Method for preparing functional edible vegetable oil

A technology for edible vegetable oil and preparation method, which is applied to the processing field of edible vegetable oil and can solve the problem of exceeding the standard. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific embodiments of the present invention will be described below with reference to the drawings.

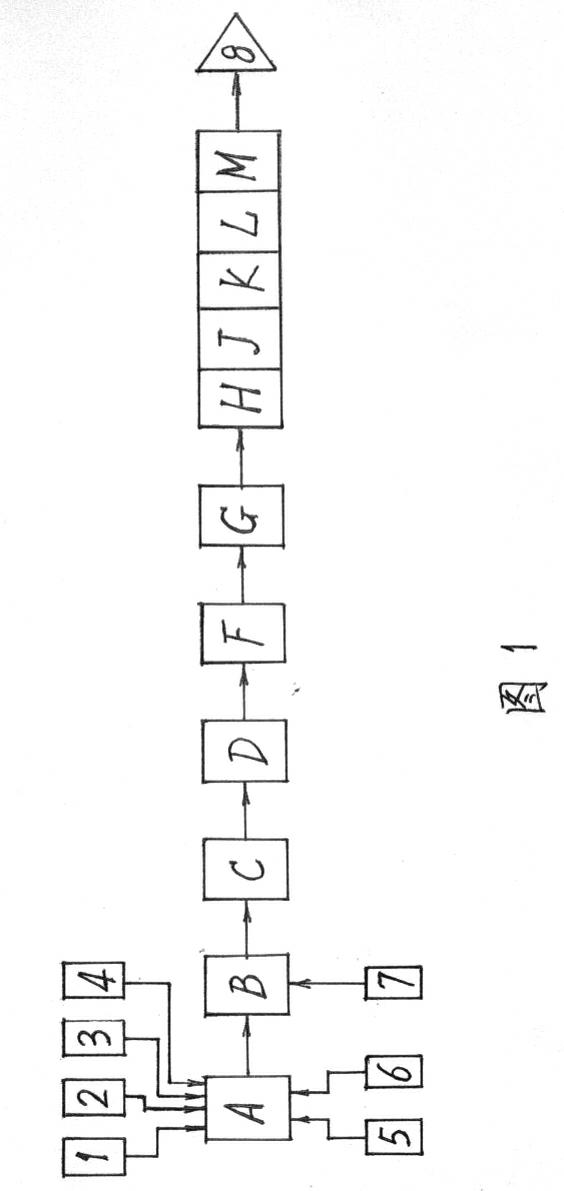

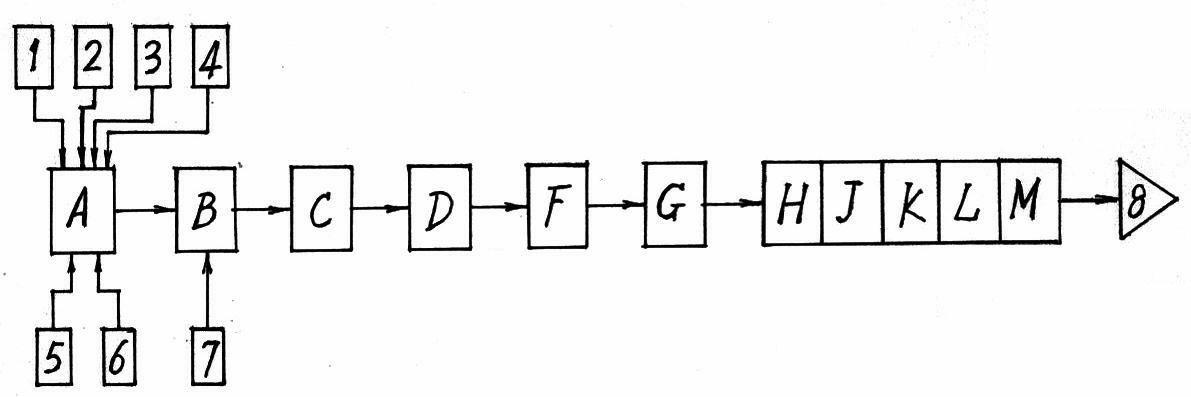

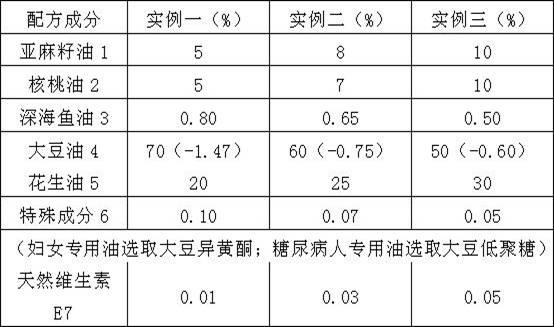

[0009] Refer to figure 1 , Consists of mixing oil tank A, agitator B, temporary storage tank C, filter D, temporary storage tank F, filling machine G, capping machine H, film sealing machine J, inkjet printer K, labeling machine L , The packaging line M is connected to form a functional special oil preparation production line. The preparation process is: according to the formula ratio, add 5-10% walnut oil 2, 0.5-0.8% deep-sea fish oil 3, 50-70% soybean oil 4, 20-30% peanut oil 5, and 0.05-0.1% special ingredients 6 into the mix. Oil tank A, keep the temperature at 20~30℃ to mix; then add to mixer B, add 0.01~0.05% natural vitamin E7, stir at 500r / min for 30min, then put it in temporary storage tank C and stand still for 15min; then add Filter D is filtered with 200 mesh filter cloth under the environmental conditions of temperature 20℃ and pressure 20Mpa; the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com