Silicon wafer detecting sorting machine and sorting method thereof

A sorting machine, silicon wafer technology, applied in sorting and other directions, can solve the problems of low work efficiency, long cycle time, difficult operation, etc., to achieve the effect of fast cycle, convenient operation, and avoid hidden dangers of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

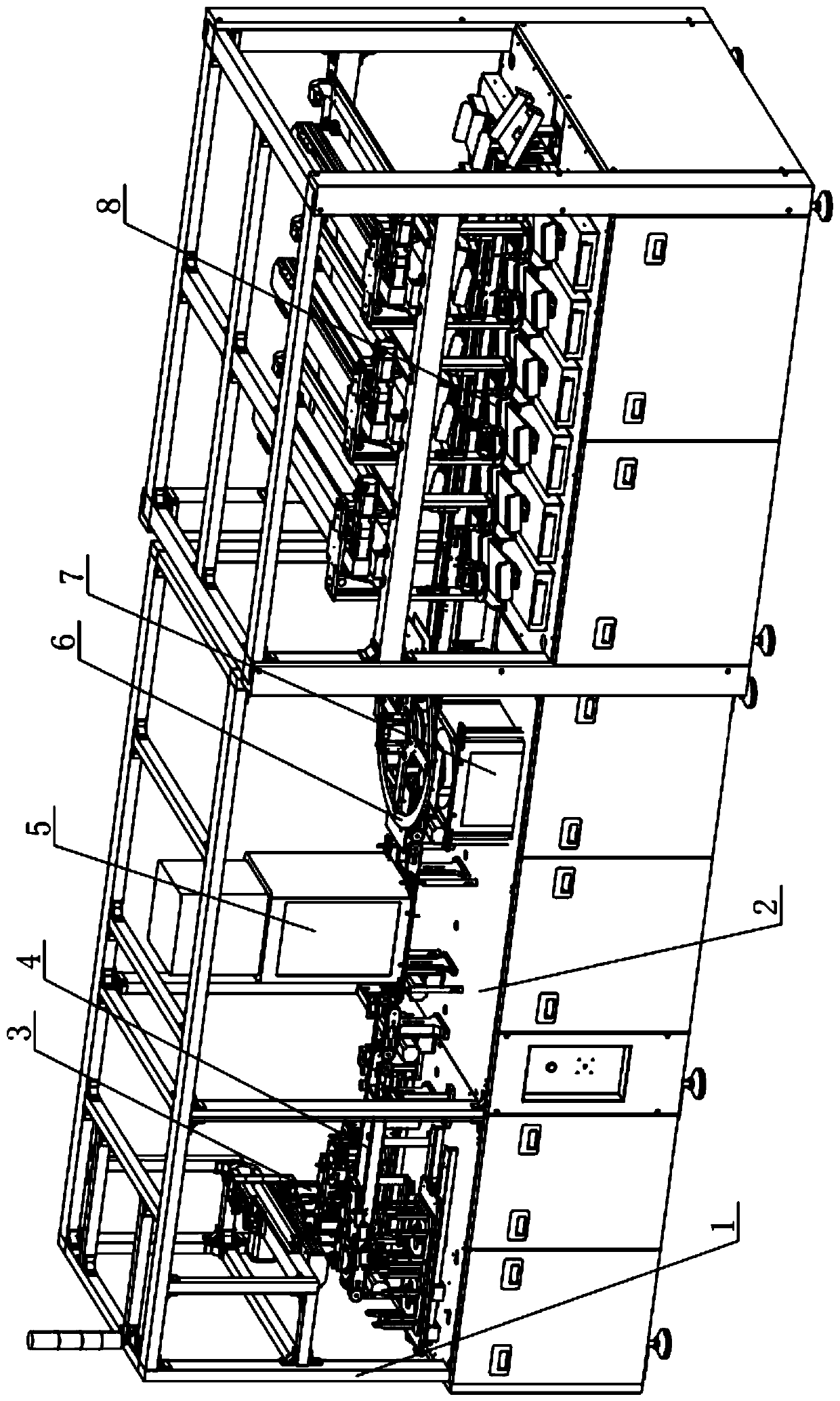

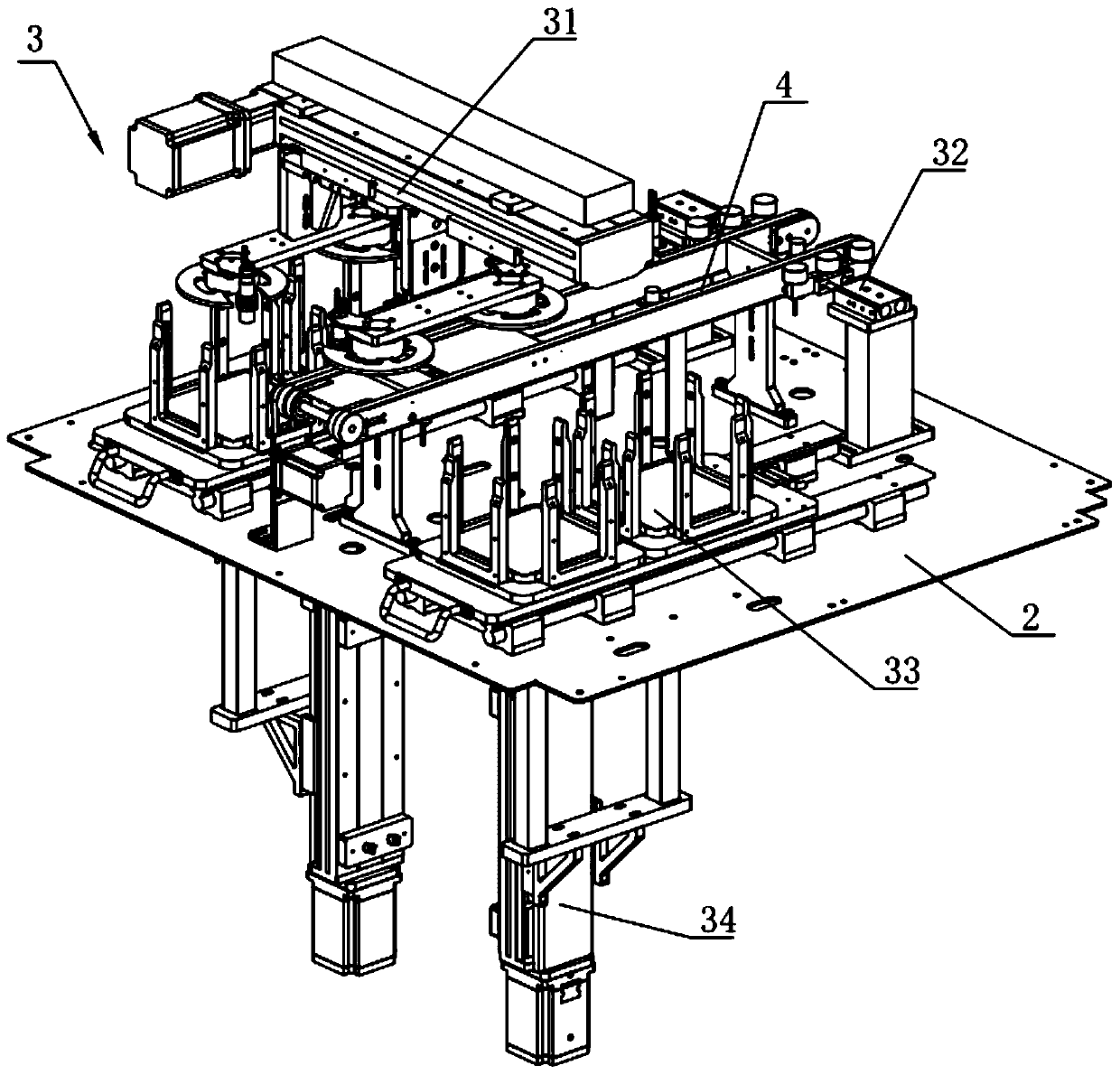

