Multi-curved surface overhung copper plate curtain wall and construction method thereof

A multi-curved, curtain wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of large errors, difficulties in spatial point positioning measurement and installation of multi-curved copper plates, and difficulties in deepening design and construction. The effect of good surface feel and the effect of enhancing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

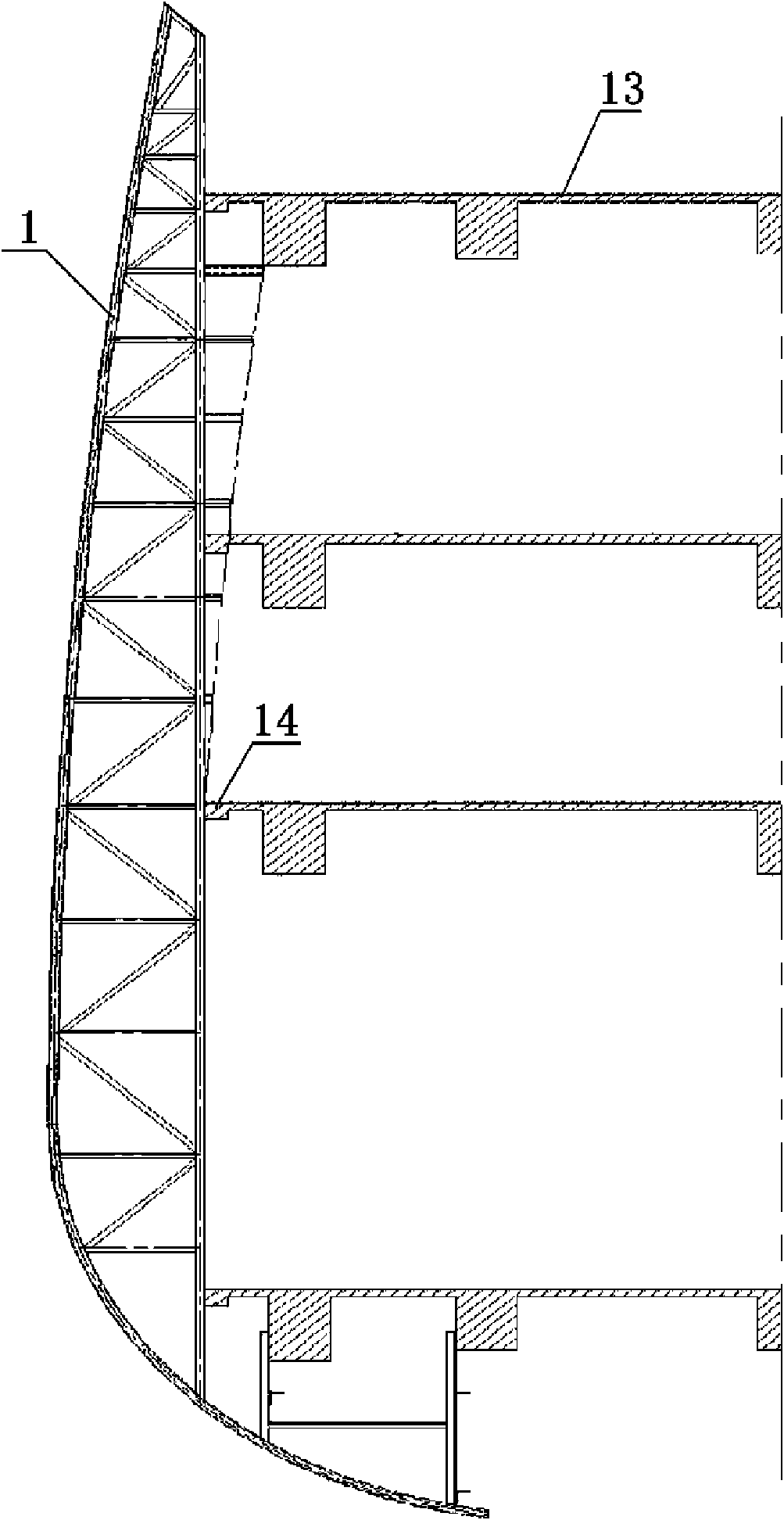

[0047] Examples see figure 1 As shown, this multi-curved cantilevered copper curtain wall includes a main keel connected to the main structure 13, a secondary keel 2, and a curtain wall panel 3 fixed on the secondary keel by a pendant. It is characterized in that: the main keel is a steel truss, and the steel truss The outer steel column is hyperbolic, the inner steel column is vertically connected to the side beam 14 of the main structure, and the inner steel column and the outer steel column are connected by connecting rods.

