Construction method of recycler mixing cement improved soil on expressway top roadbed

A technology for highways and soil improvement, applied in roads, roads, buildings, etc., can solve the problems of high compressibility and water permeability, low plasticity index, capillary development, etc., achieve fast early strength, small influence of human factors, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

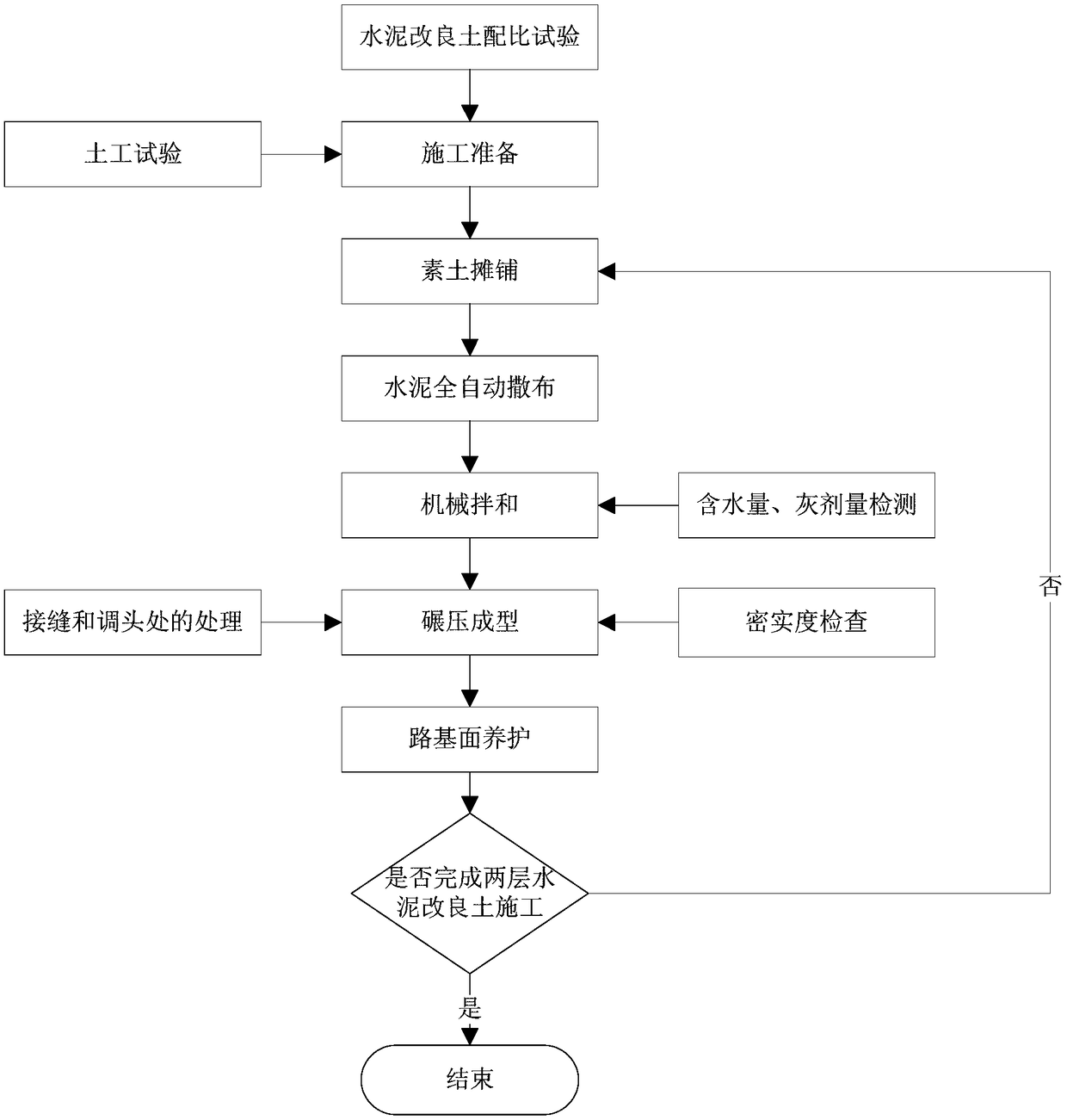

[0038] Such as figure 1 Shown, a kind of construction method of recycling machine mixing cement improved soil on highway roadbed, comprises the following steps:

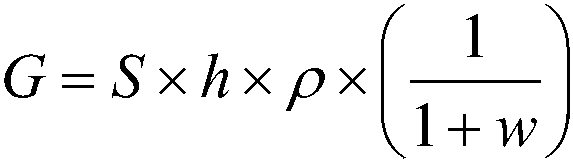

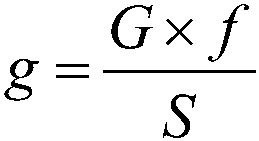

[0039] Step 1: Proportion test of cement-improved soil, conduct comparative analysis of cement-improved soil with ash mixing rate of 2%, 4%, and 6%, respectively, and determine the cement-improved soil ratio that finally meets the performance of cement-improved soil required by construction requirements Program. Specifically, the test analysis includes the effect of ash content on strength characteristics, the effect of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com