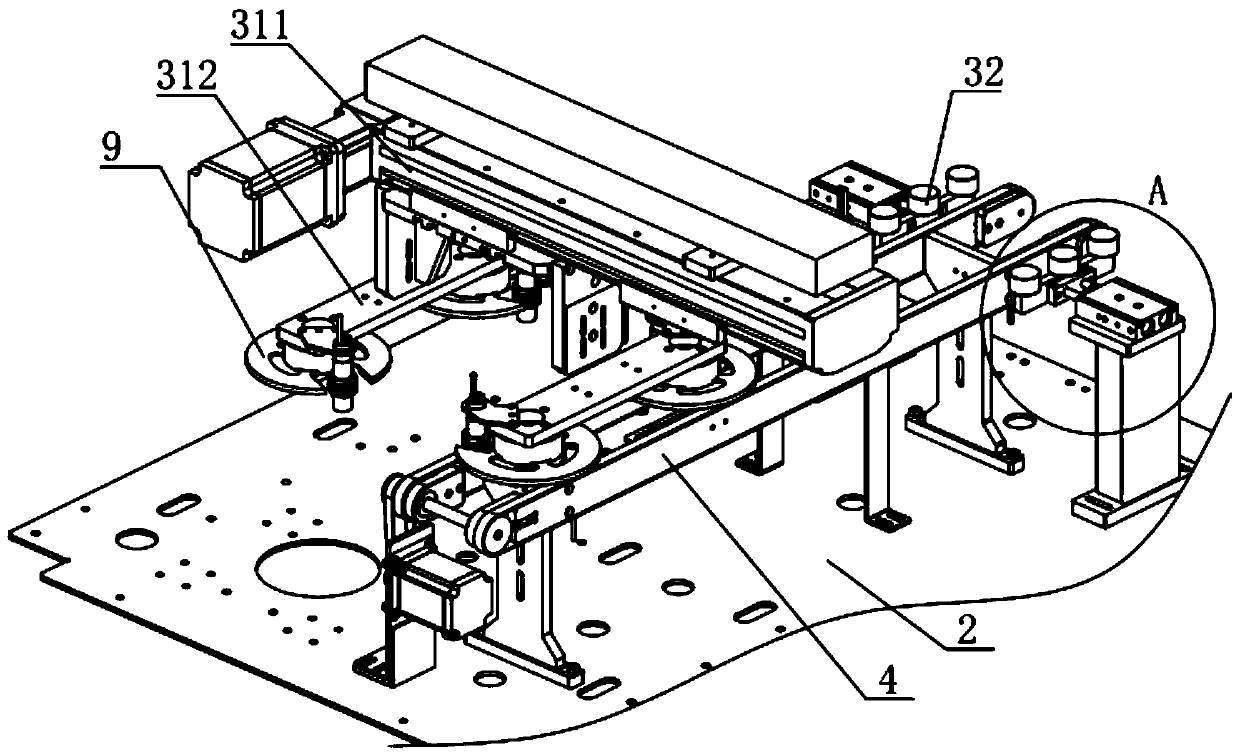

[0046] Such as figure 1 As shown, the silicon wafer detection and sorting machine of the present embodiment includes a frame 1, on which a working platform 2 is installed, and on the working platform 2, a feeding station 3, a testing station and Sorting station 8, a power conveyor belt 4 is installed in the middle of the upper surface of the working platform 2, and the power conveyor belt 4 runs through the feeding station 3, the testing station and the sorting station 8 in sequence; the testing station includes the black box one 5 and the black box two 7. Cameras are respectively installed in camera obscura 1 5 and camera obscura 2 7, one camera lens faces downward and it is located above the power conveyor belt 4, and the other camera lens faces upward and its height is lower than the height of the power conveyor belt 4.

[0047] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com