Steel reinforcement cage overall precast scaffold for wide pier body of cross-sea bridge

A technology for pier body steel bars and sea-crossing bridges, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., and can solve the problems of large negative impact on workers' health and labor enthusiasm, difficulty in precise control of steel bar binding distance, protective layer, and construction quality. It is difficult to obtain effective guarantees and other issues, so as to achieve the effect of improving the quality of protective layer control, reducing construction costs, and eliminating safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

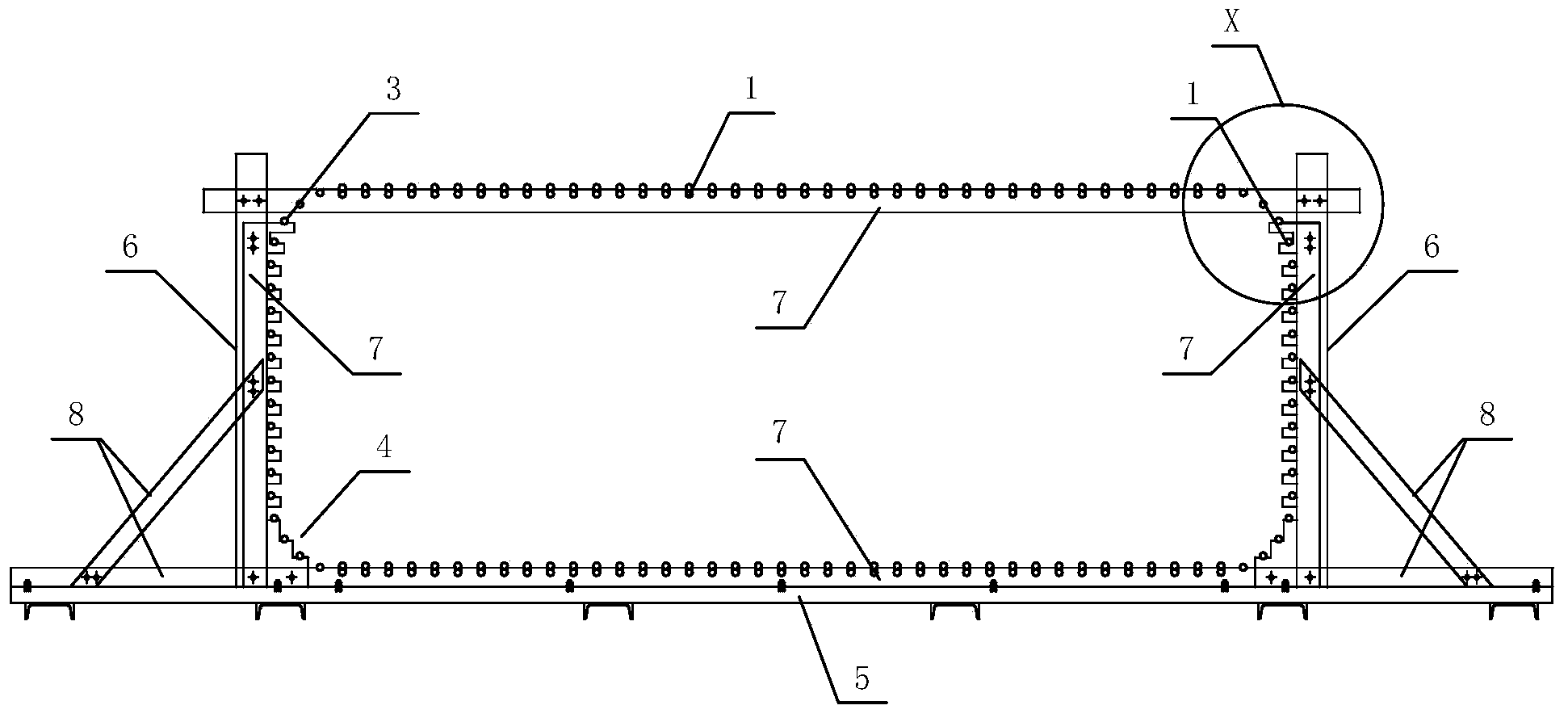

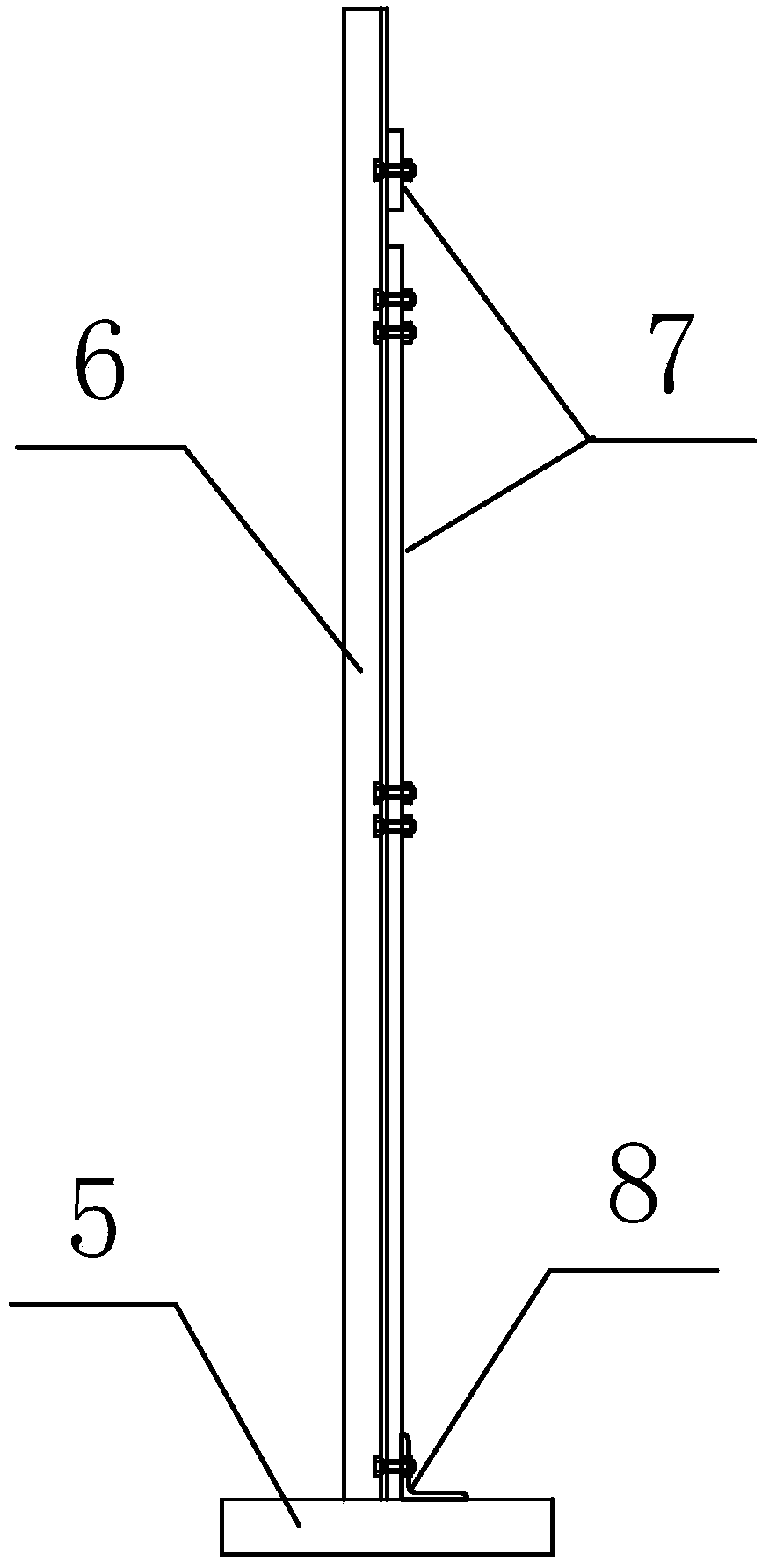

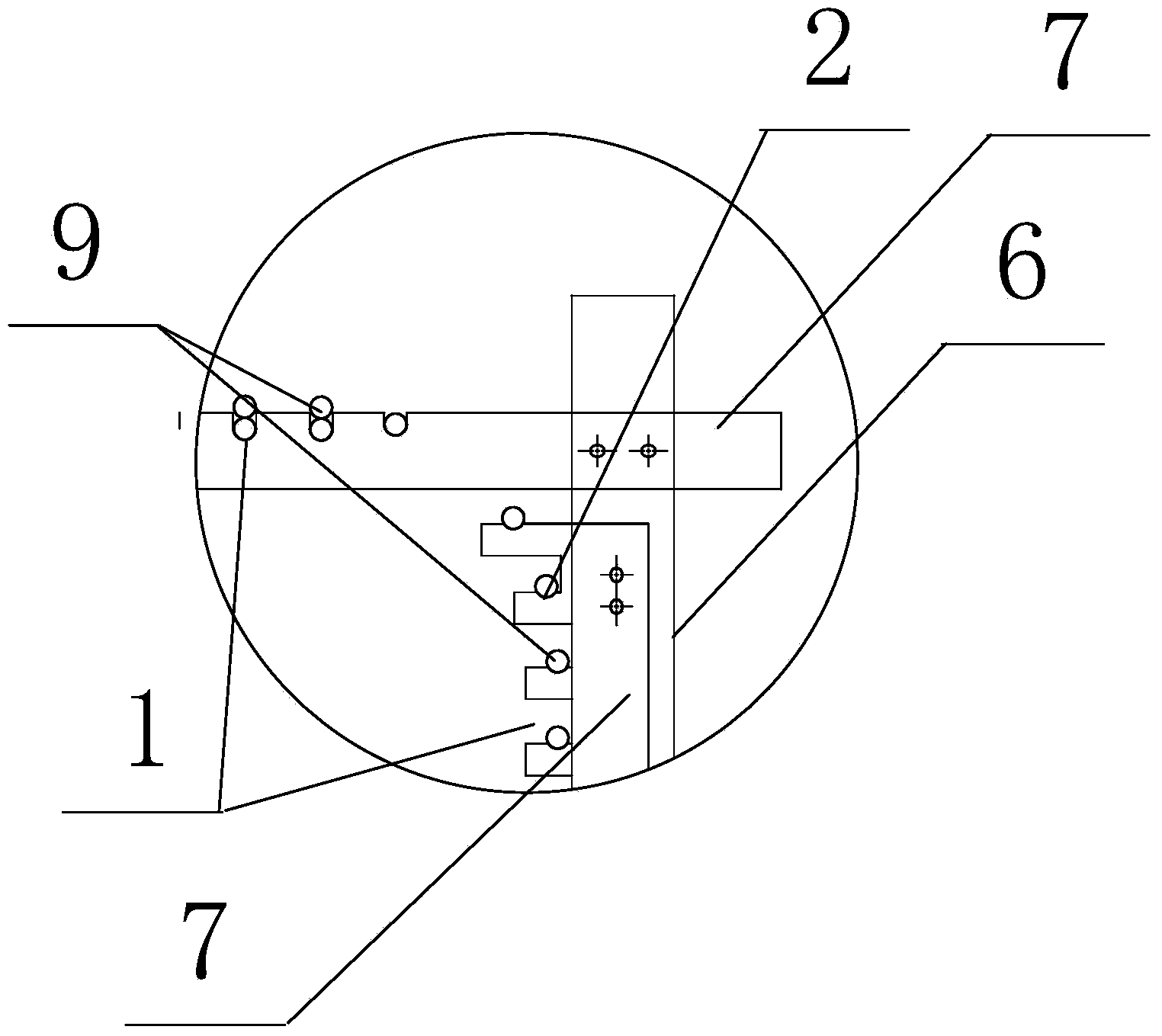

[0027] Such as Figures 1 to 3 As shown, an integral prefabricated tire frame of a wide pier body reinforcement cage for a cross-sea bridge includes a detachable frame assembly on each side, and the upper surface of the top and bottom edges of the frame assembly is provided with a number of rectangular grooves along its length direction 1 The inner surfaces of the left and right sides of the frame assembly are also provided with a number of rectangular grooves 1 along its length direction, and each rectangular groove 1 is equally spaced and evenly distributed. As the example shown in this embodiment, the rectangular groove 1 is the simplest groove formed by opening a gap on the component. In addition, as another example, it can also be formed by any other component or form as long as it can accommodate the placement of steel bars. The structure, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com