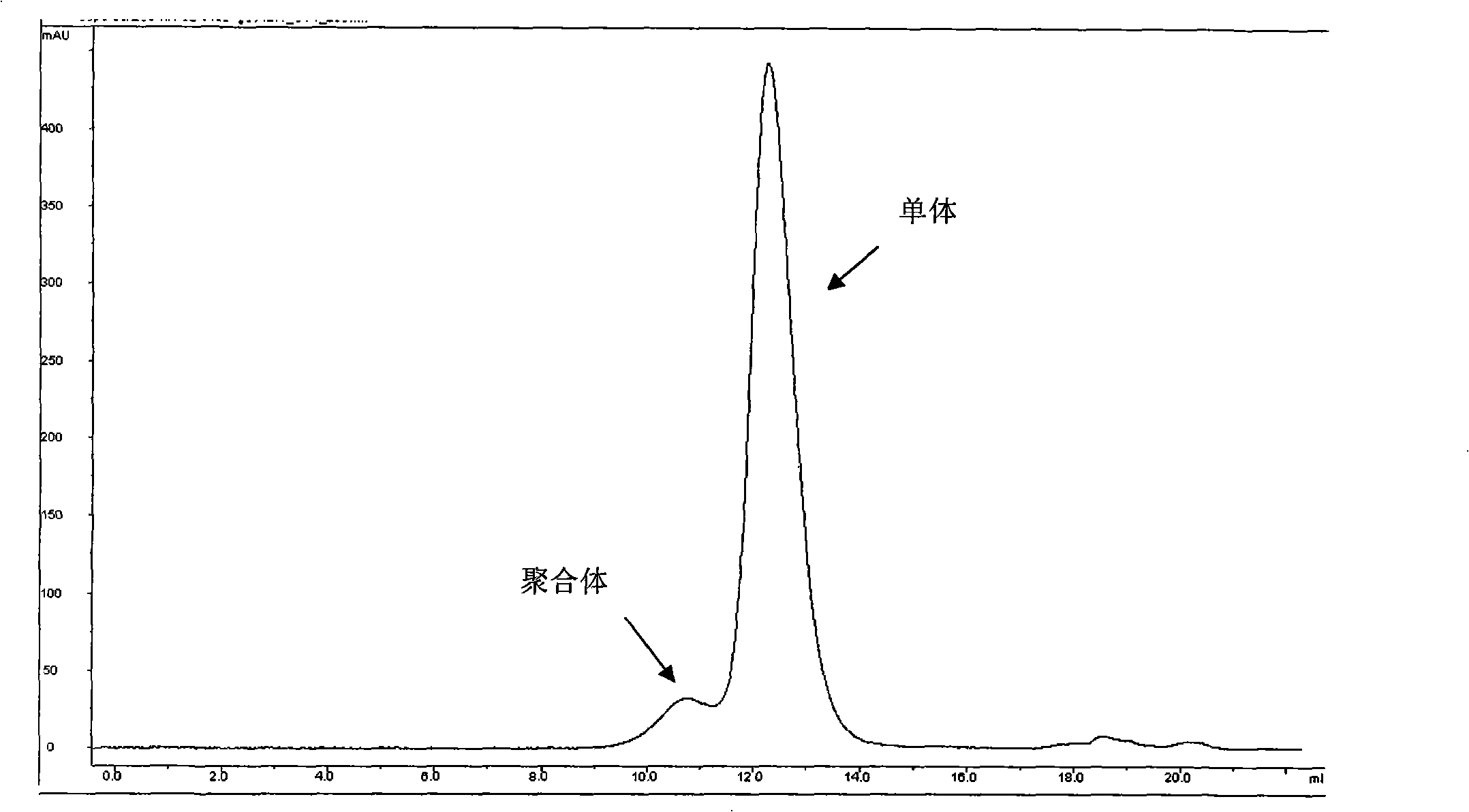

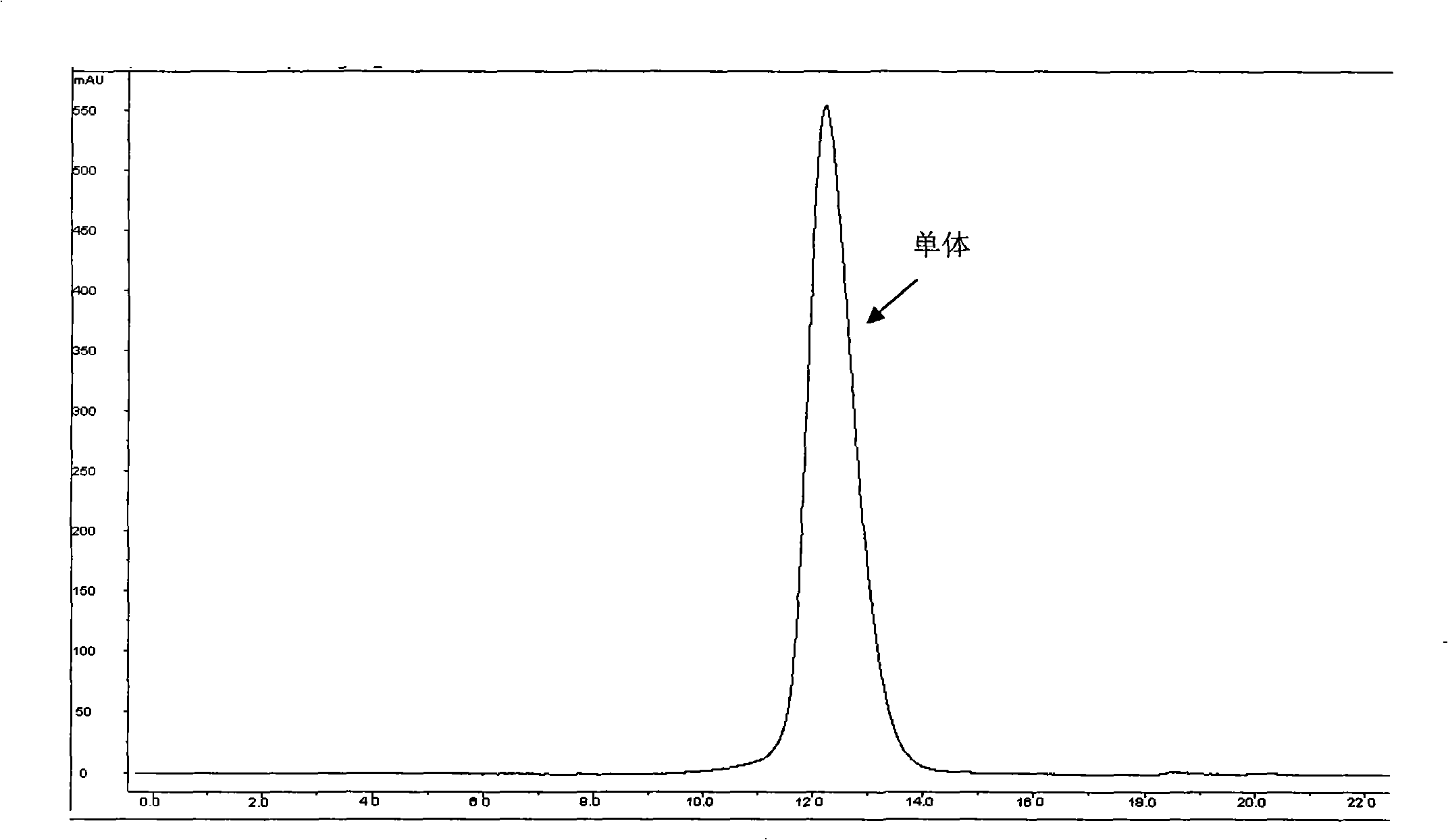

Method for syncretizing protein employing composite chromatography medium purification

InactiveCN101318991AEfficient removalIncrease capacityPeptide preparation methodsIonic strengthIon exchange

The invention discloses a method for adopting a compound chromatography medium to purify Fc fusion protein. The method comprises the following steps that: the ion-exchange hydrophobic compound chromatography medium is adopted to adjust the pH of a chromatography buffer system to be below the average pI of purification target protein and to adjust the chromatography buffer system to have high ionic strength simultaneously, utilizes proper chromatography conditions to ensure that the purification target protein exists in flow-through liquid; the flow-through liquid is collected, while polluting impurities (such as host cell protein, polymer, etc.) are adsorbed onto the compound chromatography medium, so as to improve the purity of the target protein. The method ensures that: the removal rate of final impurities reaches over 1 percent; the purity of the target protein reaches over 99 percent; the recovery rate of the target protein reaches over 90 percent. The method is compact in cohesion in realization process, can effectively remove the polluting impurities in one step, and is characterized in good stability, clear in process control index, suitable for mass production, etc.

Owner:陈志南 +1

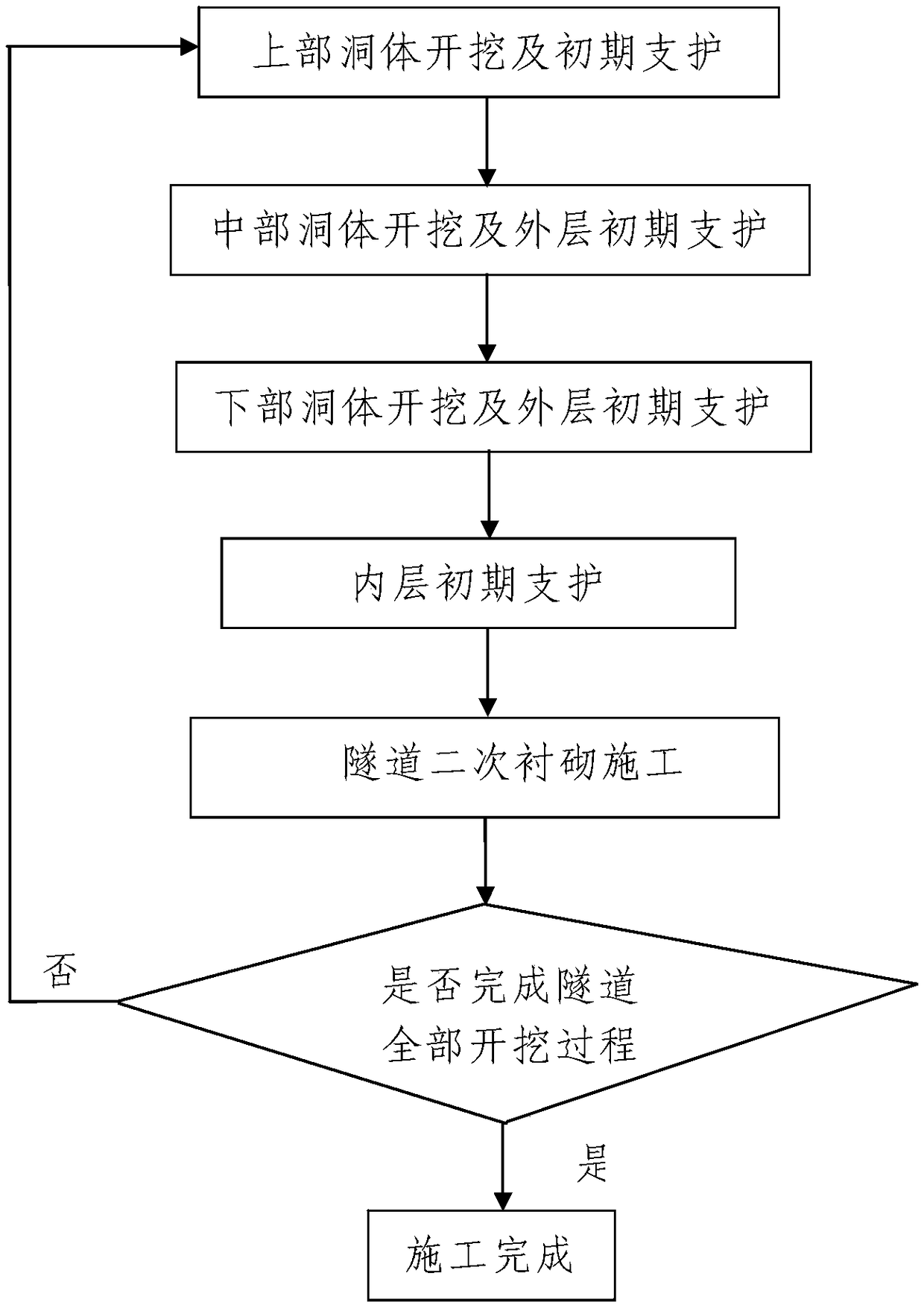

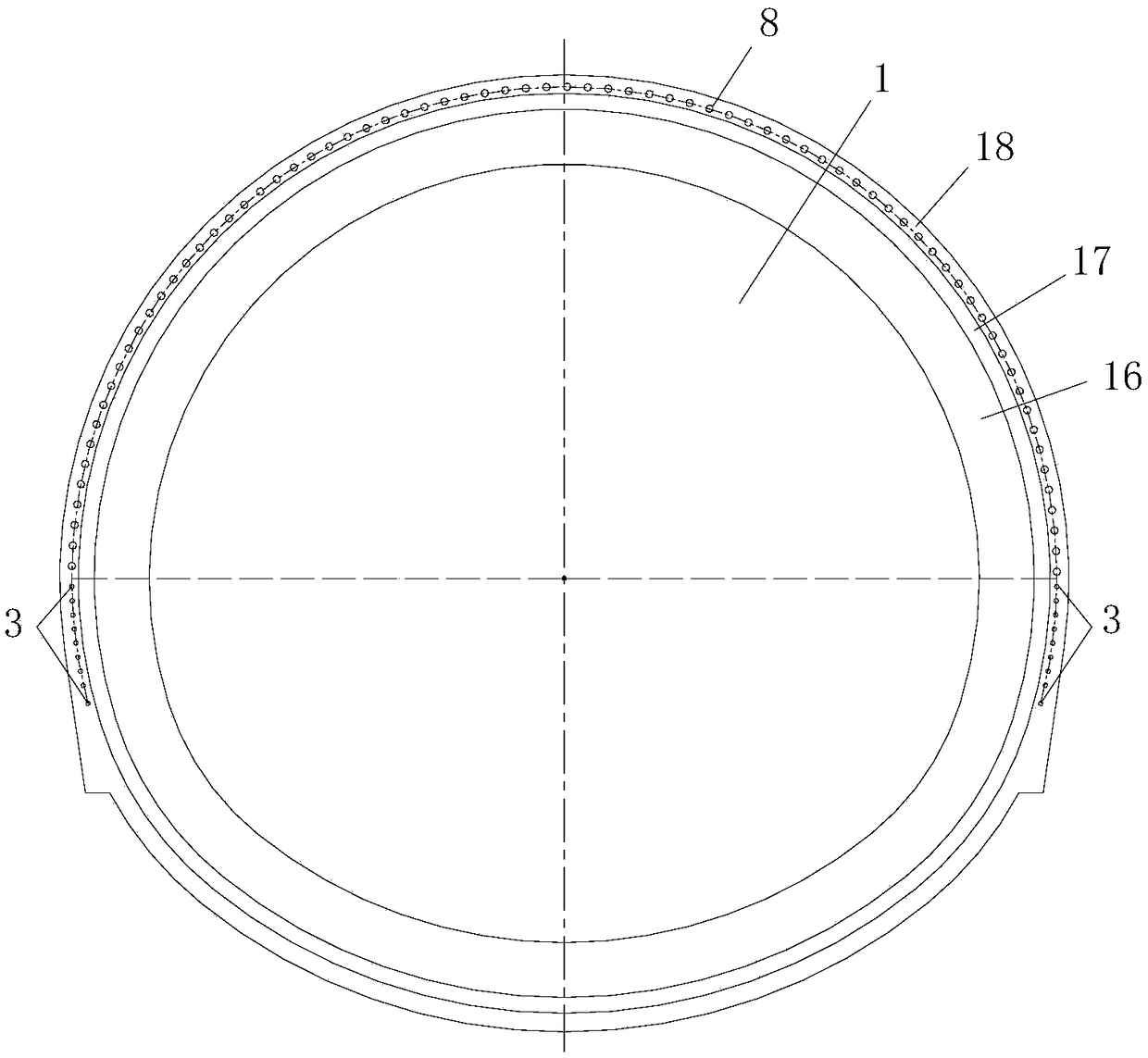

Excavation method for tunnel passing through high-angle thrust water-rich and sand-rich fault

ActiveCN109209398ASimple structureReasonable designUnderground chambersTunnel liningHigh angleStep method

The invention discloses an excavation method for a tunnel passing through a high-angle thrust water-rich and sand-rich fault. A construction tunnel hole is divided from the top to the bottom into an upper hole body, a central hole body, and a lower hole body, wherein the upper hole body is divided into a left guide hole and a right guide hole. A primary support structure of the tunnel hole is a double-layer primary support structure. During the excavation of the construction tunnel, the construction tunnel is divided into a plurality of tunnel segments from the back to the front for excavation. During the excavation of any one tunnel segment, the method comprises the steps: 1, performing the excavation of the upper hole body and the primary supporting; 2, performing the excavation of the central hole body and the primary supporting of an outer layer; 3, performing the excavation of the lower hole body and the primary supporting of the outer layer; 4, performing the primary supporting of an inner layer; 5, repeatedly performing the steps 1-4 for many times, and completing the excavation of the tunnel. The method is simple in step, is reasonable in design, is convenient for construction, is good in use effect, employs a three-step method for the excavation of the tunnel hole, employs double primary support structure for the full-section support of the tunnel hole after excavation, and can guarantee the safety of the tunnel structure later.

Owner:CHINA RAILWAY 20 BUREAU GRP

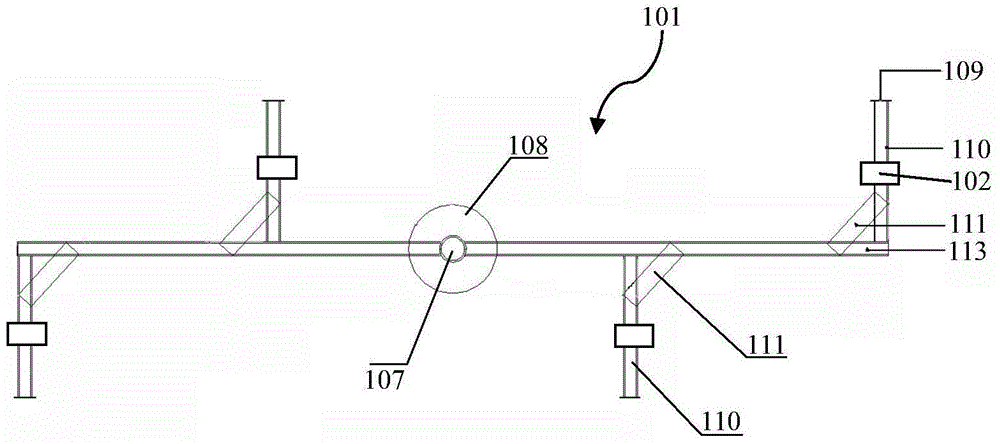

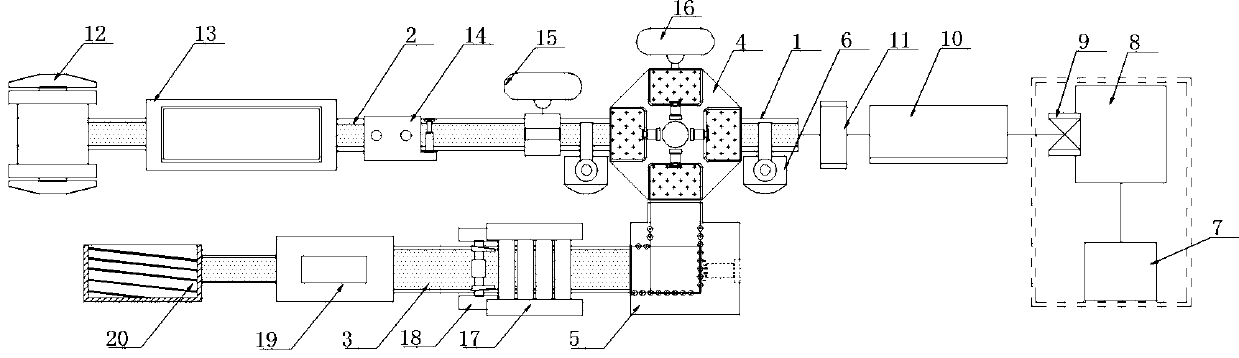

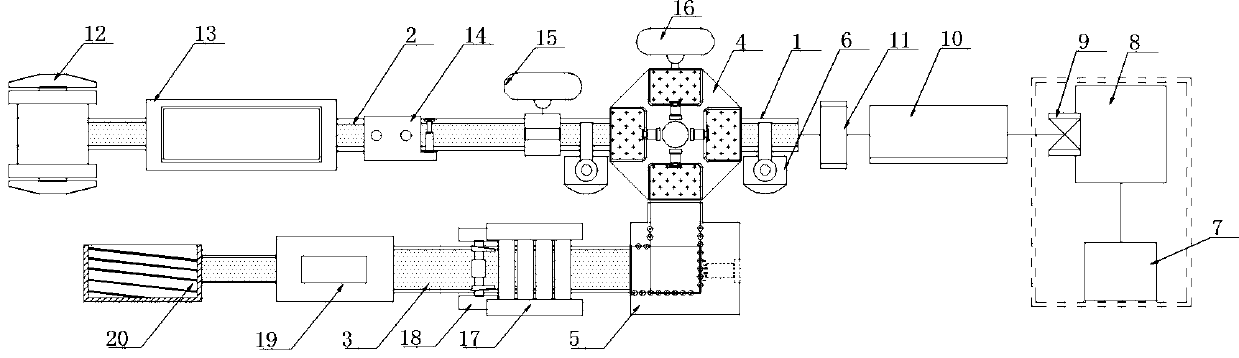

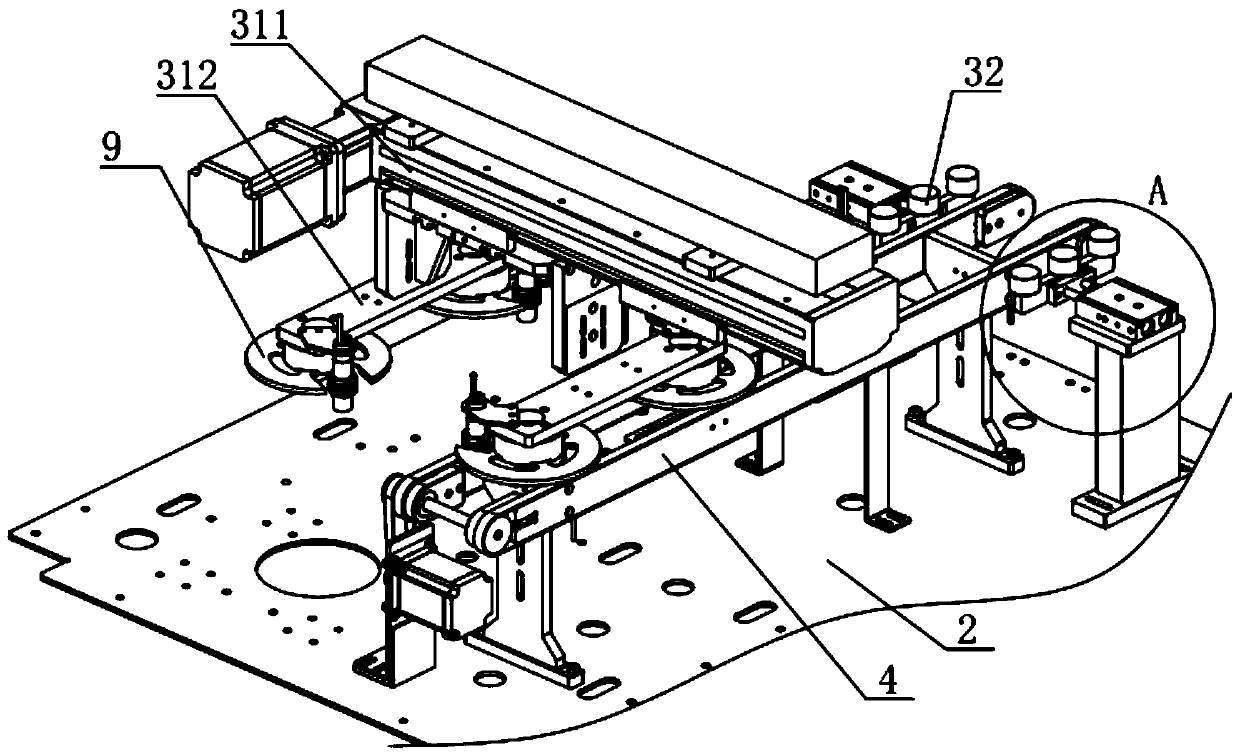

Automatic production line for heat-preservation decoration composite boards

The invention discloses an automatic production line for heat-preservation decoration composite boards and particularly relates to the field of building material processing. The automatic production line comprises a heat-preservation board production line, a veneer production line and a composite production line, a first conveying belt is arranged on the heat-preservation board production line, the veneer production line is provided with a second conveying belt, a third conveying belt is arranged on the composite production line, and a center conversion assembly is arranged at the junction of the first conveying belt and the second conveying belt. A camera and an ultrasonic sensor are matched with a single chip microcomputer for detection and analysis, the output end of a first air cylinder is controlled to extend out to remove veneer rejected products, glass fiber cotton fibers are sprayed on the surfaces of qualified boards, and thus the performance of the composite boards is improved; and the two kinds of boards are composited in a bonded mode, then conveyed to a shunting assembly and positioned on guiding boards, the positioning effect is good, then the boards are conveyed to the third conveying belt to be composited, the composite boards are clamped to be scraped by two clearing boards, the two layers of boards are aligned to remove excess binders, and the quality of the composite boards can be improved.

