Method of gas drainage for construction of tunnel and parallel adit passing through coal seamd

A gas drainage and coal seam technology, which is applied in gas discharge, earthwork drilling, mining equipment, etc., can solve the problems of increasing the gas concentration in the construction environment, failing to effectively prevent gas, increasing energy consumption and equipment investment, etc. The effect of draining the number of drilling holes, solving the problem of rapid and safe coal excavation construction, and reducing construction safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

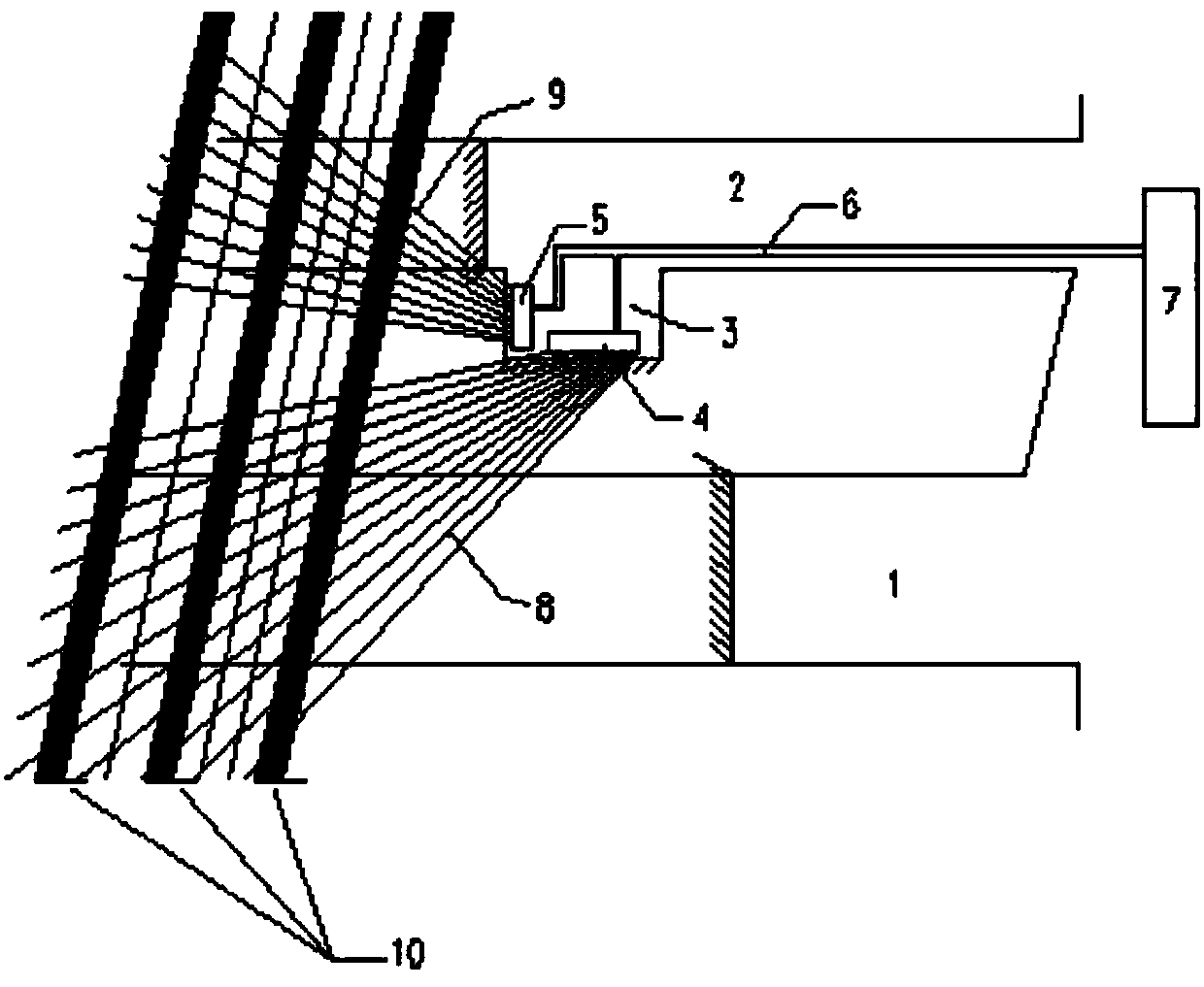

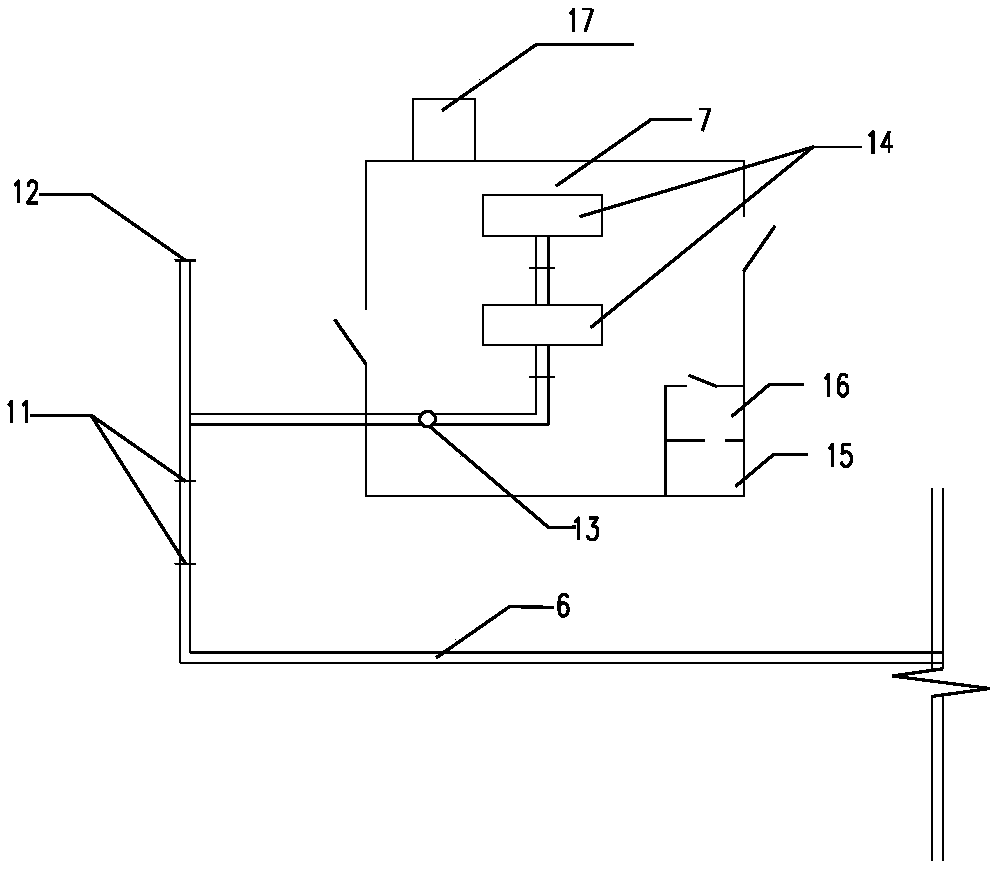

[0021] The technical content of the present invention is: before the coal is unearthed in the tunnel, the drilling site is arranged outside the side wall of the flat guide hole (abbreviated as the horizontal guide) that is excavated ahead of the frontal hole, and the frontal holes are respectively set on the hole walls of the drilling site. Drainage site and level guide discharge site, a network of drill holes are arranged towards the front hole and the coal seam ahead of the level guide, and the holes drilled from the drill site to the front hole and the front coal seam of the level guide penetrate the entire thickness of the coal seam, and the pre-discharged coal seam is drained through the drill holes. Gas, to achieve the effect of gas section drainage in coal seams that have not been unloaded. Using the air negative pressure generated by the gas drainage pump, the coal seam gas that is not affected by mining is drained through boreholes and pipelines, and the gas in the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com