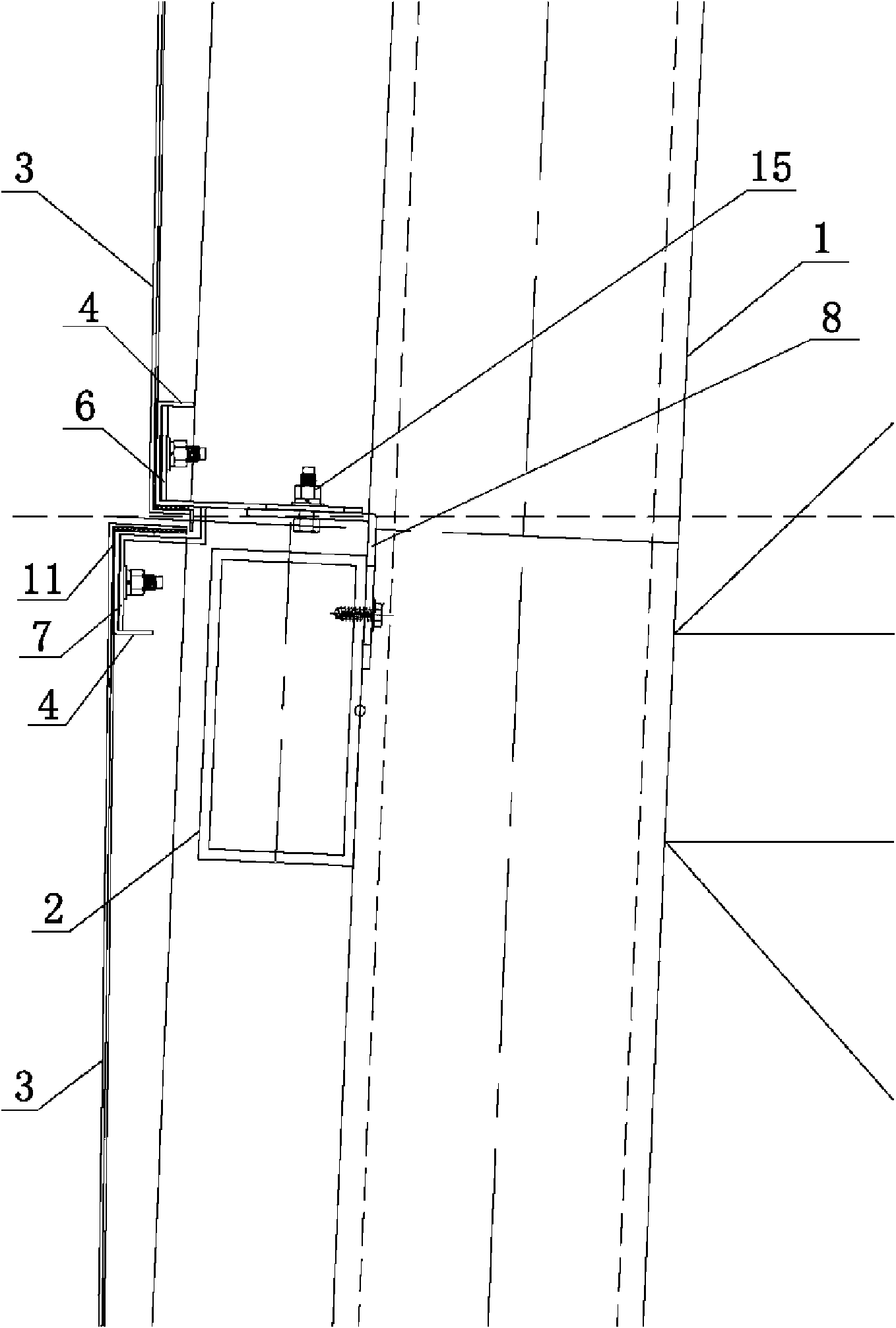

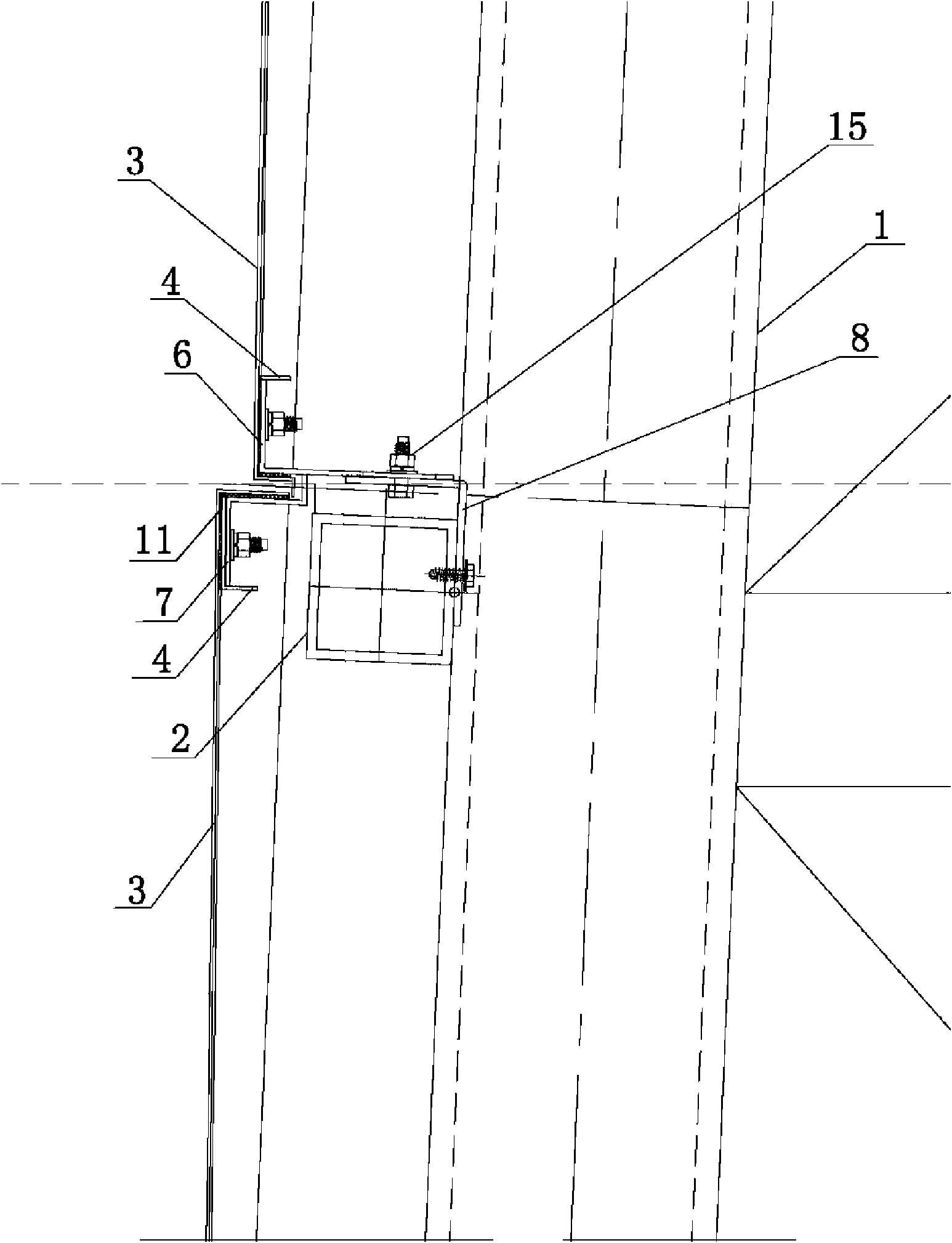

[0048] see figure 2 The outer side of the main keel steel truss is connected to the transverse secondary keel 2, the four sides of the curtain wall panel 3 have folds 5, the fold 5 of the curtain wall panel and the secondary keel 2 are connected by a combination of adjustable hangers and bolts 15, the combination can be The pendant is a combination of any two or three of the following end to end.

[0049] see Figure 5-Figure 6 , The pendant one 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com