Owner:XUZHOU COLLEGE OF INDAL TECH

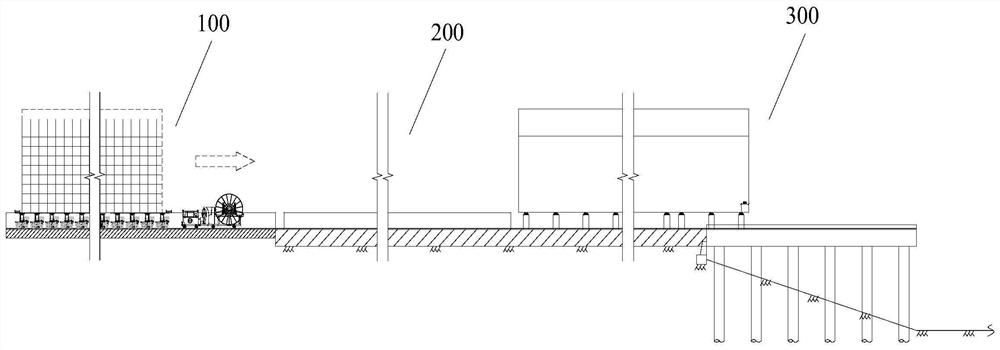

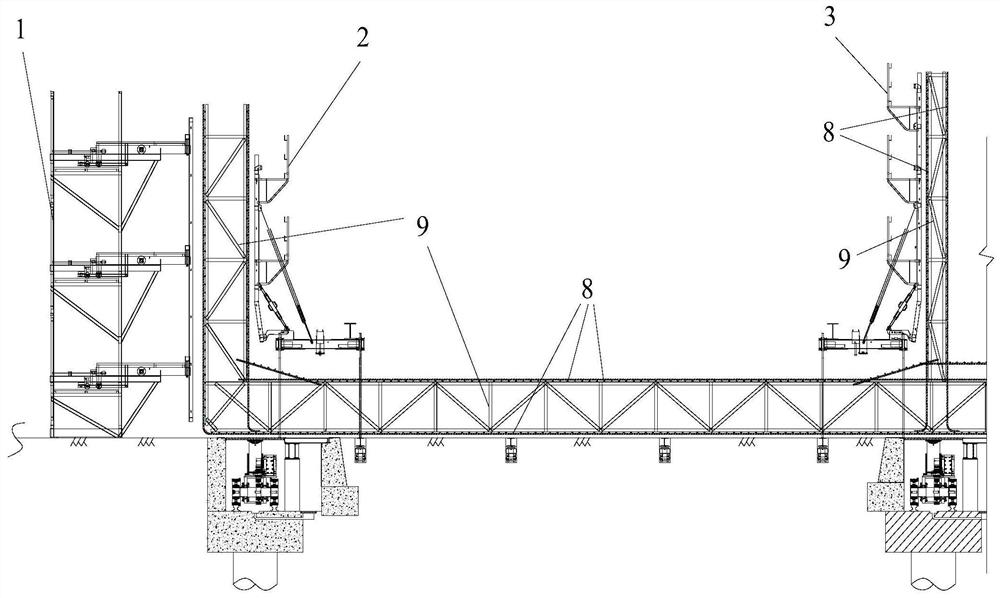

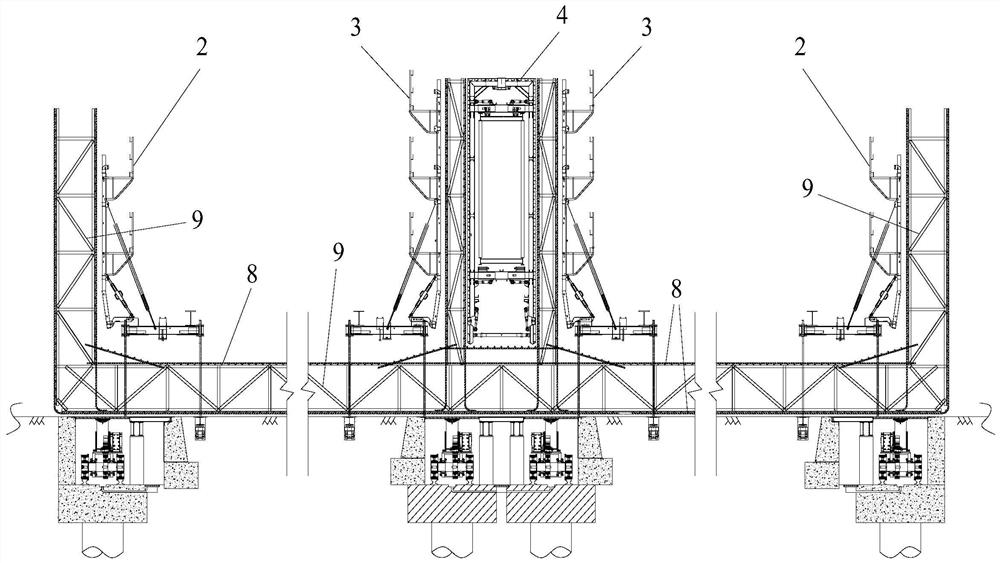

Segmented prefabrication method of immersed tube joints

ActiveCN111941637AShorten the prefabrication cycleDoes not significantly increase prefabrication costsArtificial islandsMouldsArchitectural engineeringAssembly line

The invention relates to the technical field of immersed tube tunnel construction, in particular to a segmented prefabrication method of immersed tube joints.The prefabrication period of a single tubejoint can be remarkably shortened, the prefabrication cost of a single joint cannot be increased greatly, a reinforcement cage or tube joints cannot be frequently jacked or cannot frequently ascend and descend in the prefabrication link, the waiting period that the tube joints reach the strength required by moving can be shortened, the number of times of moving is obviously reduced, the crack control difficulty can be reduced easily, the forming quality of immersed tubes is improved, and then the engineering quality is improved. Meanwhile, through the arrangement of a steel bar binding area and a pouring area and matching of the reciprocating moving positions of bed-jigs and a formwork in the method, the occupied area of the prefabrication area of a single tube joint is compact, multipleprefabrication assembly lines can be arranged in a width-limited site easily, arrangement of a prefabrication factory is facilitated, a hoisting system does not need to be erected in the moving process of the reinforcement cage, the bed-jigs and the formwork, safety is good, construction is convenient, and the construction period can be further shortened easily.

Owner:CCCC FOURTH HARBOR ENG CO LTD

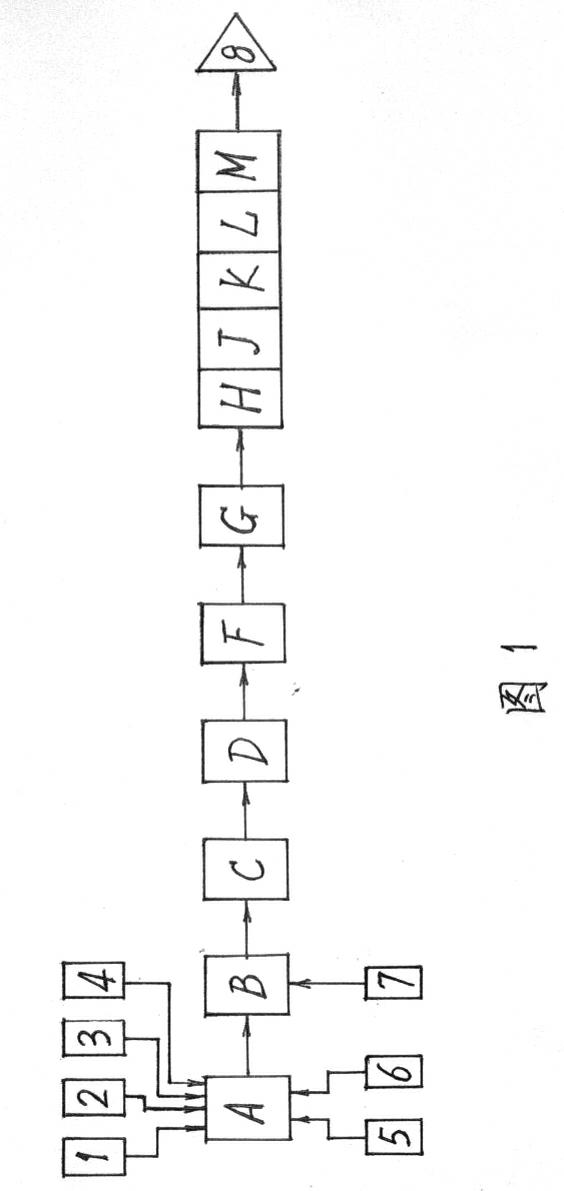

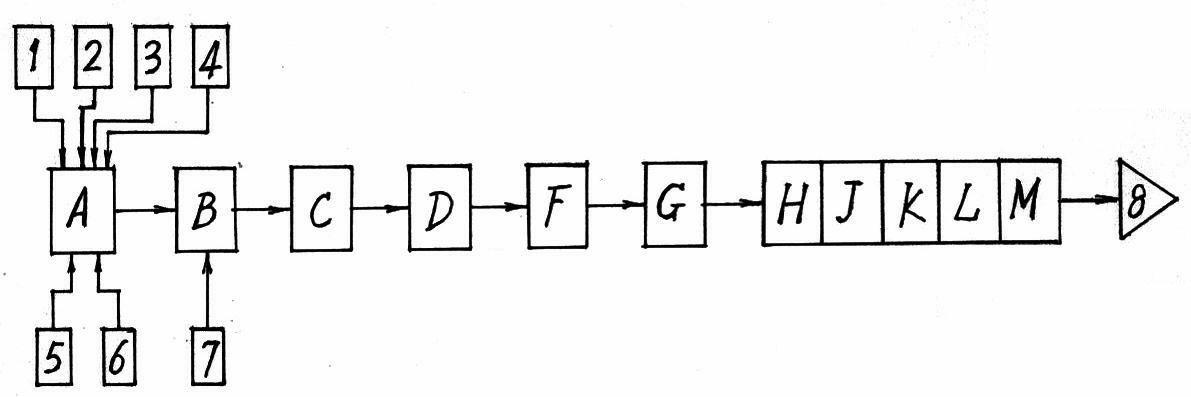

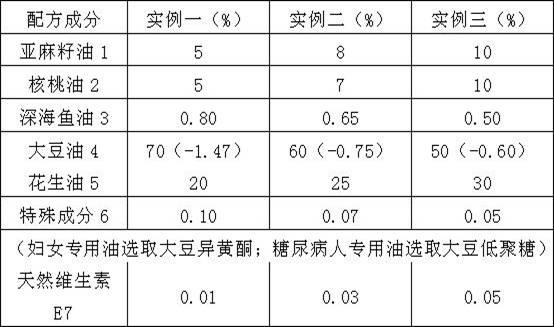

Method for preparing functional edible vegetable oil

A method for preparing functional edible vegetable oil comprises the steps of adding selected 5%-10% of linseed oil (1), 5%-10% of walnut oil (2), 0.5%-0.8% of deep sea fish oil (3), 50%-70% of soybean oil (4), 20%-30% of peanut oil (5), a special ingredient (6) for women, namely 0.05%-0.1% of soy isoflavones or a special ingredient for patients with diabetes, namely 0.1%-0.5% of soybean oligosaccharides according to a formula into an oil tank for mixing (A) to be mixed, then adding the ingredients into a stirrer (B), simultaneously adding into 0.01%-0.05% of natural vitamin E (7) into the stirrer to perform stirring for 30 min, placing the mixture into a temporary storage tank (C) to performing standing and precipitation for 10 min, adding the mixture into a filtering machine (D) to be filtered, placing mixed oil after filtration into a temporary oil storage pool (F), checking out, obtaining a functional special oil (8) finished product, placing the finished product into a canning machine (G) to be packaged in a split mode, and performing package and warehousing. The method for preparing the functional edible vegetable oil is scientific in formula, reasonable in process, effective and balanced in nutrition, the ratio of omega-6: omega-3 reaches to 2:1 or approximately reaches to 2:1, the ingredients are complementary, the quality is good, and the efficiency is high.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

An automatic production line for thermal insulation and decorative composite panels

ActiveCN110273517BImprove performanceQuality improvementConveyorsCovering/liningsGlass fiberProduction line

The invention discloses an automated production line for insulation decorative composite panels, specifically related to the field of building material processing, including an insulation panel production line, a decorative panel production line and a composite production line. The insulation panel production line is provided with a first conveyor belt, and the decorative panel production line is equipped with a first conveyor belt. There is a second conveyor belt, a third conveyor belt is provided on the composite production line, and a central conversion component is provided at the connection between the first conveyor belt and the second conveyor belt. The invention uses a camera and an ultrasonic sensor in conjunction with single-chip microcomputer detection and analysis to control the output end of the first cylinder to extend to remove defective decorative panels, and spray fiberglass cotton fibers on the surface of qualified panels to improve the performance of the composite panel and bond the two panels. After compounding, it is transferred to the transfer assembly and positioned on the guide plate. The positioning effect is good. Then it is transferred to the third conveyor belt for compounding processing. Two cleaning plates clamp and scrape the composite plate to align the two layers of boards and remove excess adhesive. Can improve the quality of composite panels.

Owner:XUZHOU COLLEGE OF INDAL TECH

Construction method for reinforcing and rolling soft soil subgrade by aid of impact-type road roller

InactiveCN102605698AImprove integrityImprove carrying capacityRoadwaysObservation pointWater content

The invention discloses a construction method for reinforcing and rolling a soft soil subgrade by the aid of an impact-type road roller. The construction method includes the steps: (1) selecting a test road section for construction and determining subgrade construction parameters including soil laying thickness, rolling times, the frequency of the impact-type road roller and the water content of soil; (2) excavating soft soil of the subgrade and excavating a subgrade base into designed elevation; (3) determining the water content of gravel and selecting a packing gravel site according to relevant provisions; (4) feeding materials to the subgrade, layering gravel filling amount according to the lay-down thickness and controlling feeding volume to be one meter on site; (5) neatly paving and initially pressing the subgrade; (6) setting a settlement observation point, setting out an elevation laying point and recording elevation; (7) performing impactive rolling by the aid of an impact compactor; (8) doubly controlling compactness detection by means of differential settlement and a construction process; and (9) trimming the compacted subgrade to finish construction. The construction method is simple in process, working procedures are compactly linked, engineering quality is improved, and cost is reduced.

Owner:XINJIANG BEIXIN ROAD & BRIDGE GRP

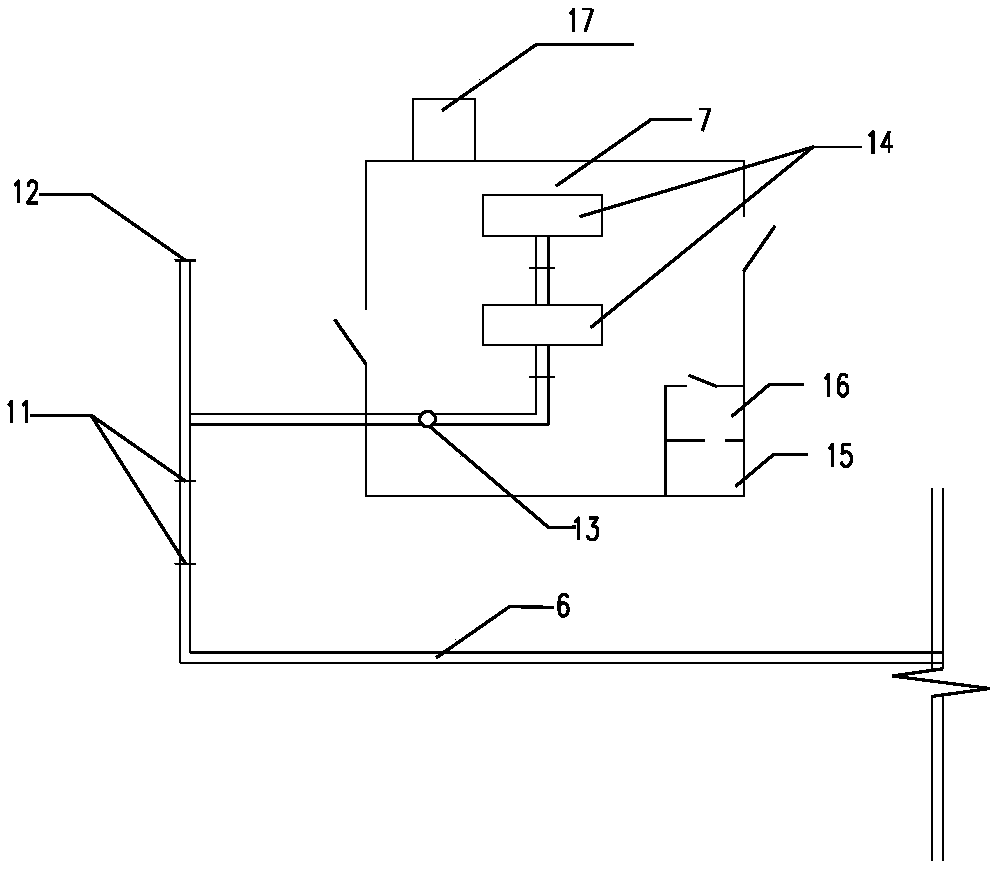

Wall template bottom plugging device, template supporting system and formwork construction method

PendingCN111502247AAdjust the forceAchieve reuseForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemArchitectural engineering

The invention relates to a wall template bottom plugging device, a template supporting system and a formwork construction method, and relates to the technical field of building construction template structures, installation and protection. The wall template bottom plugging device comprises a locker, a grouting stop structure, and an adjusting structure respectively connected with the locker and the grouting stop structure, wherein the grouting stop structure comprises a flexible sealing body; the adjusting structure comprises an adjusting frame, a first adjusting screw rod and a second adjusting screw rod with one ends being respectively in threaded connection with the adjusting frame, and a first connecting body for tightly pressing the grouting stop structure; the rotation directions ofthe first adjusting screw rod and the second adjusting screw rod are opposite; and the central axes of the first adjusting screw rod and the second adjusting screw rod are collinear, and are inclinedtowards a part to be plugged. The template supporting system comprises the wall template bottom plugging device detachably connected with a steel pipe main keel on the bottommost part. The formwork construction method adopts the template supporting system. According to the wall template bottom plugging device, the template supporting system and the formwork construction method provided by the invention, the technical problem of a poor grouting stop effect of a plugging device in the prior art can be solved, and an effect on tightly plugging is achieved.

Owner:中铁十六局集团城市建设发展有限公司 +1

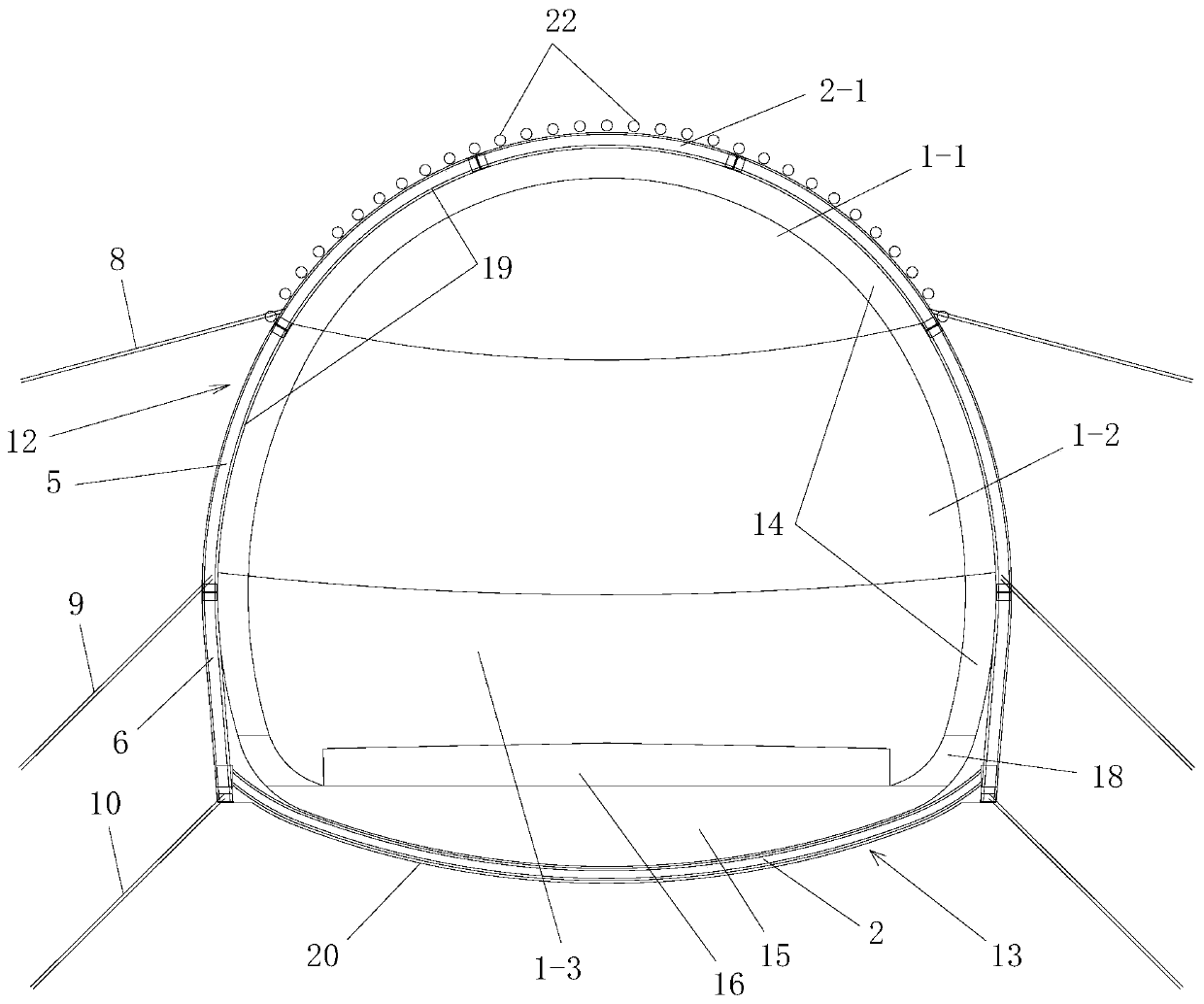

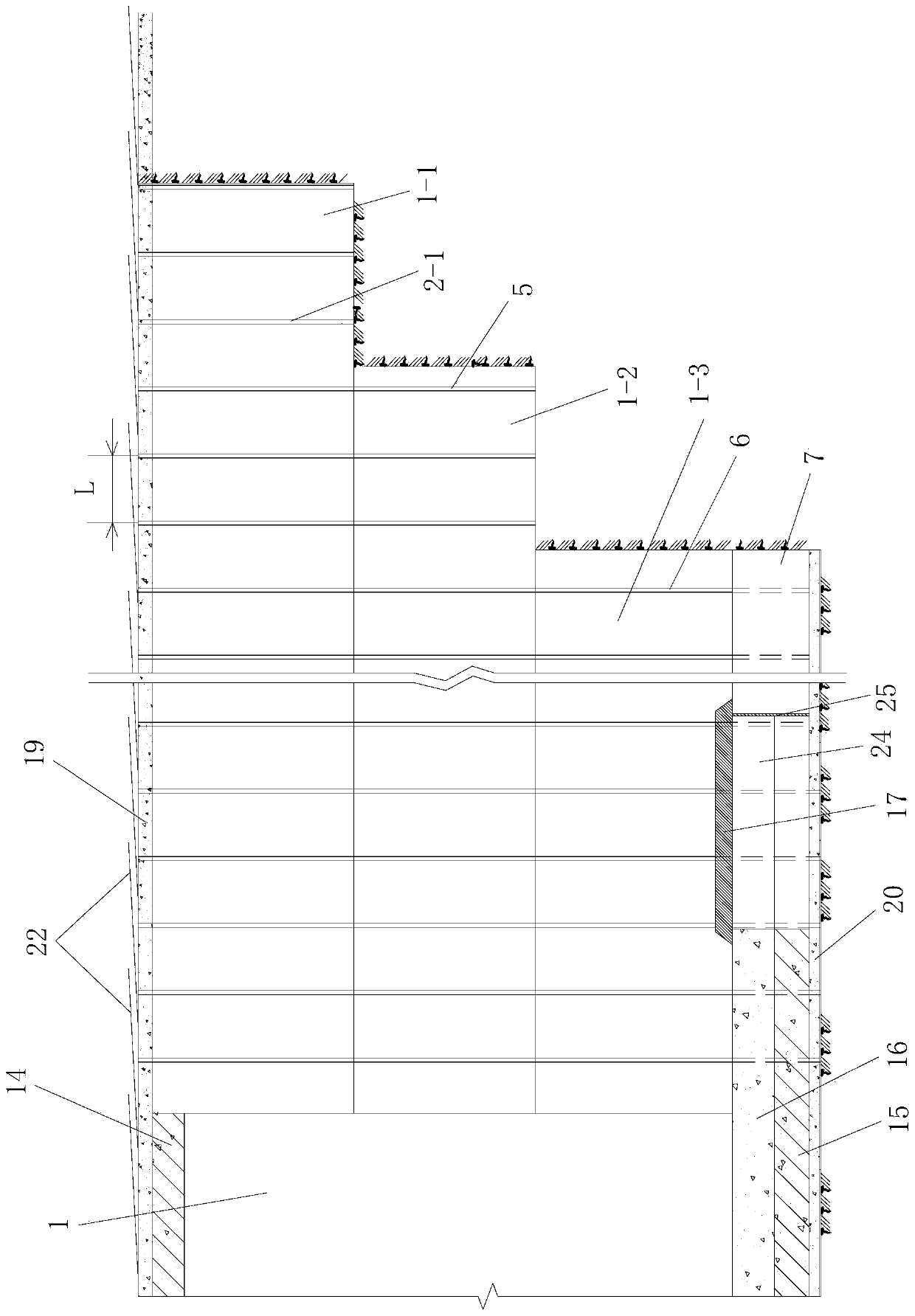

Construction organization method of complete set of tunnel mechanical equipment

ActiveCN108915696AImprove management abilityImprove the construction work environmentUnderground chambersTunnel liningArchitectural engineeringMechanical equipment

The invention discloses a complete set of tunnel mechanical equipment, which specifically refers to an excavation trolley (or an excavation gantry), a drainage and steel bar binding trolley, a liningtrolley, a spray maintenance trolley, a ditch cable trough trolley, an inverted arch self-propelled hydraulic trestle and a wet spray manipulator, referred to as five trolleys, one trestle and one wetspray machine. A construction organization method matched with the complete set of mechanical equipment comprises the following construction organization steps: S1, hole excavation; S2, initial support; S3, inverted arch lining; S4, arched wall lining; S5, ditch cable troughs and the complete set of mechanical equipment. The construction organization method is reasonable, effectively improves tunnel management effect, improves construction operation environment, ensures construction safety and quality, improves construction progress and is worthy of promotion.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

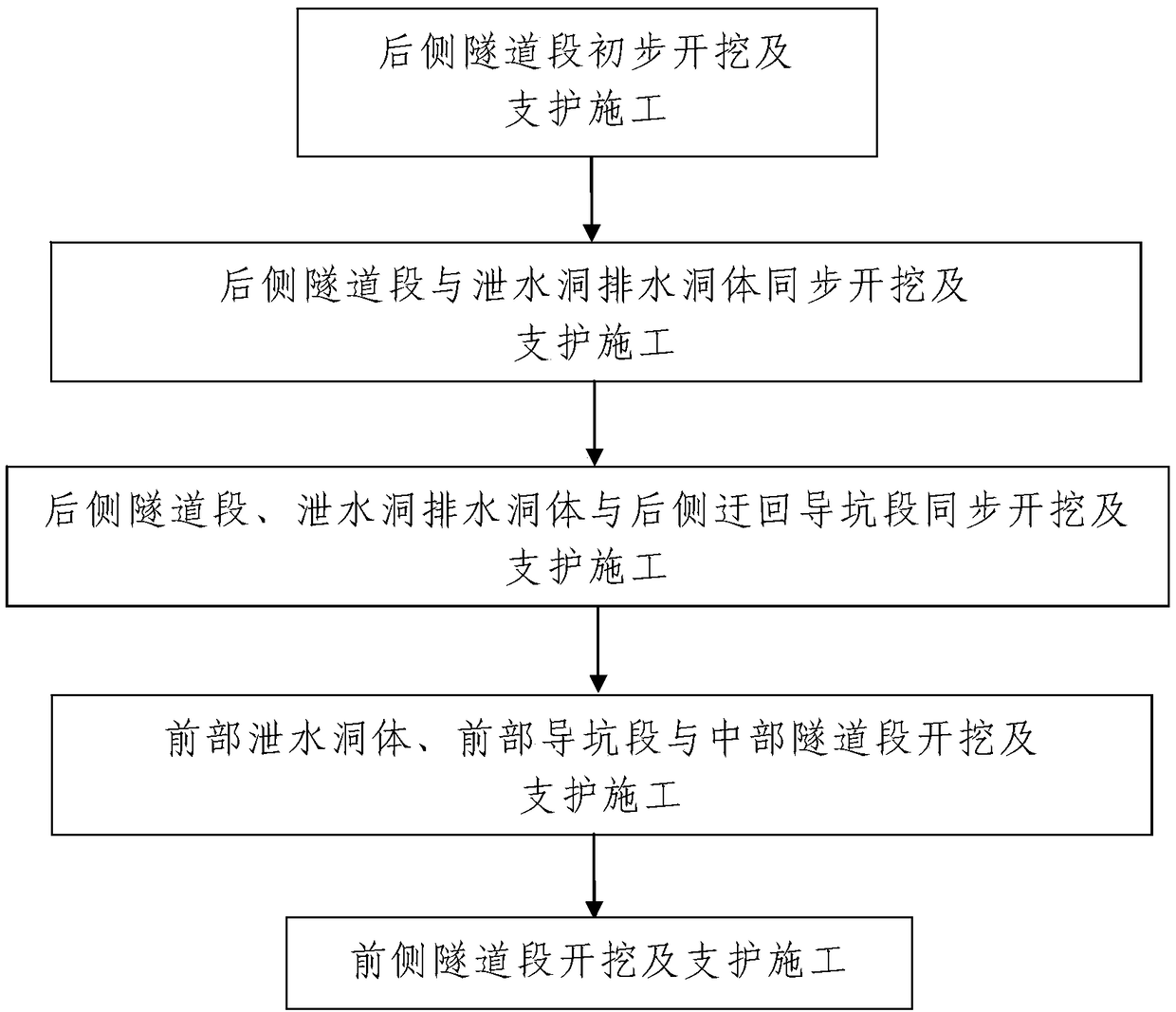

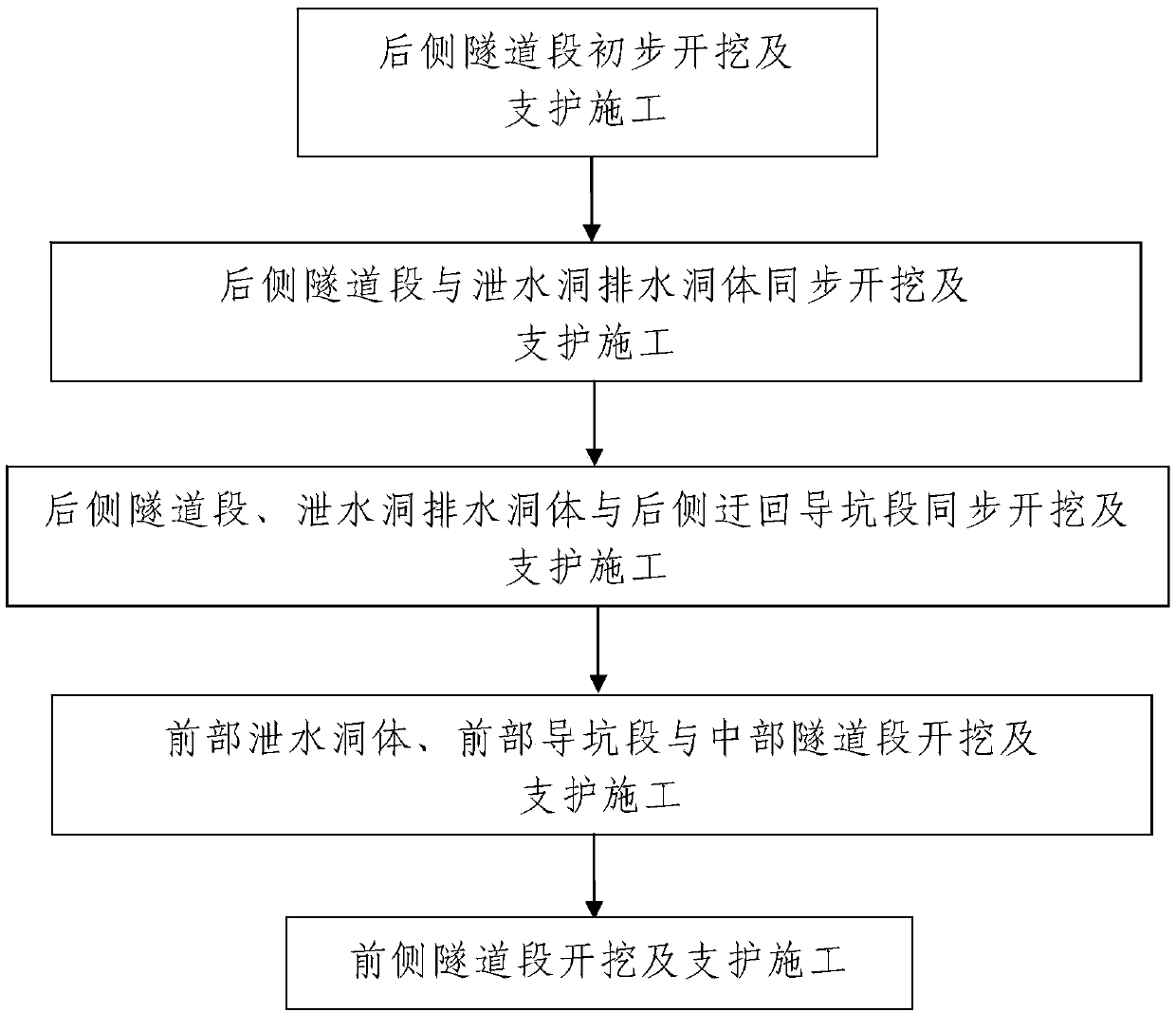

Construction method for tunnel passing through high-angle thrust water-rich and sand-rich fault

ActiveCN109209397AThe method steps are simpleReasonable designUnderground chambersDrainageStructural safetyHigh angle

The invention discloses a construction method for a tunnel passing through a high-angle thrust water-rich and sand-rich fault. The method comprises the steps: 1, performing the preliminary excavationand the supporting construction of a rear tunnel segment; 2, performing the synchronous excavation and the supporting construction of the rear tunnel segment and a water drainage hole body of a waterdrainage hole; 3, performing the synchronous excavation and the supporting construction of the rear tunnel segment, the water drainage hole body of the water drainage hole and a rear detouring headingsegment; 4, performing the excavation and the supporting construction of a front water drainage hole body, a front heating segment and a central tunnel segment; 5, performing the excavation and the supporting construction of a front tunnel segment. According to the invention, the water on the upper wall of the fault is drained through a high-level water drainage hole between a tunnel front hole and a detouring heading pit, and the auxiliary water drainage is performed through the detouring heading pit, and the fault condition in front of the tunnel face of the front hole can be explored in advance, thereby guaranteeing the construction safety of each tunnel face. The method employs the three-step method for the excavation of the tunnel front hole, employs double preliminary supporting structures for the full-section supporting after excavation, can guarantee the safety of the tunnel structure later, and shortens the construction cycle.

Owner:CHINA RAILWAY 20 BUREAU GRP

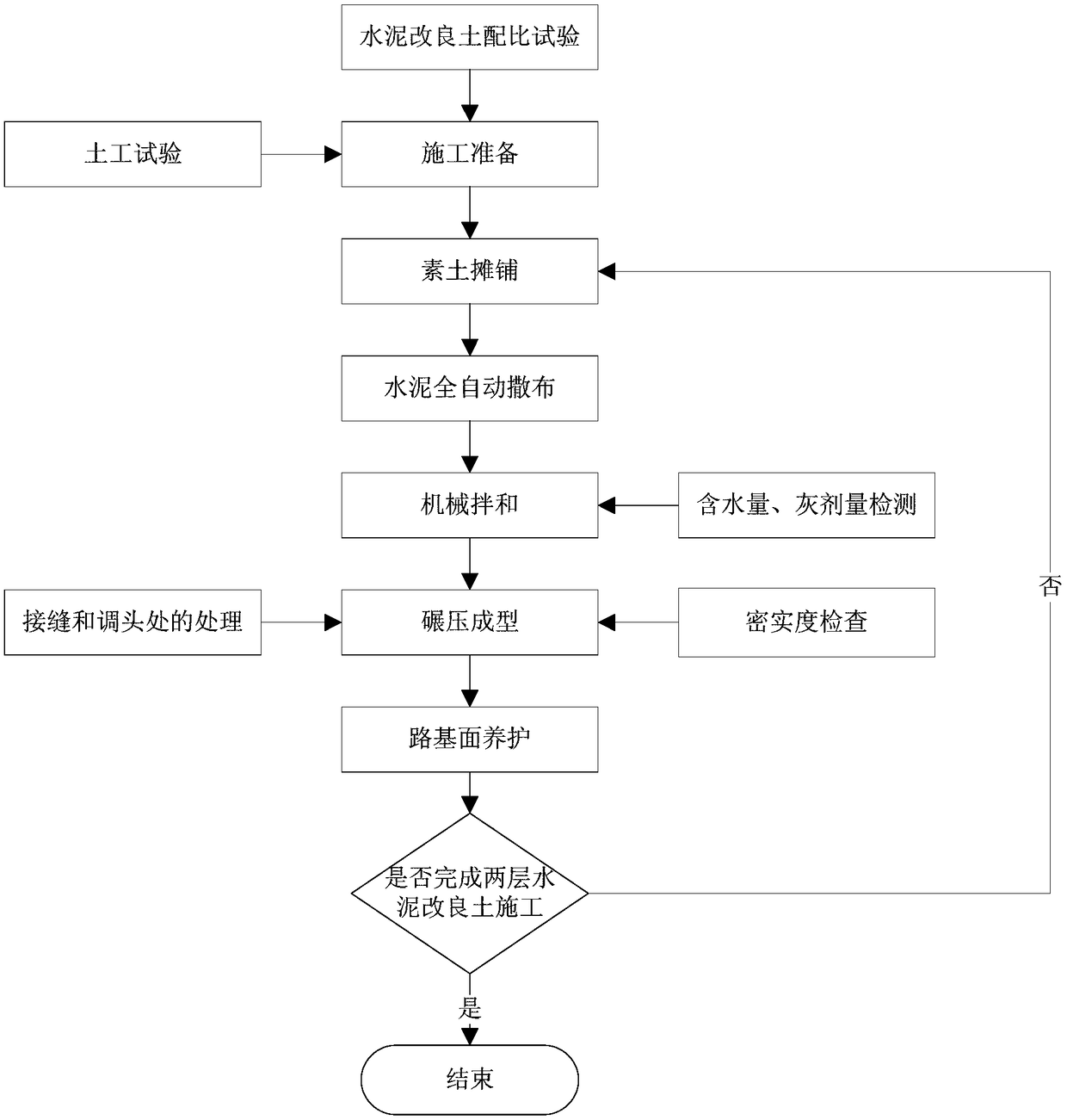

Construction method of recycler mixing cement improved soil on expressway top roadbed

InactiveCN108611940AImprove construction efficiencyImprove construction qualityRoadwaysMicrocontrollerNumerical control

The invention discloses a construction method of a recycler mixing cement improved soil on an expressway top roadbed. The construction method of the recycler mixing cement improved soil on the expressway top roadbed comprises the steps of carrying out cement improved soil mixing ratio test; inspecting parameters, such as longitudinal section elevation, of a lower bearing layer to meet a construction condition; transporting plain soil to a construction site; after the filling of the plain soil is finished, using a bulldozer to roughly level off the plain soil; using a land leveller to finely level off the plain soil and measuring the elevation of the plain soil; using a full-automatic cement disperser to disperse lime; using a numerical control high-accuracy flow regulating valve to controlthe cement dispersing number; using a recycler and a sprinkling truck to sprinkle water water and mix, controlling the mixing depth by using a microcontroller, and using the numerical control high-accuracy flow regulating valve to control the water sprinkling amount; after the cement improved soil is mixed, detecting the compaction degree after the the cement improved soil is rolled and finely leveled off; curing the cement improved soil after the detection is finished, wherein the curing period is not less than 7 days; and after the construction of the first layer of the cement improved soilis finished, the first layer of the cement improved soil is disqualified through detection and the first layer of the cement improved soil is sprinkled with water and covered by soil to be cured, repeating the step 3 to the step 7 to carry out the construction of a second layer of the cement improved soil.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

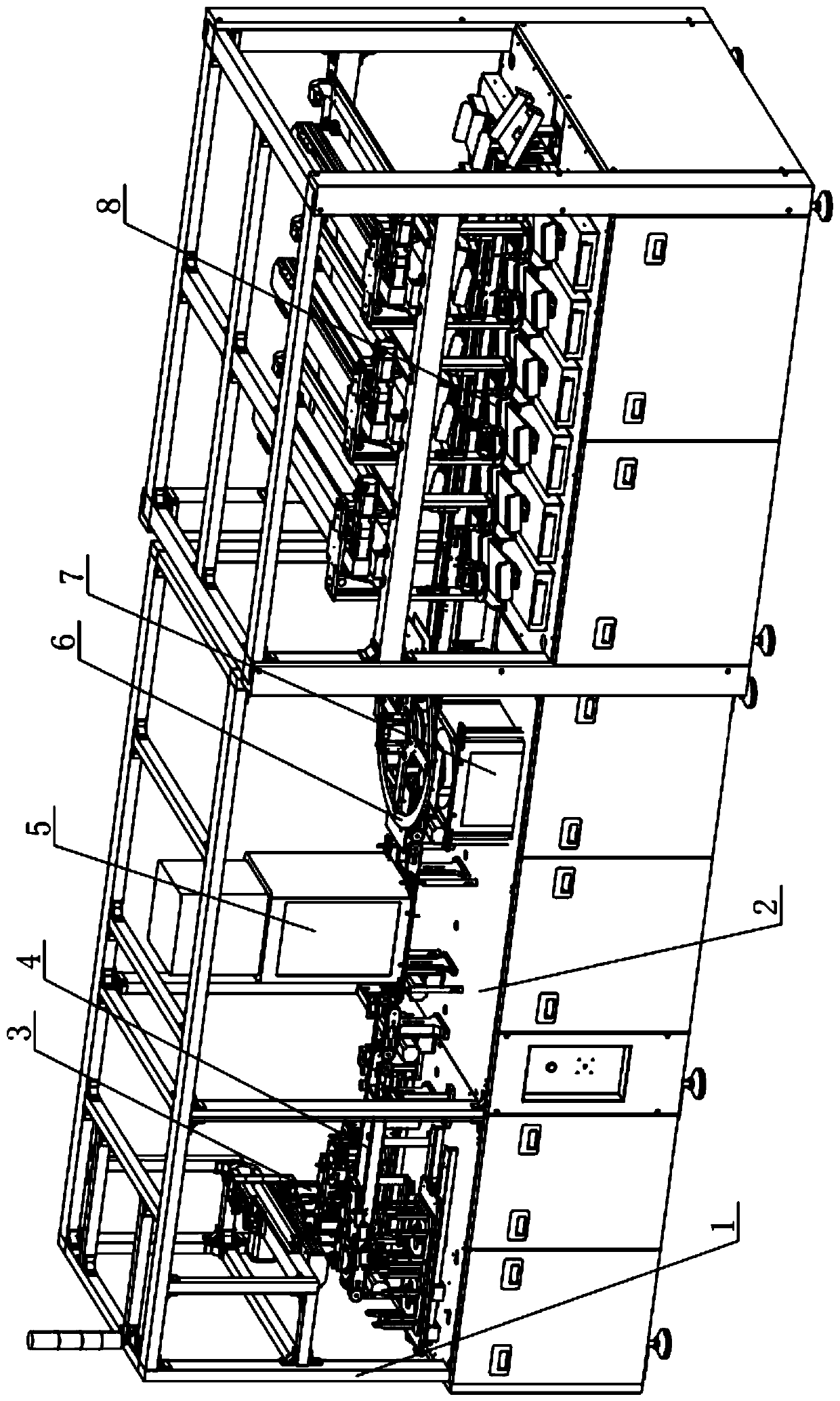

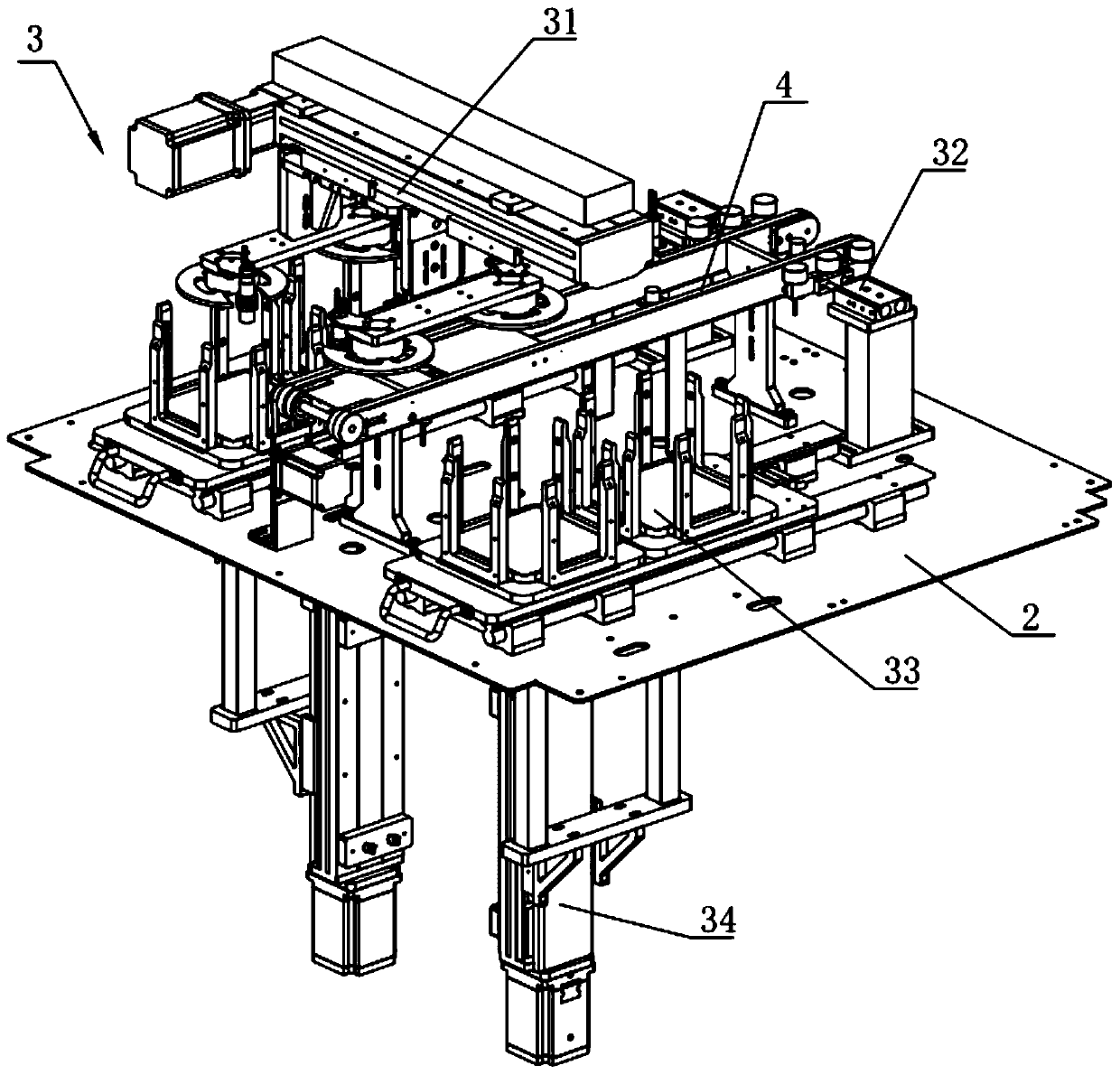

Silicon wafer detecting sorting machine and sorting method thereof

PendingCN111482374AImprove work efficiencyGuarantee delivery qualitySortingCamera lensFace detection

The invention relates to a silicon wafer detecting sorting machine and a sorting method thereof. The machine comprises a rack, a work platform is mounted on the rack, a loading station, a detecting station and a classifying station are sequentially mounted on the work platform from left to right, a power conveying belt penetrating through the loading station, the detecting station and the classifying station in sequence is mounted in the middle of the work platform, the detecting station comprises a first camera obscura and a second camera obscura, cameras are mounted in the first camera obscura and the second camera obscura correspondingly, one camera lens faces downwards and is located above the power conveying belt, the other camera lens faces upwards, the height of the camera lens is lower than the height of the power conveying belt, a transfer mechanism moves silicon wafers to the power conveying belt from a material frame one by one, the camera in the first camera obscura carriesout front face detection, under assistance of a rotating disc mechanism, the camera in the second camera obscura carries out reverse detection, the silicon wafers with qualified appearance flow to the classifying station to be sorted to different color system material boxes along with the power conveying belt, dual-face appearance detection and color system classifying of the silicon wafers can be achieved, work efficiency is high, and silicon wafer sorting is greatly facilitated.

Owner:无锡森顿智能科技有限公司

Application of trestle type beam slab bridge in inland river with beaches at both sides

InactiveCN102477716ASave timeReduce in quantityBridge applicationsBridge erection/assemblyVegetationWater flow

The invention relates to bridge construction, in particular to an application of a trestle type bridge. An application of a trestle type beam slab bridge in an inland river with beaches at the both sides comprises the following step of carrying out piled beam installation, bridge floor construction and piling operation in the water flow. The invention has the beneficial effect that when a trestle method is used for carrying out bridge construction on the inland river with the beaches at the both sides, the requirements on vegetation and fish protection can be satisfied.

Owner:CHINA MCC20 GRP CORP

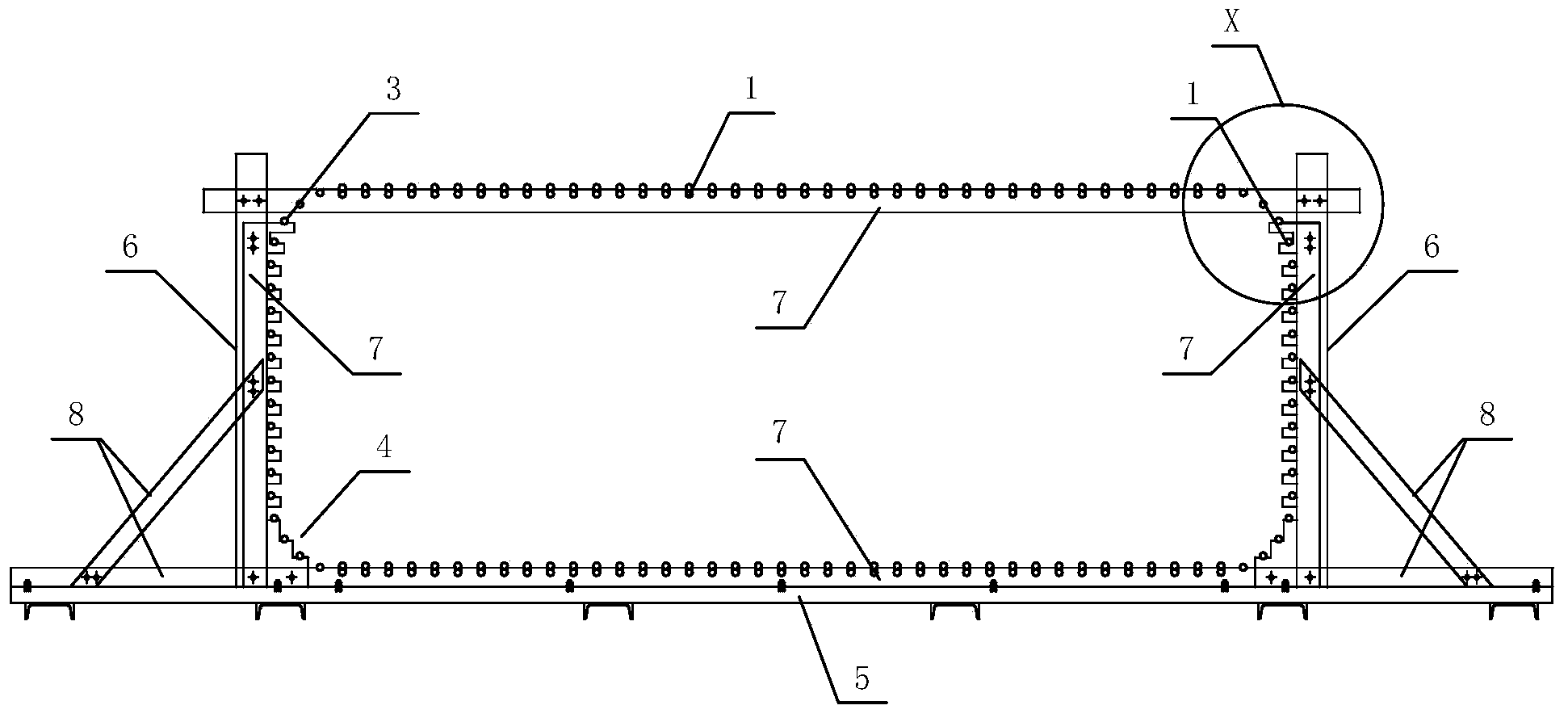

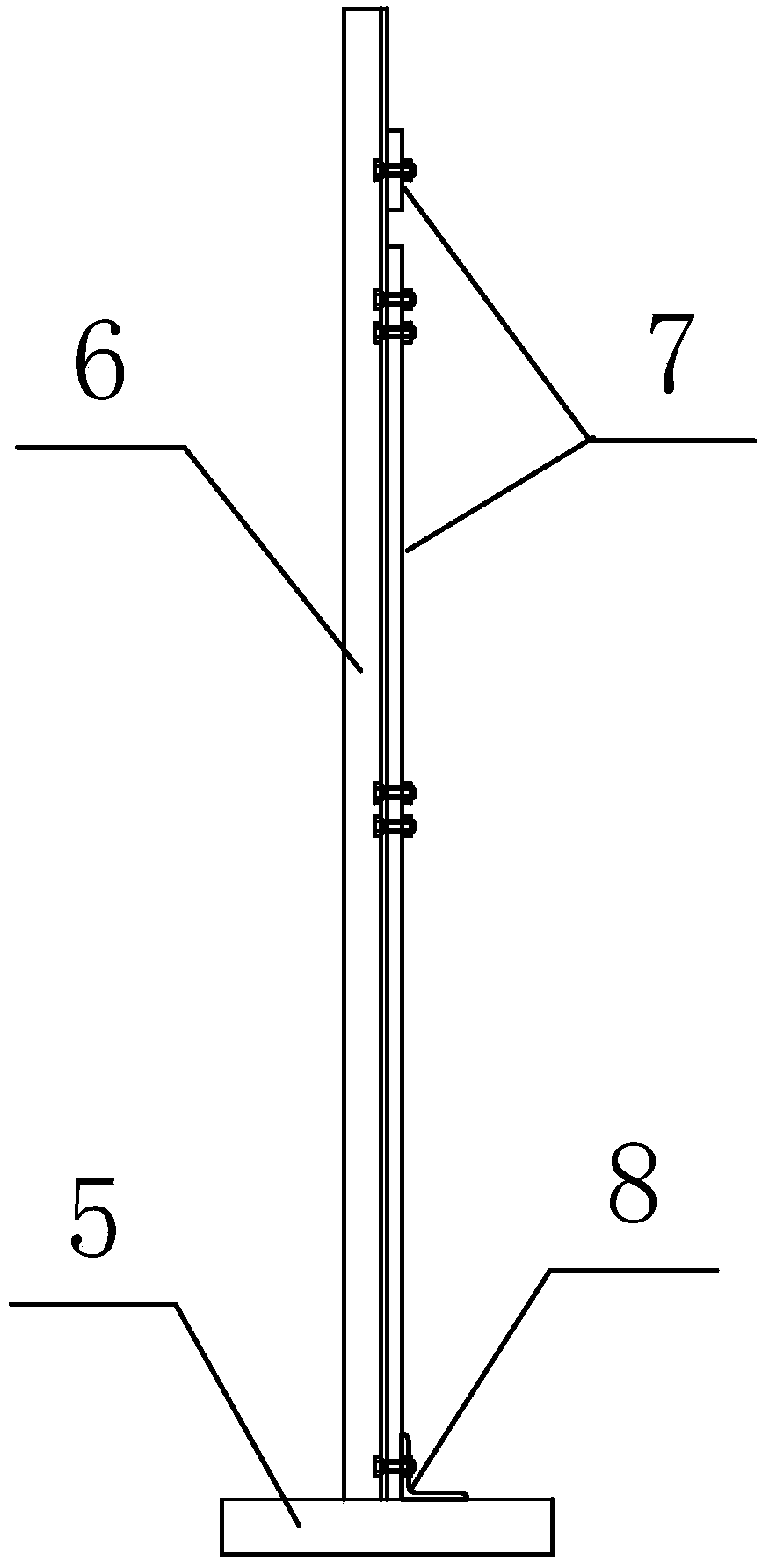

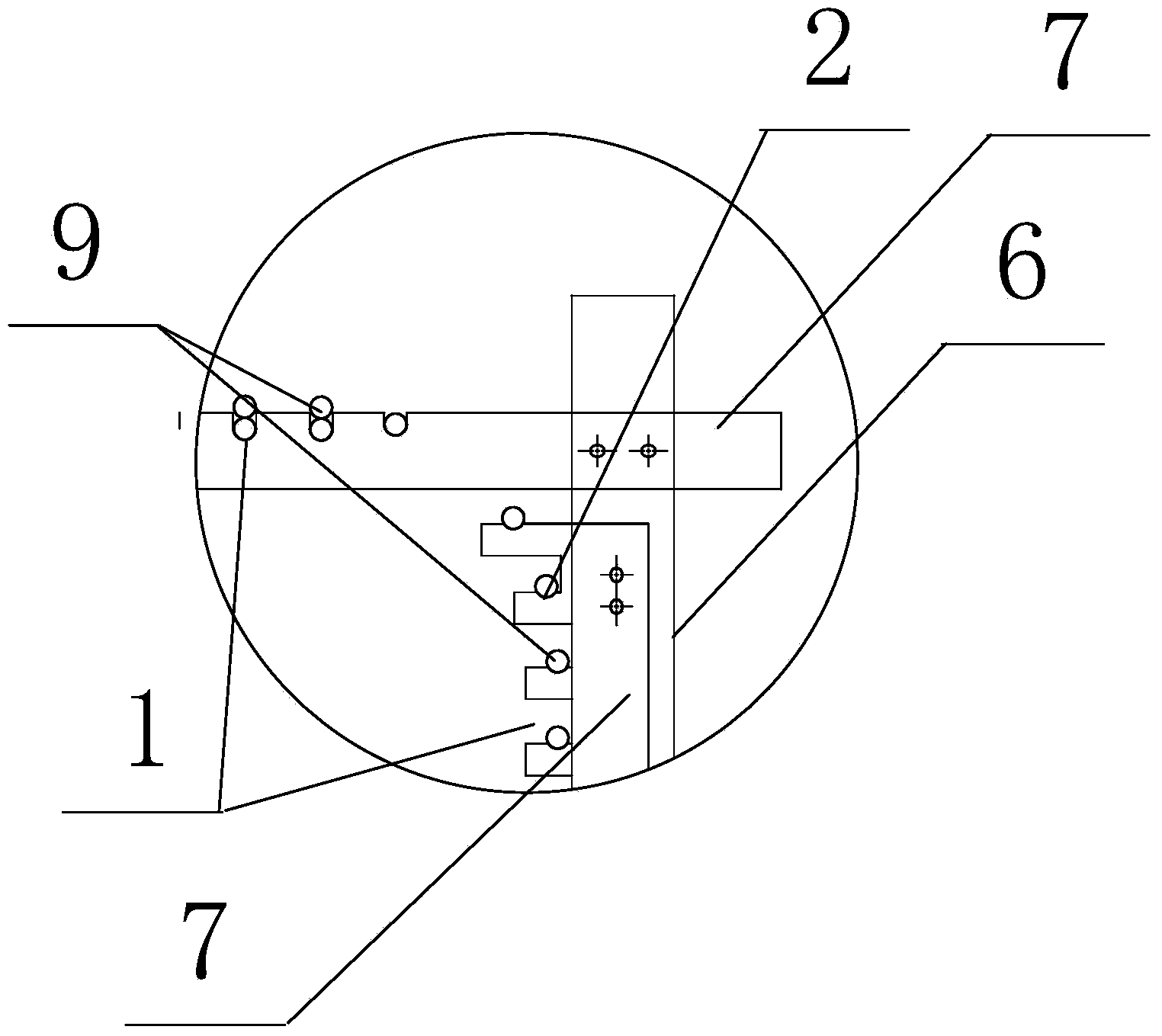

Steel reinforcement cage overall precast scaffold for wide pier body of cross-sea bridge

ActiveCN103924526AImprove working environmentQuality is easy to controlBridge erection/assemblyRebarBuilding construction

The invention discloses a steel reinforcement cage overall precast scaffold for a wide pier body of a cross-sea bridge, and belongs to the field of under bridge component construction tools. The steel reinforcement cage overall precast scaffold for the wide pier body of the cross-sea bridge comprises a frame component with all edges detachable, a plurality of grooves are formed in the upper surface of the top edge and the upper surface of the bottom edge of the frame assembly in the length direction, and a plurality of grooves are also formed in the inner surface of the left side edge and the inner surface of the right side edge of the frame assembly in the length direction. The steel reinforcement cage overall precast scaffold for the wide pier body of the cross-sea bridge is high in construction efficiency, high in quality, safe, reliable, and particularly suitable for construction of wide pier body reinforcing bar engineering under severe marine environments.

Owner:CCCC SHEC FOURTH ENG +1

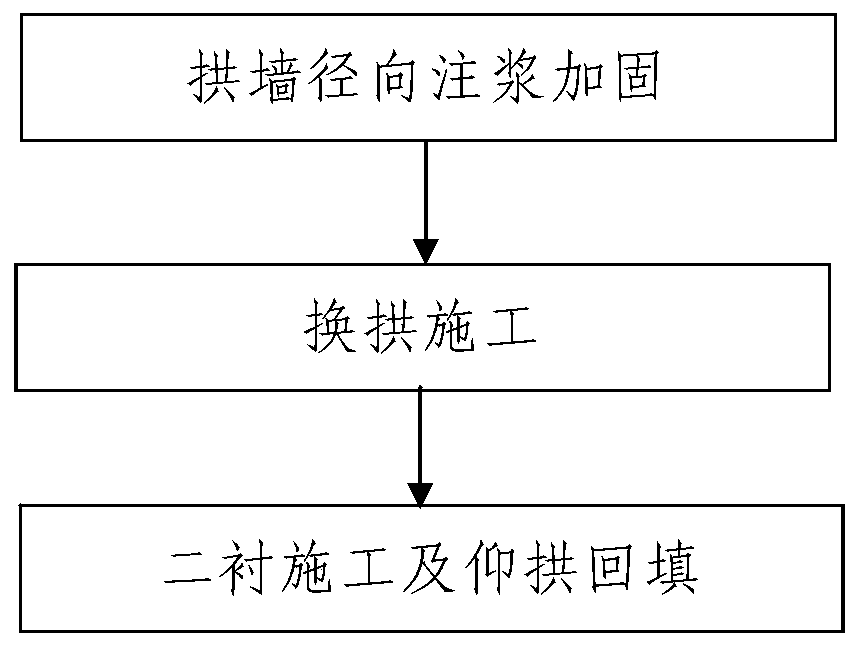

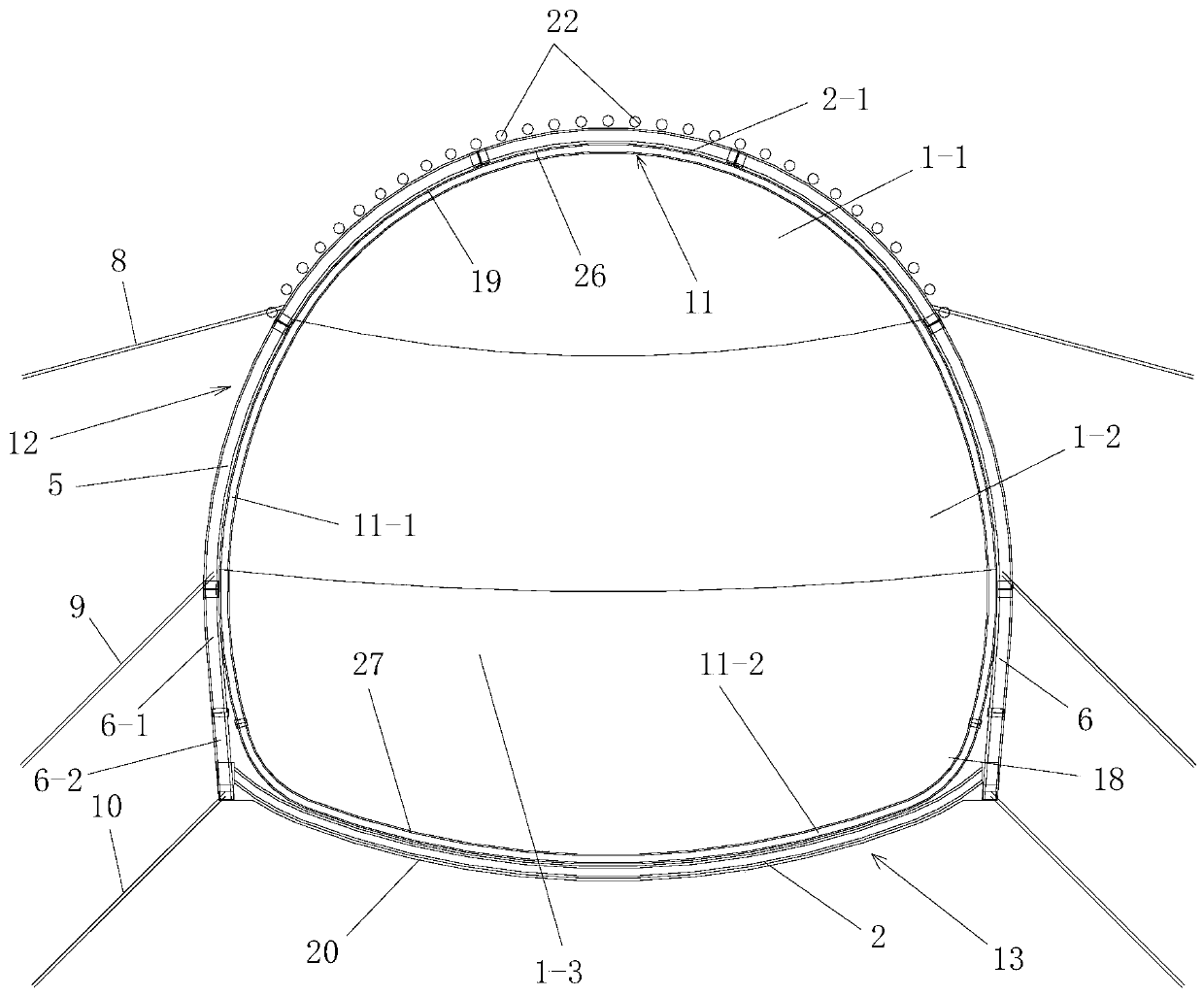

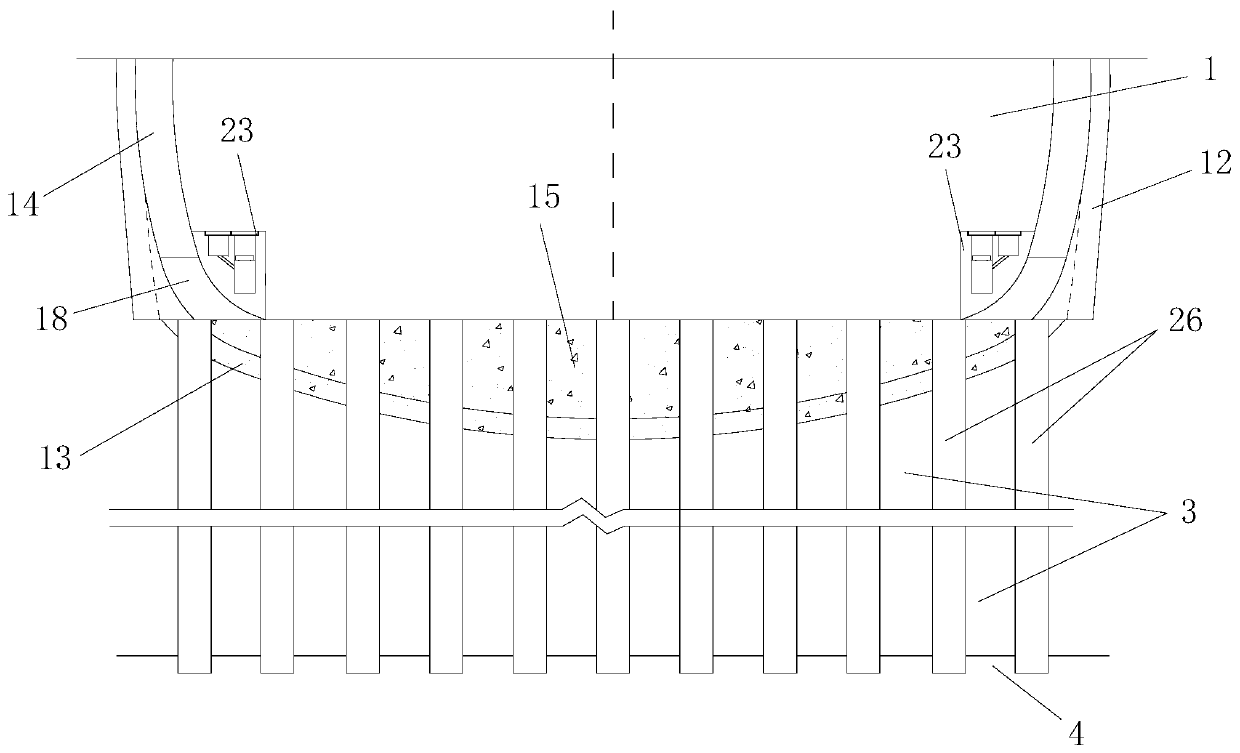

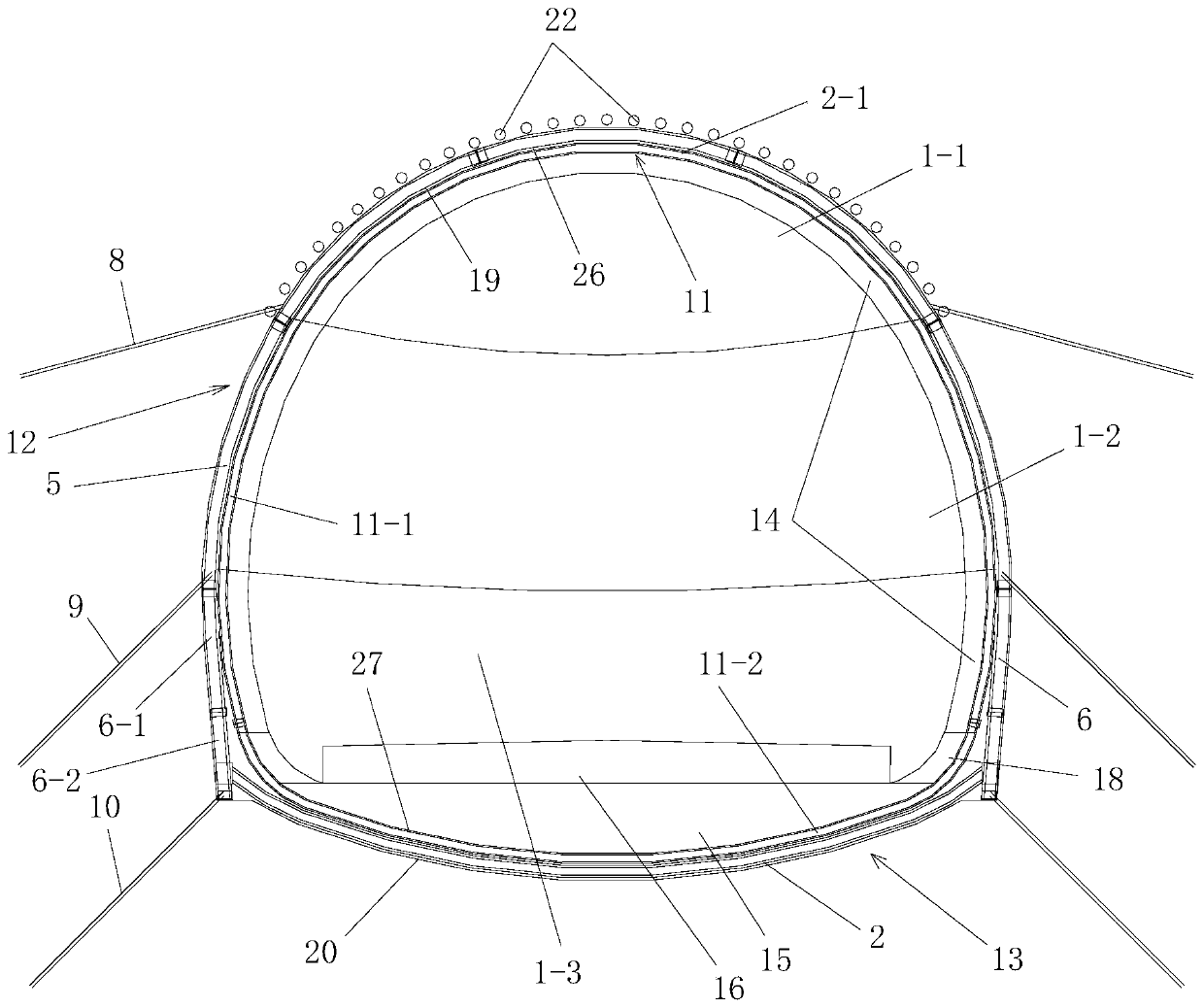

Method for beyond-limit arch replacing construction during preliminary bracing of large-section loess tunnel

ActiveCN110656959AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a method for beyond-limit arch replacing construction during preliminary bracing of a large-section loess tunnel. The method includes the steps of firstly, conducting radial grouting reinforcement on an arch wall, wherein radial grouting reinforcement is conducted on an arch replacing required section where arch replacing is required in the constructed loess tunnel from back to front; and secondly, conducting arch replacing construction, wherein a reinforced preliminary bracing structure in the arch replacing required section is detached, and preliminary bracing construction is conducted on the arch replacing required section synchronously in the detaching process. The method is simple in step, reasonable in design, simple in construction and good in use effect; theradial grouting reinforcement is conducted on the arch wall to reinforce the arch wall of a tunnel hole first, so the structural stability of the tunnel in the arch replacing process is ensured; segmented reinforcing is conducted on the preliminary bracing structure of the tunnel through a plurality of sleeve arch units for a reinforced sleeve arch in the arch replacing required section, so detaching is convenient; and moreover, the sleeve arch units are complementary and together improve the supporting force, so the adverse effects on the structural stability of the tunnel in the detaching process of each sleeve arch unit can be effectively reduced, and the safety and reliability of the arch replacing construction process are ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

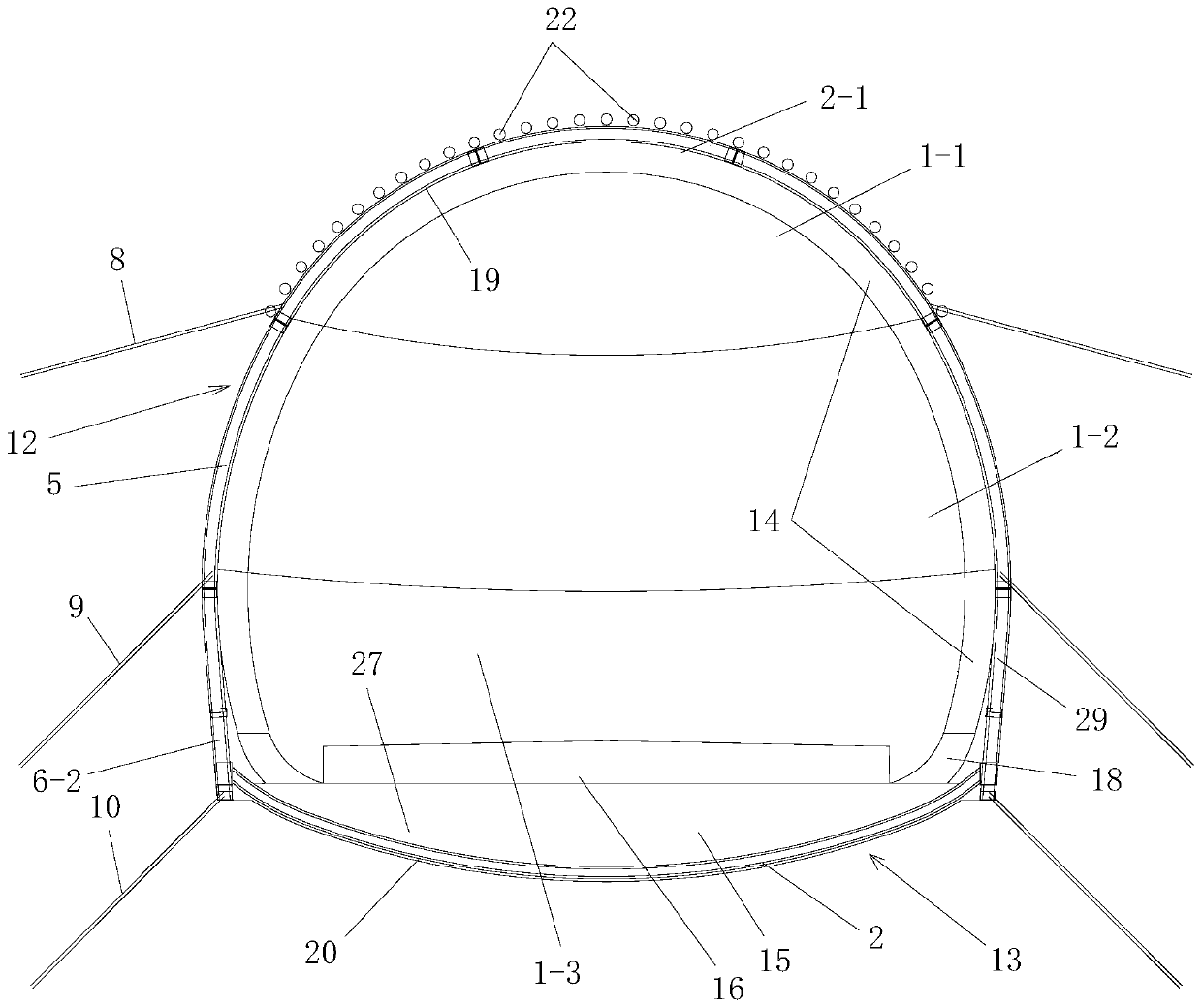

Loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles

PendingCN110671131AReasonable designReduce construction costsUnderground chambersTunnel liningStructural engineeringGeotechnical engineering

The invention discloses a loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles. The structure comprises the multiple rows of high pressure jet grouting piles for reinforcing soil on the lower portion of a tunnel, and each high pressure jet grouting pile passes through a tunnel invert structure and a collapsible loess stratum from top to bottom andthen extends into a non collapsible loess stratum. The method comprises the following steps of firstly, tunnel excavating and preliminary bracing; secondly, second lining construction; and thirdly, foundation base reinforcing. The structure is reasonable in design, easy and convenient to construct and good in use effect. The multiple rows of high pressure jet grouting piles are adopted for carrying out foundation base reinforcing on a loess tunnel, a loess tunnel foundation base can be simply and rapidly effectively reinforced, the tunnel foundation base settling volume can be effectively controlled, meanwhile, the upper surface of a secondary lining inverted arch is adjusted to the horizontal plane, a construction platform is provided for the high pressure jet grouting piles, the loess tunnel foundation base reinforcing process can be further quickened, the high pressure jet grouting piles and the tunnel invert structure are fastened and connected into a whole, and the loess tunnel foundation base reinforcing effect can be further improved.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

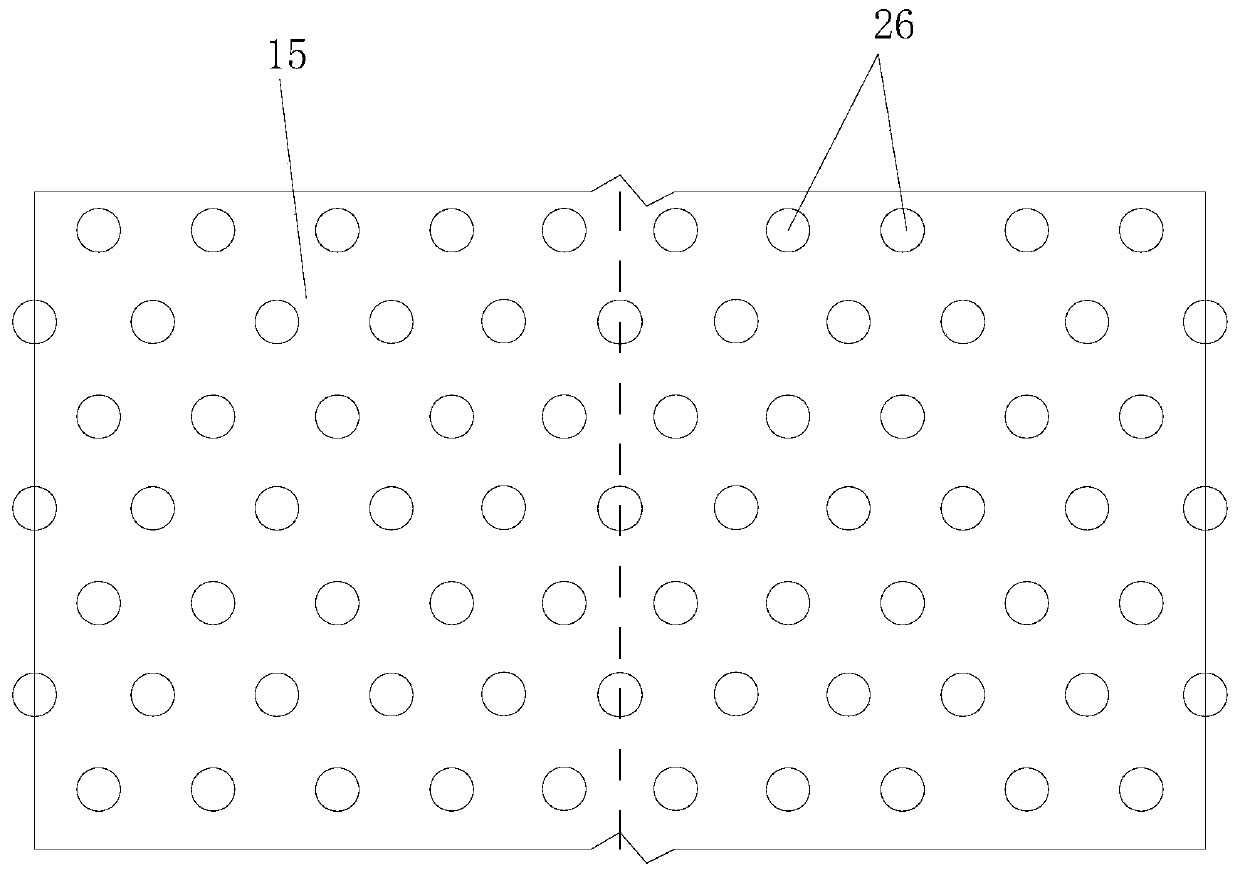

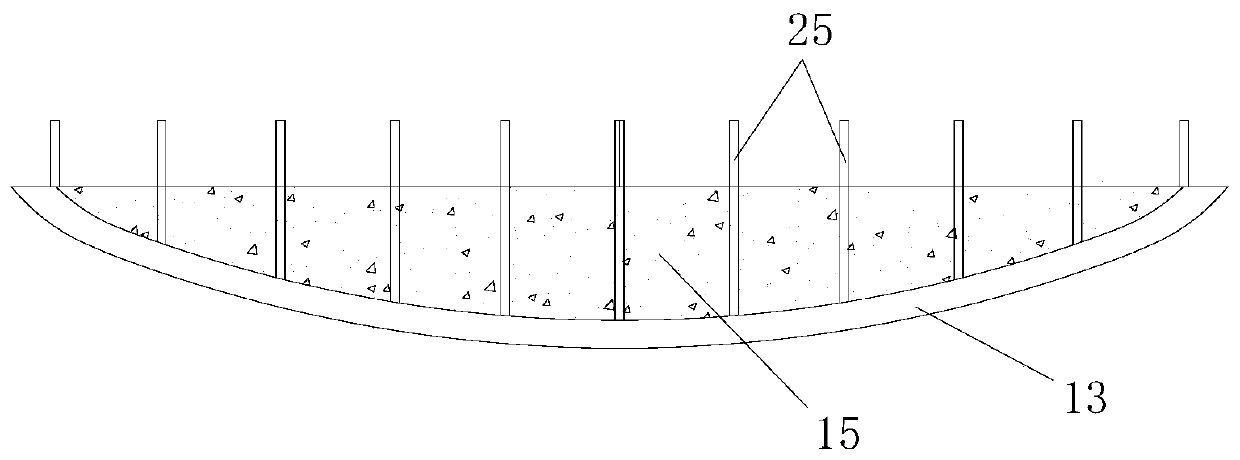

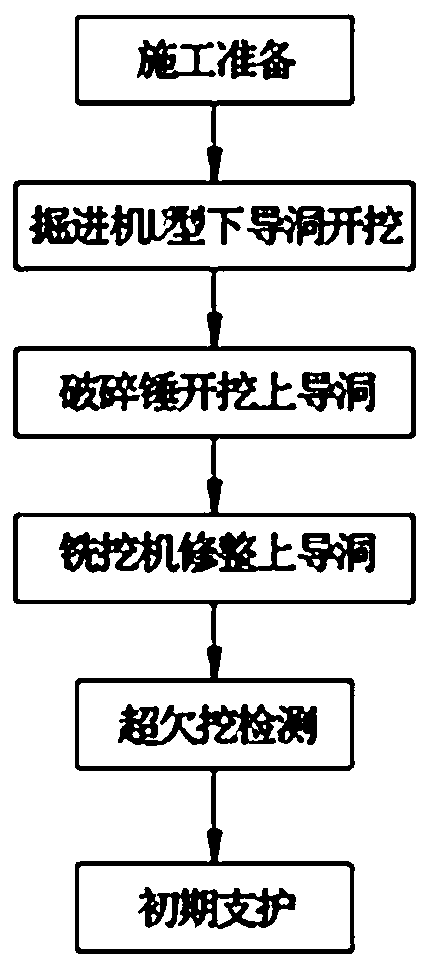

A large-section soft rock tunnel excavation construction method

ActiveCN109594988AIncrease the speed of excavationImprove construction qualityTunnelsEconomic benefitsRock tunnel

The invention provides a large-section soft rock tunnel excavation construction method which comprises the following steps that a laser reference point is projected to the section of a tunnel, a lowerpilot tunnel is excavated in the lower portion of the section of the tunnel, and muck is transferred out of the lower pilot tunnel; a side wall of the lower pilot tunnel is trimmed according to the laser reference point as a reference point; an upper pilot tunnel is excavated in the section of the tunnel from bottom to top; and after excavation of the upper pilot tunnel is completed, the laser reference point serves as a reference point, and the section contour line of the upper pilot tunnel is trimmed. By means of the construction method, the excavation speed of the large-section soft rock tunnel can be increased, procedure connection is compact, time is saved, equipment abrasion can be reduced, the construction quality is high, surrounding rock disturbance is small, safety and reliability are achieved, and the economic benefit effect is remarkable.

Owner:核工业井巷建设集团有限公司

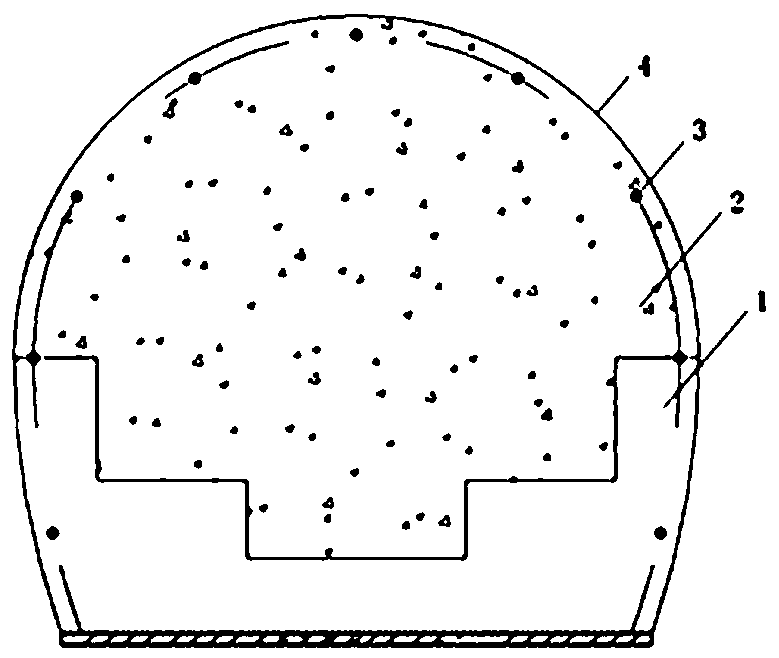

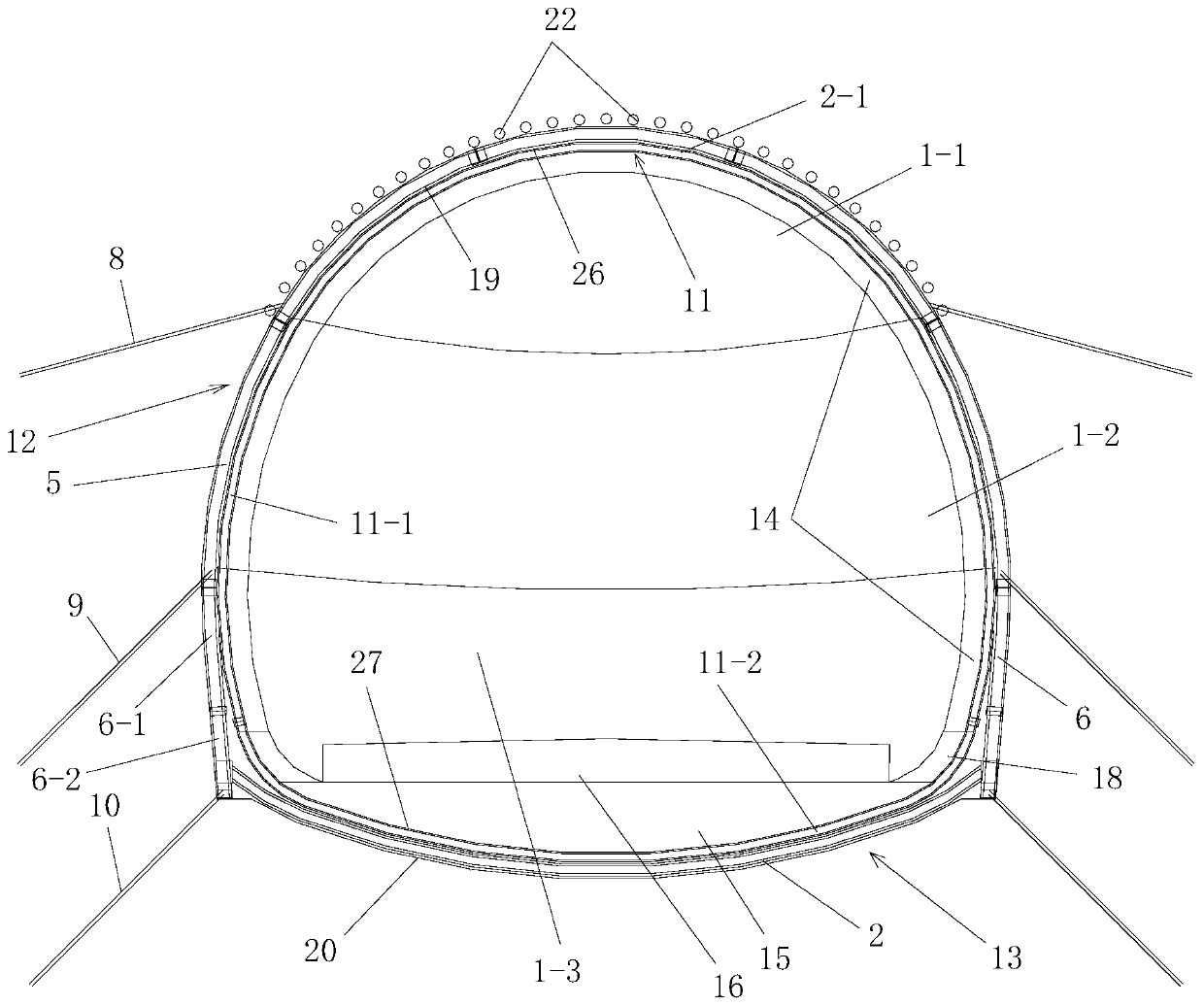

Large-section loess tunnel supporting system and supporting construction method

PendingCN110761808AReasonable structural designEasy constructionUnderground chambersTunnel liningGeotechnical engineeringStructure support

The invention discloses a large-section loess tunnel supporting system and a supporting construction method. The large-section loess tunnel supporting system comprises a tunnel forepoling structure, atunnel initial supporting structure and a tunnel secondary lining. The upper surface of an inverted arch secondary lining in the tunnel secondary lining is a horizontal plane, and an inverted arch backfill layer is arranged on the horizontal plane. The supporting construction method comprises the following steps of firstly digging a tunnel and conducting initial supporting; and secondly constructing the secondary lining and backfilling the inverted arch. The large-section loess tunnel supporting system is reasonable in design, easy and convenient to construct, high in construction efficiencyand good in use effect, the tunnel forepoling structure, the tunnel initial supporting structure and the tunnel secondary lining constitute a combined supporting system to stably and reliably supportthe large-section loess tunnel, the upper surface of the inverted arch of the secondary lining is adjusted to be a horizontal plane, the construction process of the inverted arch of the tunnel can beeffectively simplified, and the rigidity of the inverted arch of the tunnel is greatly improved; in this way, the construction efficiency of the tunnel secondary lining is improved, the ring sealingtime of the tunnel secondary lining is shortened, the integrity of the tunnel secondary lining is higher, and the overall force bearing effect is better.

Owner:CHINA RAILWAY 20 BUREAU GRP

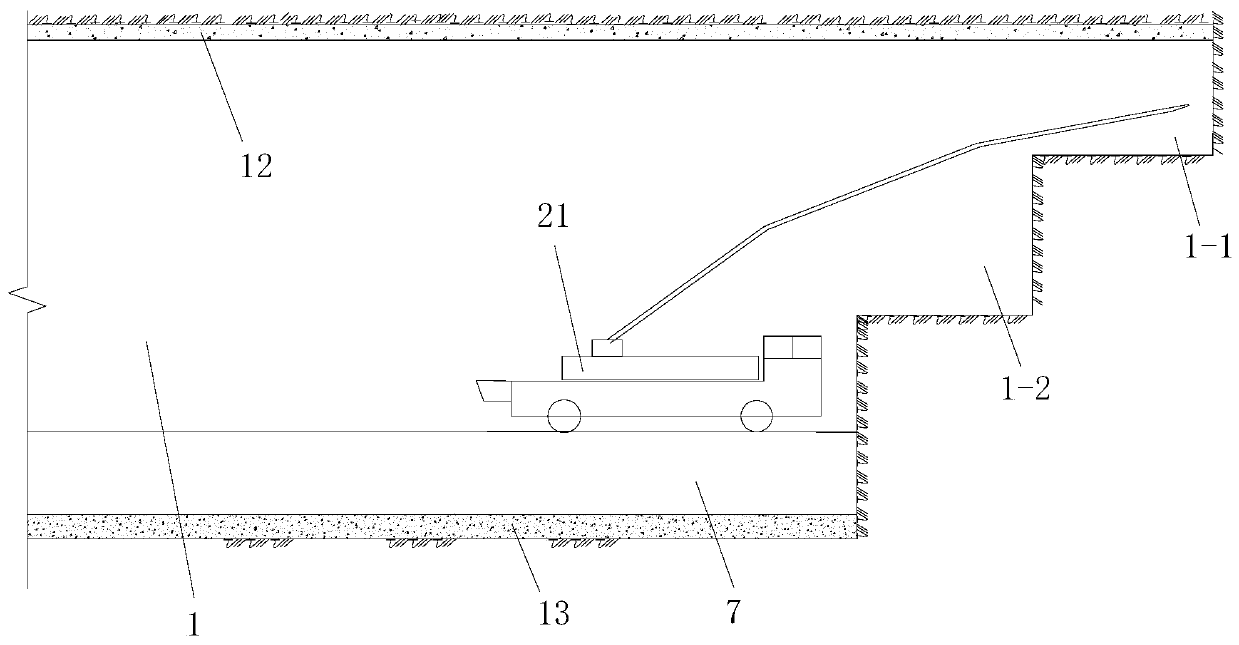

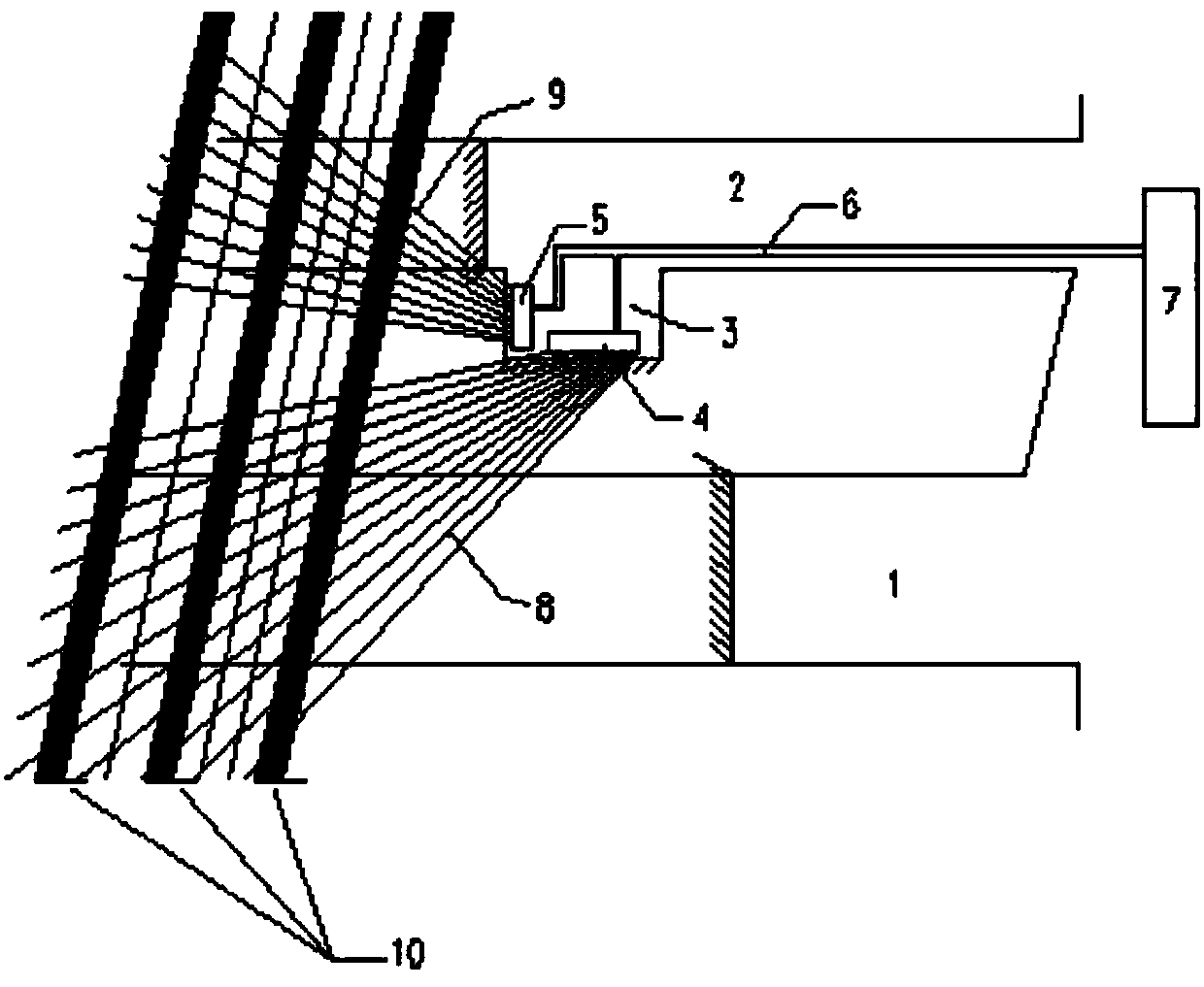

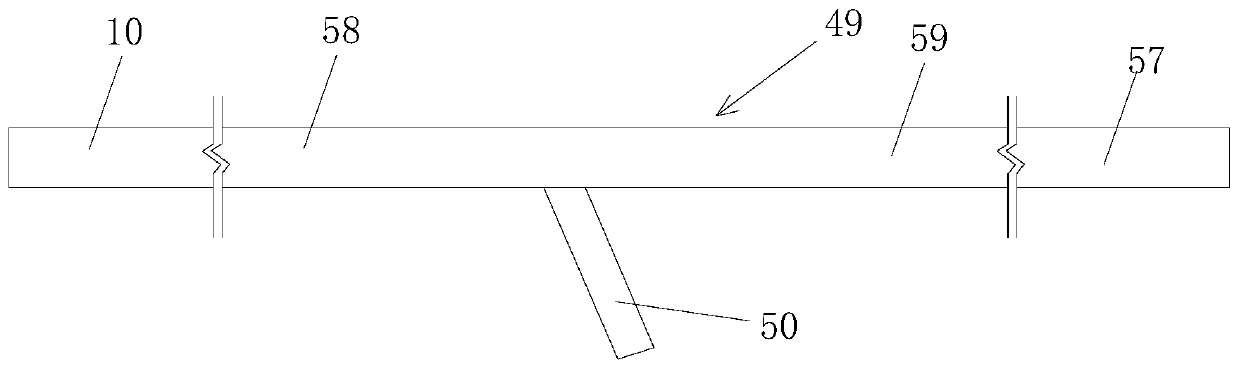

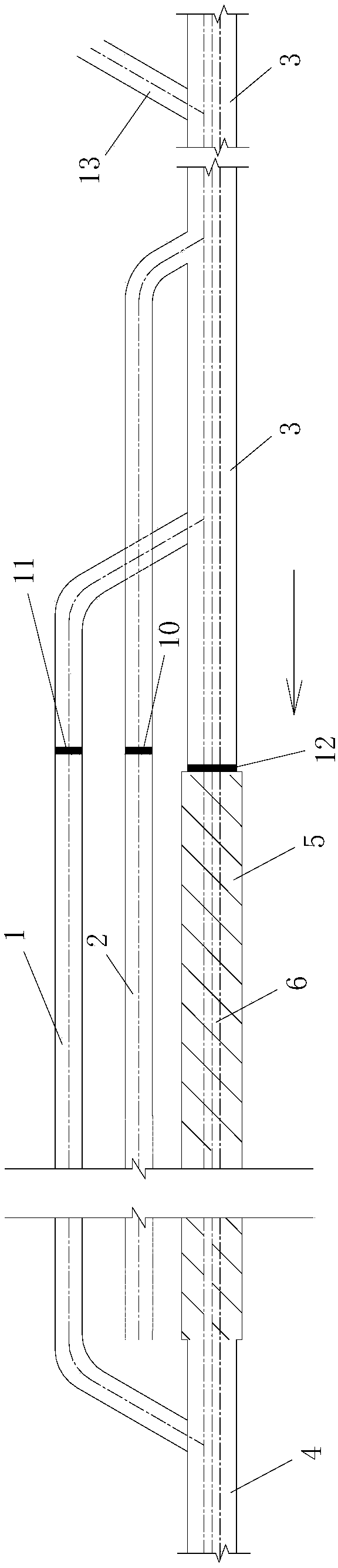

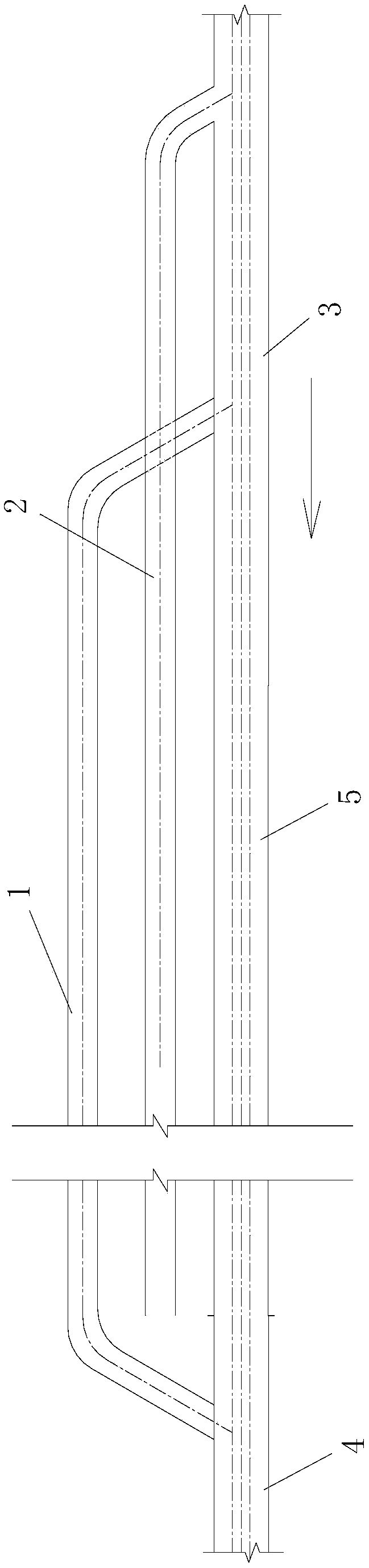

Method of gas drainage for construction of tunnel and parallel adit passing through coal seamd

InactiveCN110067591AThe process is closely connectedStrong maneuverabilityGas removalTunnel engineeringCoal

The invention discloses a method of gas drainage for the construction of a tunnel and a parallel adit passing through coal seams, and relates to a tunnel engineering technology. The method comprises the following steps that (1) at least one parallel adit hole is formed in a main hole independently in the tunneling direction of the main hole; (2) holes are drilled in the direction of a coal seam inthe parallel adit holes in the step (1), parallel adit drainage holes and main hole drainage holes are formed, the parallel adit drainage holes are drilled to a coal seam in front of the parallel adit holes, and the main hole drainage holes are drilled to a coal seam in front of the main hole; and (3) gas is drained from the parallel adit drainage holes and the main hole drainage holes and is discharged out of the parallel adit holes. According to the method of gas drainage for the construction of the tunnel and the parallel adit passing through the coal seams, advanced gas drainage through the tunnel and the parallel adit passing through the coal seams is realized, the working procedure connection is compact, the operability is high, the drainage effect is reliable, and the requirementsof energy saving and environmental protection are met.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

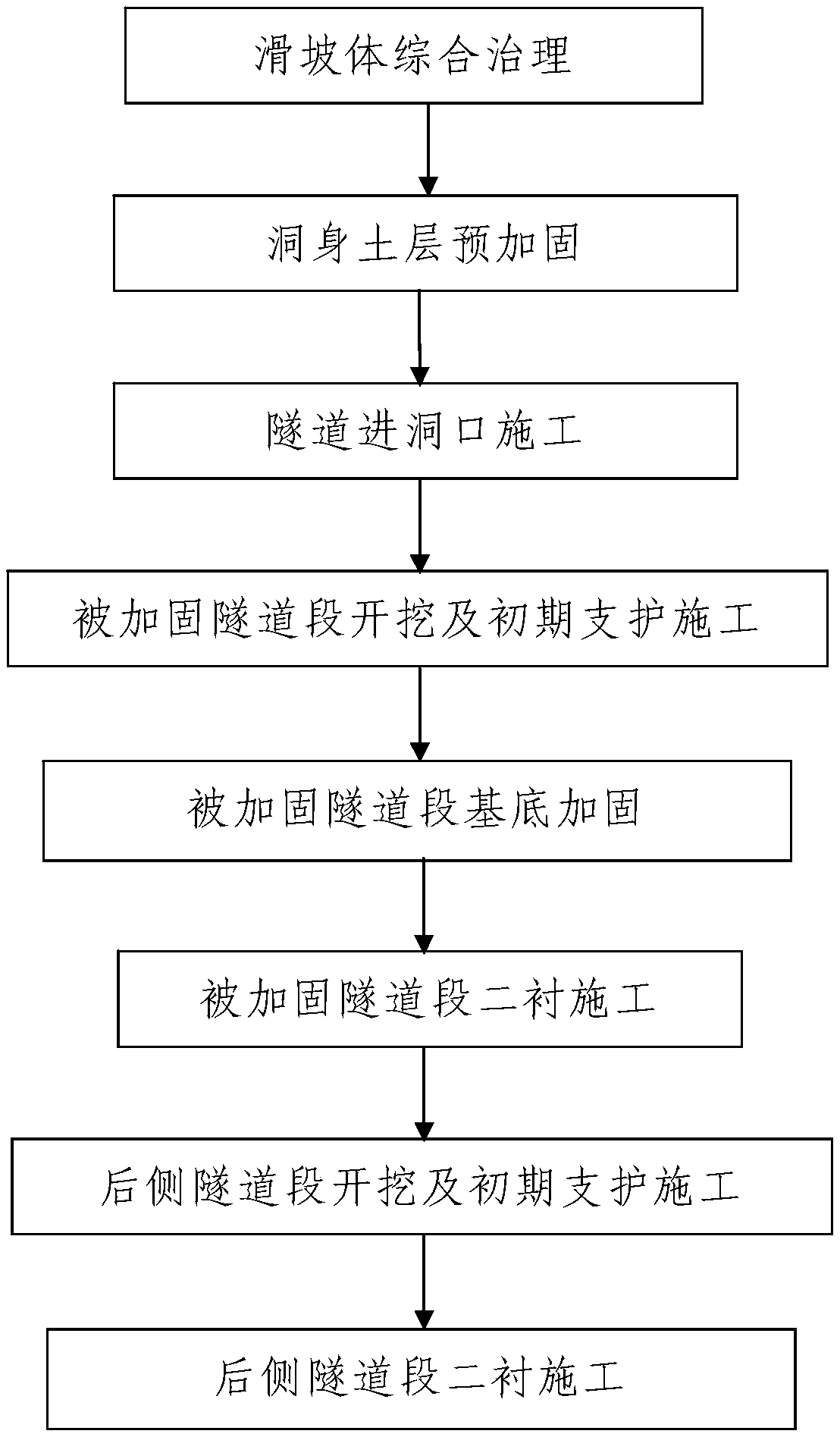

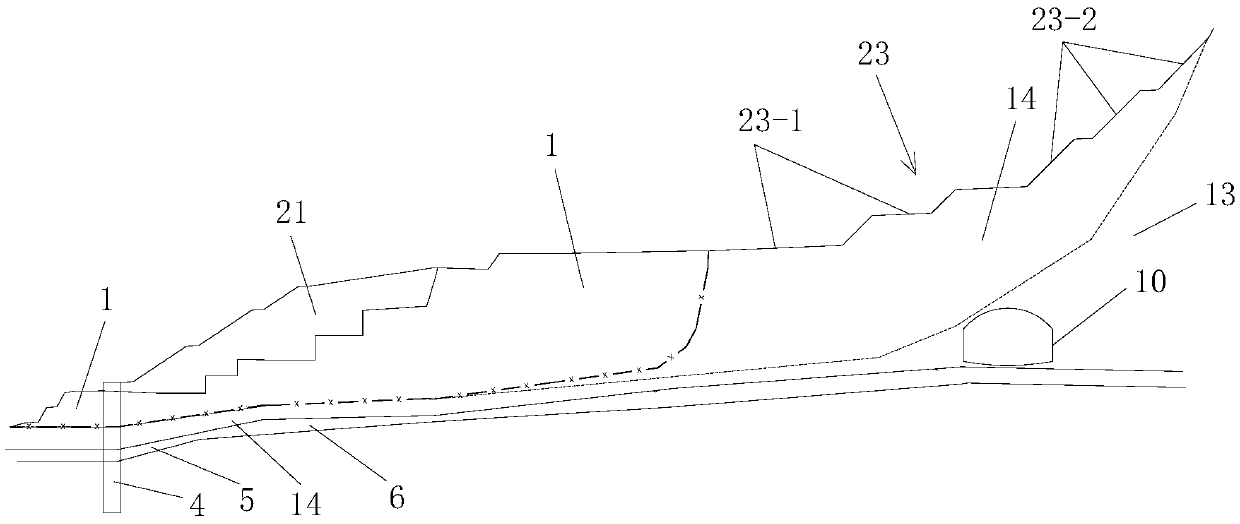

Construction method of loess tunnel entrance section through landslide mass

ActiveCN110778328AThe method steps are simpleReasonable designUnderground chambersExcavationsLandslideStructural engineering

The invention discloses a construction method of a loess tunnel entrance section through a landslide mass. The method comprises the following steps that 1, an entrance soil layer is pre-reinforced; 2,a tunnel entrance is constructed; 3, excavation and initial support construction is conducted on the reinforced tunnel section; 4, a reinforced tunnel section base is reinforced; 5, the reinforced tunnel section is subjected to secondary lining construction; 6, excavation and initial support construction is conducted on a rear side tunnel section; and 7, the rear side tunnel section is subjectedto secondary lining construction. The method is reasonable in design, simple and convenient to construct and good in use effect, cement-soil mixed piles are adopted for pre-reinforcement before excavation, a construction process of the tunnel entrance section through the landslide mass is guaranteed to be safe and reliable, meanwhile, the tunnel entrance section is excavated by adopting a three-step excavation method, the reinforced tunnel section base is reinforced, an excavation process of the tunnel entrance section through the landslide mass can be guaranteed to be safe and reliable, in addition, the influence on the stability of a soil layer on the circumferential side of the tunnel entrance is small, and the stability of the excavated and formed tunnel entrance can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP

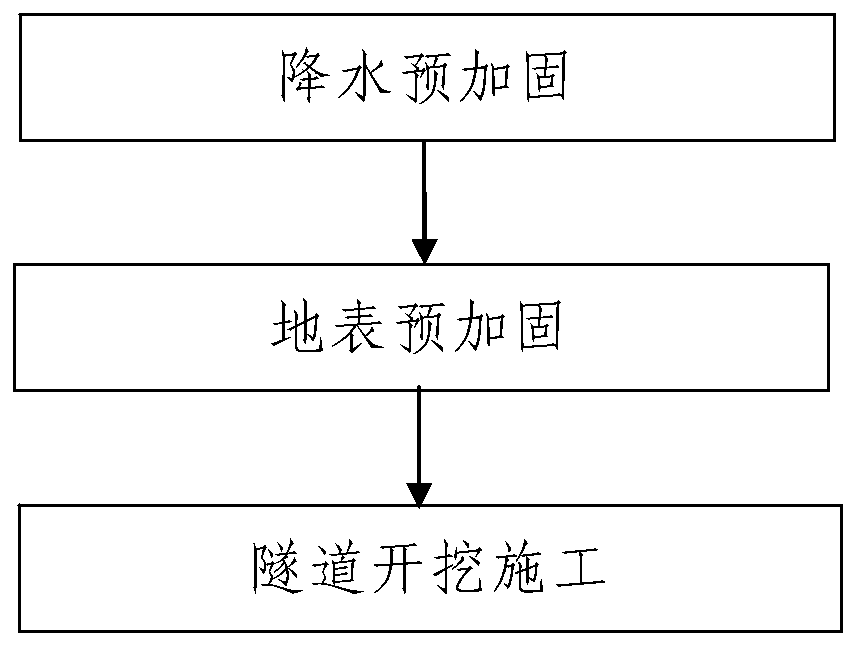

Tunnel portal section pre-reinforcement and excavation construction method based on partition blasting

ActiveCN110847929AConstruction safetyStable structureUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a tunnel portal section pre-reinforcement and excavation construction method based on partition blasting. The construction method comprises the following steps of 1, precipitation pre-reinforcement; 2, earth surface pre-reinforcement, and specifically, reinforcing the surface of a backfill section in a construction tunnel portal section through adopting a cement soil stirring pile; and 3, tunnel excavation construction, and specifically, carrying out excavation construction from rear to front in a plurality of excavation sections, wherein the process comprises the following steps of surveying and setting out, performing drilling and blasting construction, excavating an upper portal body, excavating a middle portal body and excavating a lower portal body. The construction method is reasonable in design, simple and convenient in construction and good in use effect; the underground water level is reduced through precipitation pre-reinforcement, and then surroundingrock is effectively reinforced; after the backfill section is subjected to surface pre-reinforcement through using the cement soil stirring pile, a three-step synchronous excavation mode is used forcarrying out partition blasting excavation, so that it is ensured that the tunnel excavation process is safe and reliable and a tunnel structure is stable.

Owner:CHINA RAILWAY 20 BUREAU GRP

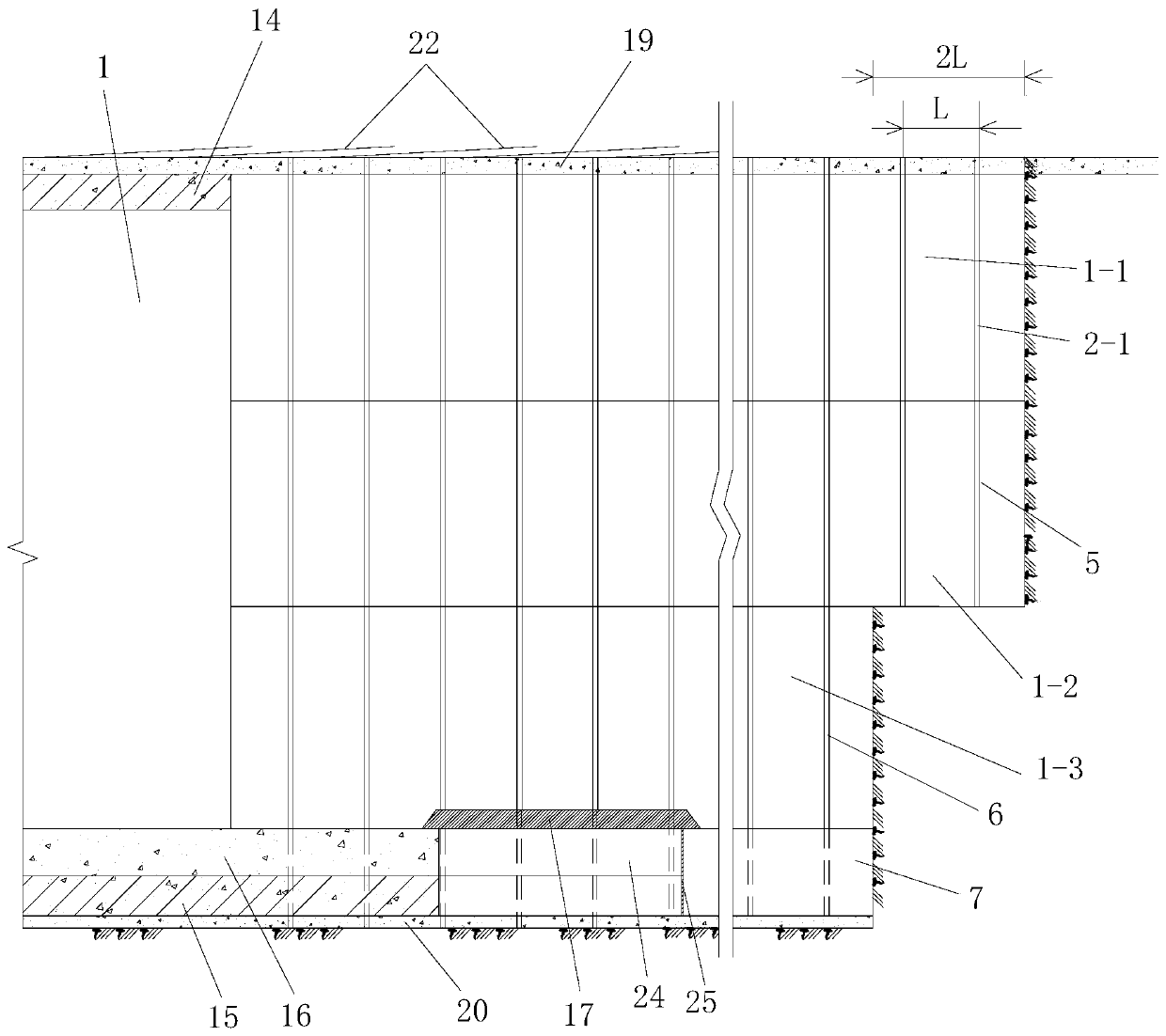

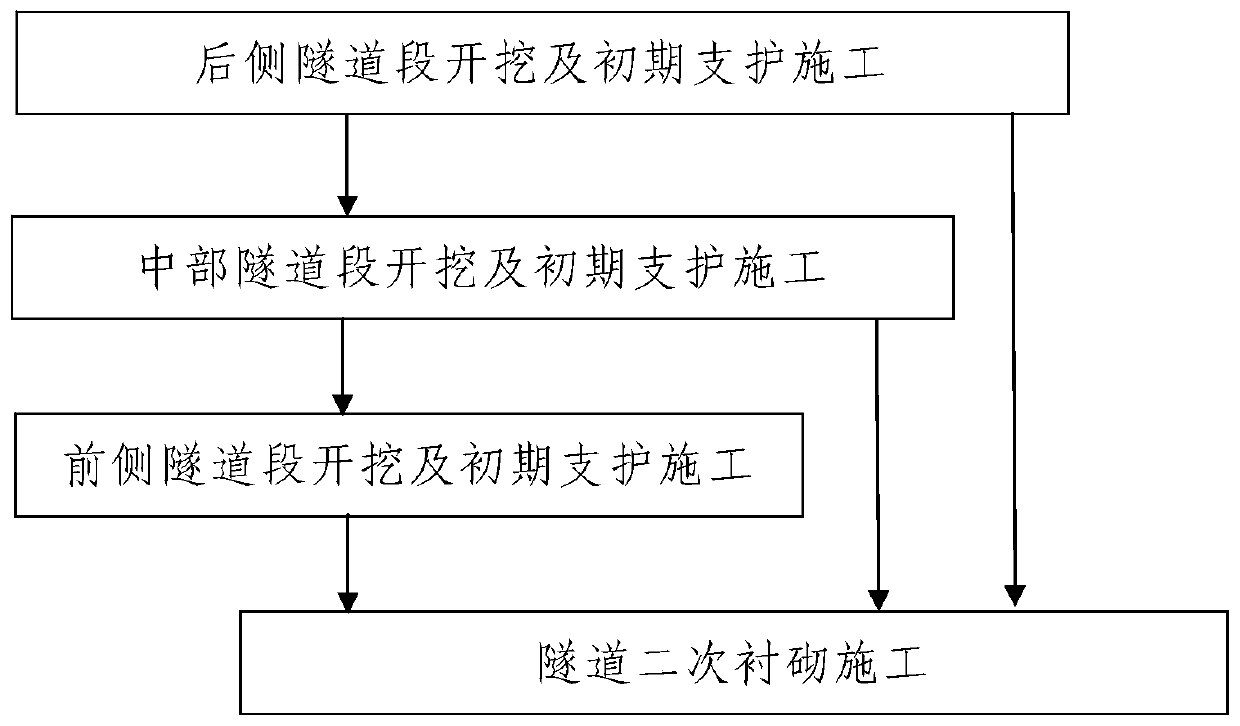

Tunnel construction method for passing through boundary strata of earth and stone

ActiveCN110985003AEffective reinforcementThe method steps are simpleUnderground chambersDrainageArchitectural engineeringDrilling and blasting

The invention discloses a tunnel construction method for passing through the boundary stratum of earth and stone. The tunnel construction method comprises the following steps: I, excavation of a reartunnel segment and initial supporting construction; II, excavation of a middle tunnel segment and initial supporting construction; III, excavation of a front tunnel segment and initial supporting construction, wherein the rear tunnel segment, the middle tunnel segment and the front tunnel segment are all three-step synchronous excavated tunnel segments; and in the process of excavation from rear to front, constructing the secondary lining of the tunnel on the inner side of the initial supporting structure of the constructed tunnel from rear to front. The tunnel construction method has the advantages of reasonable design, simple construction and good use effect. The tunnel construction method selects an appropriate drilling and blasting method according to the position relationship betweenthe earth and stone interface and a tunnel hole, adopts a three-step synchronous excavation way to carry out blasting excavation, can ensure the safe and reliable excavation process of the tunnel passing through the boundary stratum of earth and stone, and can ensure the stable structure of the tunnel. Moreover, in the excavation process, the initial supporting structure and the secondary lining of the tunnel are adopted to provide stable and reliable supporting for the large-section tunnel.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Polycondensation production technology of melamine moulding particles and melamine moulding powder

The invention relates to a polycondensation production technology of melamine moulding particles and melamine moulding powder. The technology comprises the following steps: 1. in the slurry preparation phase, adding 55-65 parts of formaldehyde, 3-5 parts of thinner and 3-5 parts of water in a slurry reaction tank, heating and stirring, adjusting the pH value of slurry to 8.0-8.5 at 50 DEG C, adding 35-45 parts of melamine at 60 DEG C, heating for boiling to ensure the ratio of material to water to be 1:2, then performing cooling water circulation to reduce the temperature of material to 30-40DEG C, adding additives of which each accounts for 5-8 parts, stirring evenly, filtrating to prepare the desired slurry; 2. in the evaporation and polycondensation phase, adding the slurry in a vacuumwet pelletizing reaction tank, stirring at high speed, adding additives of which each accounts for 3-5% and 30-40% of auxiliary material, heating the materials to 70 DEG C to perform polymerization for 40min, breaking vacuum, reducing the temperature to 60 DEG C, discharging to obtain the finished melamine moulding particles; in addition, adding the melamine moulding particles in a grinder to grind to obtain the melamine moulding powder with the fineness of 80-100 meshes. The sealing production cycle is four hours, the charging powder yield is 60%, the water content of the finished product is3-5% and the cost of the finished product per ton is reduced by 500-900 RMB.

Owner:任志广

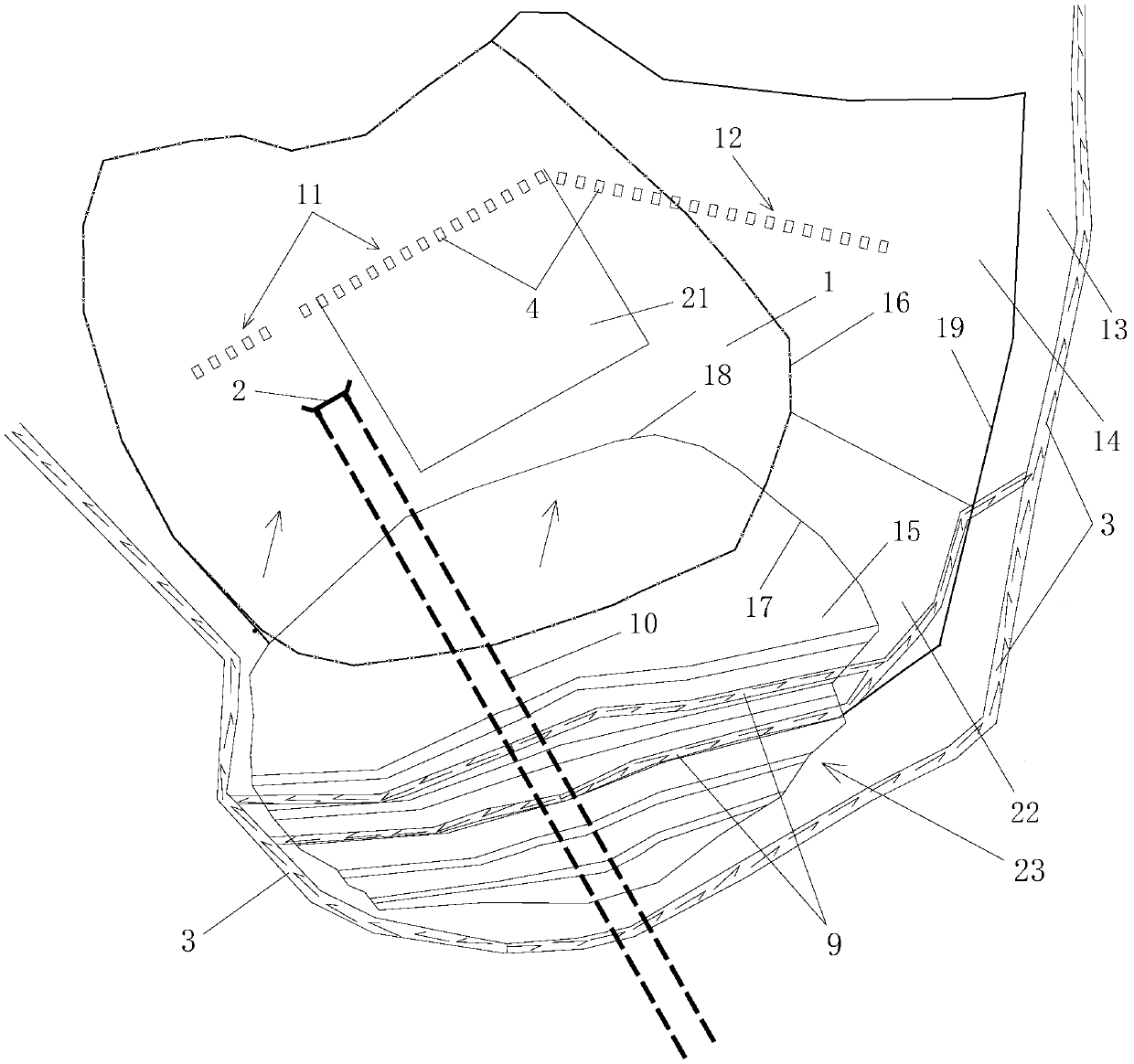

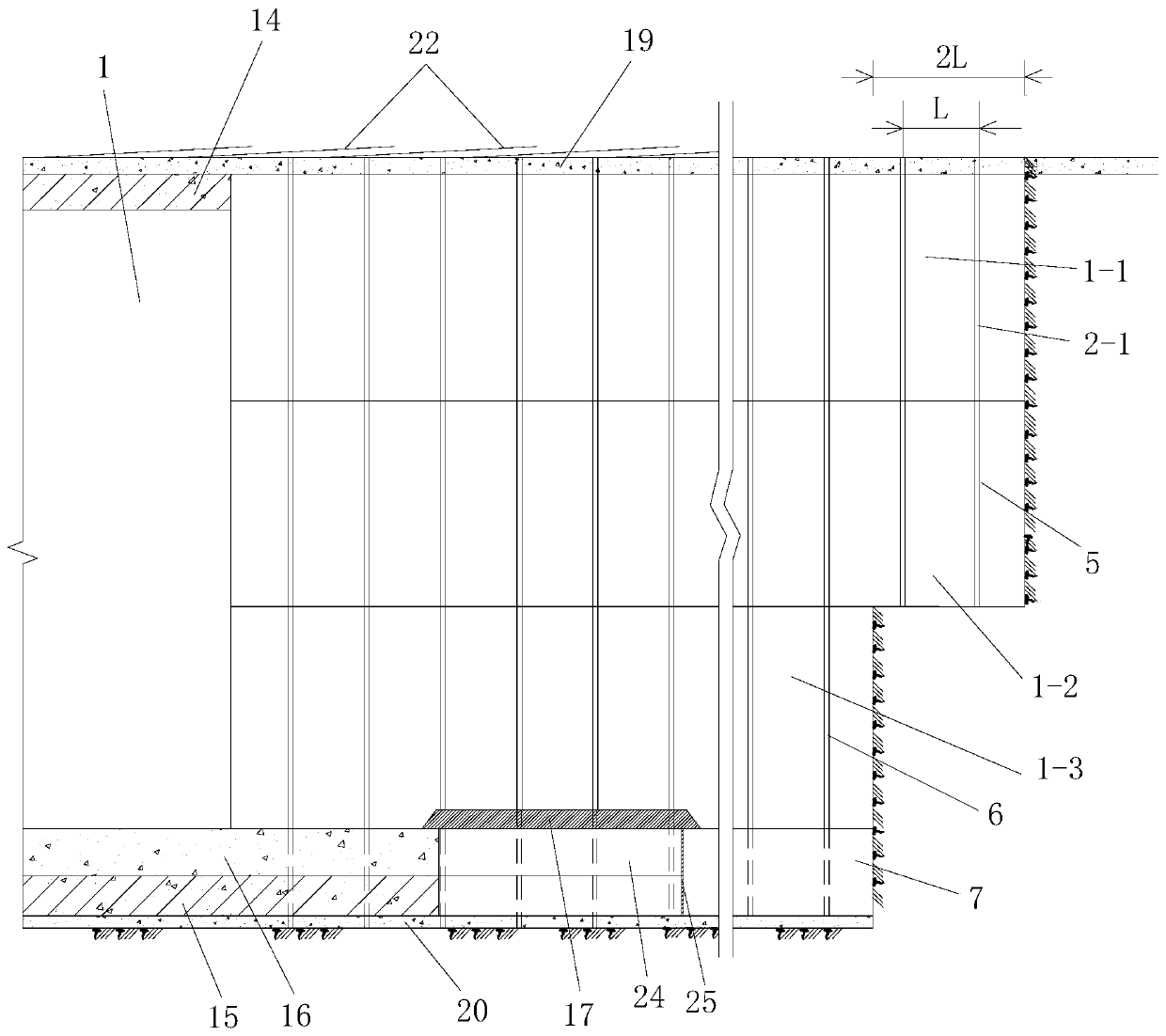

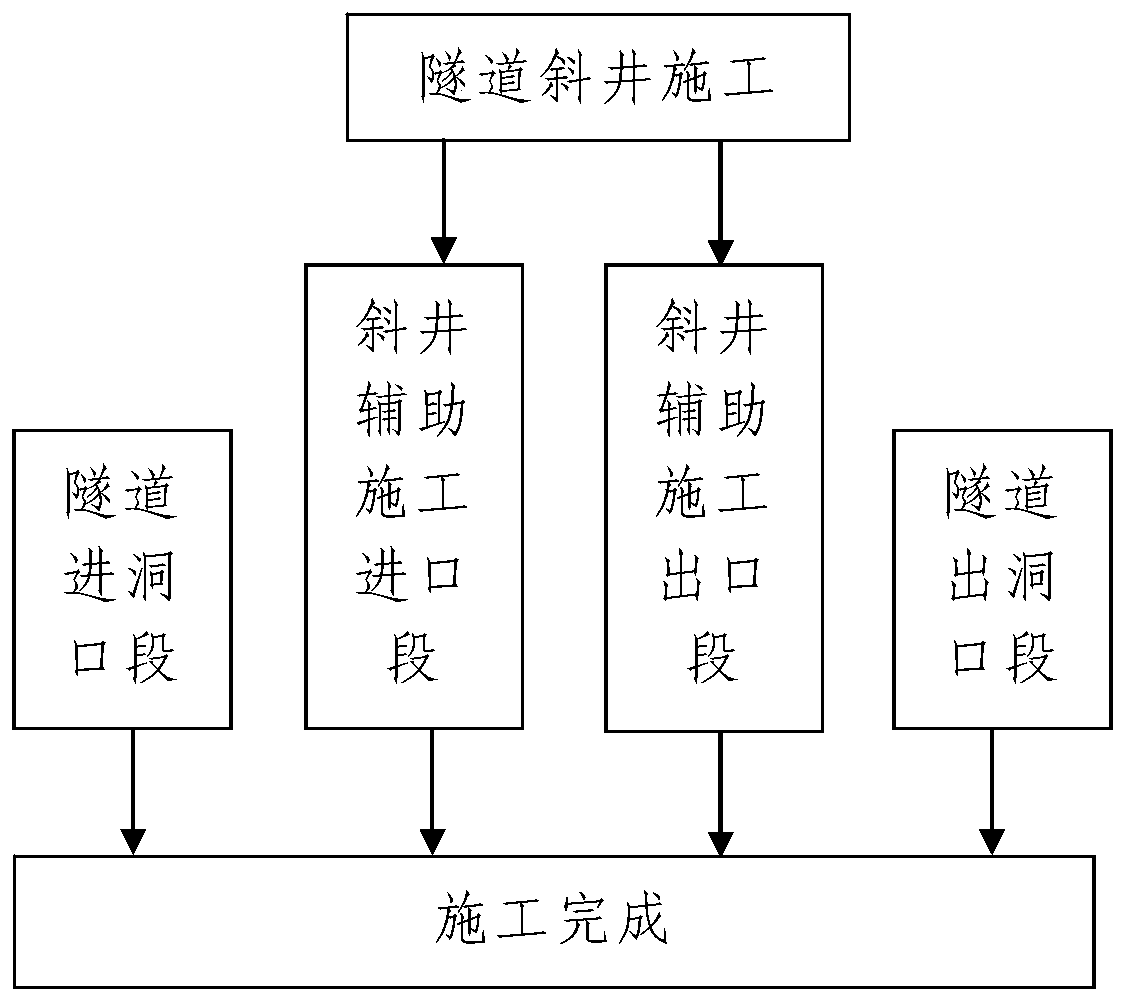

Through landslide body loess tunnel construction method

ActiveCN110905529AThe method steps are simpleReasonable designUnderground chambersTunnel liningTrackwayLandslide

The invention discloses a through landslide body loess tunnel construction method. The through landslide body loess tunnel construction method comprises the following steps of constructing a tunnel entrance section and a tunnel exit section simultaneously; and respectively constructing an inclined shaft auxiliary construction inlet section and an inclined shaft auxiliary construction outlet section through a tunnel inclined shaft when the tunnel entrance section and the tunnel exit section are constructed. The through landslide body loess tunnel construction method is reasonable in design, convenient to construct and good in using effect; the loess strata in the construction area where the tunnel entrance section is positioned is subjected to reinforcement treatment by using a cement soilmixing pile in advance before excavation, and the reinforcement length and the reinforcement depth are effectively limited; a loose soil body on a hole body of a tunnel hole is solidified in advance so as to ensure the safety and reliability of the construction process of a hole inlet section of the through landslide body loess tunnel; meanwhile, in the construction process of the tunnel by adopting a three-step excavation method, the construction process of track plates is completed synchronously, so that the construction process of the loess tunnel can be completed easily, conveniently and quickly; and the stability of an excavated and formed tunnel hole can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP

Grounded flat steel manufacturing platform special for power grid construction

InactiveCN105127756ASimple structureEasy to operateOther manufacturing equipments/toolsWork benchesPower gridAssembly line

The invention provides a grounded flat steel manufacturing platform special for power grid construction. The grounded flat steel manufacturing platform comprises four supporting feet, an iron partition plate, an iron operating platform, a bending device, a punching device, a shearing device and a hydraulic pump station. The grounded flat steel manufacturing platform is simple in structure and convenient to operate, the proper length is cut off through the shearing device according to the requirement of a construction site, and punching and bending are performed, so that assembly line work is formed, operators conveniently work, and the construction efficiency can be improved. The shearing device is fixedly arranged at one end of the iron operating platform, the bending device and the punching device are oppositely arranged on the two sides of the iron operating platform, the surface position of the iron operating platform is reasonably applied, finite space is saved, and various working procedures are linked more compactly in the assembly line type using process.

Owner:国网山东夏津县供电公司

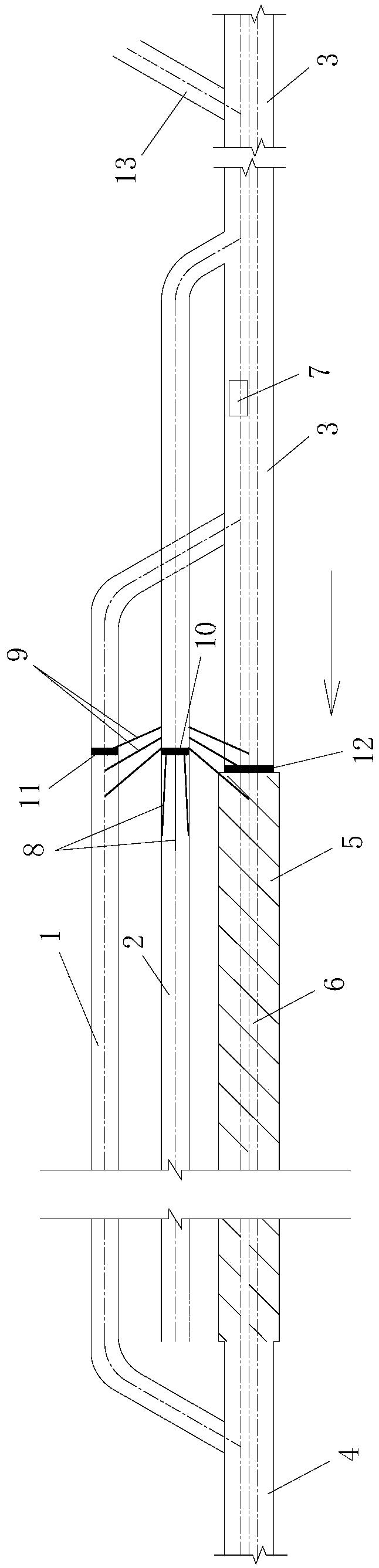

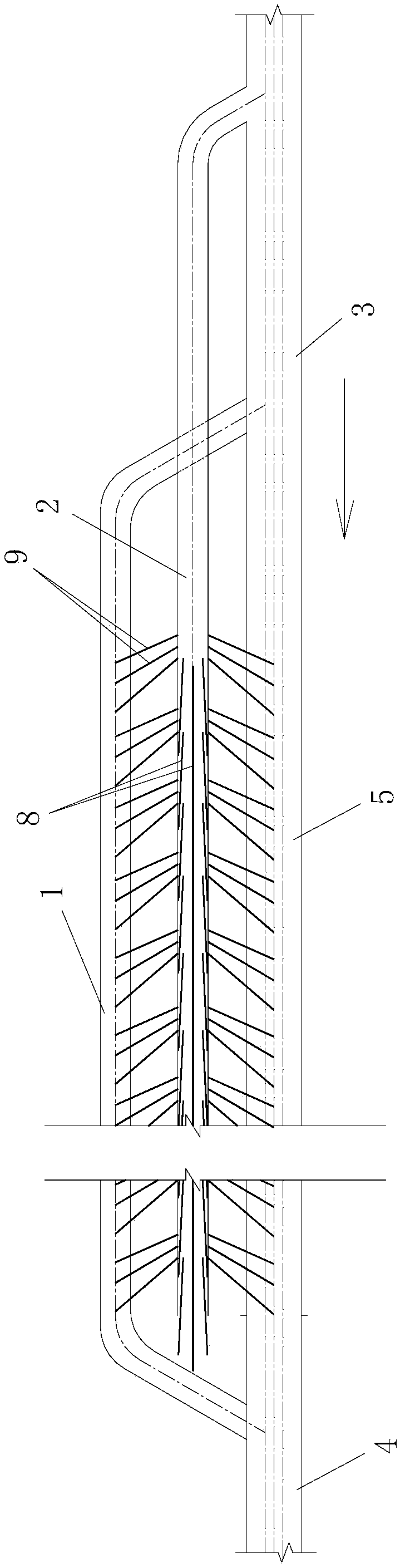

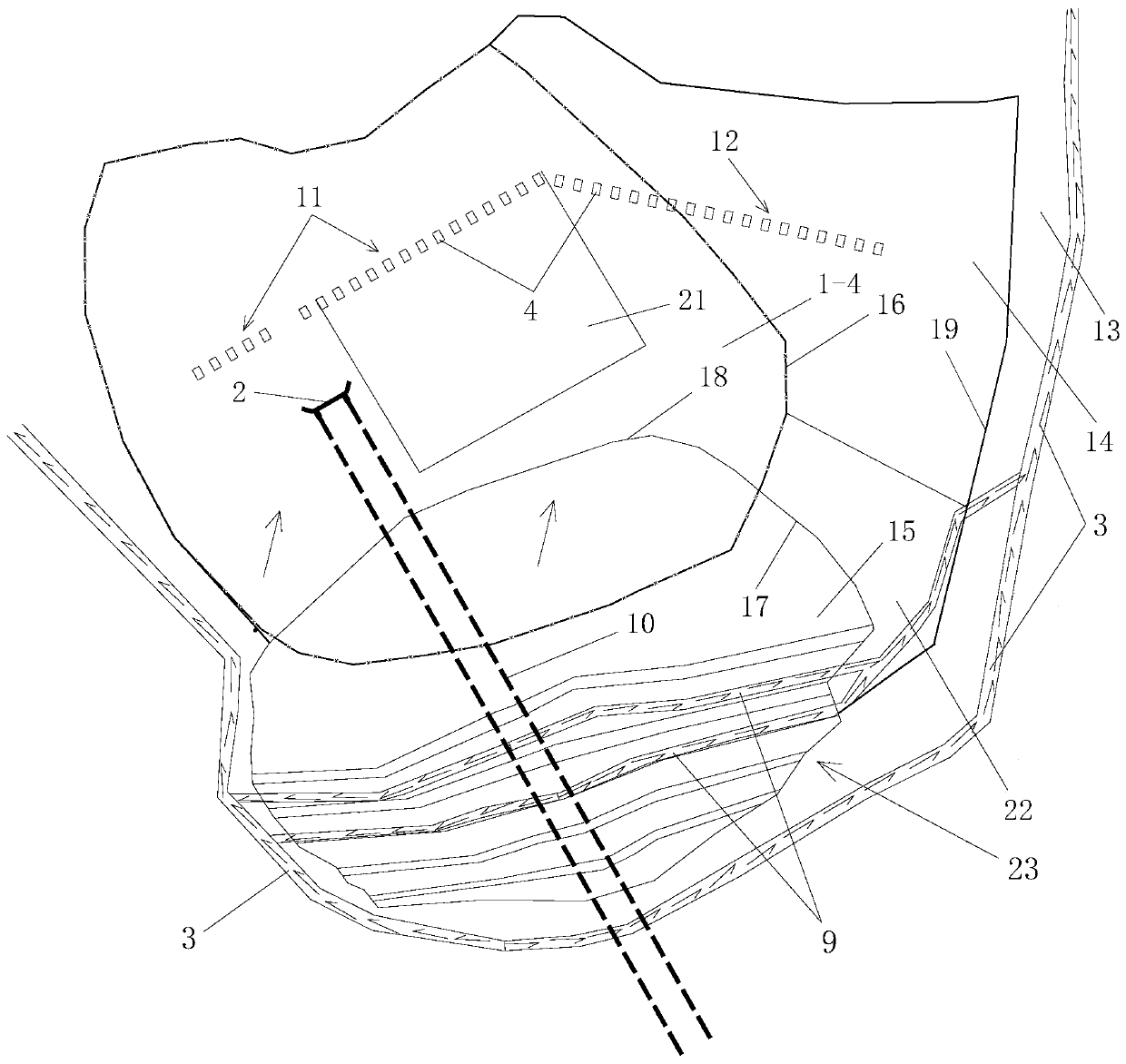

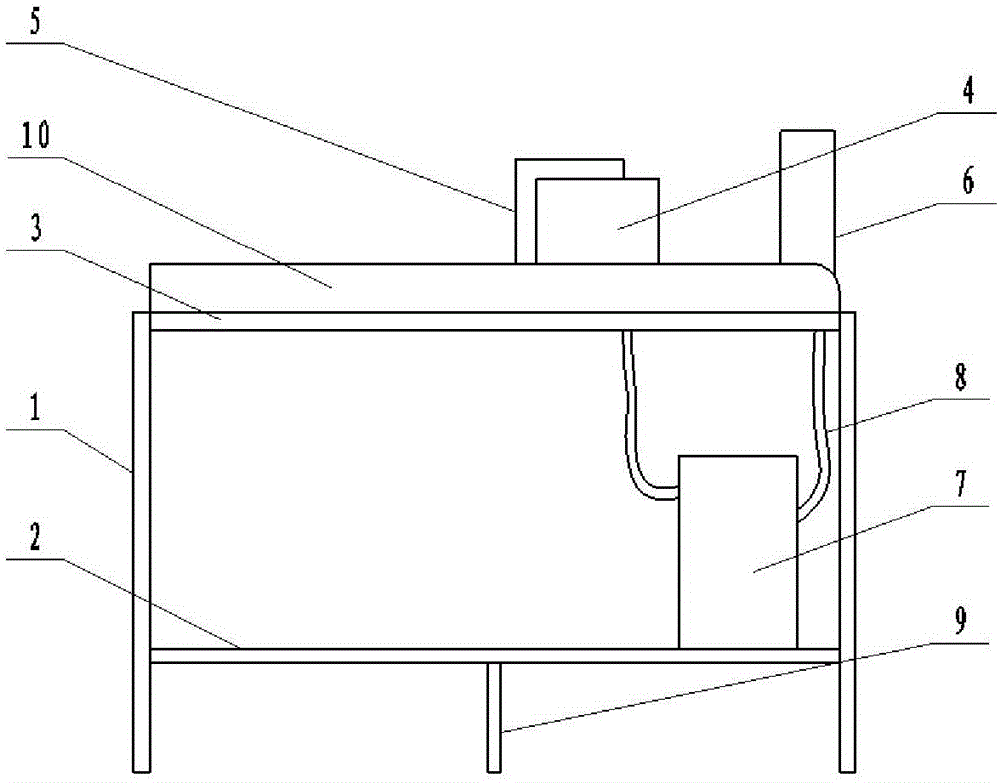

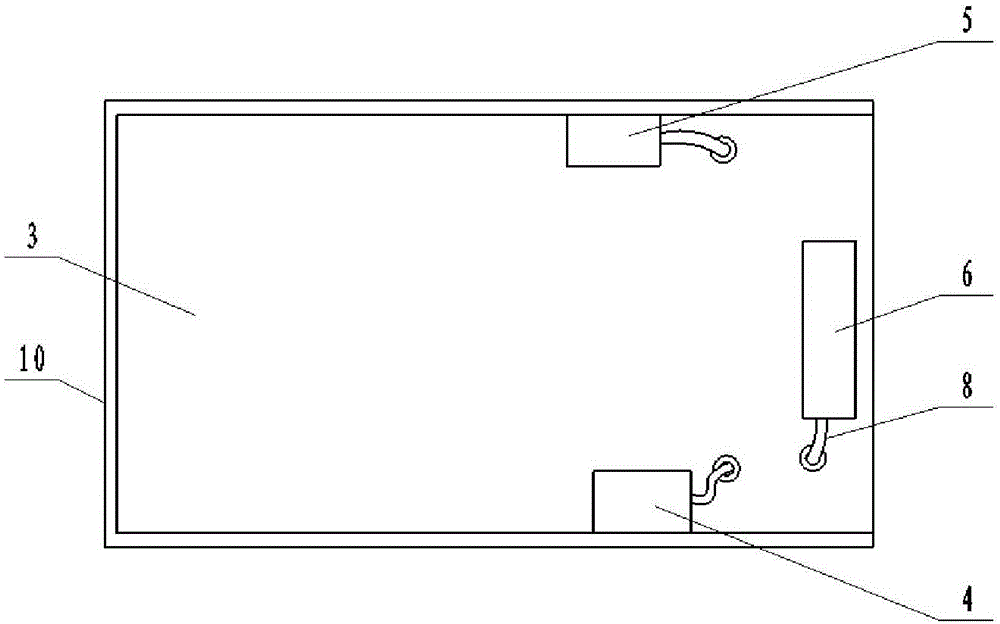

Excavation and supporting method for tunnel crossing high-angle thrust water-rich and sand-rich fault

ActiveCN109555528AThe method steps are simpleReasonable designUnderground chambersDrainageHigh angleStep method

The invention discloses an excavation and supporting method for a tunnel crossing a high-angle thrust water-rich and sand-rich fault. A circuitous pilot tunnel and a drainage tunnel are arranged on asame side of a tunnel main hole. When excavation and supporting construction is carried out on a construction tunnel, the excavation and supporting method for the tunnel crossing the high-angle thrustwater-rich and sand-rich fault comprises the steps that 1, preliminary excavation and supporting construction is carried out on a rear side tunnel segment; 2, synchronous excavation and supporting construction is carried out on a rear side tunnel segment and a drainage tunnel body of the drainage tunnel; 3, the synchronous excavation and supporting construction is carried out on the rear side tunnel segment, the drainage hole body of the drainage tunnel and a rear side circuitous pilot tunnel segment; 4, the excavation and supporting construction is carried out on a front drainage tunnel body, a front pilot tunnel segment and a middle tunnel segment; and 5, the excavation and supporting construction is carried out on a front side tunnel segment. According to the excavation and supportingmethod for the tunnel crossing the high-angle thrust water-rich and sand-rich fault, the steps are simple, design is reasonable, construction is simple and convenient, the using effect is good, the tunnel hole is excavated by adopting a three-step method, full fracture surface supporting is carried out on the tunnel hole by adopting a double-layer preliminary supporting structure after excavation,and the safety of a later tunnel structure can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com